Home

Project 7- Electronics Production

This week I milled something and soldered it together

Goals

Class Assignment:

- redraw an echo hello-world board

- add (at least) a button and LED (with current-limiting resistor)

Things I took away from this week

- Learned how to use Eagle vs Kicad

- LIBRARIES ARE THE WORST

- more practice laying out a PCB

The ~Process~

- KiCad and Eagle

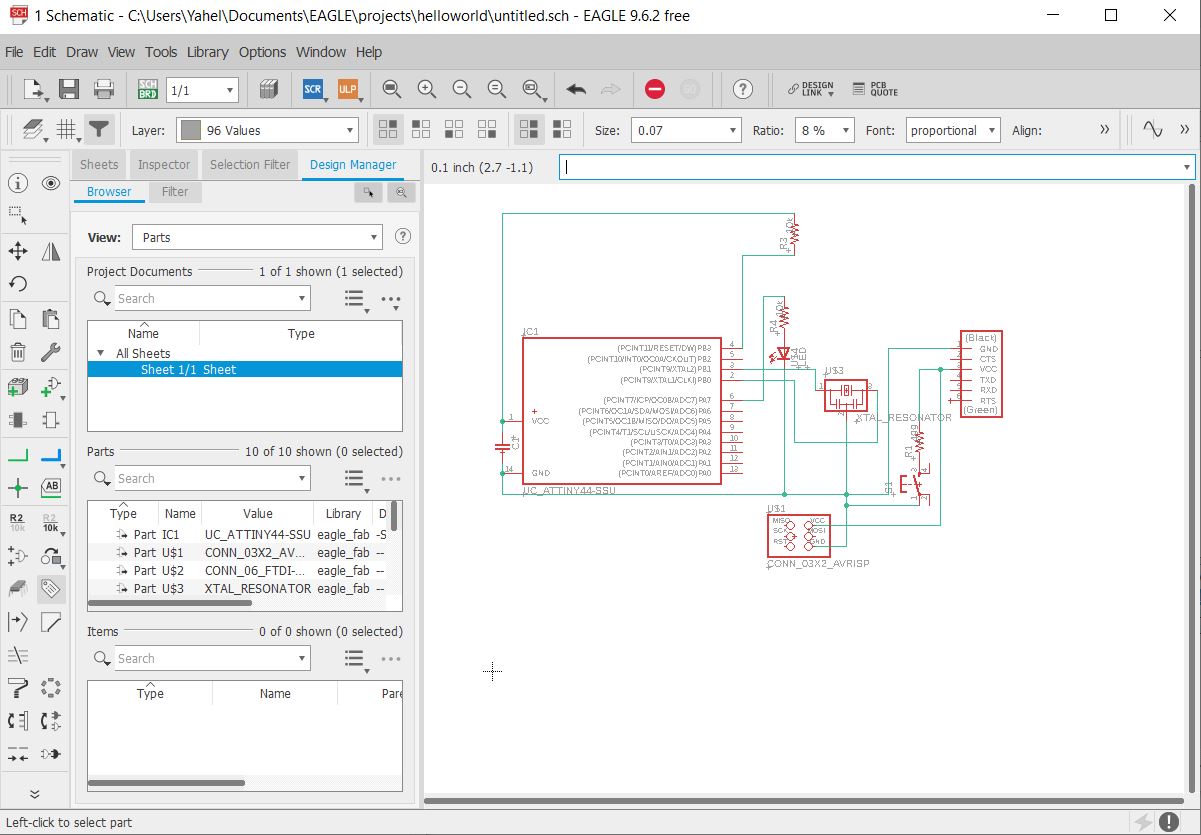

At first, I began working in KiCad because I've used it before and thought it would be fine. It was not. I had a lot of problems trying to import the libraries into KiCad and never figured out the problem (it was likely that I didn't put it in the correct directory, but who knows). I ended up switching over to Eagle, which was frustrating to get the library to work, but eventually I figured it out. The problem was were I was putting the library. The correct location was in Documents>Eagle>Libraries.

Once the library was correctly imported, then came the part to add components to the schematic and connect all the nodes.

Once the library was correctly imported, then came the part to add components to the schematic and connect all the nodes.

- PCB Layout

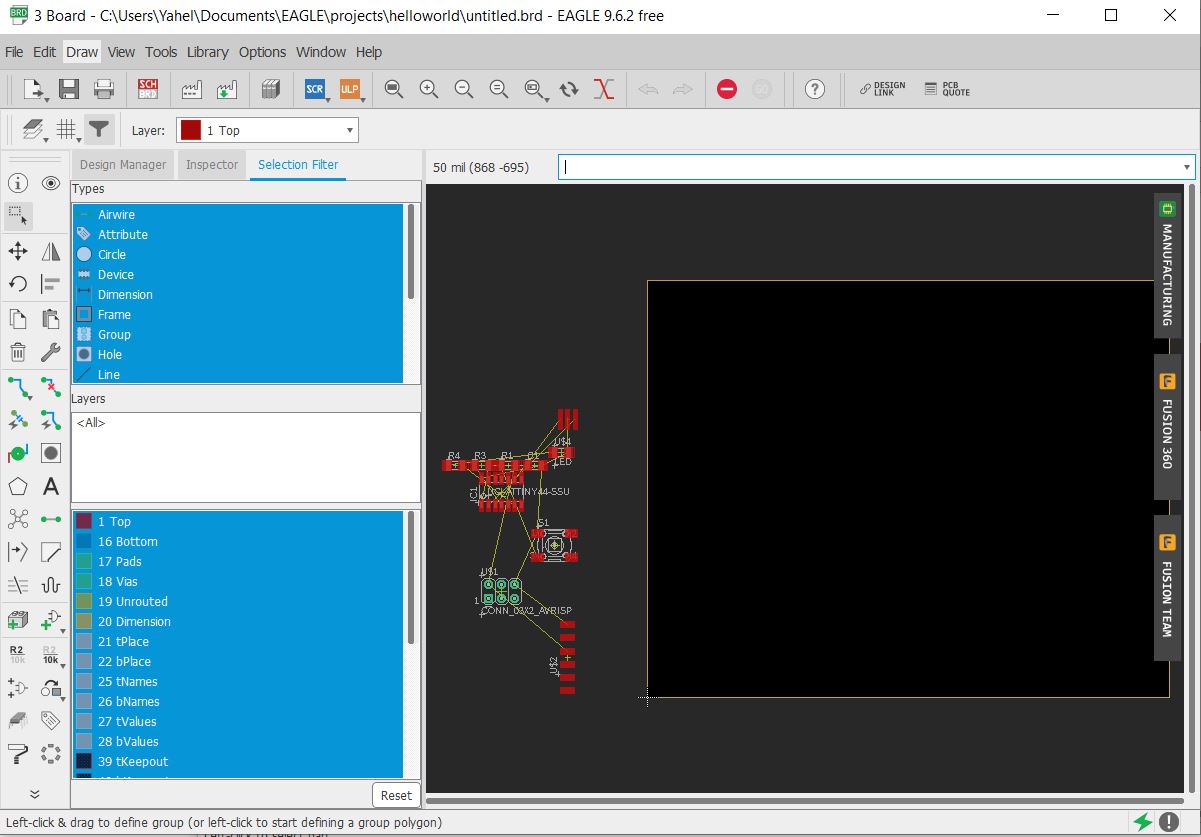

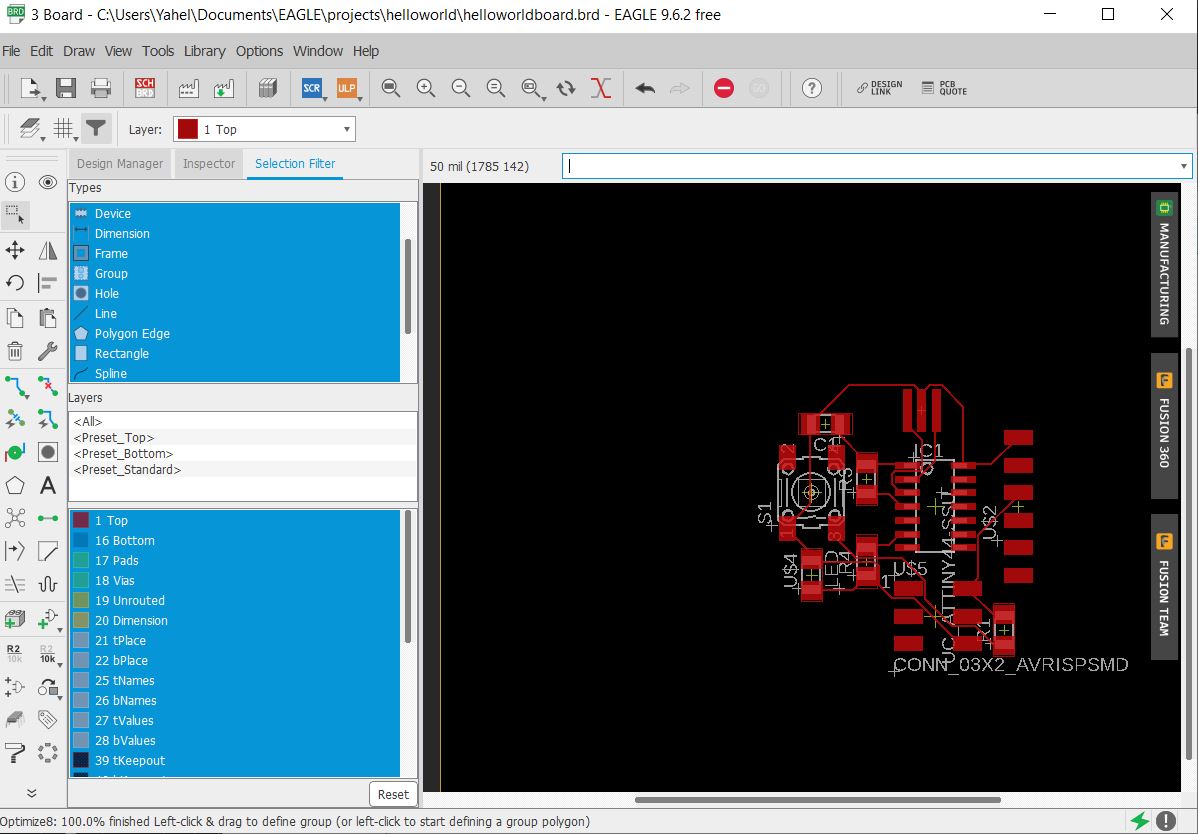

After the schematic was done I needed to create the PCB layout. To do this I just created a new board and imported the netlist from the schematic. This then gave me this ~beautiful~ conglomerate of parts. This is called the 'ratsnest'.

I untangled the ratsnest so that the airwires didn't overlap and to get the parts close to each other (within the constraints of the design rules). I made sure that the traces weren't too close and of course, made sure that none of the traces made sharp turns. If we have turns of 90 degrees or so, you get a lot of loss in your signal, since current is an electromagnetic signal and *something about TEM lines that I definitely remember*. 45 degree turns are pretty standard, although for our purposes this likely won't matter too much. I tried out the autorouter to lay down the traces, which mostly worked. However, the autorouter used a trace width of 6 which I couldn't figure out how to change. The autorouter also had a couple of traces that were really long or other wise wonky. So I redid them by hand.

I untangled the ratsnest so that the airwires didn't overlap and to get the parts close to each other (within the constraints of the design rules). I made sure that the traces weren't too close and of course, made sure that none of the traces made sharp turns. If we have turns of 90 degrees or so, you get a lot of loss in your signal, since current is an electromagnetic signal and *something about TEM lines that I definitely remember*. 45 degree turns are pretty standard, although for our purposes this likely won't matter too much. I tried out the autorouter to lay down the traces, which mostly worked. However, the autorouter used a trace width of 6 which I couldn't figure out how to change. The autorouter also had a couple of traces that were really long or other wise wonky. So I redid them by hand.

- Milling!

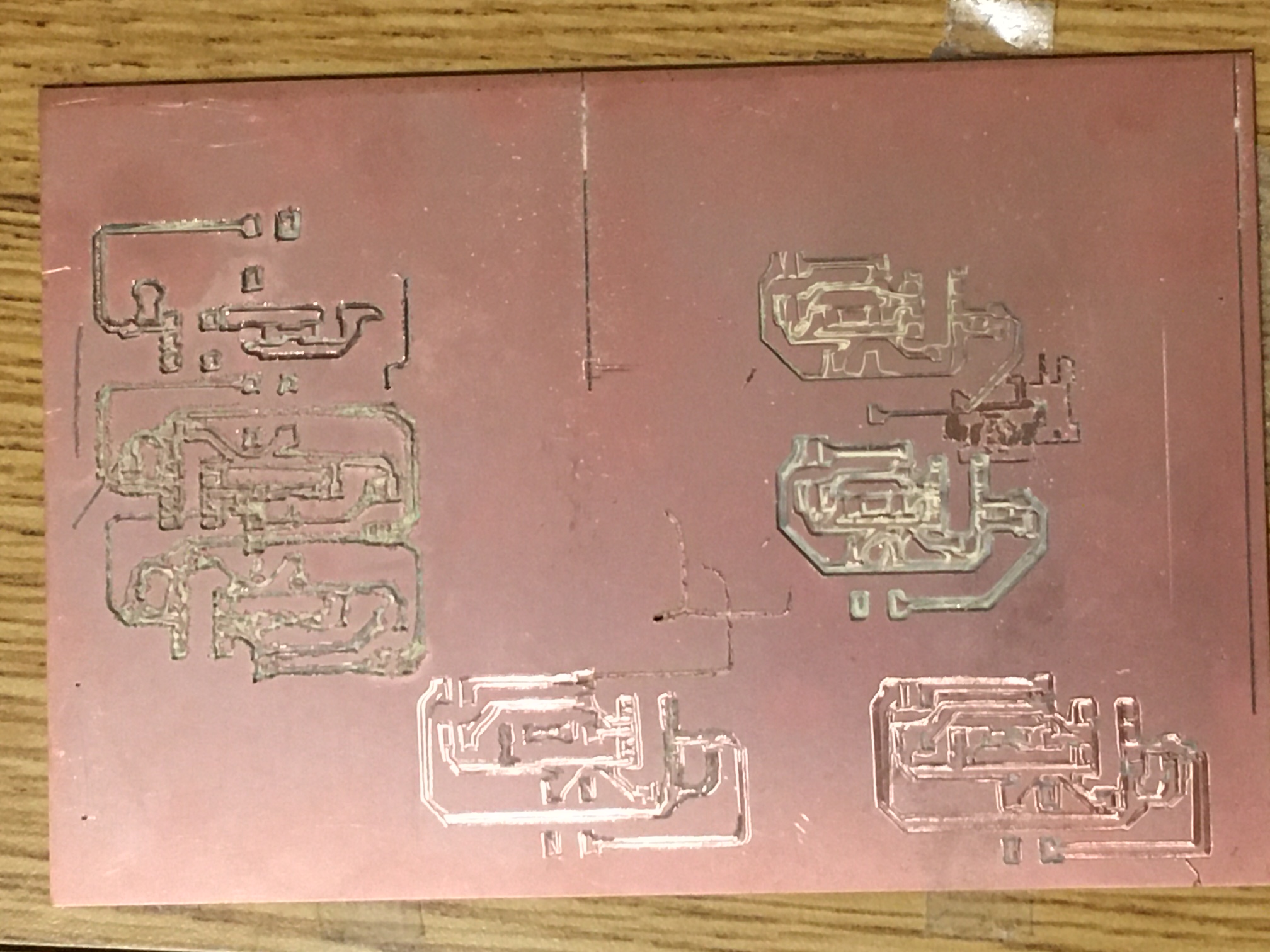

I just got Clank operational, but had * a lot * of trouble trying to get good cuts. I thought Clank was having a problem with my png file, so redid the traces.. a couple of times. Nothing worked, unfortunately. Here is a picture of all of the failures:

I talked to Anthony about this and the problem is likely because the belts on Clank aren't tight enough and maybe also my spindle. I will have to check this and bring Clank by EDS to have it looked at. In the meantime, I used the PCB Mill to cut out the new version of the board. This is what it looks like cut out.

I talked to Anthony about this and the problem is likely because the belts on Clank aren't tight enough and maybe also my spindle. I will have to check this and bring Clank by EDS to have it looked at. In the meantime, I used the PCB Mill to cut out the new version of the board. This is what it looks like cut out.

Update! I took clank into EDS and got some help. Turns out, I have a bunch of screws loose (tehe). No but actually like a bunch of the screws were too loose. I tightened a bunch of them, tightened the belts for the X axis, and switched the spindle direction. Once these were all done, clank was finally fixed. I reflattened the bed and did a quick test cut and it worked! Special shoutout to Anthony for staying a bit late to help me :) if you're reading this, you are the real MVP.

Update! I took clank into EDS and got some help. Turns out, I have a bunch of screws loose (tehe). No but actually like a bunch of the screws were too loose. I tightened a bunch of them, tightened the belts for the X axis, and switched the spindle direction. Once these were all done, clank was finally fixed. I reflattened the bed and did a quick test cut and it worked! Special shoutout to Anthony for staying a bit late to help me :) if you're reading this, you are the real MVP.