Week 2:

Vinyl & Laser Cutting

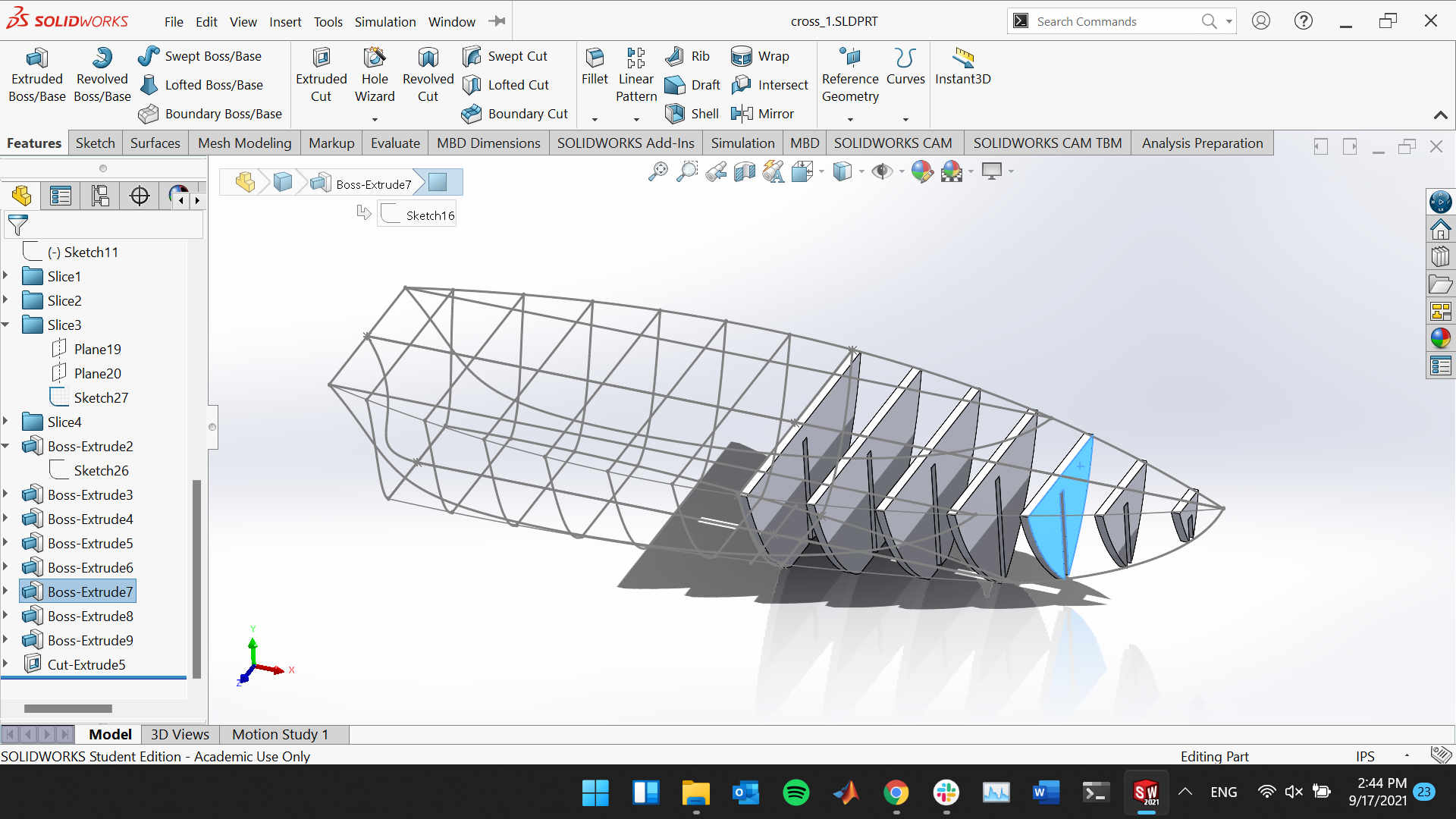

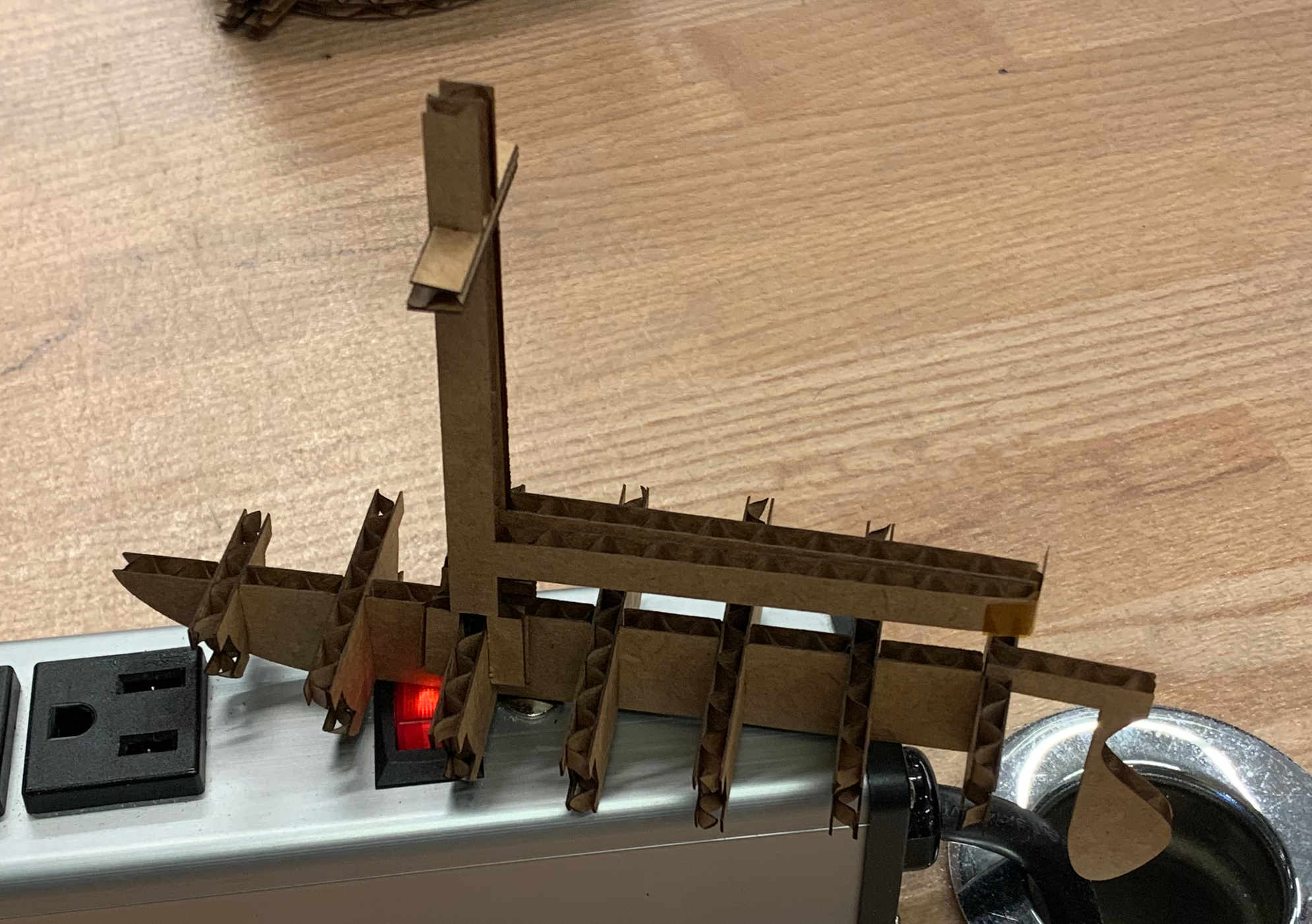

Vinyl cutting was easy, but I really struggled with designing in laser cutting

Important Data:

Besting press fit joint cut width: 3.9-4.1 mm (all you need for parametric)

Laser Kerf: ~0.28 mm (you need this if precision cutting is necessary)

To cut through: 100% power, 10% speed, 1000 ppi

To score one side: 25% power, 10% speed, 1000 ppi

Vinyl: F = 50 g, speed = 2 cm/s

Today I Learned:

Forming a complex curve and trying to cut it out on laser cutter difficult, might try more later on...

- © Untitled

- Design: HTML5 UP