The first assignment this week was getting set up with git and building a basic webpage. This is the only topic we’ll cover this semester that I have previous experience in, so I savored being not-so-stressed-out.

The one twist was that for my entire career, using git == using GitHub. But HTM(A)A uses GitLab instead. This didn’t end up being much of a twist, I just had to set up a new SSH key and get used to the GitLab interface, which has all the same features.

More importantly, this was the week I started building stuff. Specifically, I had to cut something out using the vinyl cutter, and then design/cut some shapes out of cardboard which could be assembled in multiple ways.

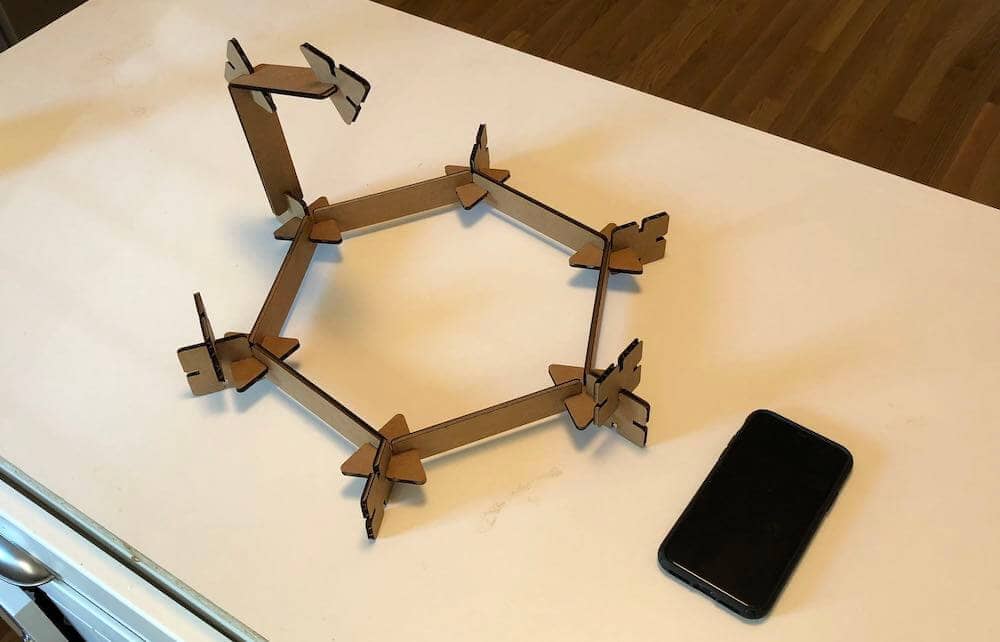

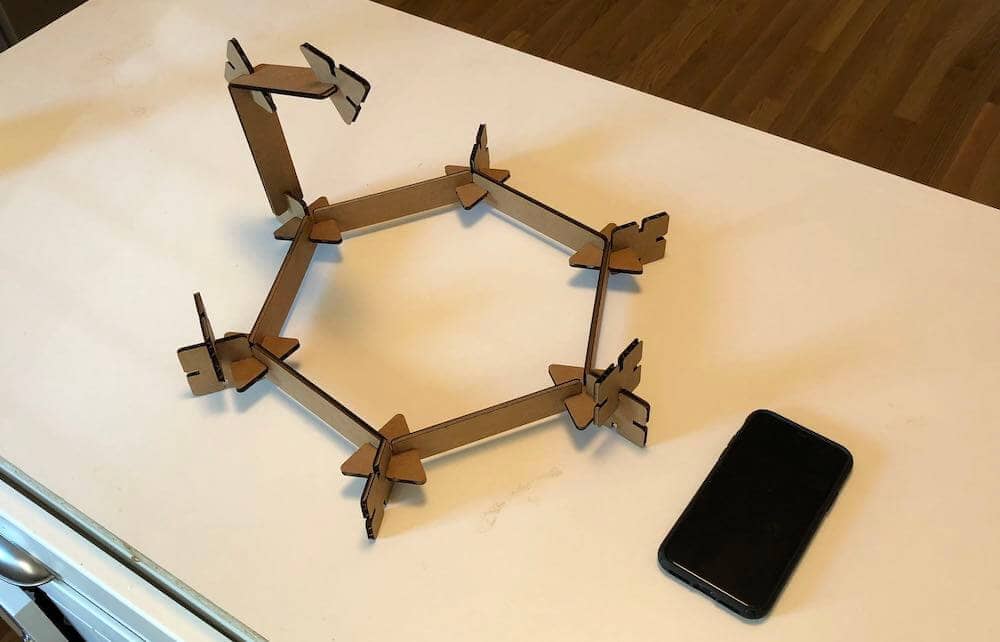

On Thursday I got trained on the laser cutter, and was overwhelmingly pleased with myself for making this cardboard circle. I showed it to like three different people. Also loved the toasty smell of the burnt edge. I also participated in the group assignment a little by trying to figure out how we might measure our laser cutter’s kerf. (Harvard section final kerf analysis is here. Plus a cool joint analysis is here.)

On Friday I took my first shot at the vinyl cutting tool, using a creepy little image that happened to be on the computer already. But the vinyl sheet was “swinging” as the knife moved, because the sheet wasn’t properly lined up under two rollers. So it came out funky, and then I had to run to a different class.

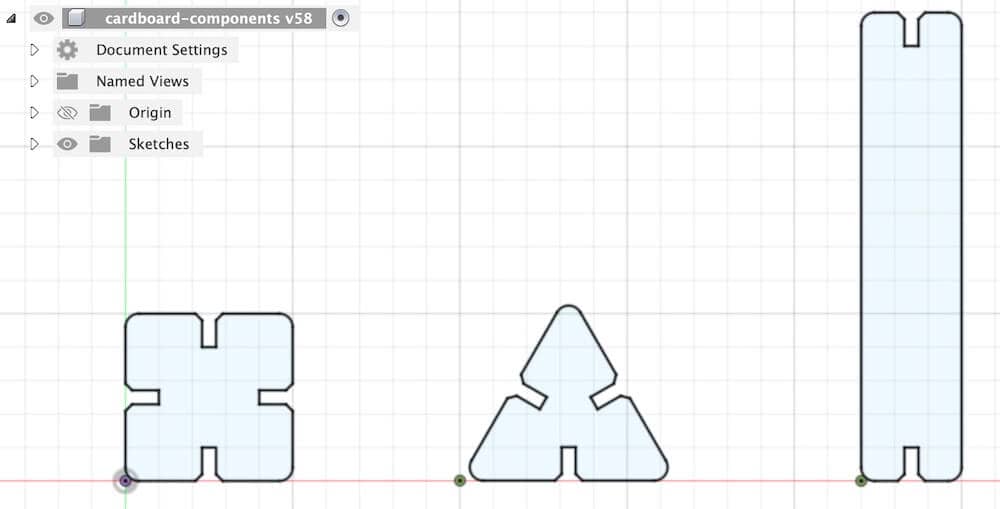

On Saturday I sat down and actually tried to learn the sketch tool in AutoDesk Fusion 360 for real. This was a slog but it ended up working out and I was very pleased with myself.

I didn’t have anything super intentional in mind for my cardboard kit, so I designed a square connector, triangular connector, and rectangular extender that I thought would give me some nice modular flexibility. Everything is parameterized and I could adjust for cardboard width and kerf width.

A small thing I’m particularly proud of figuring out. The first square went really smoothly, but when I made the triangle and the rectangle I was getting frustrated that a) I couldn’t totally constrain them, and b) whenever I increased their dimensions using parameters they stopped being lined, because they grew from the center, instead of from the baseline.

Turns out these two problems had the same solution! I had to set a fixed constraint to the bottom left point of each.

On Sunday, I sat down and made this website. I programmed like it was 2016 and used a Gulp/Pug setup that I also use on my personal website. I’d wanted to try a “drawer” design with stacked horizontal strips for a while and this class seemed like a nice spot for it. Makes all my updates fit on one page! I’ll definitely keep messing with it.

Later that evening it was time to actually go to the shop and cut my stuff out for real. First things first I used the vinyl cutter to make these stickers of Great Spruce Head Island, Maine. Coastline is from NOAA’s Continually Updated Shoreline Product (CUSP), with some light editing in Illustrator.

I’m super impressed by the detail that the cutter can handle. That little spike in the top left corner of the island is a real rock outcropping. I did run into one problem though: resetting the origin of the vinyl cutter so it would cut in an empty spot on a scrap piece of vinyl. I solved this by … starting a new piece of vinyl instead.

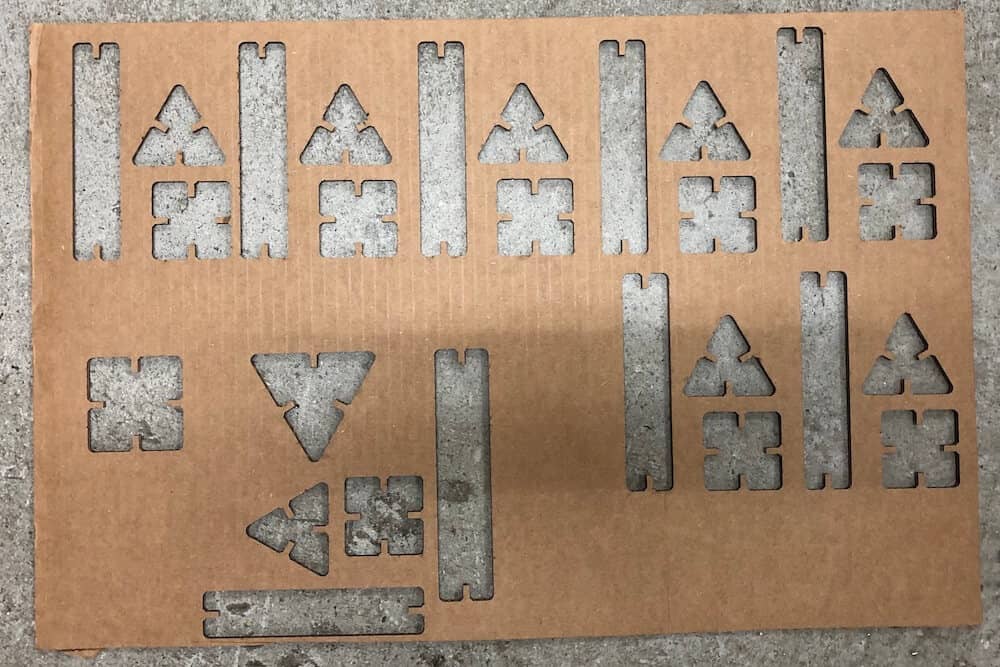

Then it was on to the laser cutter. I’d exported my shapes as a .dxf file, and with a slight assist from the TA I was able to load them in. It was fun to watch and they fit together sort of nicely, but, alas, one of the joints was a bit loose.

I measured my cardboard and found that it was a little thinner than what we’d measured as a group when getting trained: 4.3 mm vs. 4.5 mm. My AutoDesk parameterization actually came in handy! I made that parameter tweak, made the shapes a little bit smaller overall, and also packed them more closely together so I wouldn’t waste as much cardboard when cutting.

The next test run had a much better joint fit, so I went to town. Here’s the remains of my cardboard sheet.

Back home I used my cardboard to build a beautiful hexagonal snowflake shape, which I added a scorpion tail to just so I could say I used all the pieces.

One final mistake I made. My joints were a little too deep (this was also parameterized! should have fixed) and/or my final triangle was too small. Because there wasn't quite enough space in the middle of the triangles and the edges of the rectangles and squares ended up colliding slightly.

Files: Here’s the final DXF file I used to build my cardboard components.