Group Assignment

Characterize the Large Scale Milling Machine

One perk of being in the Architecture section is that we have big machines. Specifically, our section had the Onsrud CNC machine, which is huge! For our group assignment, we had to test runout, alignment, speeds, feeds, materials, and toolpaths for our machine. Big thanks to Emily for cutting the shapes to test runout and best fit.

The slits ranged from 0.6in to 0.3in. Expectedly, the 0.5in-0.5in fit the best, and this makes sense because the OSB board is 0.5in thick. We also measured the slits after the cut to see how they compared to the programmed width. Emily found that the slits are about 0.003in smaller.

Individual Assignment

Make Something Big

For this week our assignment was simple - make something big. This is my first time working in a woodshop, so my approach for this week was to err more on the side of simplicity, but build something that would be very useful for me. I decided to build an adjustable lap desk, because I'd like to sit on my sofa and/or bed with my laptop and not have it overheat or lie awkwardly in my lap. I'd also like to have a nice platform on which I could eat breakfast in bed. Here is my design (made in Fusion 360):

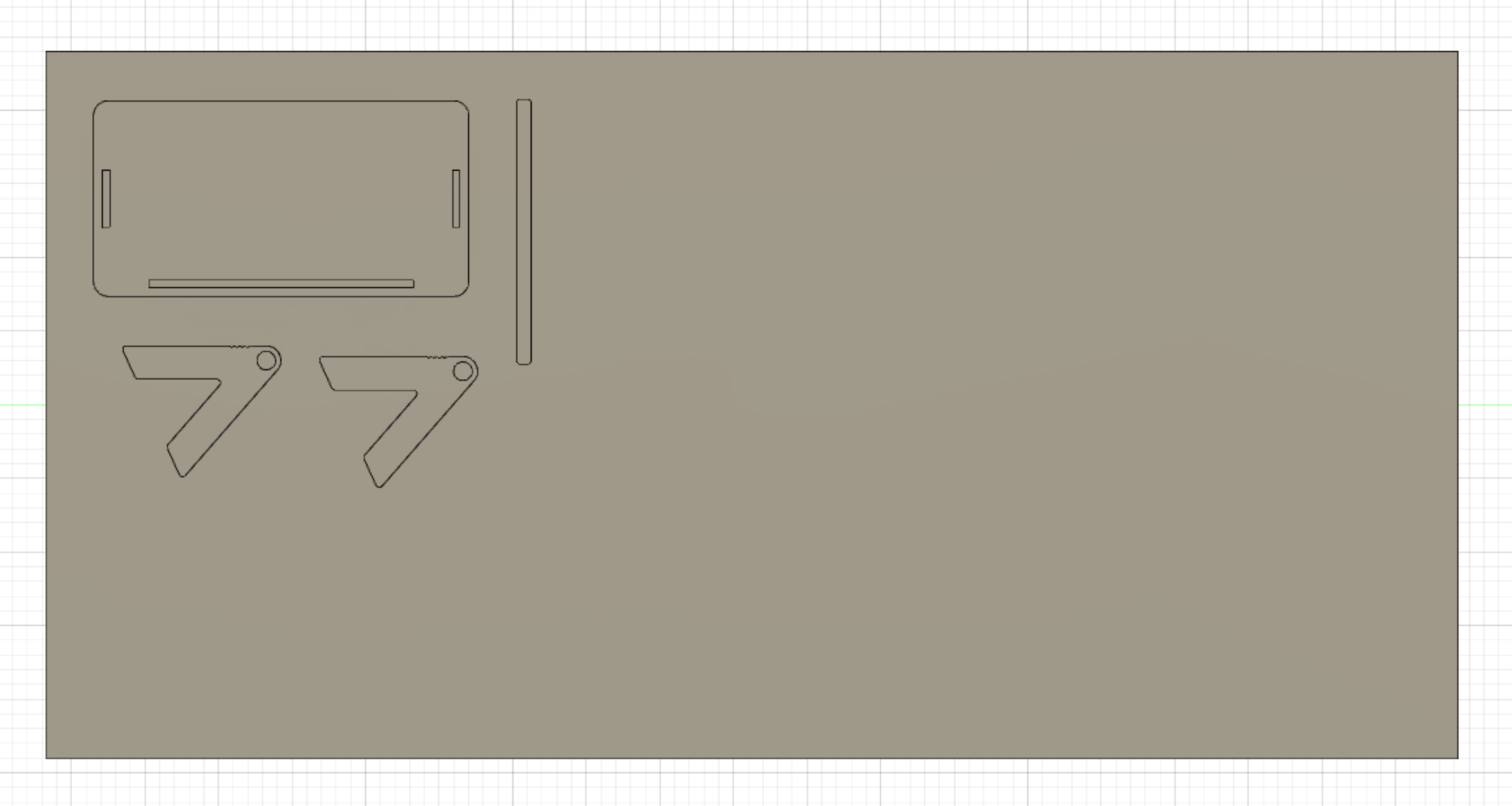

It's very simple - it just has two legs, a table top, and a ledge to prevent stuff from sliding down. The legs slide directly into the two slits in the table. I added teeth along one side of the legs so that the table's angle could be adjusted and stick in place. The whole design is parameterized. Lastly I layed out all my components on a 4ft x 8ft sheet, and exported the faces as a .DXF file. I made sure not to place my pieces too close to the edges because otherwise they may break easily since OSB is a brittle wood.

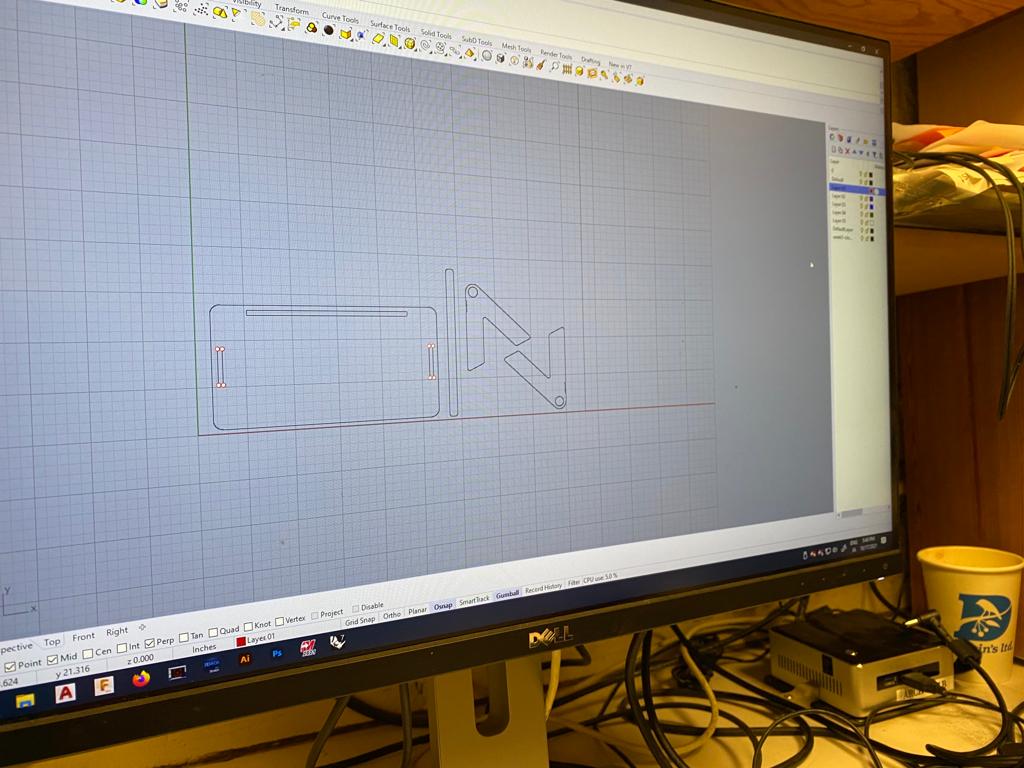

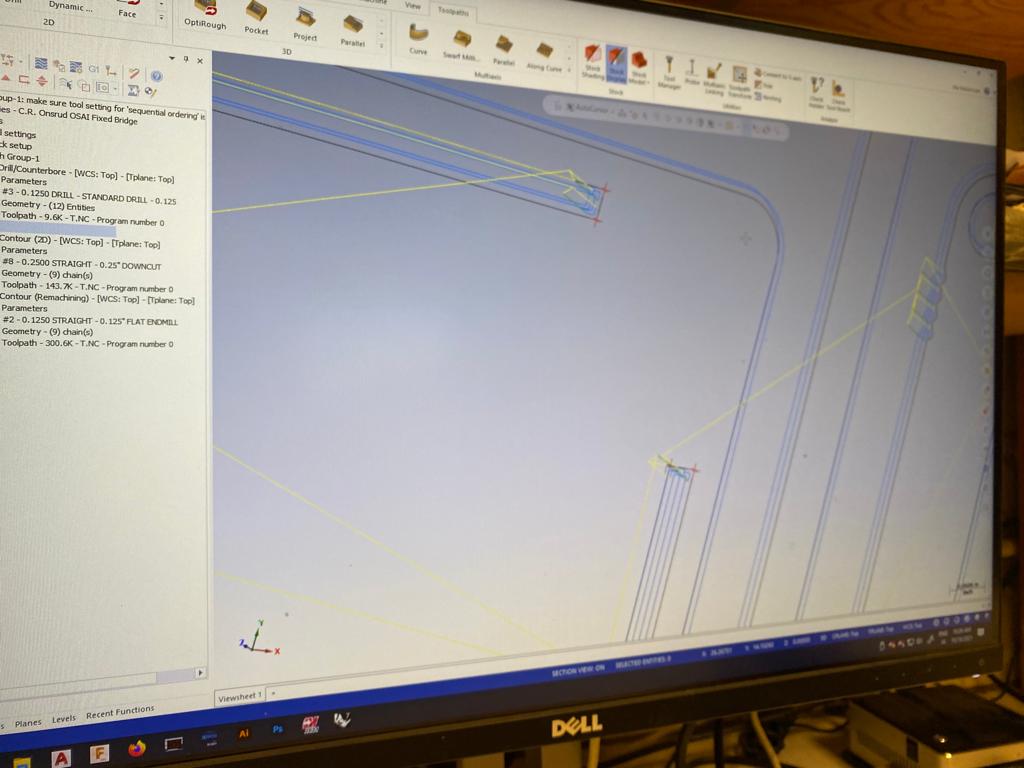

Next step was to import my .DXF file into master cam. Calvin helped me from here on out. I emailed him my .DXF file, and he already had it prepped and ready to go by the time I reached the shop! First thing Calvin did was rearrange my pieces to fit tighter together to save space. There were a lot of complicated steps that Calvin did to set up my file in master cam, and to be honest I did not fully understand all of them. At a high level, we needed to split my file into 3 different layers, each corresponding to a different sized router bit. The three layers are basically: drilling (for inner corner points), cutting (for lines), and re-machining (to fix corners). As an example, we used a 0.125in drill bit for drilling holes in the inner corners. This creates the so-called mickey mouse ears, and this makes it so that straight edges can fit into the slits.

Now that the file is preppeed, it's time cut! The first thing we did was perform an air-cut, meaning we don't actually cut the wood becaue we set the z height above the stock. This is to test out our gcode and make sure the machine is following the correct instructions. Once the air-cut passed, we adjuts the z height and began cutting the actual stock. The actual cut time was about 7 minutes because my design was simple.

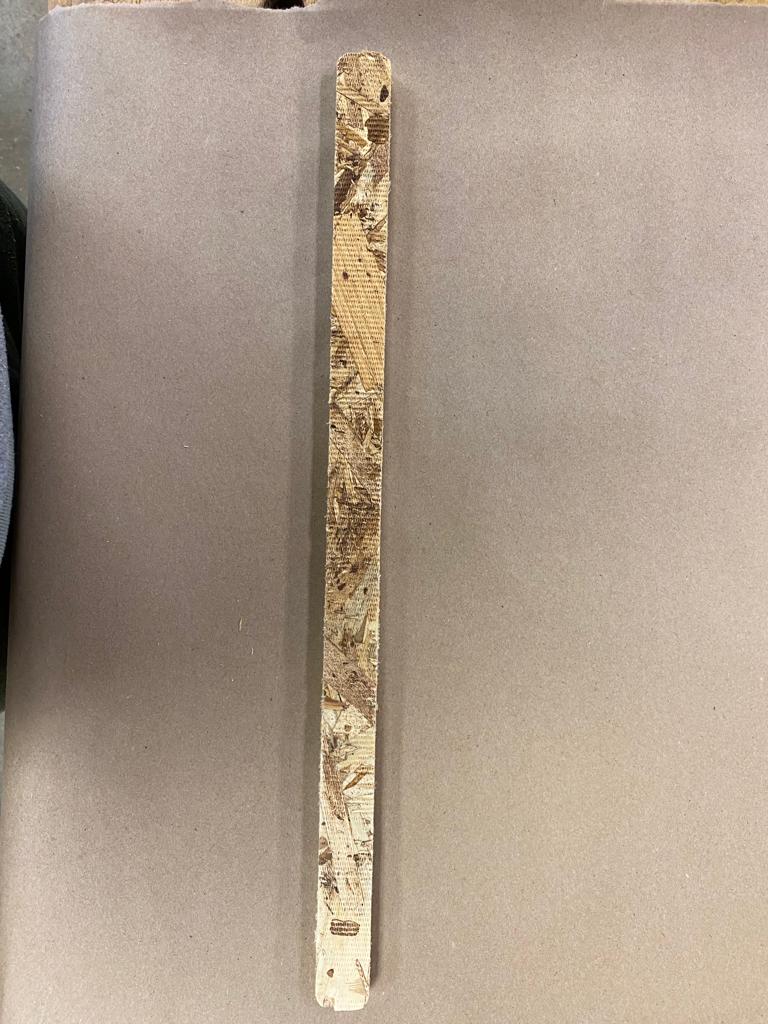

Here is what the stock looked like after machining, and what the pieces looked like after I popped them out:

The pieces were quite rough around the edges, so I got to work sanding and filing. I used a sanding machine, as well as regular sand paper and filing tools. The sand machine was quite powerful so I had to be careful not to keep an edge pressed on there too long otherwise I could take a way too much wood.

After sanding and filing, these are what my pieces looked like. I was nervous at first that my teeth might be too fine to come out clearly in the machining, but I was pleasantly surprised with how well they turned out. I used the round filing tool to make them more defined.

And here is my lap desk fully assembled. Overall I'm quite pleaed with how it turned out! I'm most happy to see that my adjustment mechanism is working.

Unfortunately it is a little wobbly, as you can see. I can think of a couple things that could have gone wrong. I could have over-sanded the face of the leg, or I could have over-filed the slit in the table, or both. This may explain the not so snug of a fit.

To fix the wobble, I could be more careful next time when I sand/file. I could also add a then support beam across and connecting both of the legs underneath the table. I did not use glue here to fix the wobble because if I did I would no longer be able to change the angle of the table.

All wobbles aside, it is still a useful piece of furniture! Here it is being used in a real life environment :)