Week 2

PCB production

Electronics Production

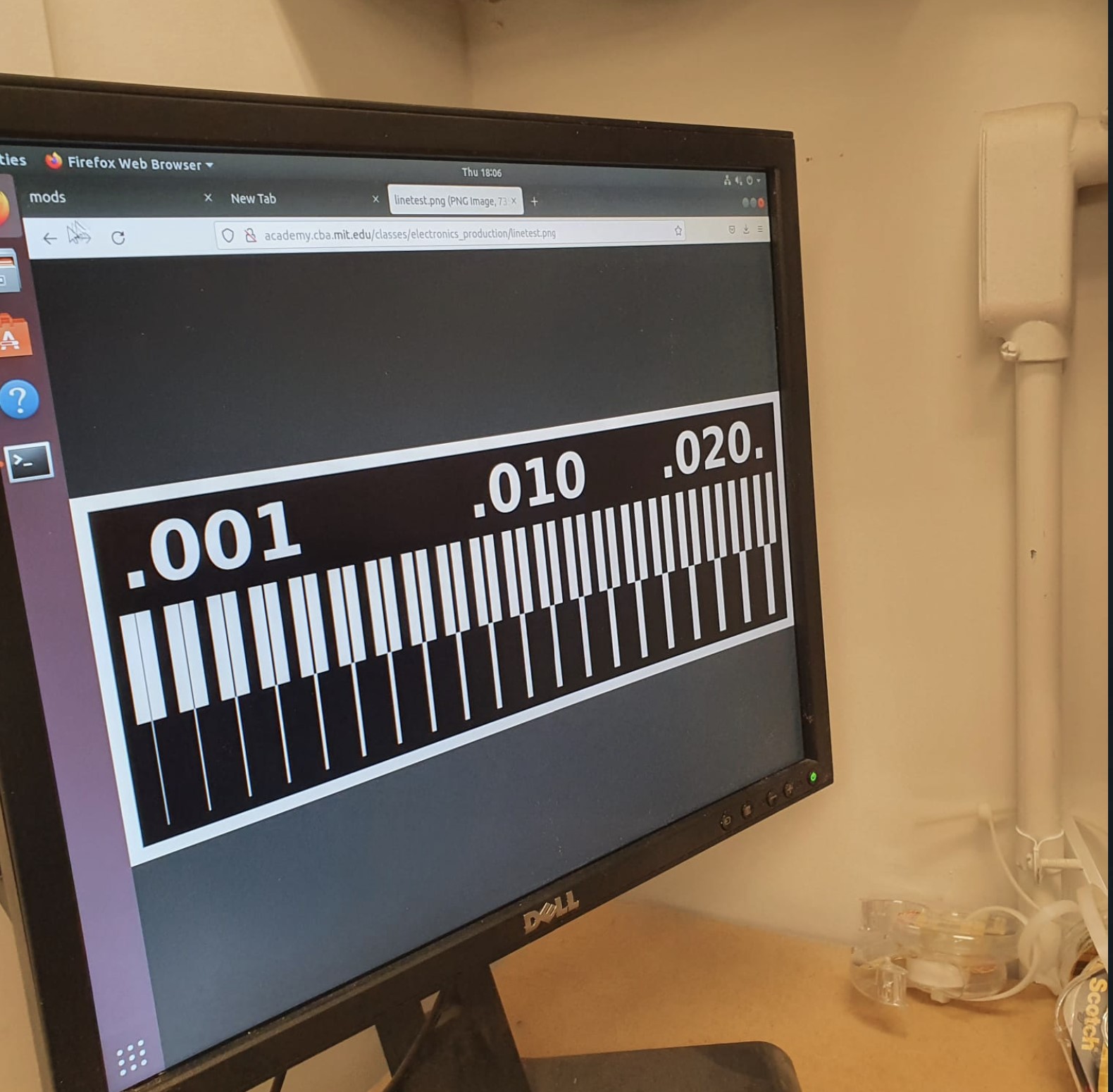

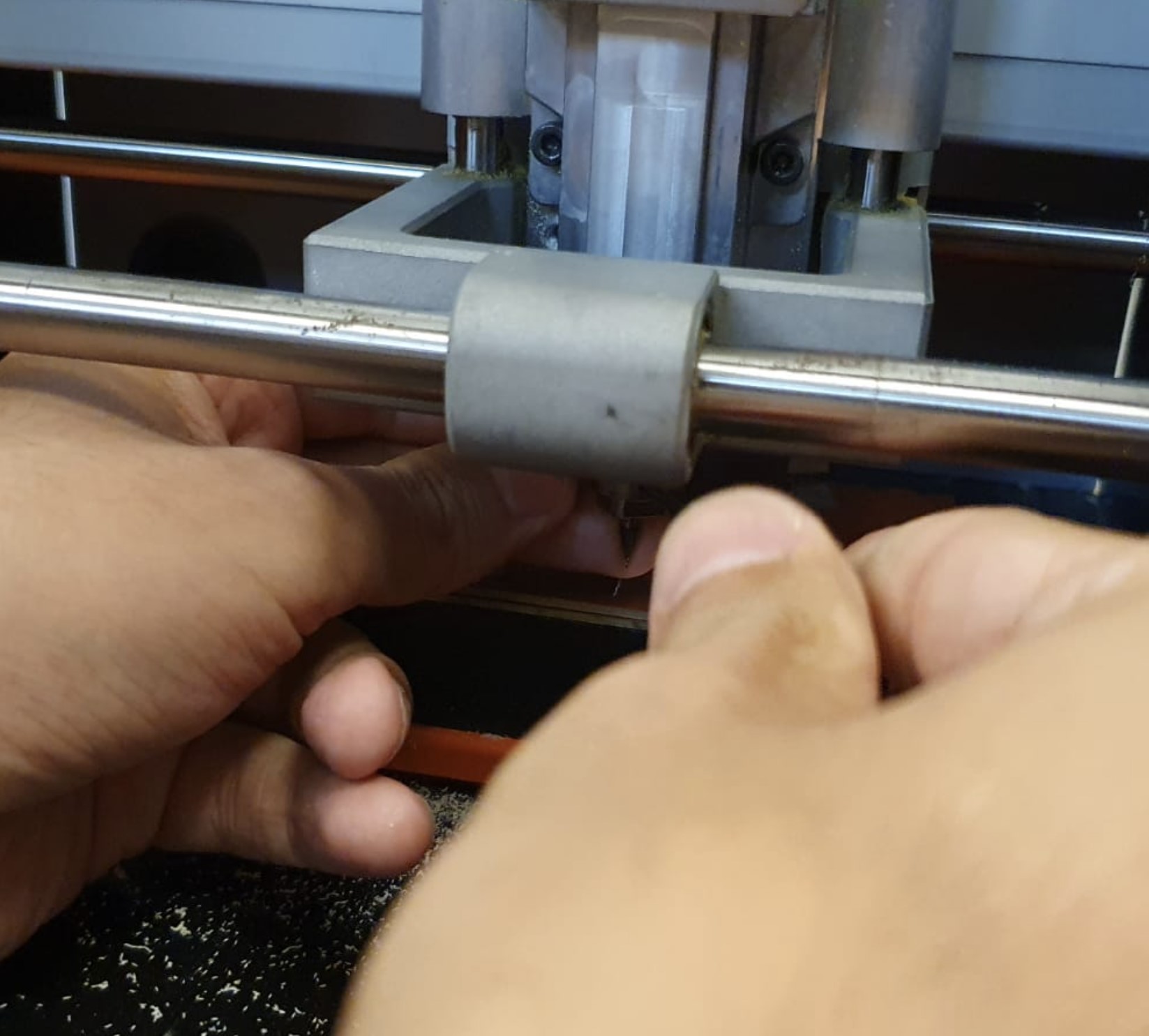

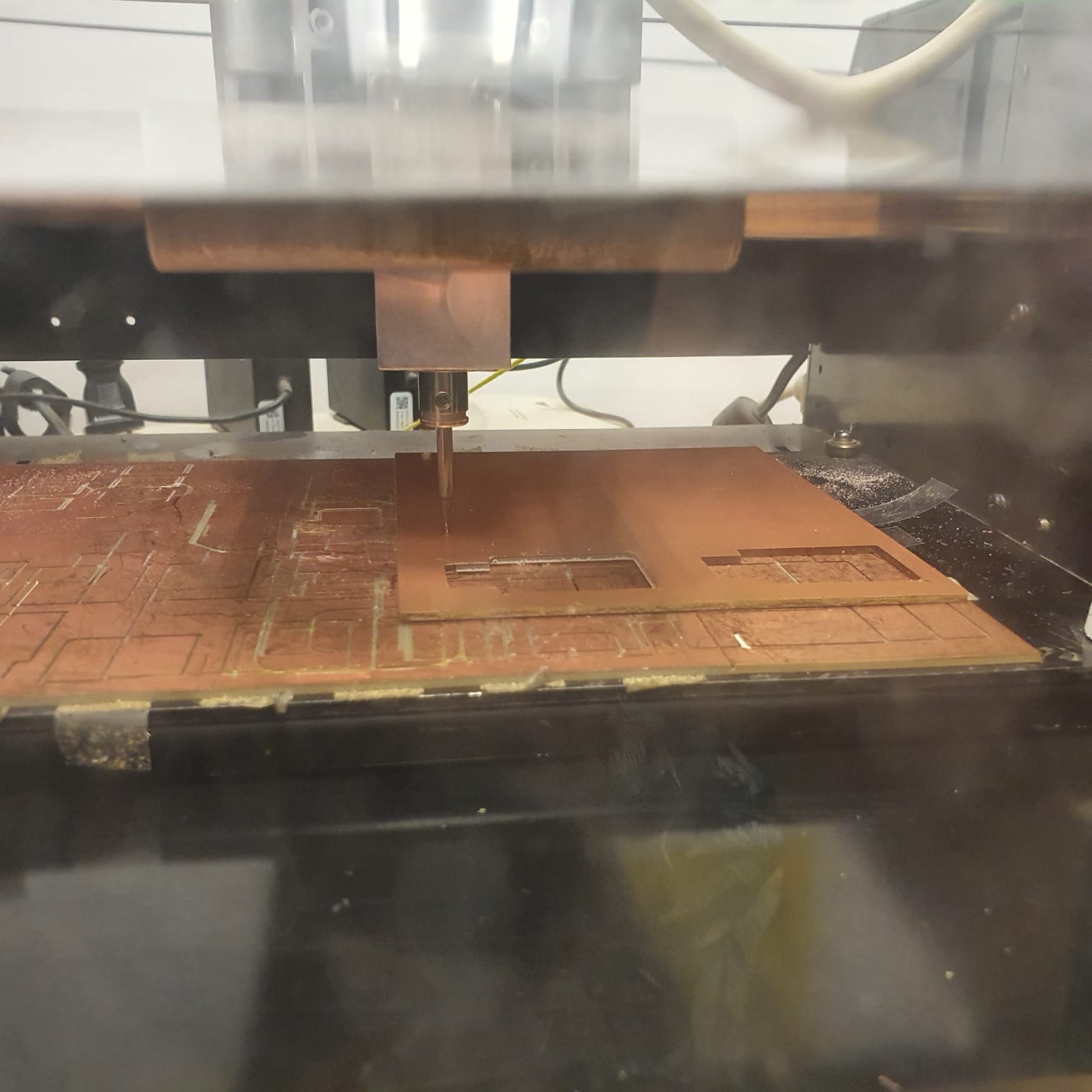

For the second week assignment, we had two tasks to explore the creation of PCB production from scratch using milling machine and soldering parts. I was using the Roland SRM-20 in the Arch shop. Firstly, the group assignment was to characterize the design rules for PCB production. I worked with Demircan, Zach, Kim and MQ from Arch department!

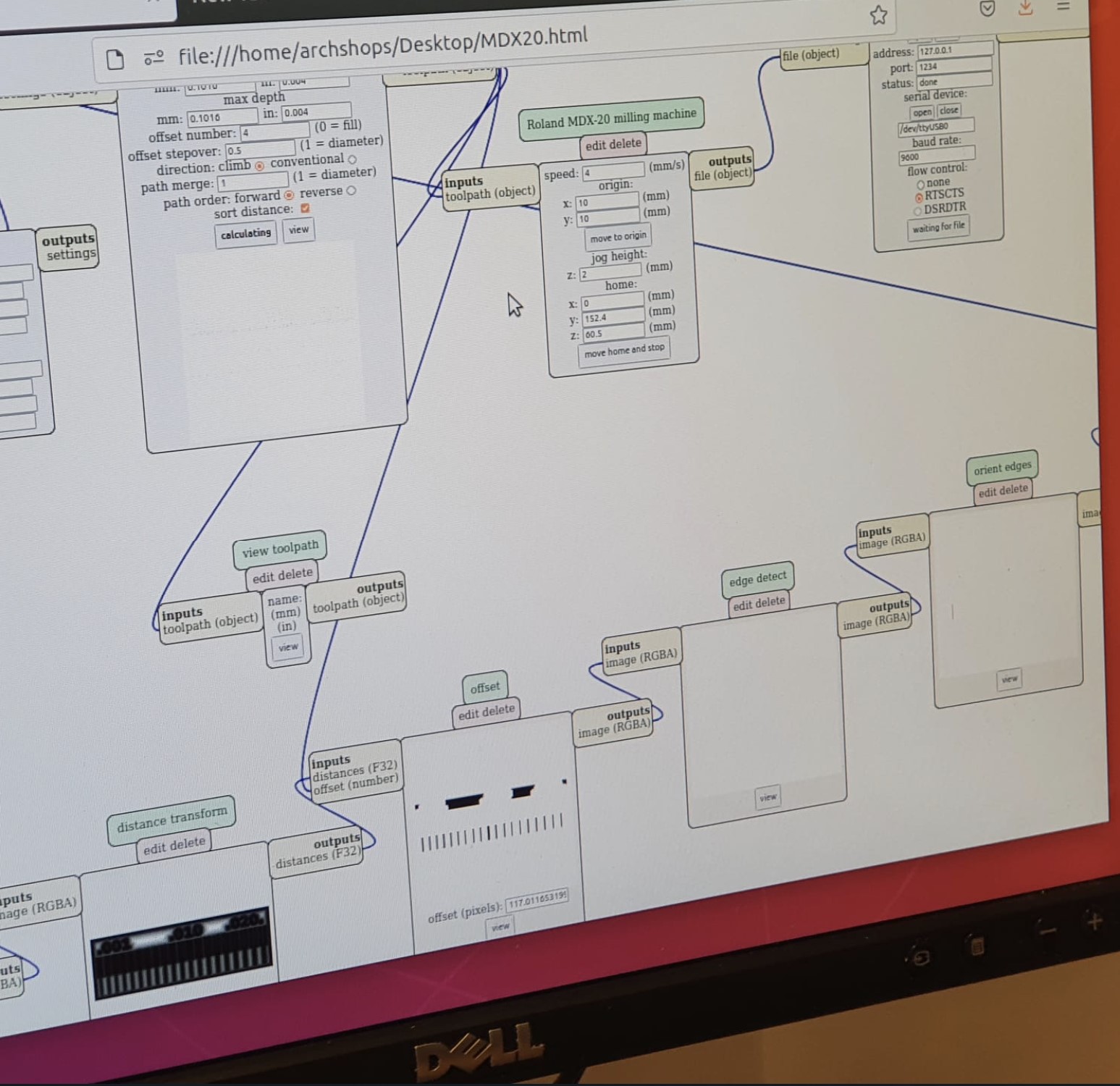

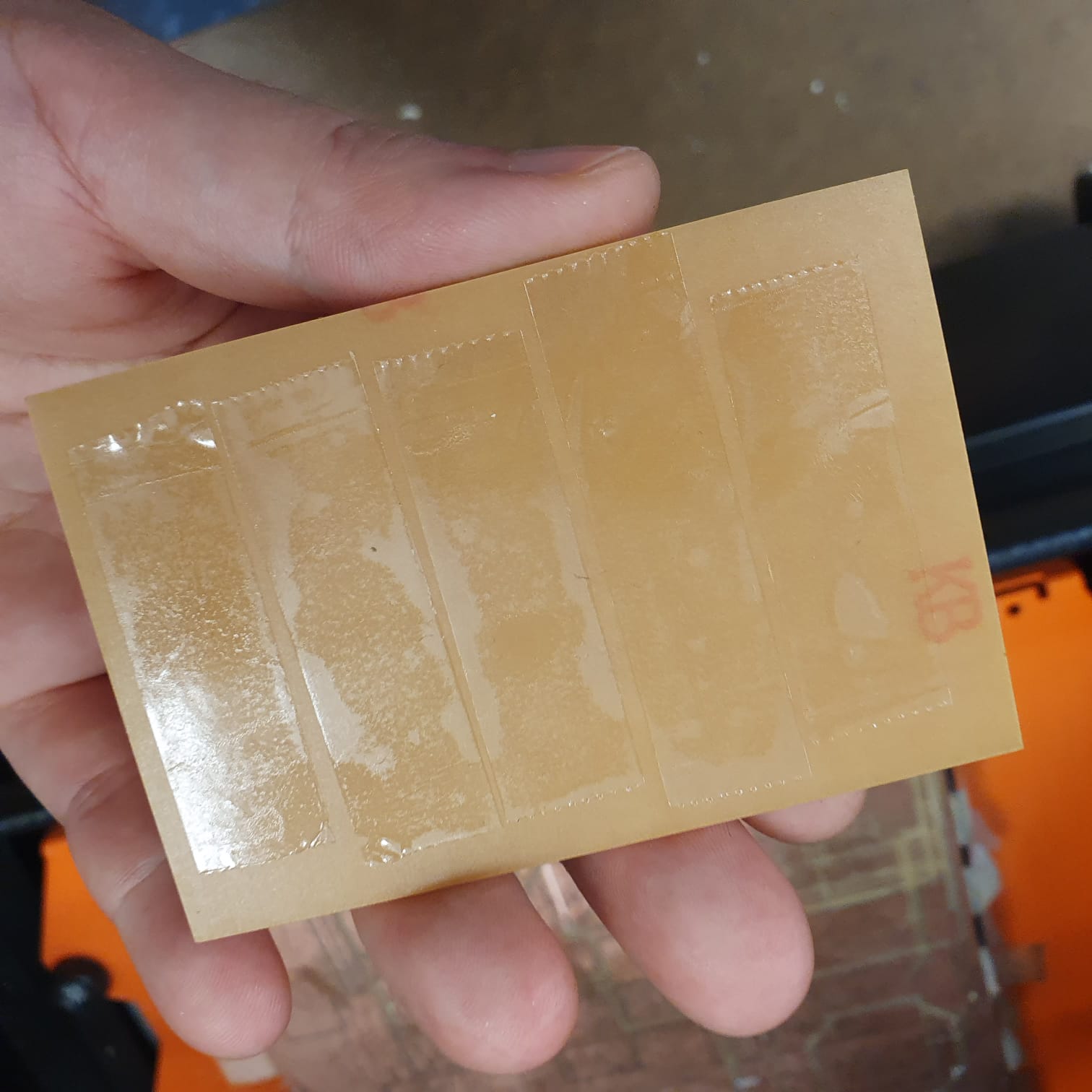

We used the CBA mods app to load the design, software. It was important to use the double tape to the board for a safe departure!

We learned how to change the parameters in the software (depth, offset etc) and coordinate the origin to our copper board.