Tools: Sindoh FDM 3D Printer

Materials: clear fishing line | nylon push-in rivets | white 3D printing filament | glue

3D Printing

To optimize for time and detail, I split the model into accessory parts, and components where precise dimensions where necessary for functioning. On the abs printer, I printed all the vertebrae with PLA plastic, Sadly, the holes for the thread still closed up, but the joints were clean and I fixed the thread holes with the drill press. The skull, hands, bottom ribs, limbs, and hands were all printed on the Sindoh's.Assembly

Having pushed off the manufacturing until 3 days before the open house due to have a bad case of the flu, I was nervous about my tolerance calculations. As intended, the vertebrae were a tight fit on the teflon, and they slid on perfectly. A mistake I made is not updated the model dimensions in length to adjust for the Mastercam push-in rivets being out of stock: the Grainger ones were longer, which damaged the functionality of some of the joints as they ran into the teflon tube. The original functionality of the joints was to control the vertical curve of the spine. Many of the joints were still functional, and I fixed the remaining error by strategically placing the fishing line for hanging, leveraging gravity to curve the portions where the joints snapped or ran into the spine.The rest of the assembly involved hot gluing the accesory limbs on, measuring threading the fishing line tendons, and a deceptive amounts of double knots secured by glue (fishing line doesn't like knots).

My timeline was very tight - some of the assembly was done the day of. Unfortunately, I ran out of hot glue, and was unable to suspend the motors in tension under the spine, meaning I had to manually hold them in place, or else the servo's would turn the motors not the robot's frame. The rest of my model was fully functional, and this would have been a ~1 hour fix to get it to perform perfectly.

Final Project Materials and Prices

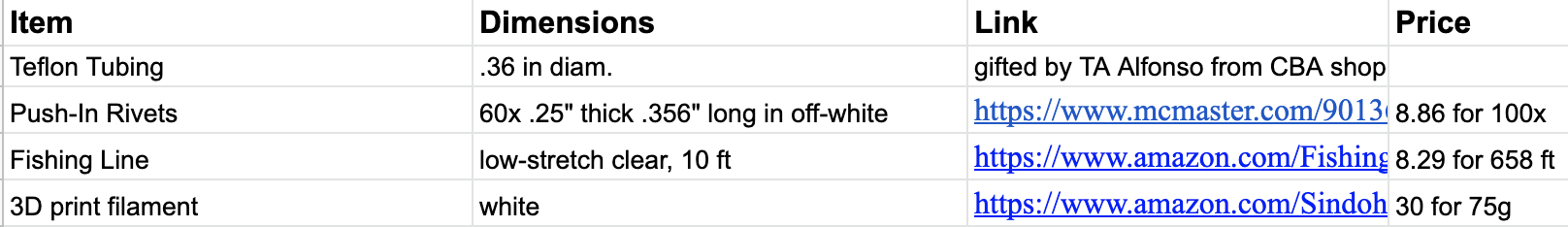

I had minimal ordering to do, most of my supplies could be found in the FAB inventory. Total price of ordered parts: $15.

Here is a complete list of all the parts used:

Mechanical Tools: Epilog Laser Cutter | Roland SRM Milling | Drill Press | Band Saw | Belt Sander | Sindoh 3D printer |

Soldering Iron | ABS Printer | Glue gun

Software: Autodesk Eagle | Fusion 360 | Rhinocerous 3D | Adobe Photoshop | Mods | Arduino | Processing

Electronics: Printed Circuit Board | ATtiny 44 | 3x2 Header | 10 uF Capacitor | 5V Voltage Regulator | 20 mhz Resonator | 2x2 Header | 3x2 SMD Header | 10k Resistor | USB to USB cable

Hardware: 3/16 Corrugated Cardboard | Acrylic | White PLA filament | Nylon Push-in Rivets | Fishing Line | Teflon Tube | Adjustable DC Power Supply