generally speaking, with board assembly projects Big --> Structural Issue --> Renforcement vs Simplicity

Design a table with board assembly

Goal: Make a Table that DOSEN'T WOBBLE with simple structure (none visible renforcement) out of plywood sheets

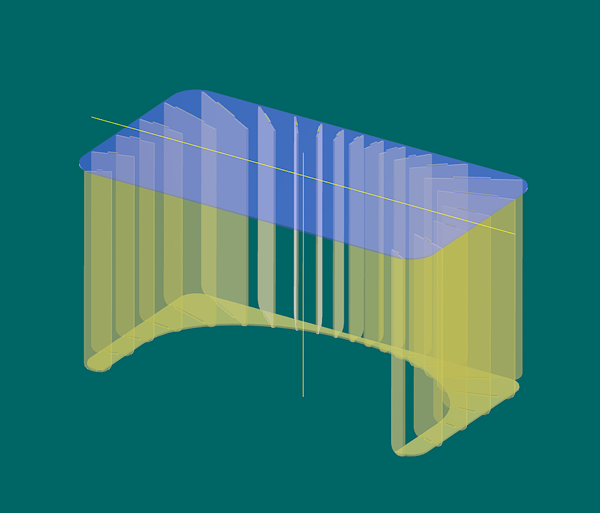

Solution: Use radial distribution to make pillars that "invisibly" support each other.

Design Step by Step

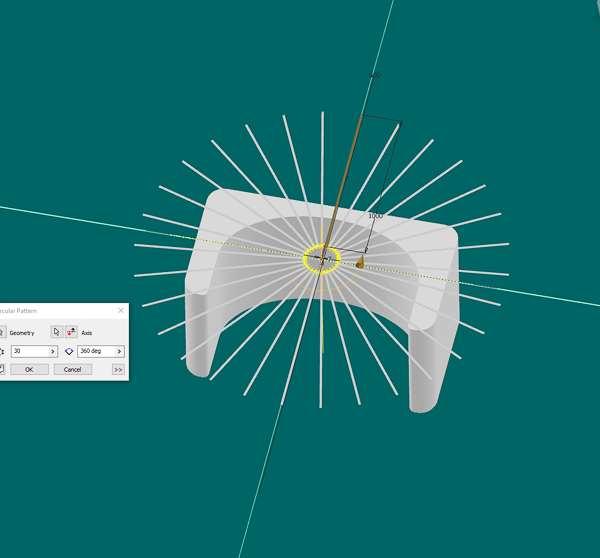

1. define the table (pillar) feature with a solid, find a fitting radial arrangement with the thickness of plywood sheet.

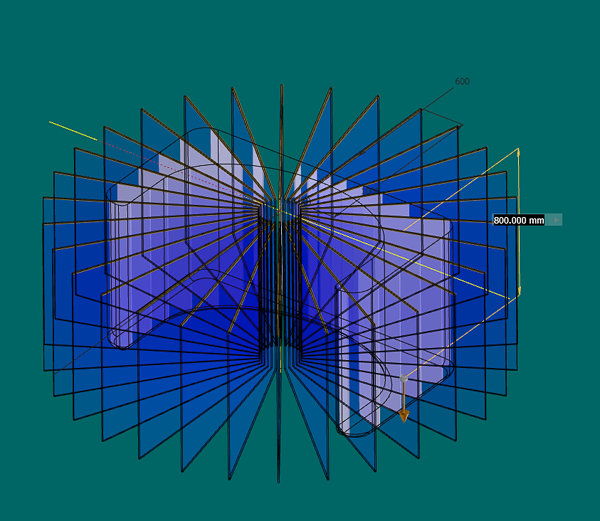

2. Boolean! Plywood sheet AND Table feature.

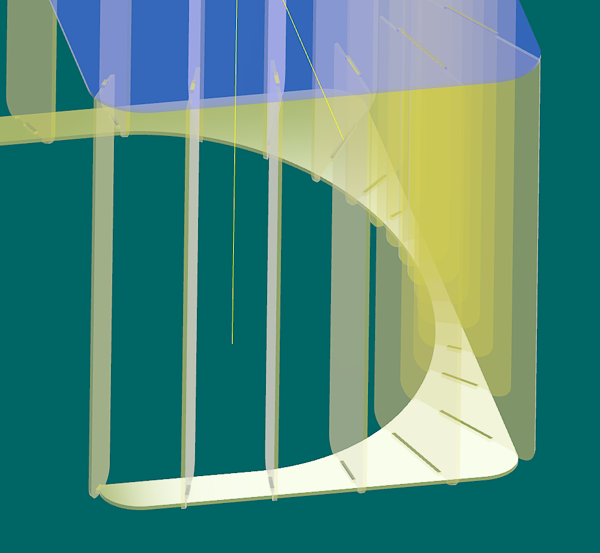

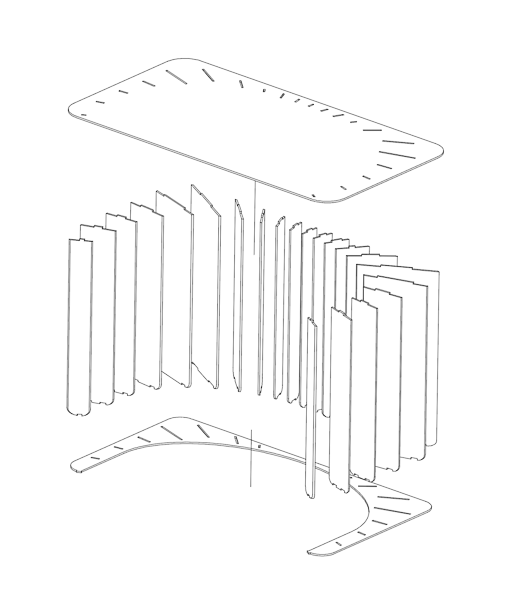

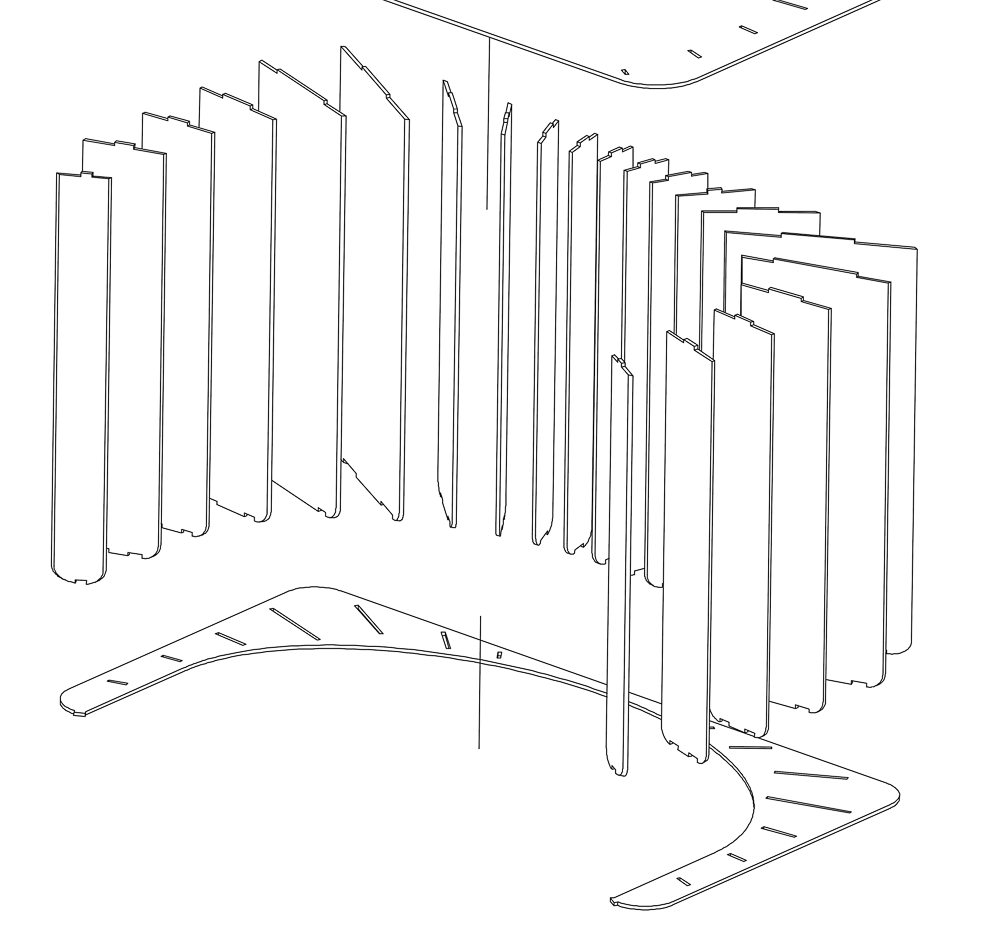

3. Using an under board to hold the radial distribution of pillars. Make slots and rivets to join them together.

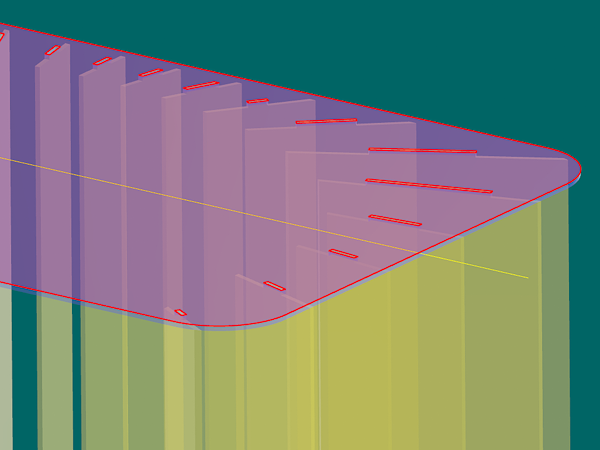

4. Same thing on the table top

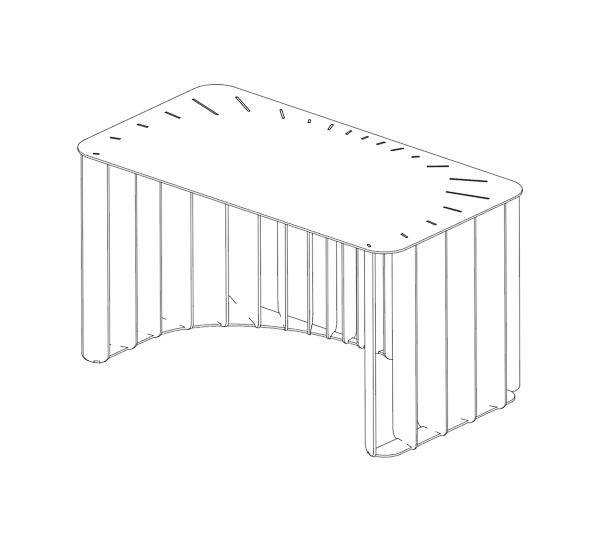

5. TADA!

6. Create individual profile for each piece

7. Make an IKEA style assembly diagram

8. Recheck all the details

Making (WIP, still waiting for the wood)

Goal: CNC the plywood sheets and assemble the table

End of today :)