This week, each of our team members built theor clanks. Here, we shoe Andres' clank with some of the common problems and insights that we obtained while building the machines.

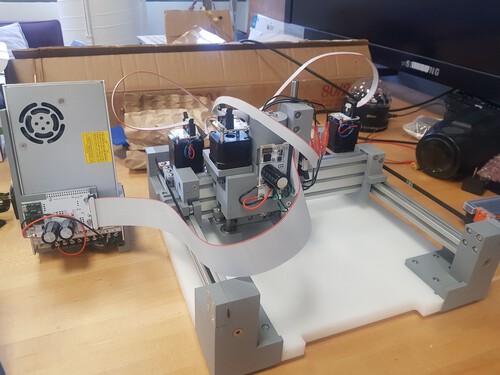

This is what the final built machine should look like. The machine runs Gcode in order to mill the surface of a copper board. Bits remove material to form circuit traces.

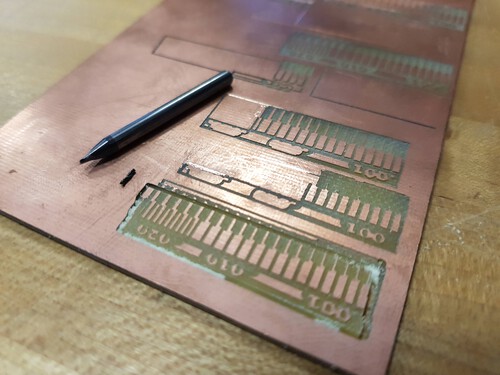

Calibrating the machine took a while for all of our team members. Making sure that there are no overwhelming vibrations is crucial for the machines proper operation. A common mistake was running the machine when it still had more vibrations than it should. The result of doing so were many broken bits, uneven traces and skewed patterns.

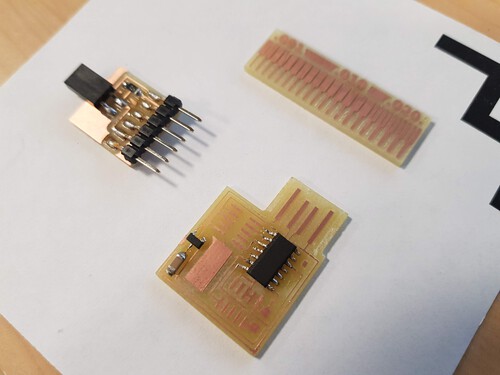

It is also very important to zero the device properly. If not zeroed in the perfect spot, you can get very deep traces, which are also dangerous for bits as or you can air cut which is also a bit of a waste of time. After adjusting machines and taking into account some of the lessons on this page, all of our members managed to make good quality boards. The clank is able to perfectly cut the traces on the test png. We are all looking forward to creating more boards with our machines!