Assignment 1: Work through a git tutorial, build a personal site in the class archive describing you and your final project

Status: Done. You're looking at the assignment right now, how cool is that!

Assignment 2: Cut something on the vinylcutter

Learnings: If your design is finicky, you can stick your vinyl cut-out on another adhesive surface before trying to whack it on your laptop.

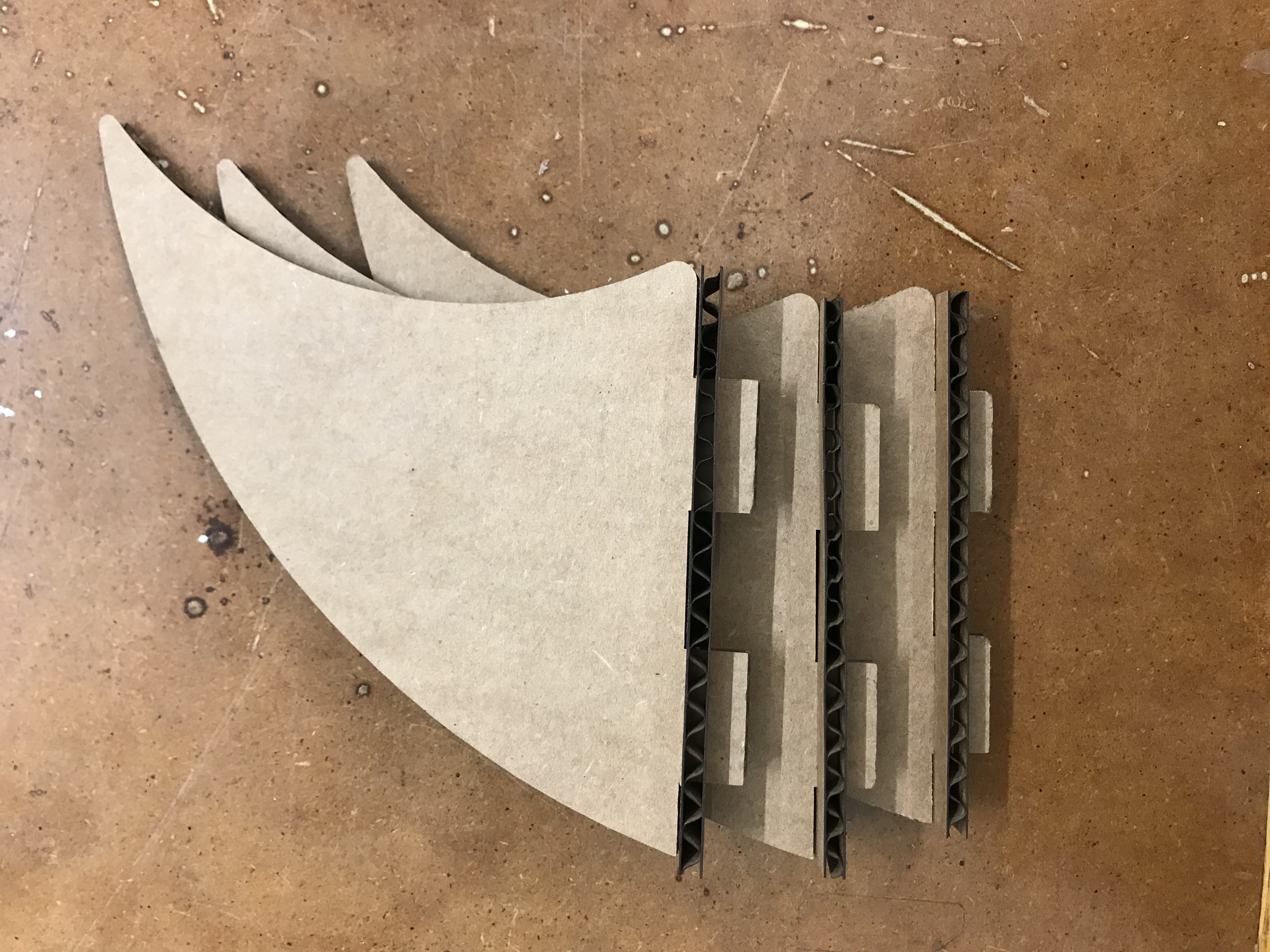

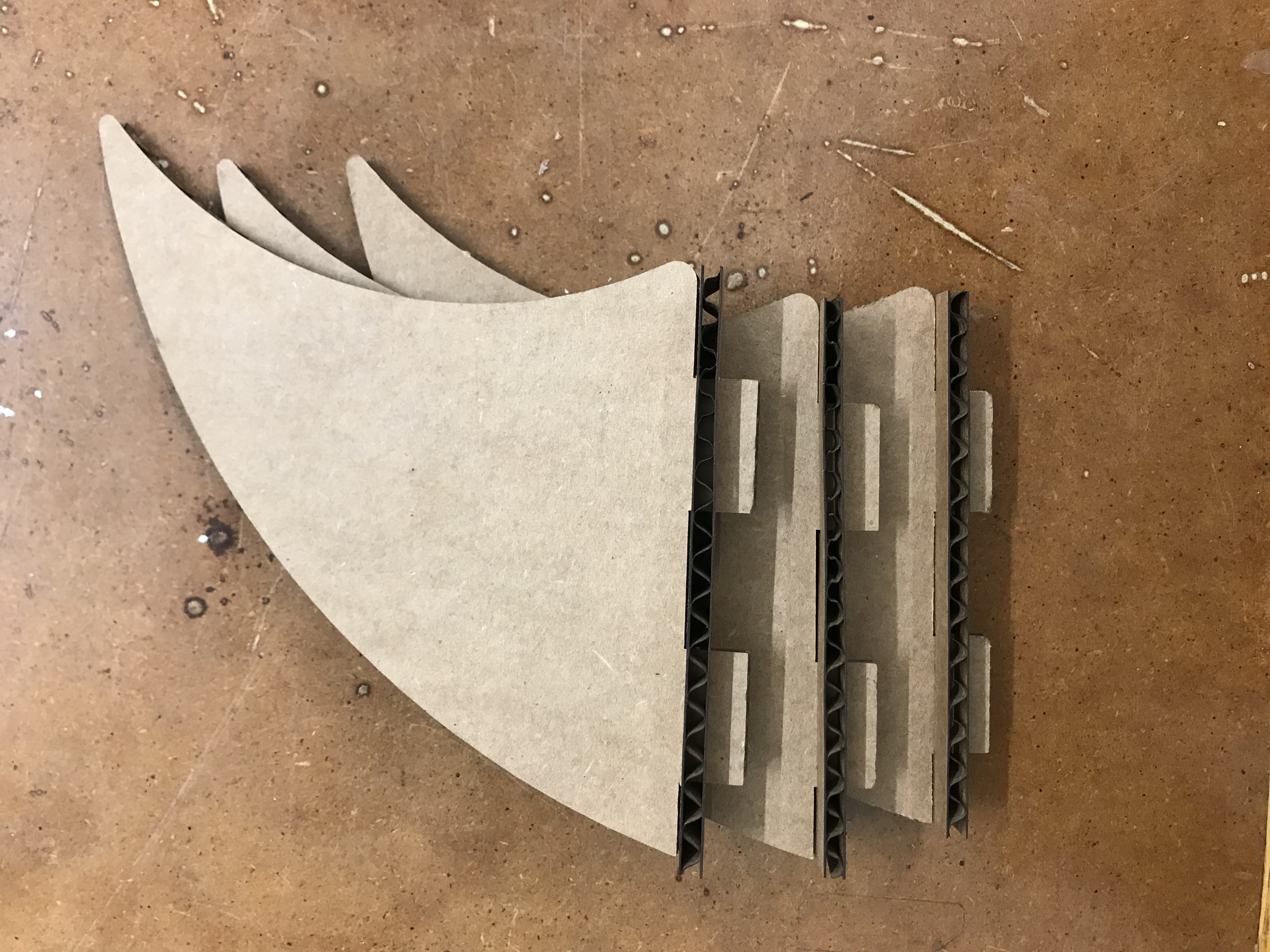

Assignment 3: Design, lasercut, and document a parametric construction kit,

accounting for the lasercutter kerf,

which can be assembled in multiple ways

Learnings: I don't think what I did was technically a parametric construction kit. I got lazy because CAD modelling was harder than I expected. BUT, my fins fit nicely into the finbox! I think I got a little lucky, but if you'd ever seen me try to make a picture frame in my parents' garage, you'd understand why this was a big win.

Group assignment: Characterize your lasercutter's focus, power, speed, rate, kerf, joint clearance and types

Status:Complete!

Learnings: Kerf is kind of like the measurement problem in quantum mechanics (I think!) where you can't just use the laser cutter without accounting for how the thickness of the cutter itself will impact the dimensions of your final product. When we experimented with the impact of the cutter, we found that for a fixed amount of power, if we increased the speed of the laser it reduced the amount of kerf. Side note: kerf is a funny word, don't you think?