Week 8

Group assignment

The group assignment this week was to read the safety data sheets for our molding and casting products, and then make test casts.

We read the sheets for EcoFlex 30, Smooth Sil 945, Oomoo 30, Hydro-stone, Task-9 urethene resin, and Foam-iT. One big takeaway was that going off the NFPA 704 safety diamonds, the ”soft” materials like Oomoo were actually quite safe. Not shove-them-in-your-mouth safe, but they aren’t particularly hazardous.

The harder casting materials were more serious. For example the Task-9 resin scored a 2 on both flammability and health. The Hydrastone scored a two on health. All of the molding materials scored a 1 on health and 0 on flammability (as did the foam.)

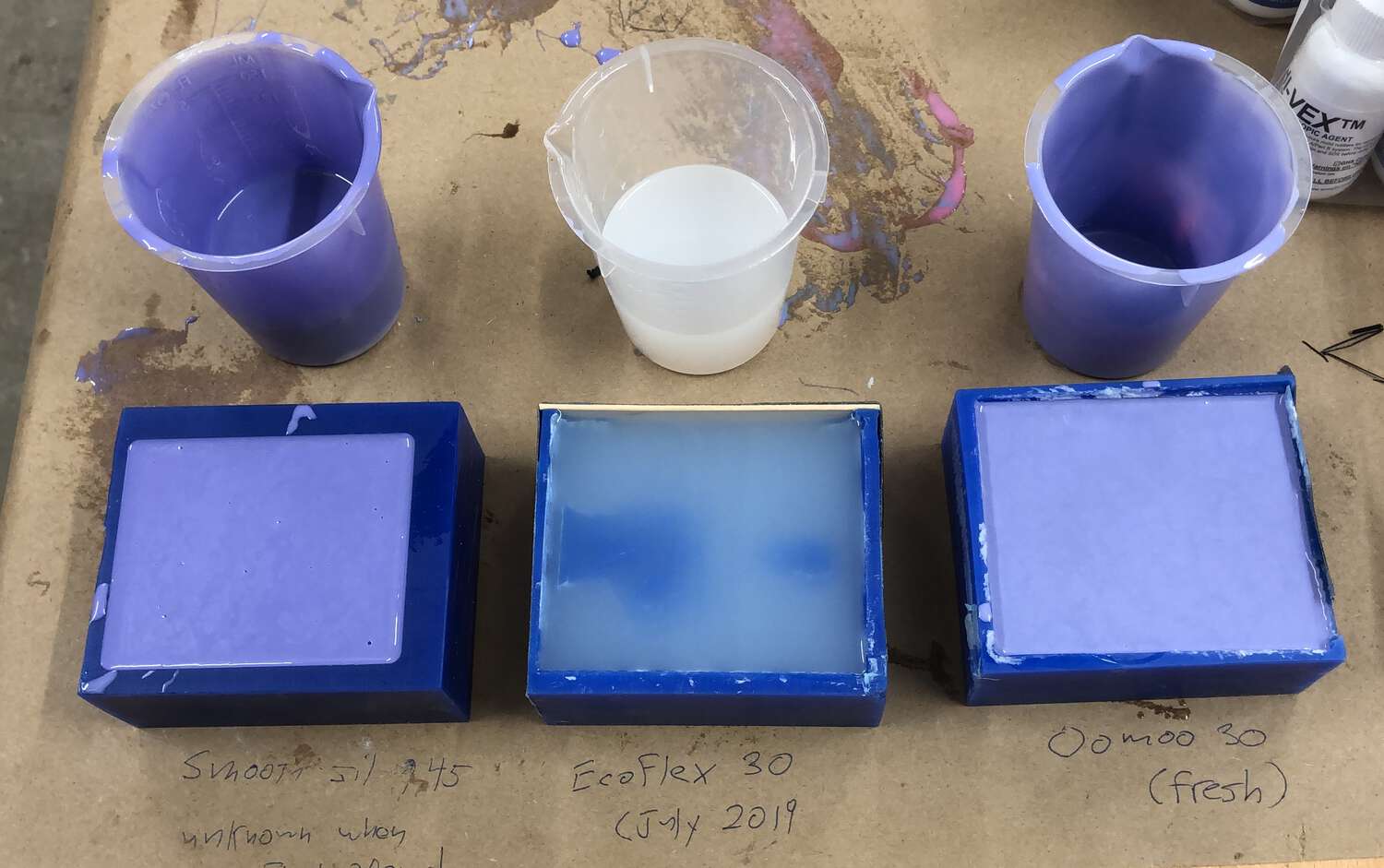

For test molding, we compared (from left to right below) Smooth Sil 945, EcoFlex 30, and Oomoo 30. The Oomoo was just opened, but the EcoFlex had been opened in July 2019, and the Smooth Sil didn’t have an open date on it. So that could affect the final results.

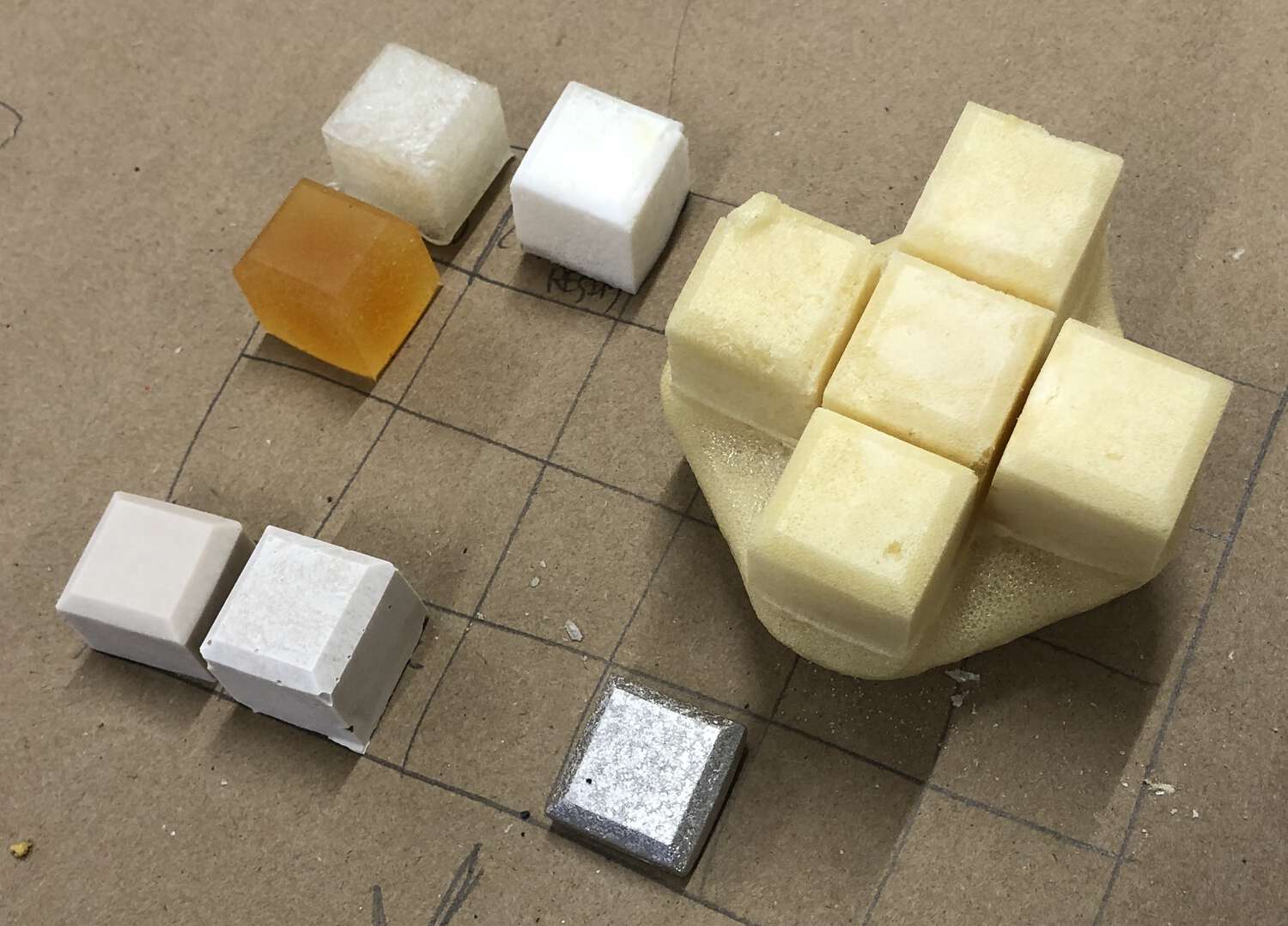

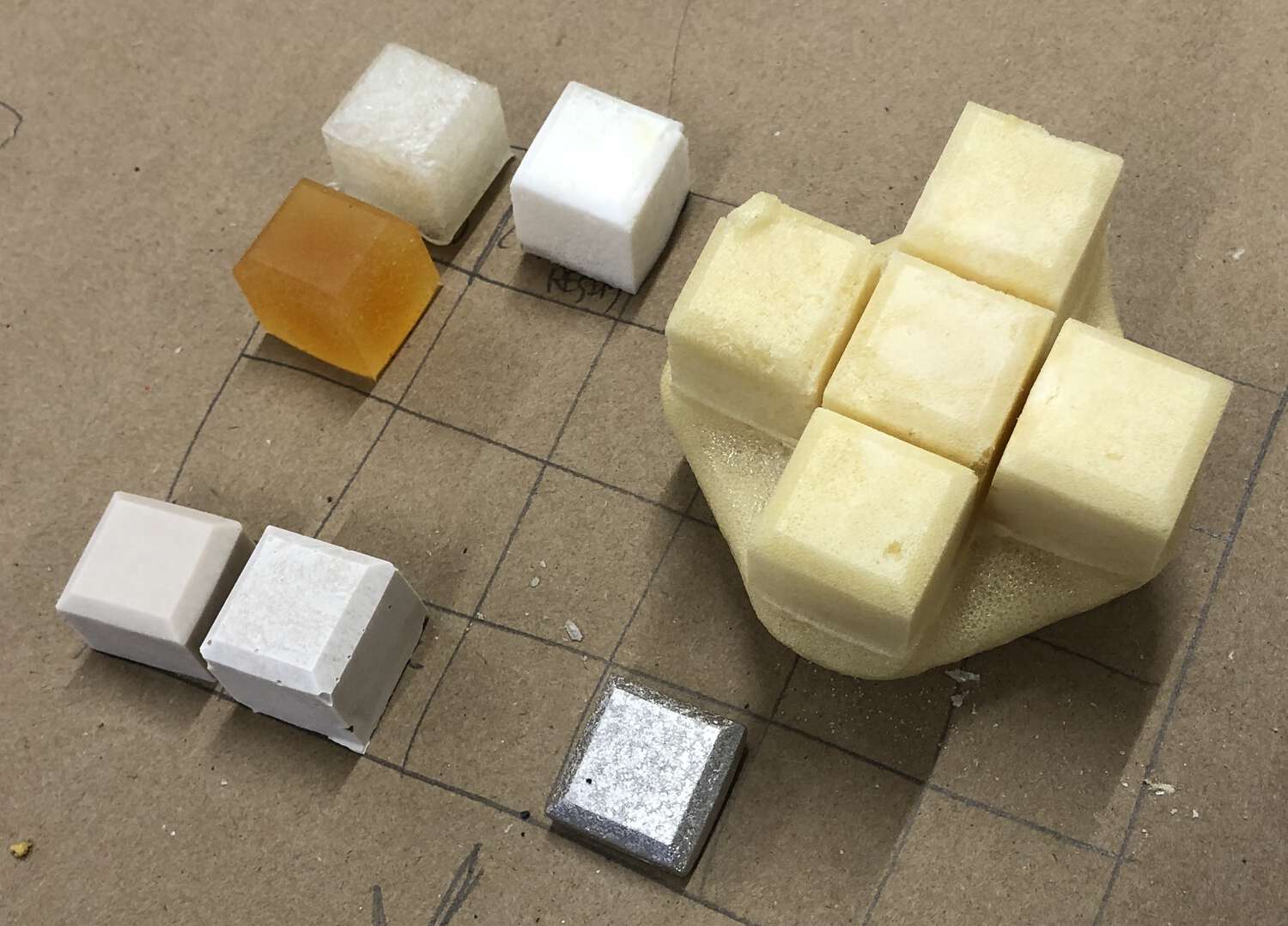

On the casting side, we tried a much wider ranger of materials. Look at all these beautiful casting materials! Starting in the top left and going row by row, we have Task-9 urethene resin, Task-21 urethene resin, 5-min epoxy, Foam-3 (can’t miss it), Hydro-stone, Drystone Casting Media, and bismuth tin.

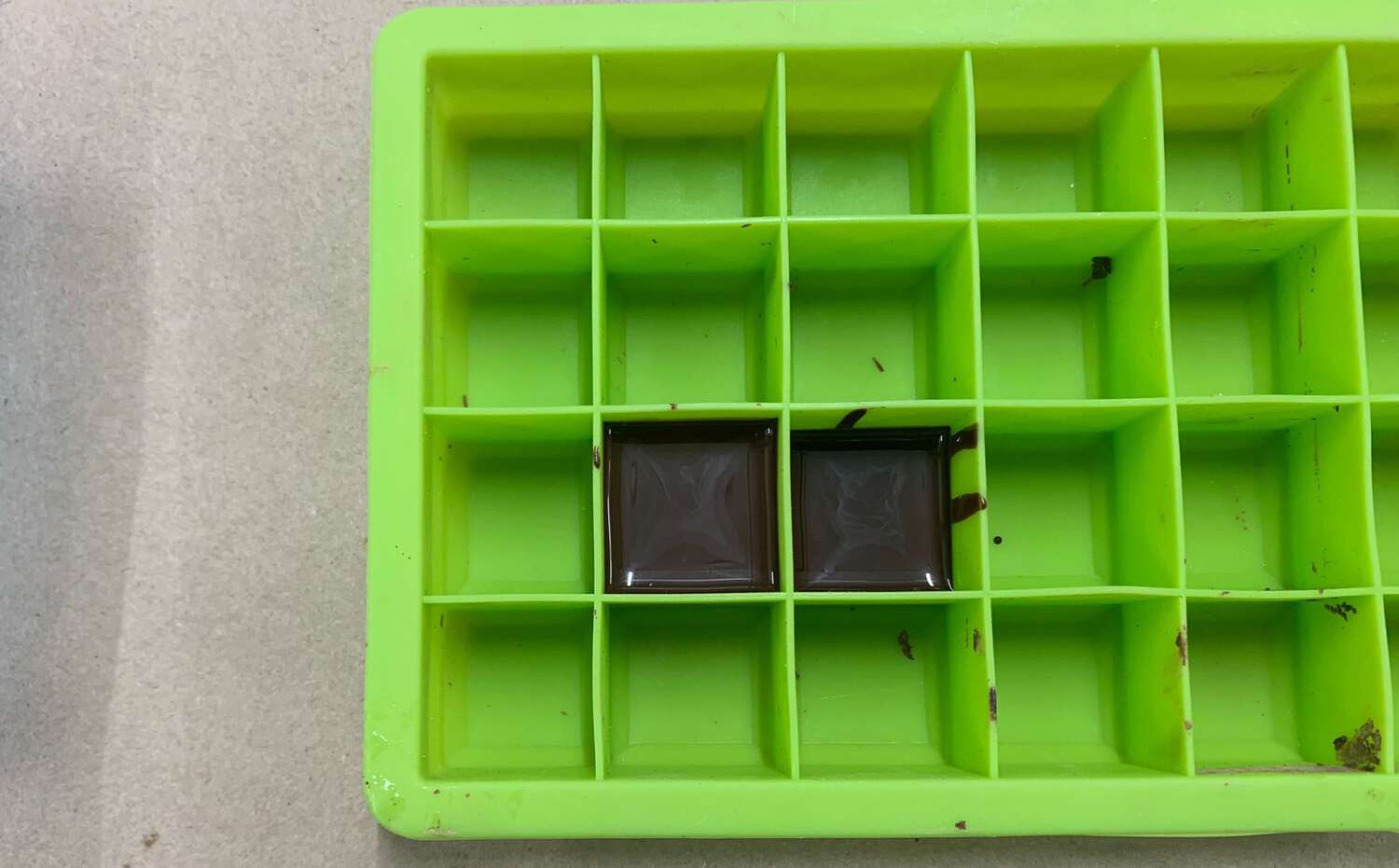

And, of course, chocolate.

We also had some material chips from Reynolds, which was helpful for letting us see some stuff we didn’t currently have in stock, including many transparent materials and an alternative foam.

Results

After an overnight wait, our molds and casts were done!

On the molding side, the Smooth-Sil 945 was really impressive, giving a rigid, sharp finish. The Eco-Flex came out nicely as well with a more rubbery texture, although it ended up a little more more opaque than we would have guessed during the pour.

The Oomoo was actually the loser of the bunch. It was by far the most difficult to remove from the wax mold, and the final material ended up being most heterogenous. We also poured a cube of it, which ended up with most air bubbles and also left a sticky mess in the silicon tray.

On the casting side, the foam was fun. Nice surprise after a stressful week. This is not the most advanced observation, but unlike the other casting materials foam does not maintain volume.

In general the casts worked out great. For the plaster-like materials, the Hydro-stone was a little less lumpy/bubbly than the Drystone. In the battle of the urethene resins, Task-21 ended up smoother and less sticky than Task-9. The bismuth tin came out well, although there were a couple impurities/unmelted parts that rose to the top.

The 5 minute expoxy was maybe the most impressive. It gave a super consistent cast, although with lots of internal bubbles. But the matte finish and coloration were beautiful.

Can’t forget about the chocolate. Looked tasty.