Week 4

3D Printing & Scanning

Printer Calibratoin

Before any work could be done, our EECS group needed to test the characteristics of our 3D printers, a Prusa and Sindoh. The goal of this work is to determine certain limits that inform the design of objects. The categorical tests can be seen in the table to the right. For more information, visit the group site.

| Characteristic Tests | |

|---|---|

| Supported Overhang | |

| Supported Clearance | |

| Unsupported Overhang | |

| Unsupported Angle | |

| Unsupported Bridging | |

| Wall Thickness | |

| Dimensions | |

| Anisotropy | |

| Surface Finish | |

| Infill | |

3D Printing

After testing the characteristics of the printer, I set out to design a 3D object in OnShape with a specific challenge, to test the limits of an unsupported object

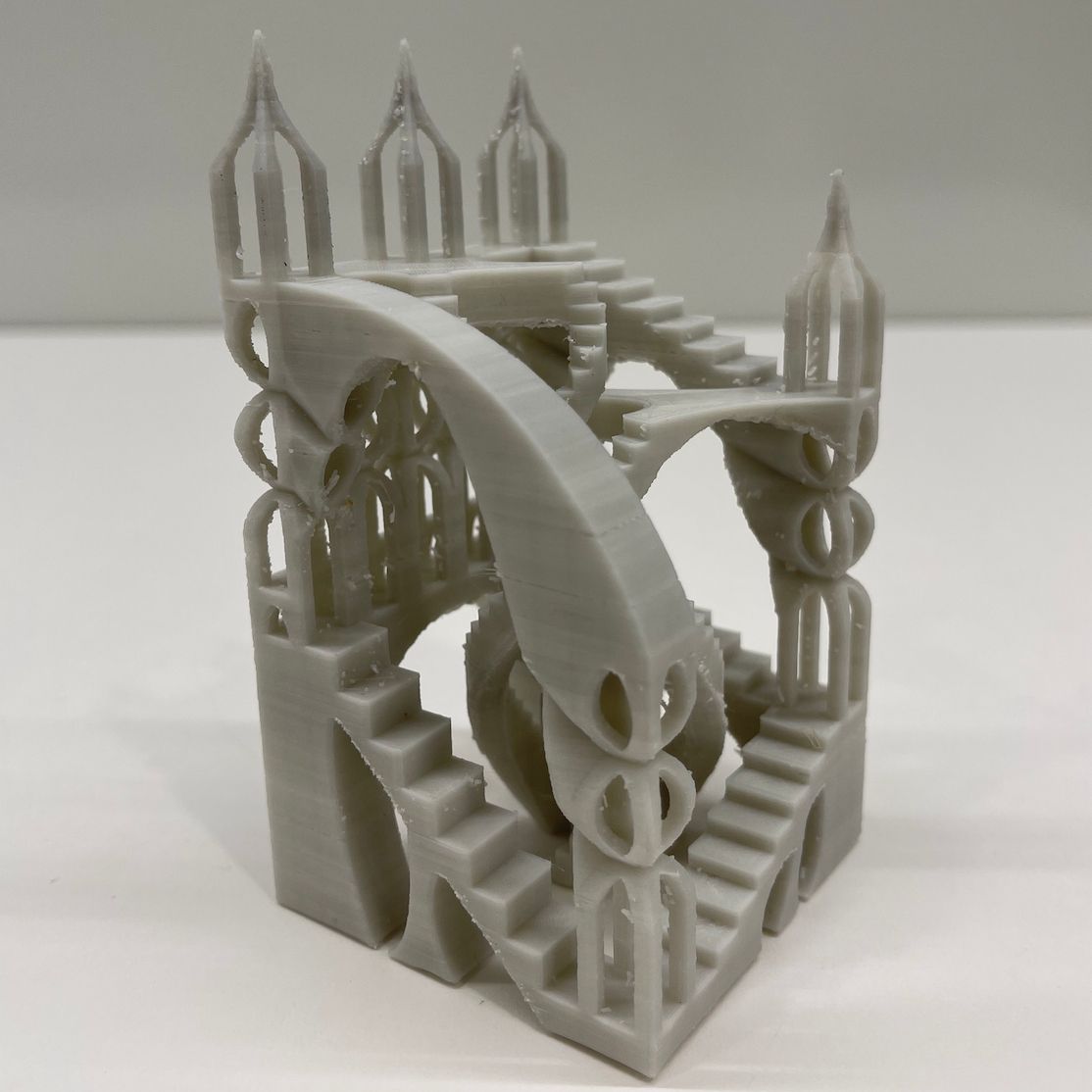

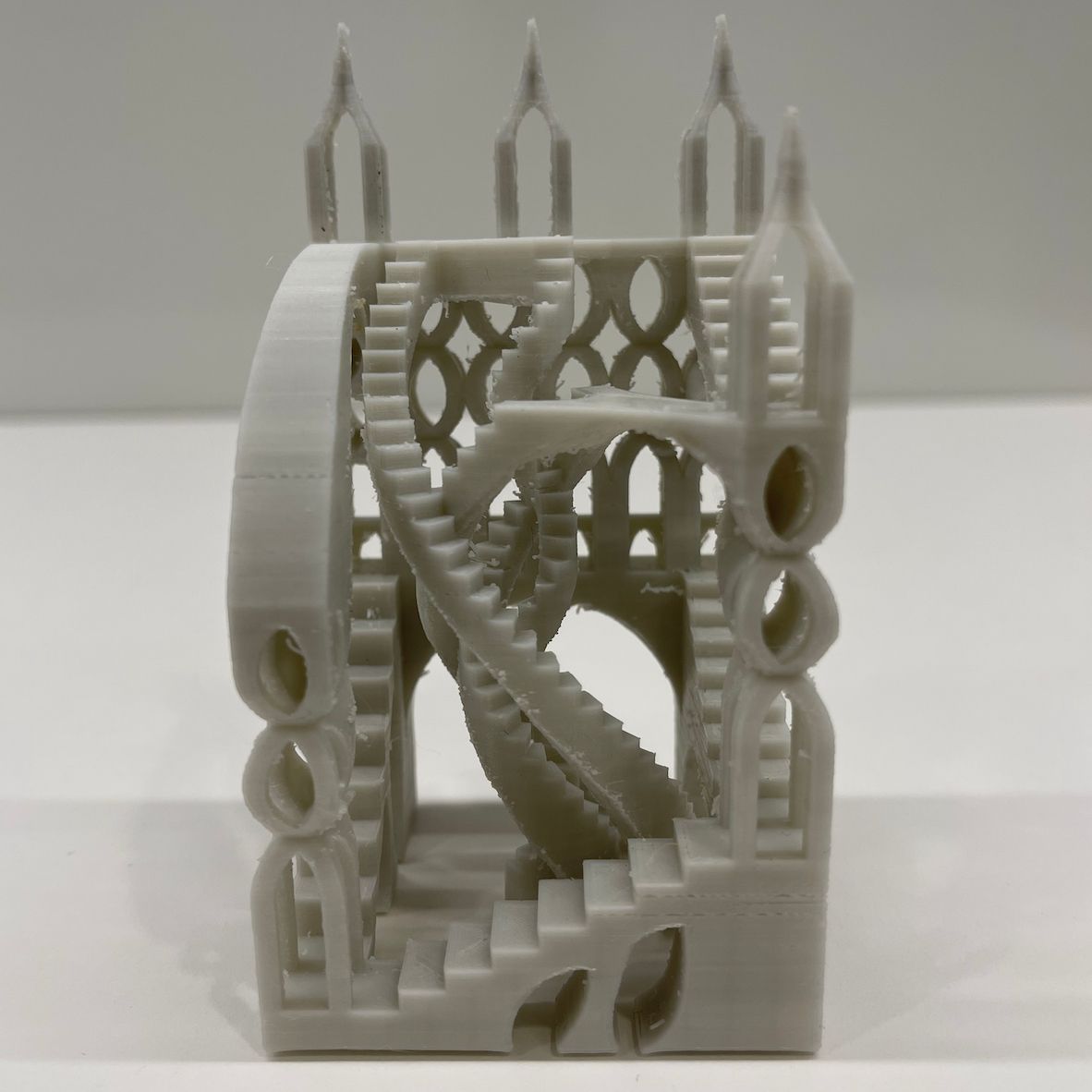

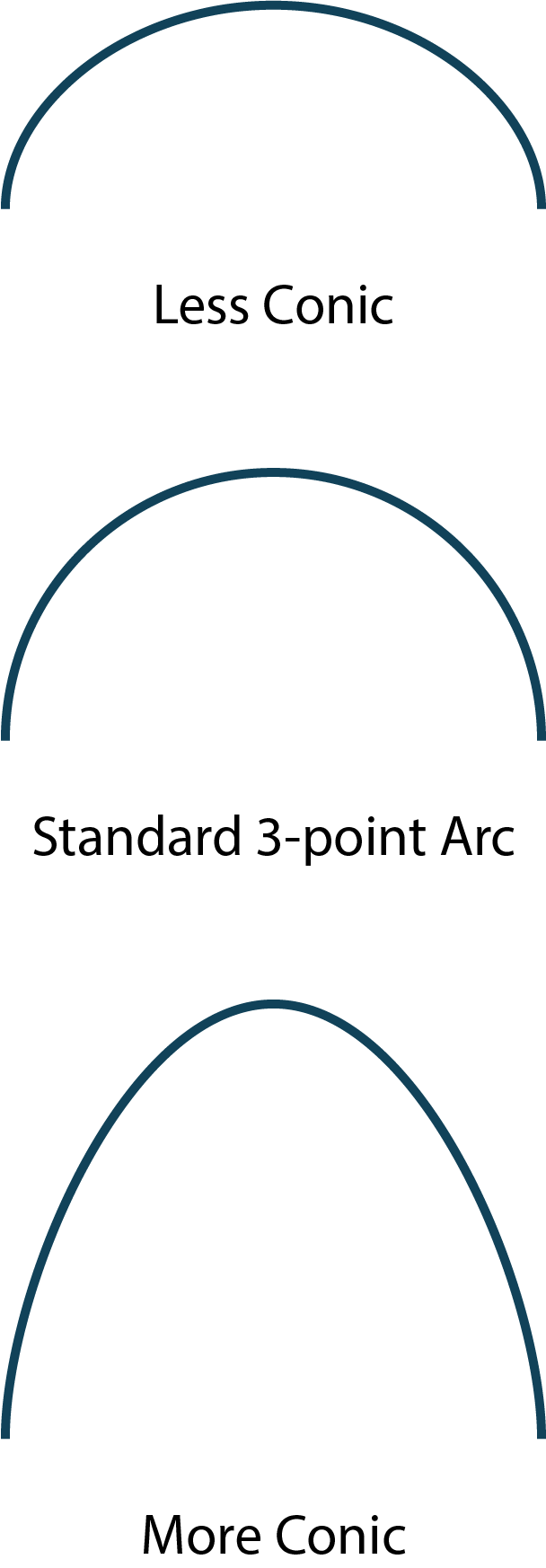

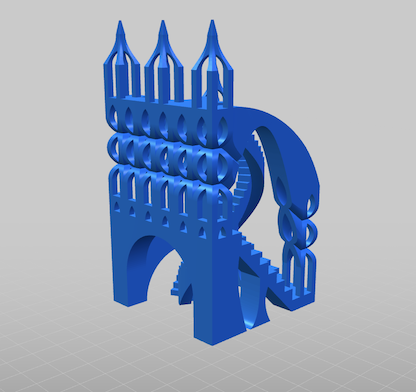

A key piece of learning that informed the design is that you can extend the limits of bridging by incorporating arches. Since 3D printers print in layers, small overhangs that extend with each new layer are securely supported by the previous layer. This facet can be further utilized by incorporating arches that are more conic in shape, which increase the proportion of the spanning element that is rising (Z) faster than it is extending (X or Y).

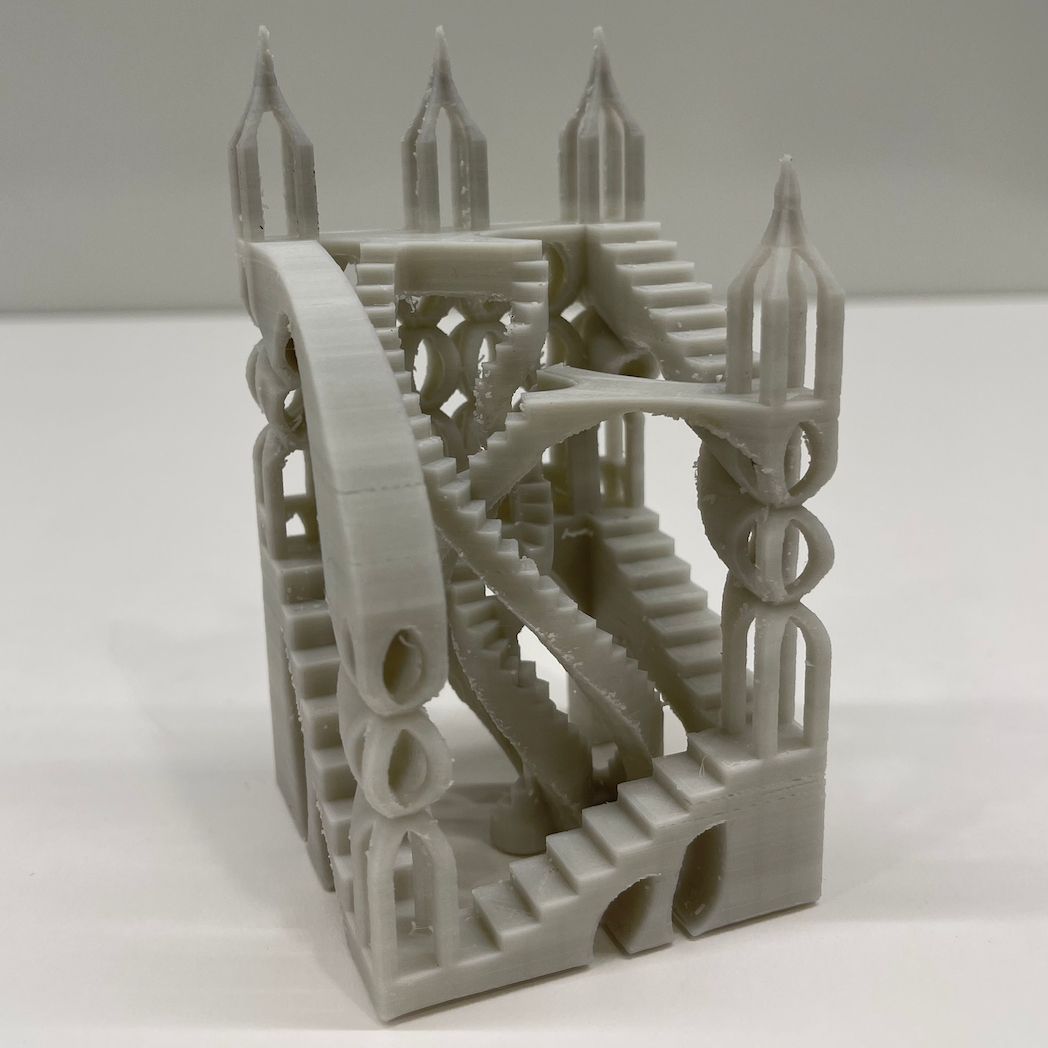

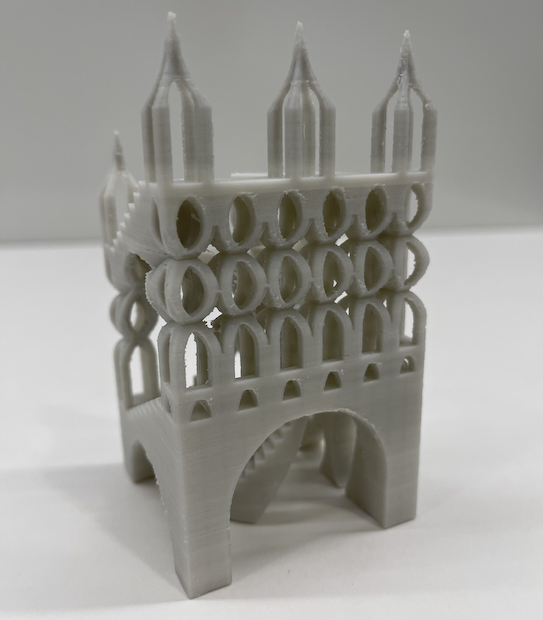

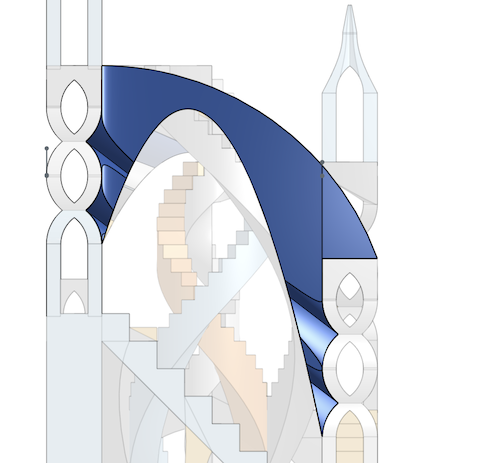

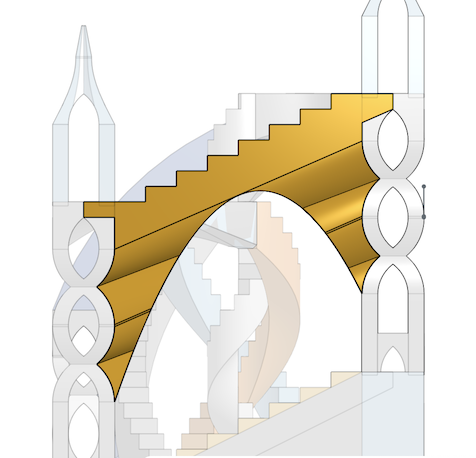

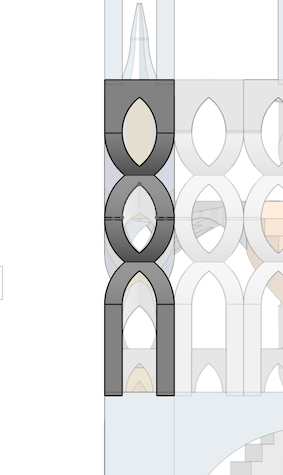

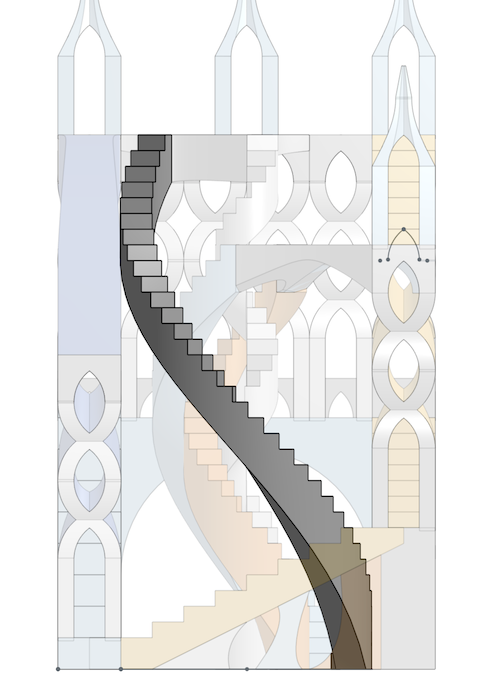

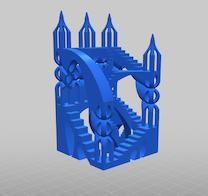

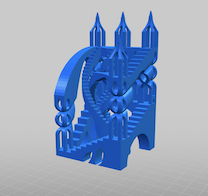

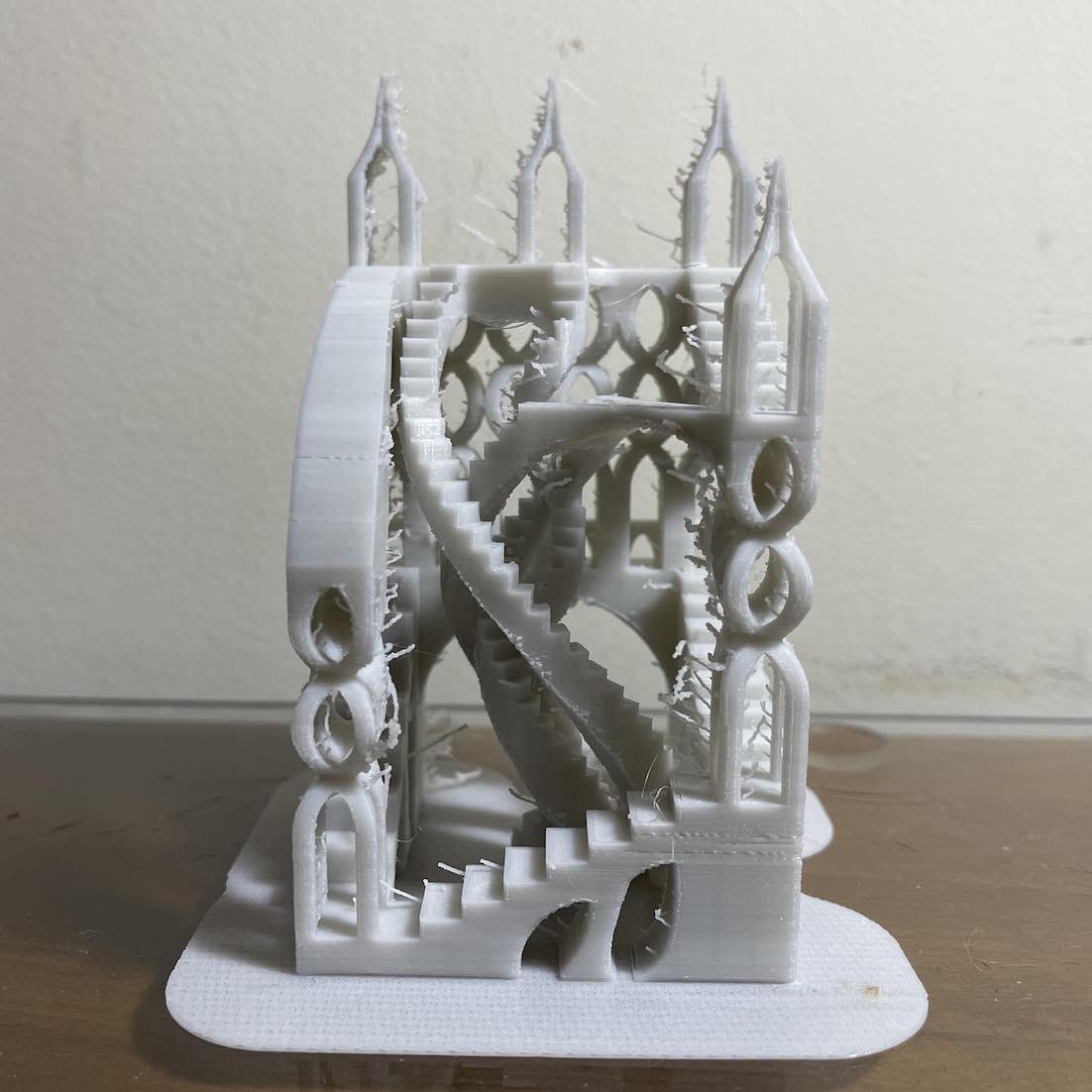

With this learning in mind, I constructed an object using OnShape with inspiration from Escher and a game called Monument Valley. The object is a fantasy architecture in which I used arches and layer building to create whimsical shapes. Almost every arch in the design is conic in shape or at a standard 3-point arch, except for one. This can be done, so long as the span is limited.

Full CAD Images

Printing

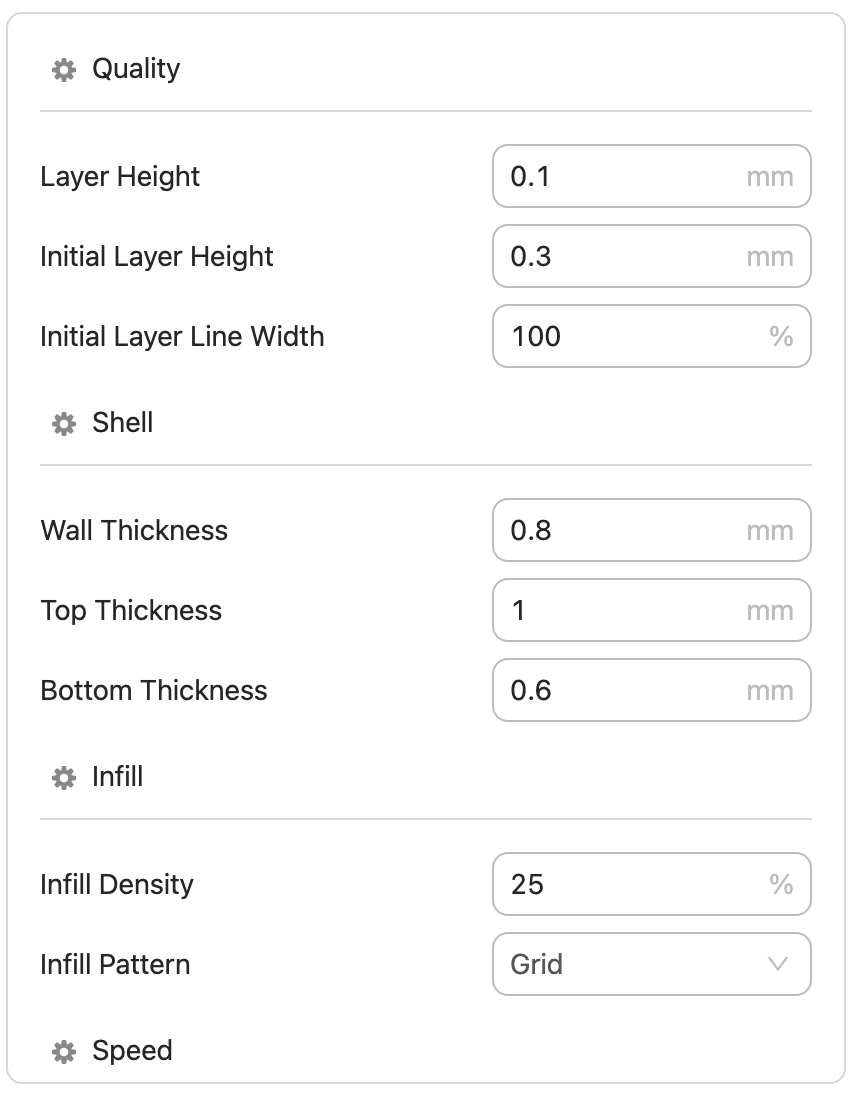

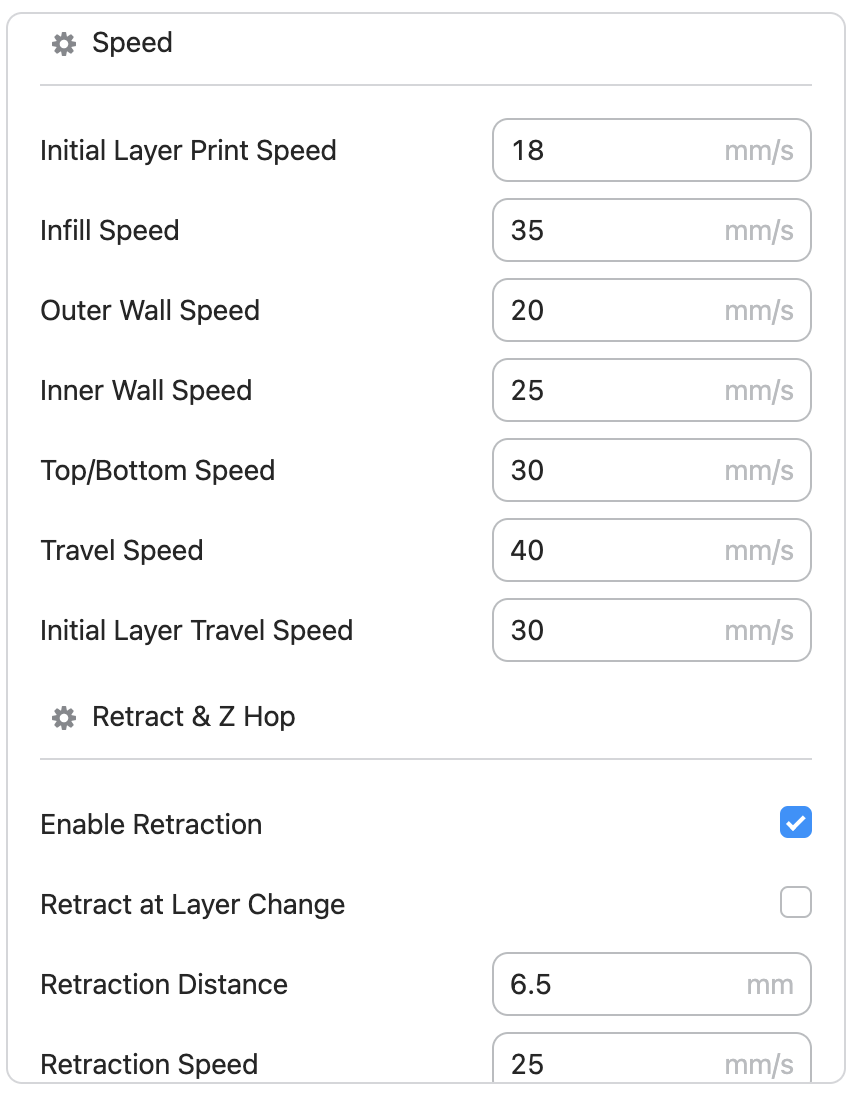

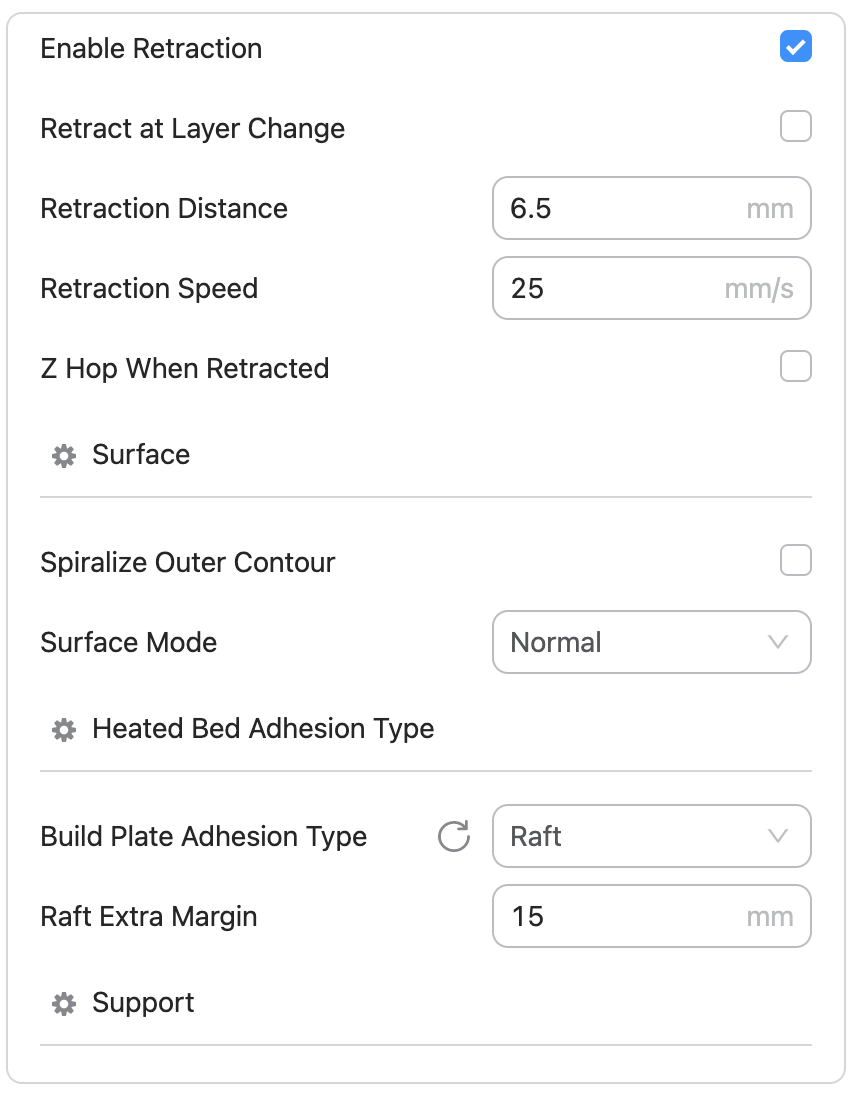

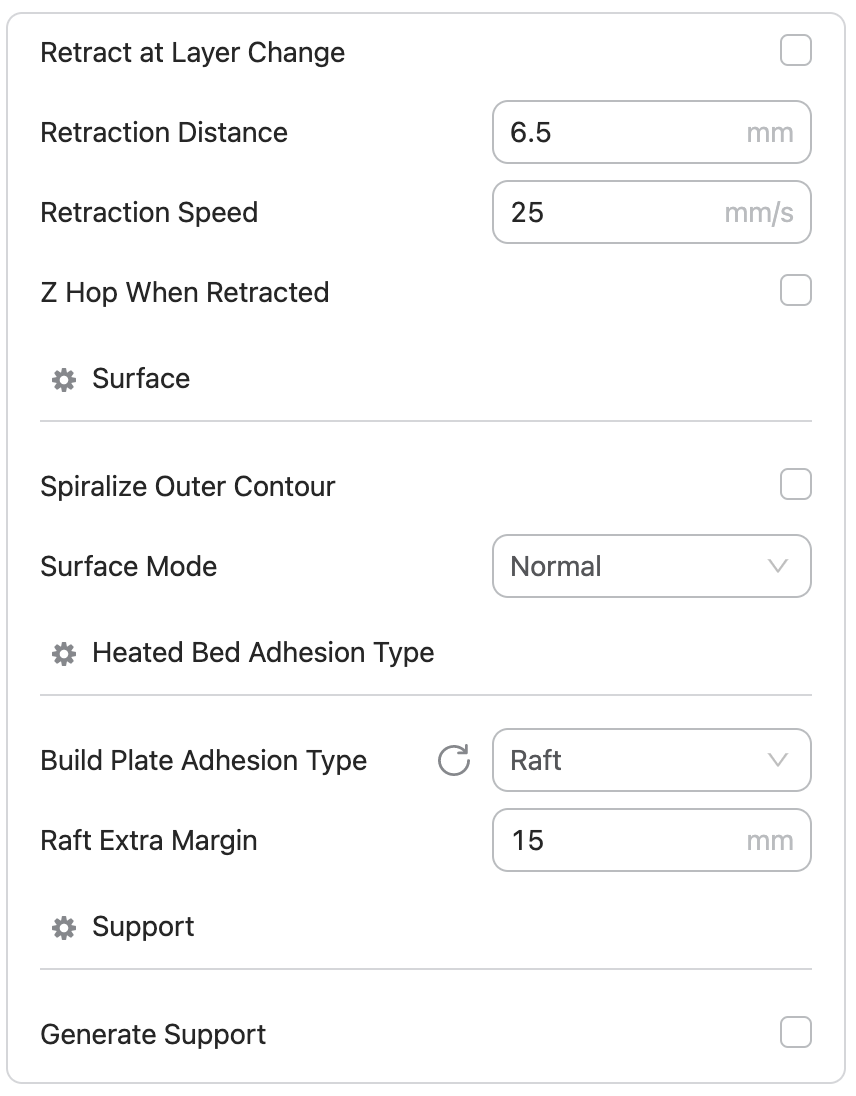

To print the object, I used a Snapmaker 2.0 with a 3D modular head. I didn't use the EDS lab printers due to COVID protocols. I ran some preliminary tests to ensure the characteristics would be similar, but Snapmaker is a lower quality print. Therefor, I used higher quality settings

The first print was successful, but a bit messy. In particular, the printer left many PLA trails when moving between features that aren't connected (such as 2 towers). This was cleaned up using tweezers, an exacto knife, and 400 grit sandpaper. I would have used a hot blade, but I did not have one available.

Additionally, the bottoms of certain arcs were a bit messy, the individual strands of PLA are visible and the "spaghetti" effect is slight. This is fine for the overall structure and I believe the 3D printers at the lab would have performed better. I could also provide supports for those areas, purely for aesthetics.