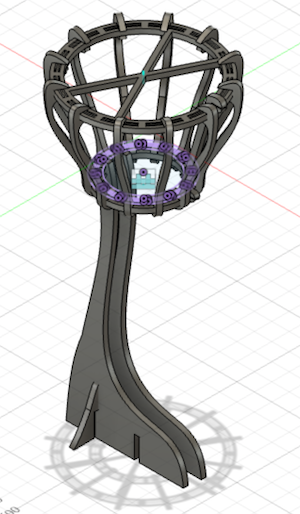

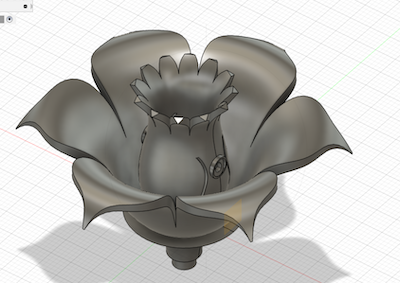

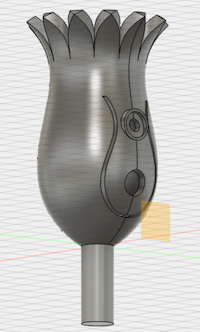

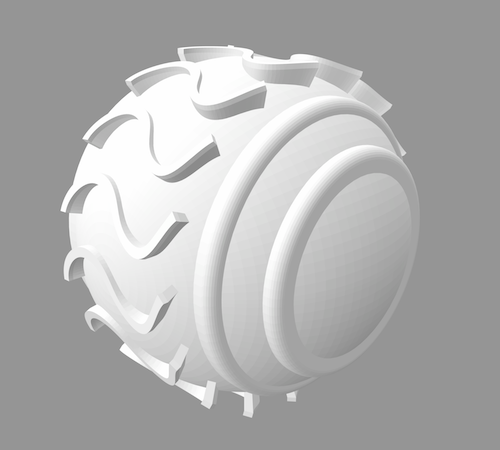

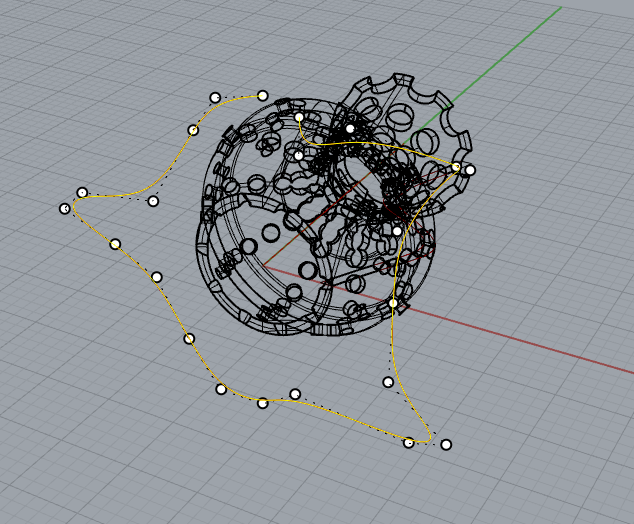

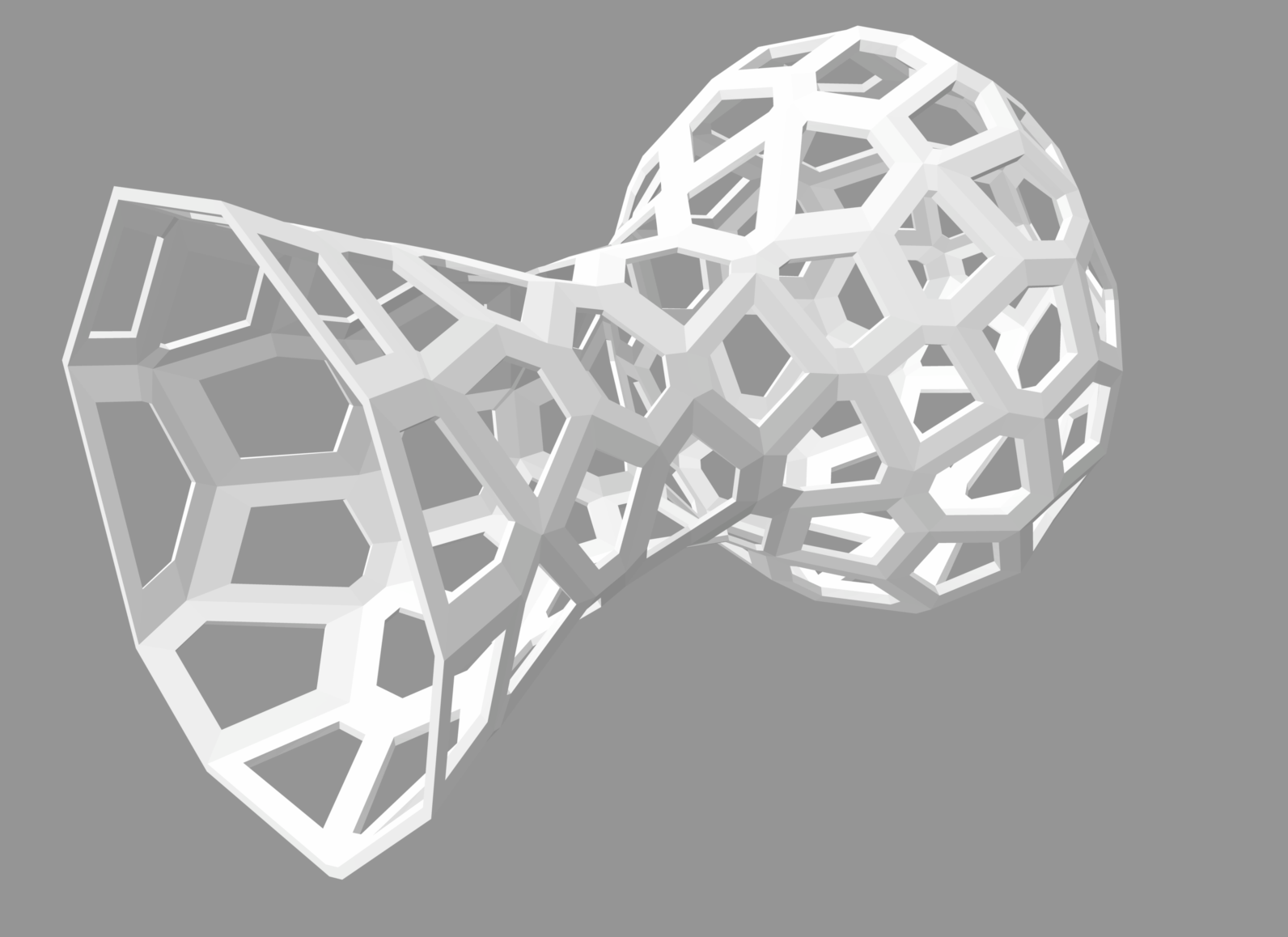

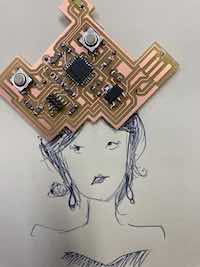

I made a very simple model of a snitch.

I didn't have much time, plus, a super exquisite affair just isn't fitting for a non-champion, say what?

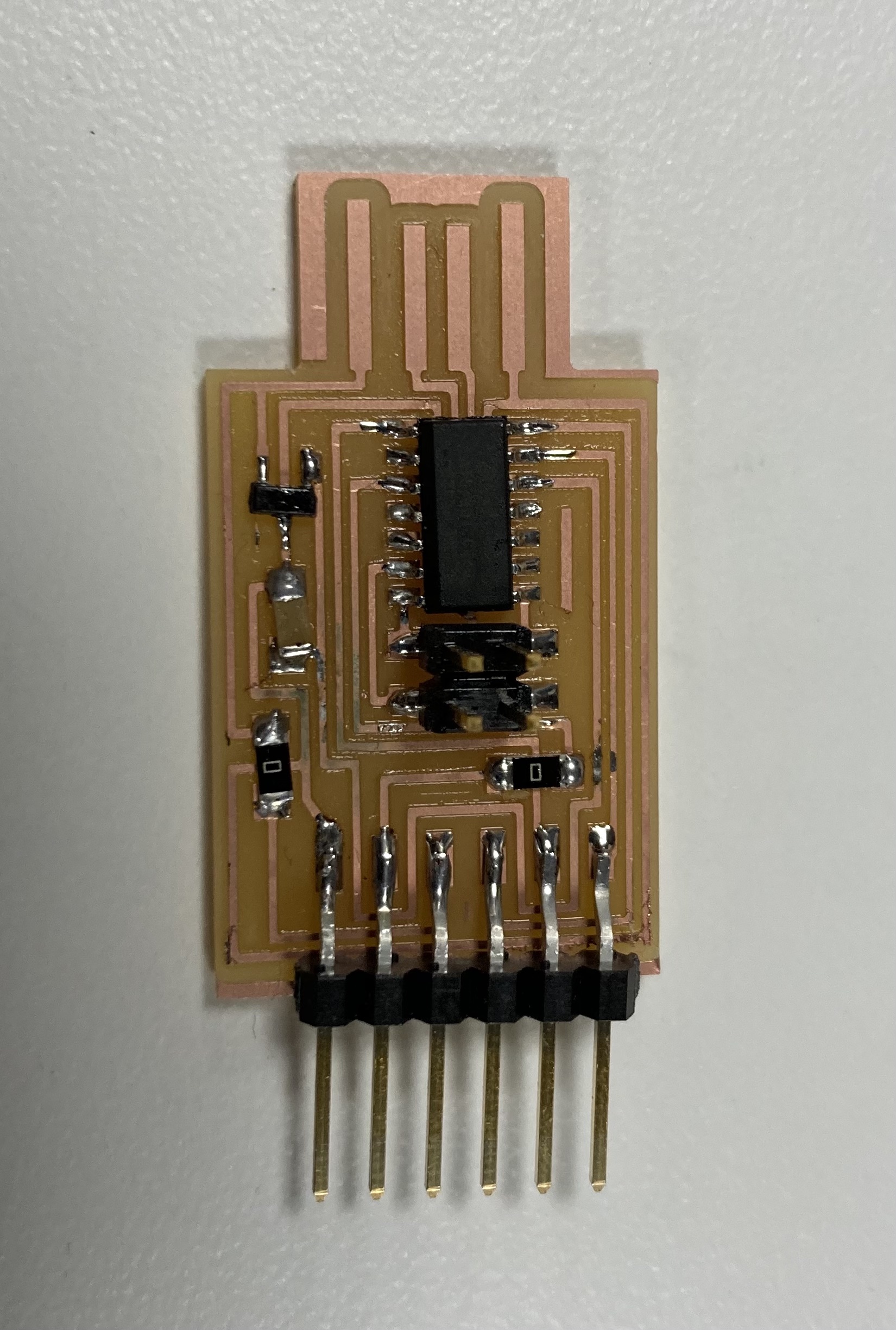

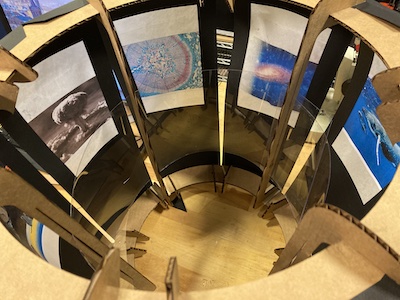

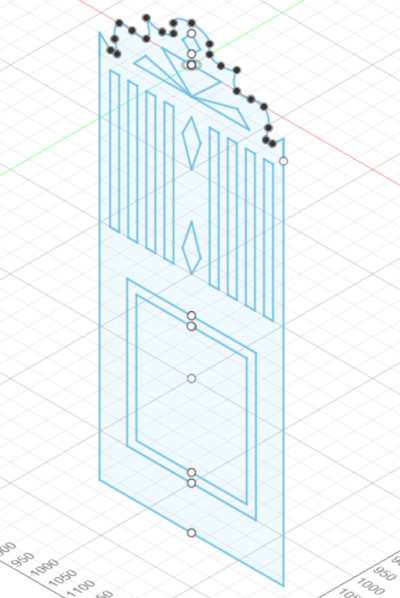

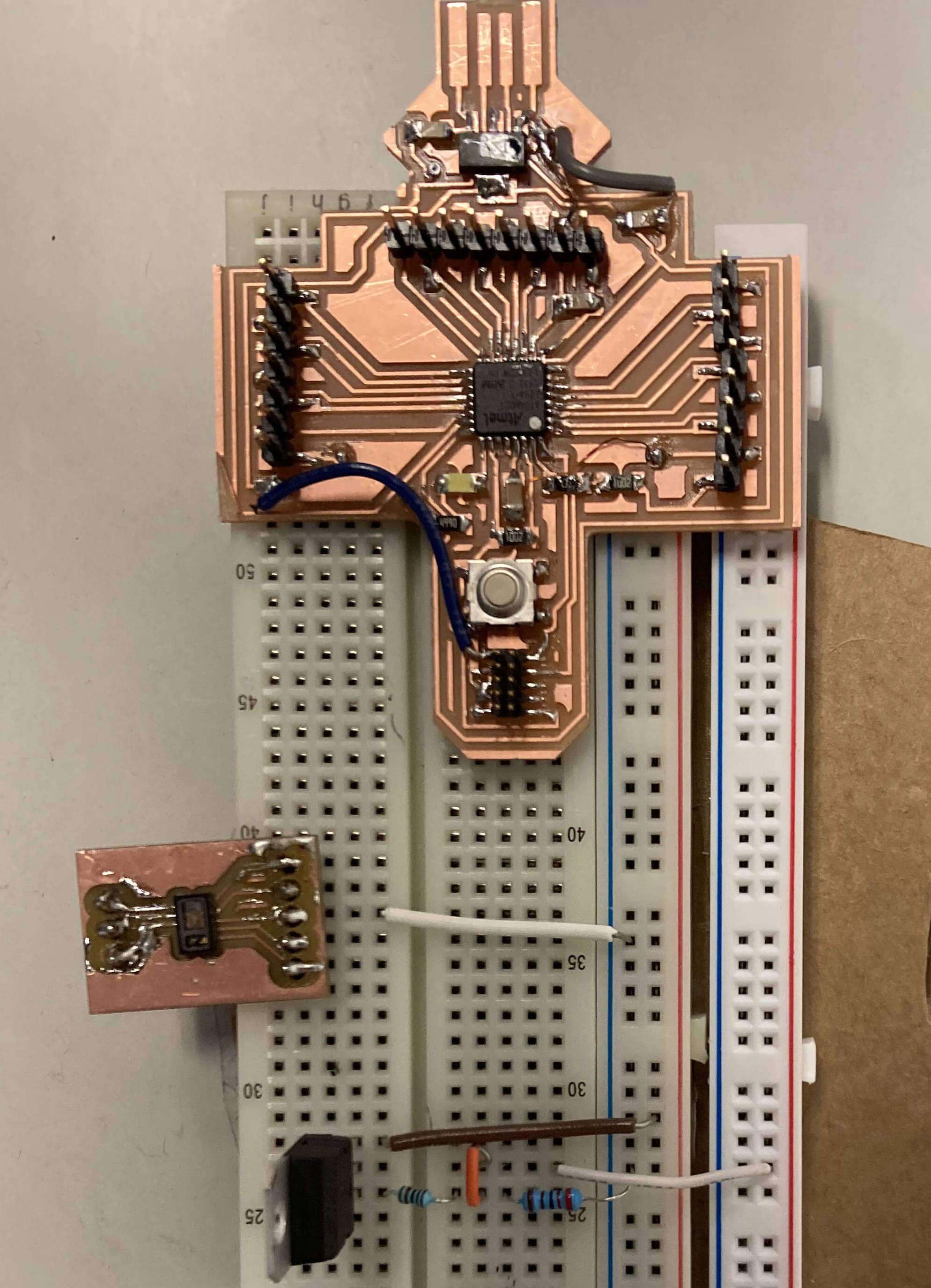

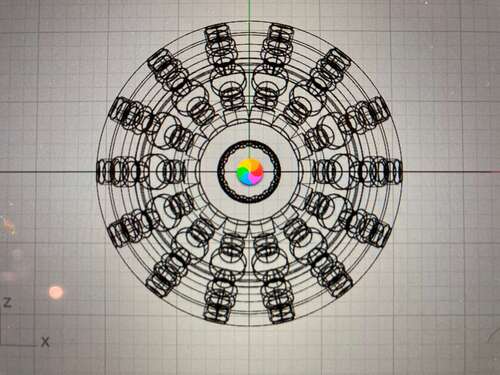

I then imported my model to SB Part-Works 3D to set-up the 3D toolpath. I split the model in half using a cutting plane and made a symetrical 2-part mold.

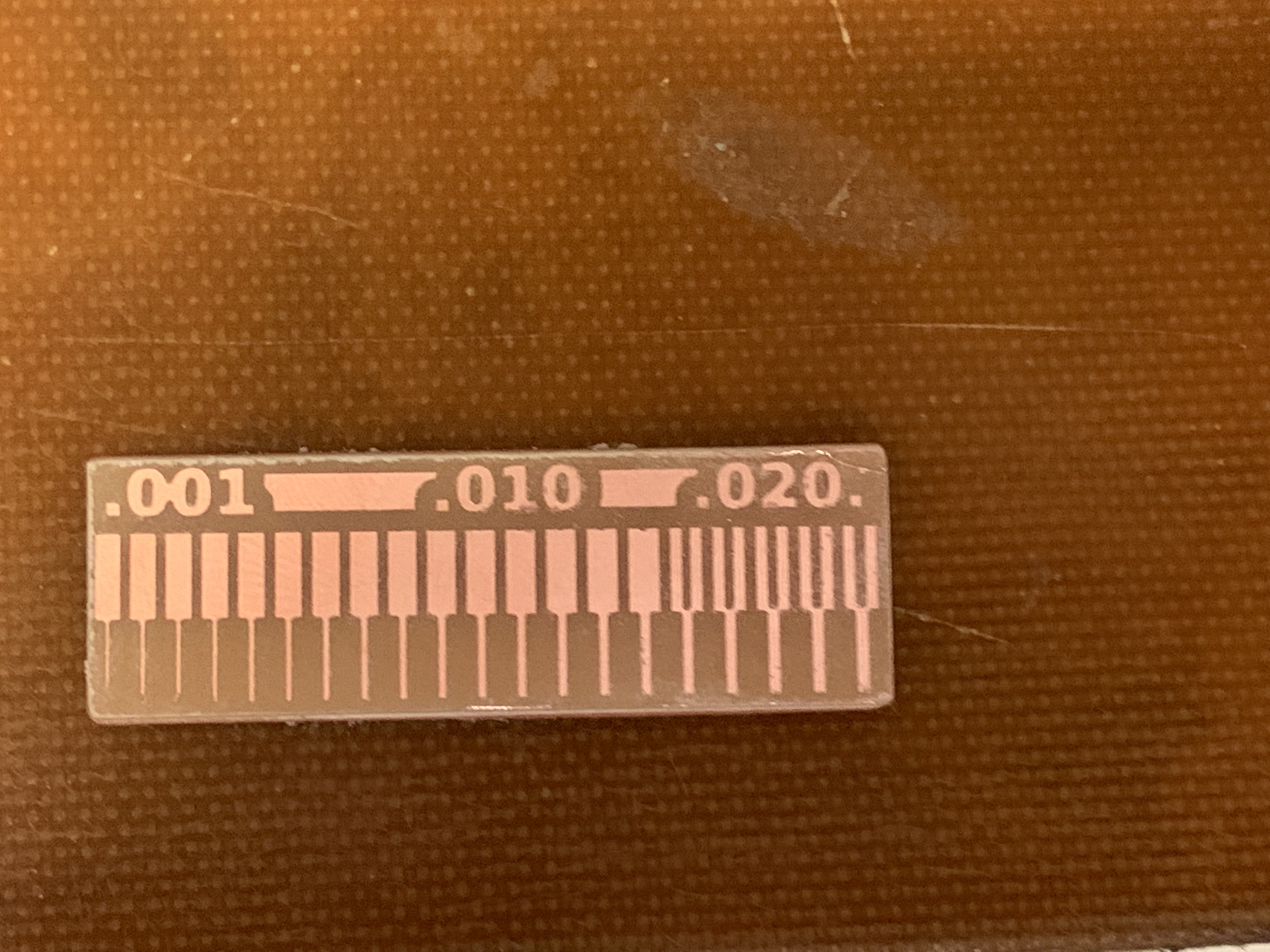

We were skeptical about how the small wavy features (~2mm thickness) at the lower edges of the snitch would turn out, but the toolpath render looked really good.

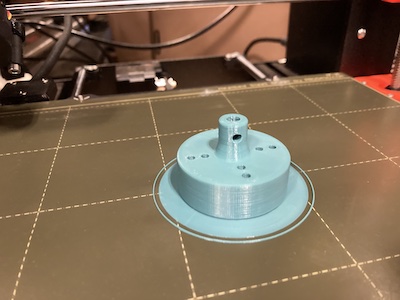

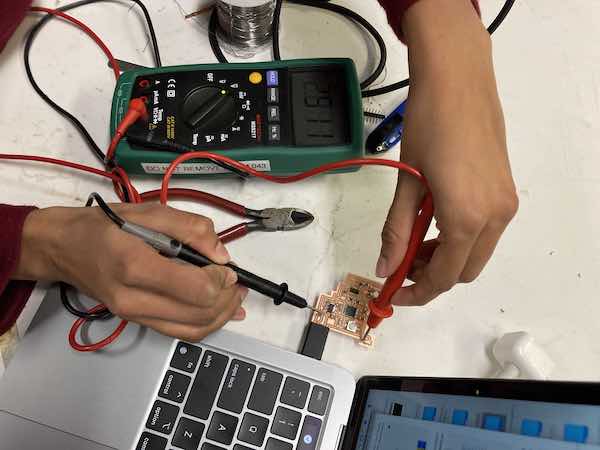

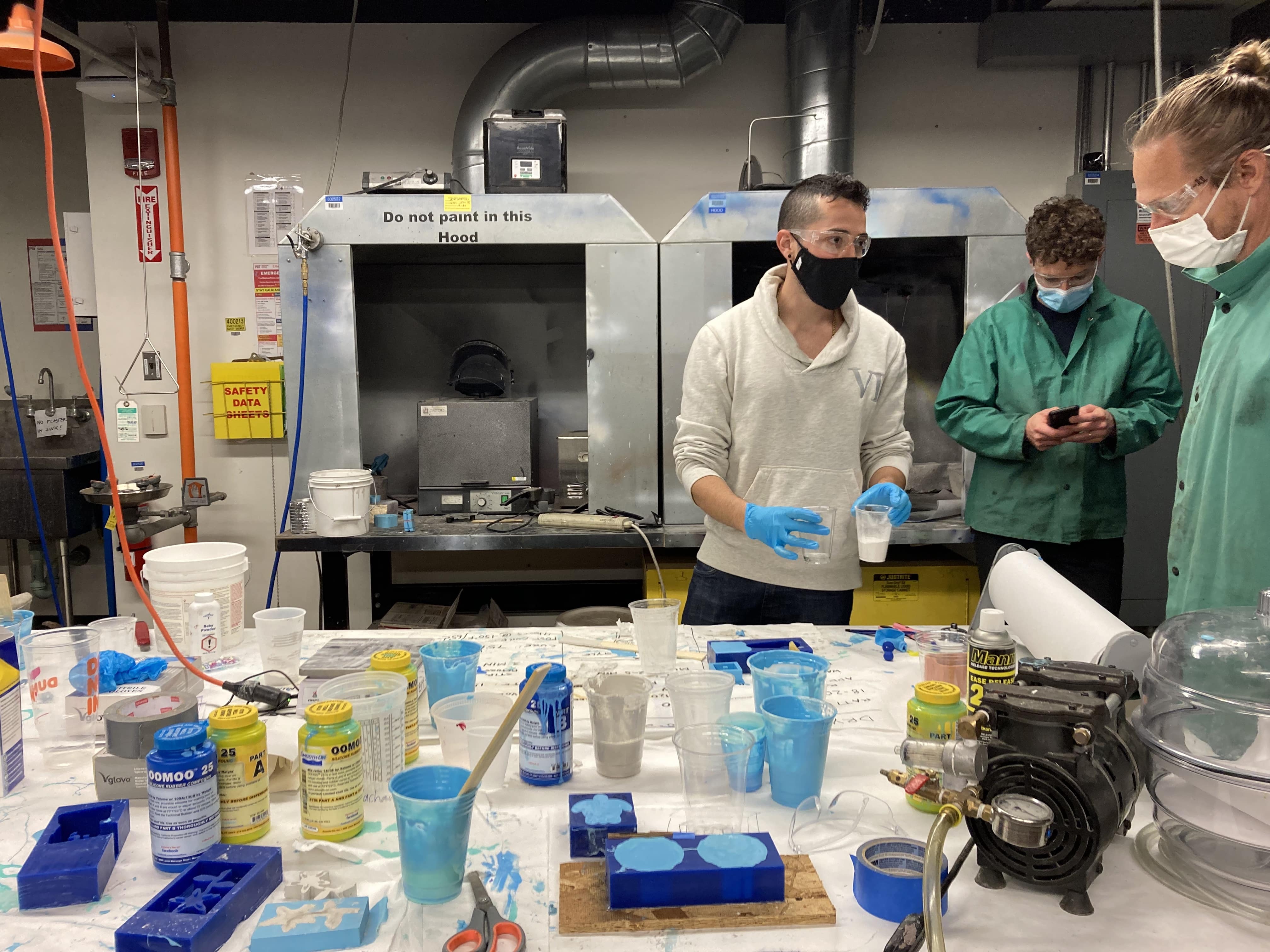

I started my milling job and it took about ~20ish minutes for the roughing path, and 12 minutes for the finish path.

Since I had a symetric 2-part mold, I had the choice to either mill twice (~35 minutes/run) or make my silicon mold twice (~ 3 hours/run (which includes time for pouring, mixing, panicking, casting, curing)).

The choice was obvious.