Week 4:

3D printing and Scanning

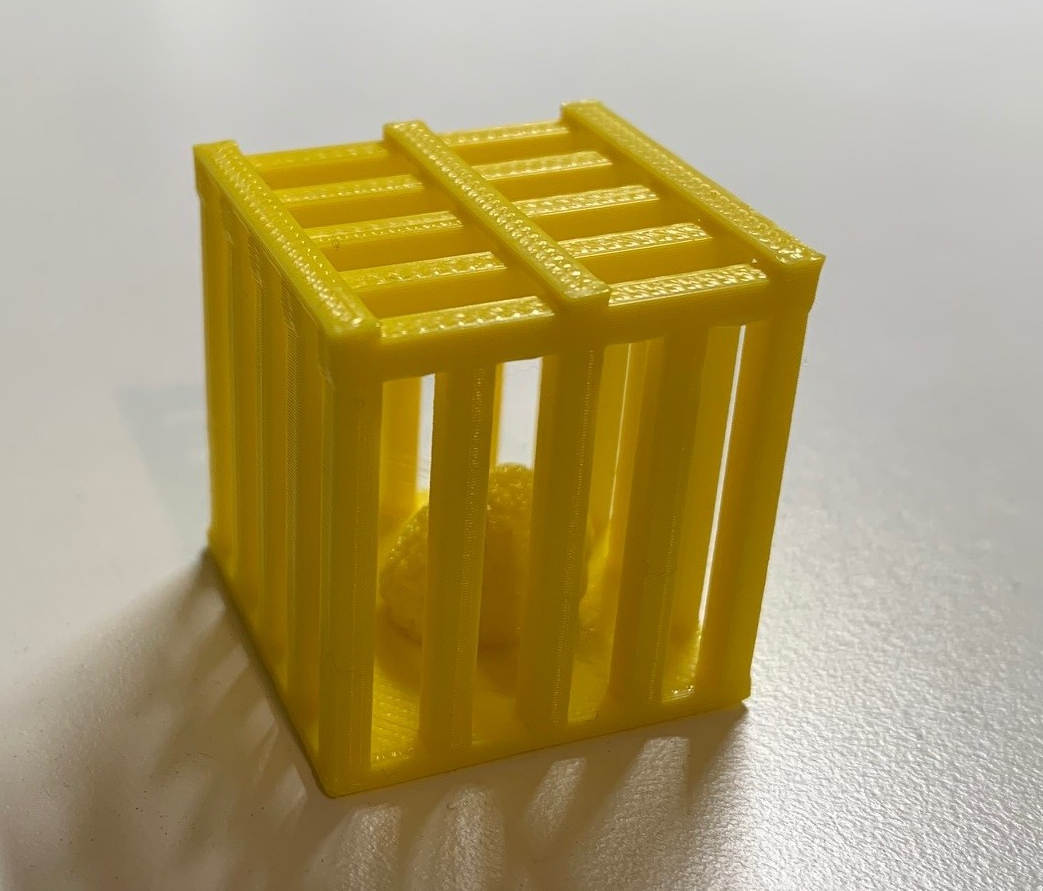

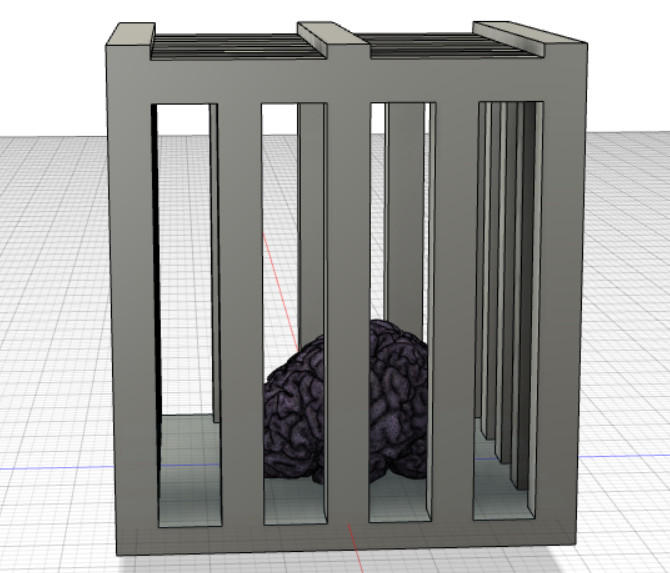

Printing something that can not be manufactured/machined subtractively.

Important Data:Group assignment documentation

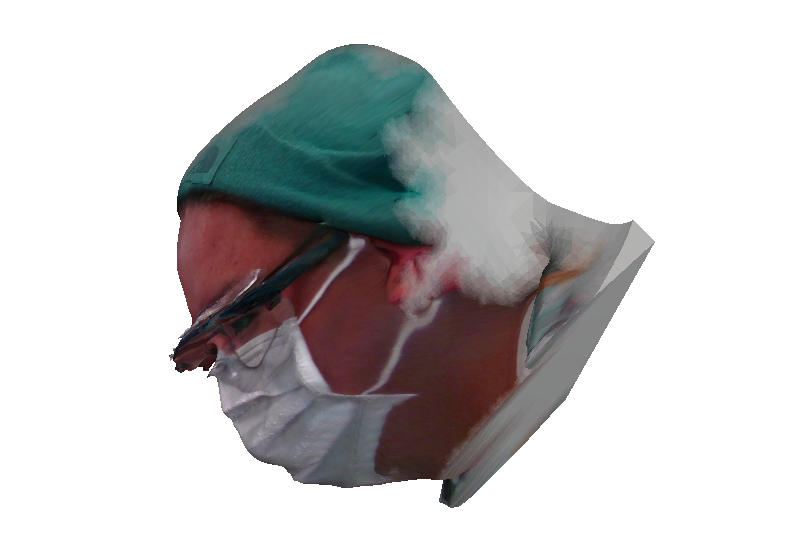

This is me! We used the 3D sense in EECS shop to produce my 3D model. You can see in the side view that certain angle on the back of my head was

not covered by the 3D scanner. If you look closely, the 3D scanner also struggled with reconstructing my safety glasses. (Credits: Rima Das, I scanned her lol)

On one interesting note, my computer had a hard time to convert/smooth this mesh model of human brain. I suppose there are simply too many vortices and calculation to do. Not sure how to improve this. But if you look at the model, there are amazing details on the outside of the brain, which was somewhat realistically reproduced by the sindoh printer in the EECS shop.

Today I Learned:

Bridging might be able to support longer hanging parts? Need to push the limit.