Final Project

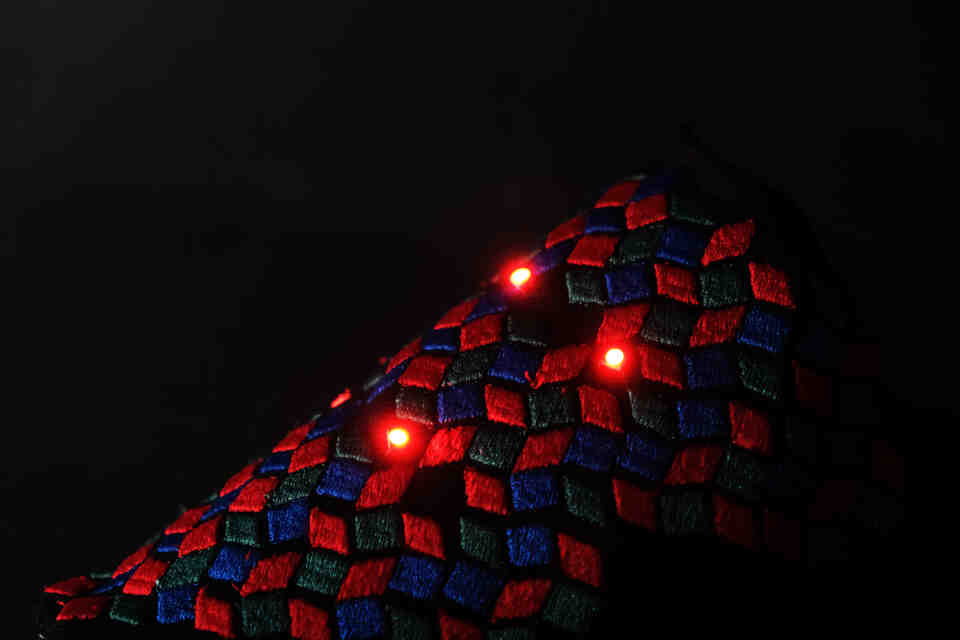

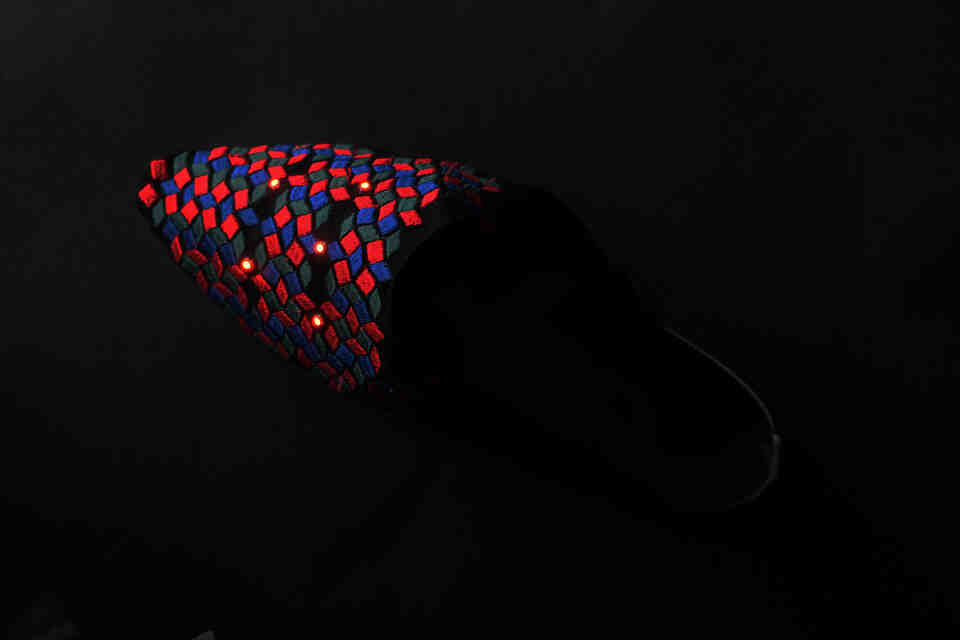

CHAMELEON SHOE

FINALLY! After intense few weeks, everything worked out to build the CHAMELEON SHOE that combines 3D printing with conductive embroidery and embedded color sensor that change the LED colors according to the stepping surface. Here the video + images that summarize my journey along the semester with all the 6 steps of building the shoe: PCB design, Color sensor + programming, CAD + 3D printing, Conductive Embroidery surface, Assembly of the the parts together and prototype test.The shoe printed with Flexible filament, and prouced with 4 different parts that connected together to a rechargeable wireless shoe

FINAL VIDEO LINK - CHAMELEON SHOE, Ganit Goldstein .mp4

FINAL REPORT

>What did you design?

I designed the entire 3D printed shoe with embbeded PCB with a color sensor working wireless with internal battery. the 3D model of the part of the shoe,the embroidery elements and the LED system (made with conductive thread and singular RGB LED. The shoe contain 4 different elements that assembly together to one piece.

What materials and components were used?

I used flexible filament for 3D printing, wool fabric, Embroidery, conductive threads, Lithium battery with charging element from Adafruit. The electronics parts consist D11C microcontroller, phototransistor and RGB LED.

Where did they come from? How much did they cost?

All the electronics are used from the Arch shop. I used flexible TPU filament from previous shoe projects.

What parts and systems were made?

All the parts were made customized to allow the wireless integration of the electronics inside the shoe. The Color sensor, RGB strip, and the conductive embroidery needed to work smoothly to allow the translation of the

What processes were used?

I used Rhino for designing the shoe parts, and 3D printing for producing the skeleton of the shoe for building the areas that the PCB will be located into the design. I also used embroidery and InkStitch software to translate my design into layers of 3 colored threads.

What questions were answered?

Can accessories communicate with our surroundings in a seamless way? And how fashion-tech could be more intuitive in producing customized garments? In am fascinated by the opportunity for us as humans to collaborate with our soundings in a seamless way. Shoes are the most interesting wearable in my opinion that can by playful and enjoyable and transfer information from our body to our surrounding and vice versa.

What worked?

The transfer of the colors to the customized LEDs through conductive embroidery, the wireless charging, the customized production of the 3D printed shoe with the PCB integration

What didn't?

It was very difficult to design and fabricate the RGB strip from scratch. It was fascinating to me to see the process with the conductive threads, but I also wished that I could use the addressable LED with my D11C microcontroller. Next time I will use different microcontroller.

How was it evaluated? What are the implications?

I believe that there is potential to work on more wearables that change colors and appearance and make seamless integration of electronics within fabric creations.

I wanted to thank sincerely to the great TA and friends along the course who keeped being the most amazing inspiration to me. Kim, Demircan, Zach, Eyal, Anthony and many more that were such a brilliant inspiration for me to work with you. THANK YOU!