Week 4 - Electronic Design

— weekly — 2 min read

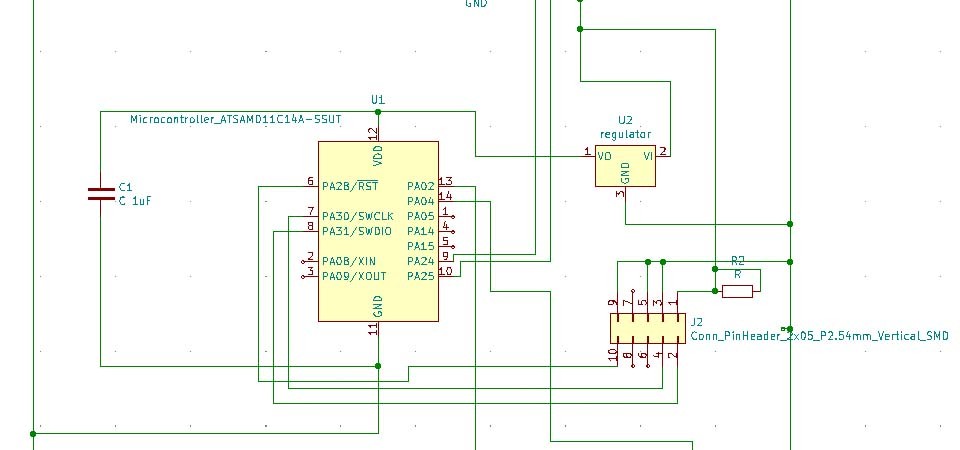

In this week we were asked to design our own PCB board. I followed the recitation and decided to use KiCAD for that task. While my experience with KiCAD was relatively OK, the learning curve was quite long mainly due to lack of knowledge of the electronic parts and how to read a diagram properly. After some TA help, I ended up designing a board that is based on Neil's D11C.echo board. I added an LED and a button from the lab library and life looks good!

But, then other people at the lab said that the 4-pin header used in this board won't work, and in order to be able to program the board I had to redesign my board to use a 5x2 programmer header (problem #1):

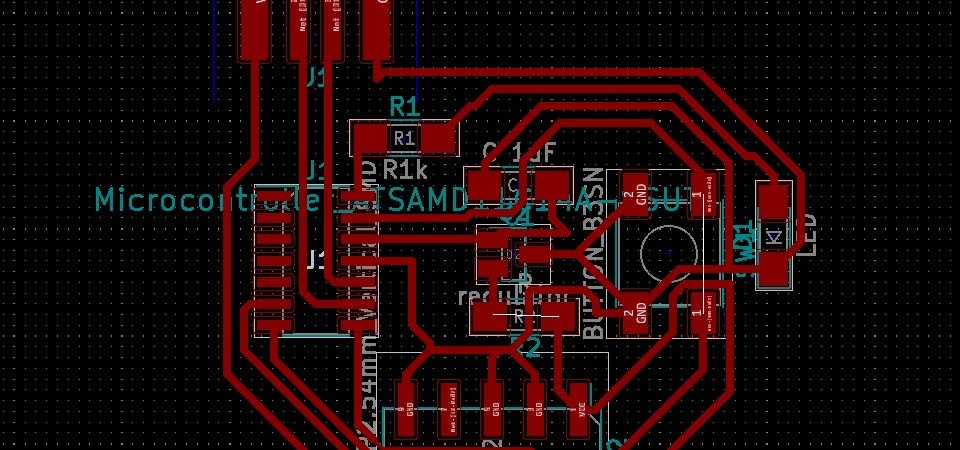

After hours and hours of work trying to connect the traces, I ended up with this circuit:

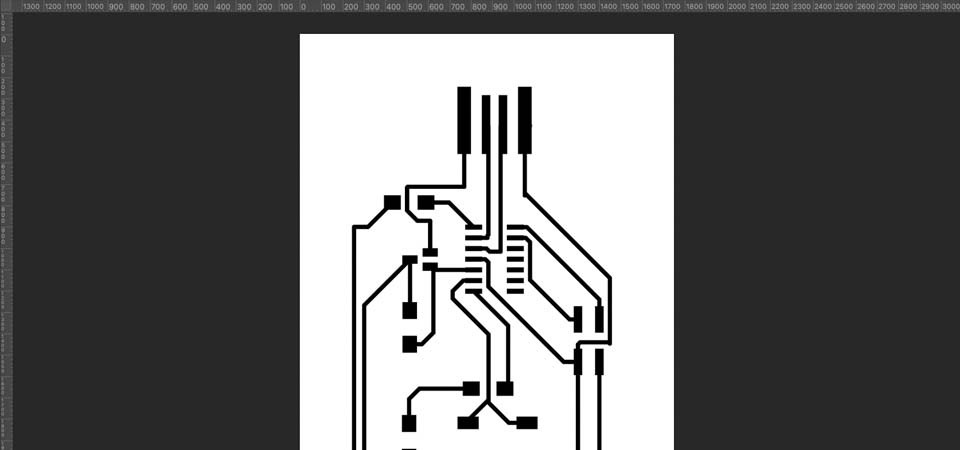

Unfortunately, this didn't work because in order to relax all the constraints I had to make a trace with clearance lower than the minimum allowed with our milling machine. So I had to come up with another plan. Luckily, while I'm looking for alternatives, I was informed that the 4 header programmer actually can work! So I happily went back to my original plan. Now I had to export the traces from KiCAD to some vector software in order to create a suitable SVG image for MODS. My software of choice was Adobe Illustrator.

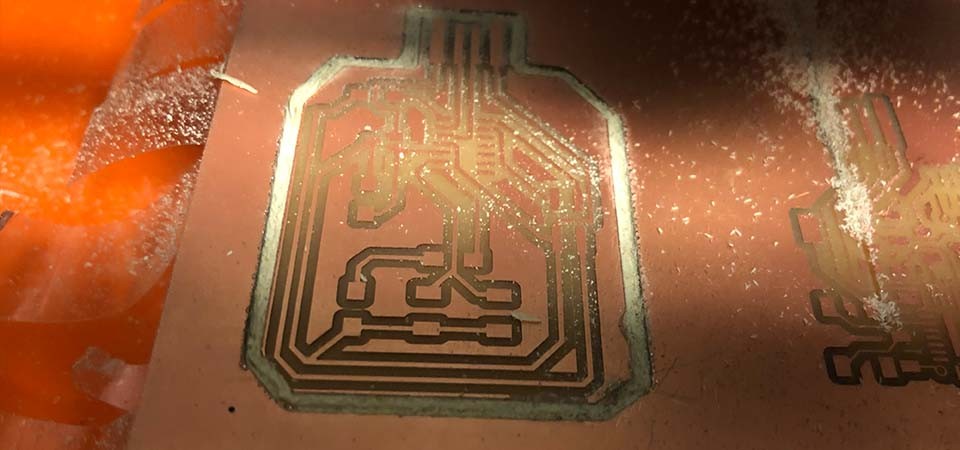

Now comes problem #2: Illustrator output SVG cannot be imported properly to MODS. This forced me into using the PNG mode. I turned to Adobe Photoshop to do the outlines part and went on milling:

And here's problem #3 - after 4 hours of waiting to the one (!) milling machine we have in the shop, the outlines that I manually added in Photoshop were too close to the traces which made my (seemingly ok) board crop. Moreover, apparently the endmill was broken and it did not cut all the way through, and I had to pass my turn on the machine to the next guys on the list. This had significantly killed all the time I had to work on the project and I could not even make it to the soldering and programming parts. I hope to complete those in the upcoming week, hopefully there will be less demand to the machines by then.