Group assignment: Test the design rules for your 3D printer(s)

Status: Complete!

Learnings: We tried to see how long of a bridge you could make in the Prusa i3 MK3 without supports. The top of the bridge was connected at every length up to 160mm, but the bottom got increasingly saggy and the bridge got looser the longer it got!

Individual assignment: Design and 3D print an object (small, few cm3, limited by printer time) that could not be made subtractively. 3D scan an object (and optionally print it)

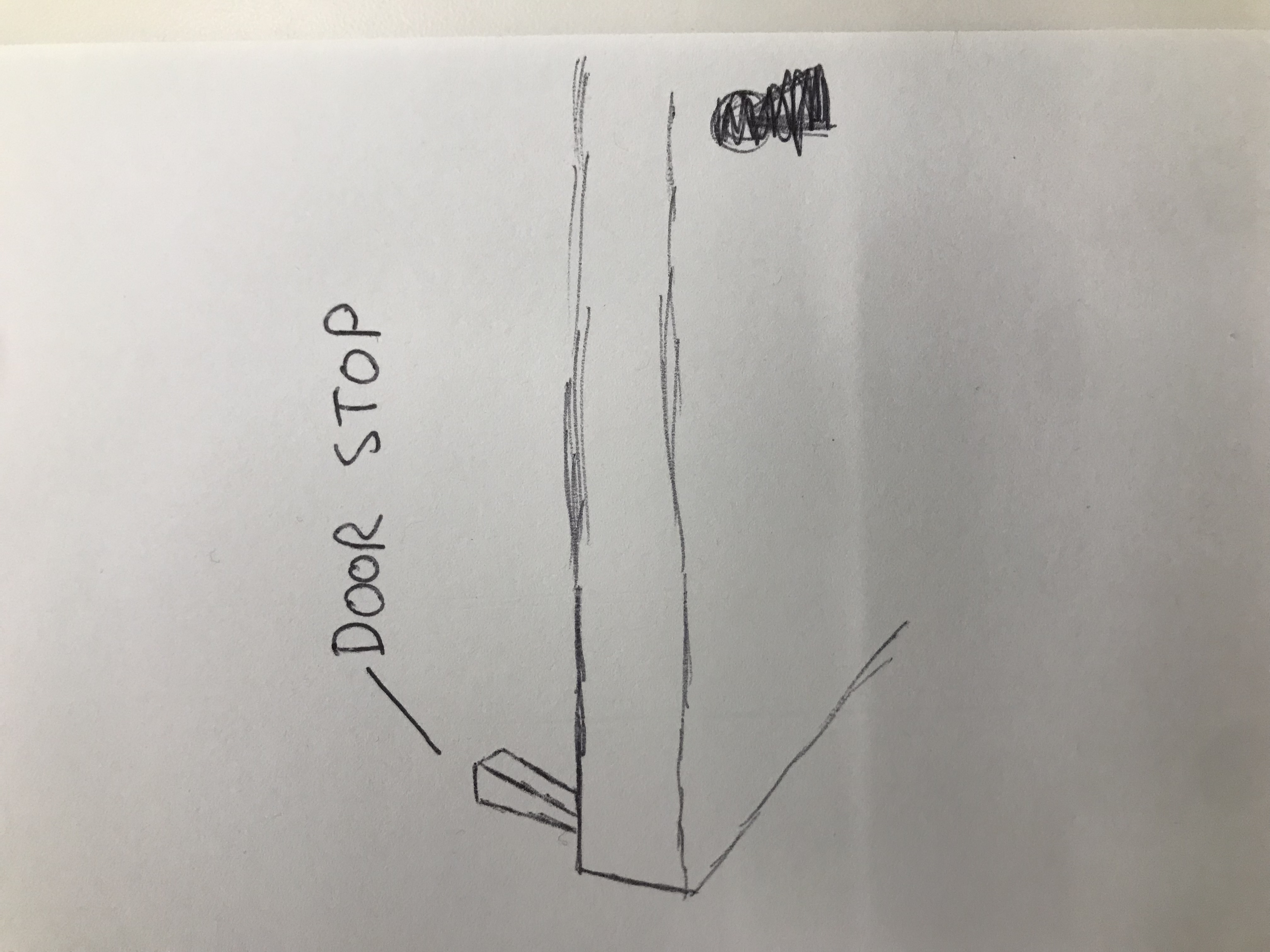

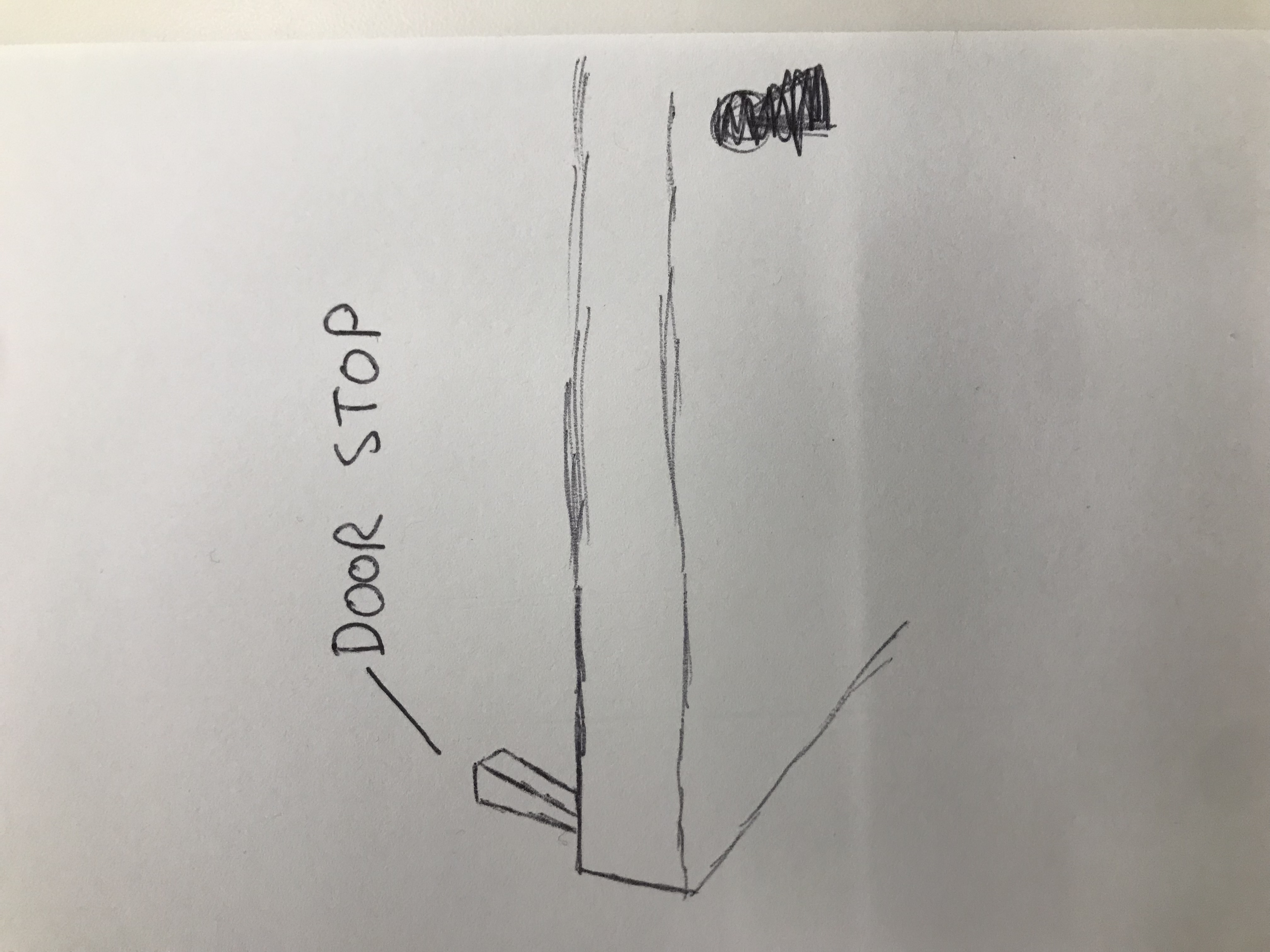

The production story - Introduction: Okay, so one of my doors at home doesn't lock and sometimes swings eerily open in the middle of the night. I had to STOP this! Enter the 3D printer and a humble plan.

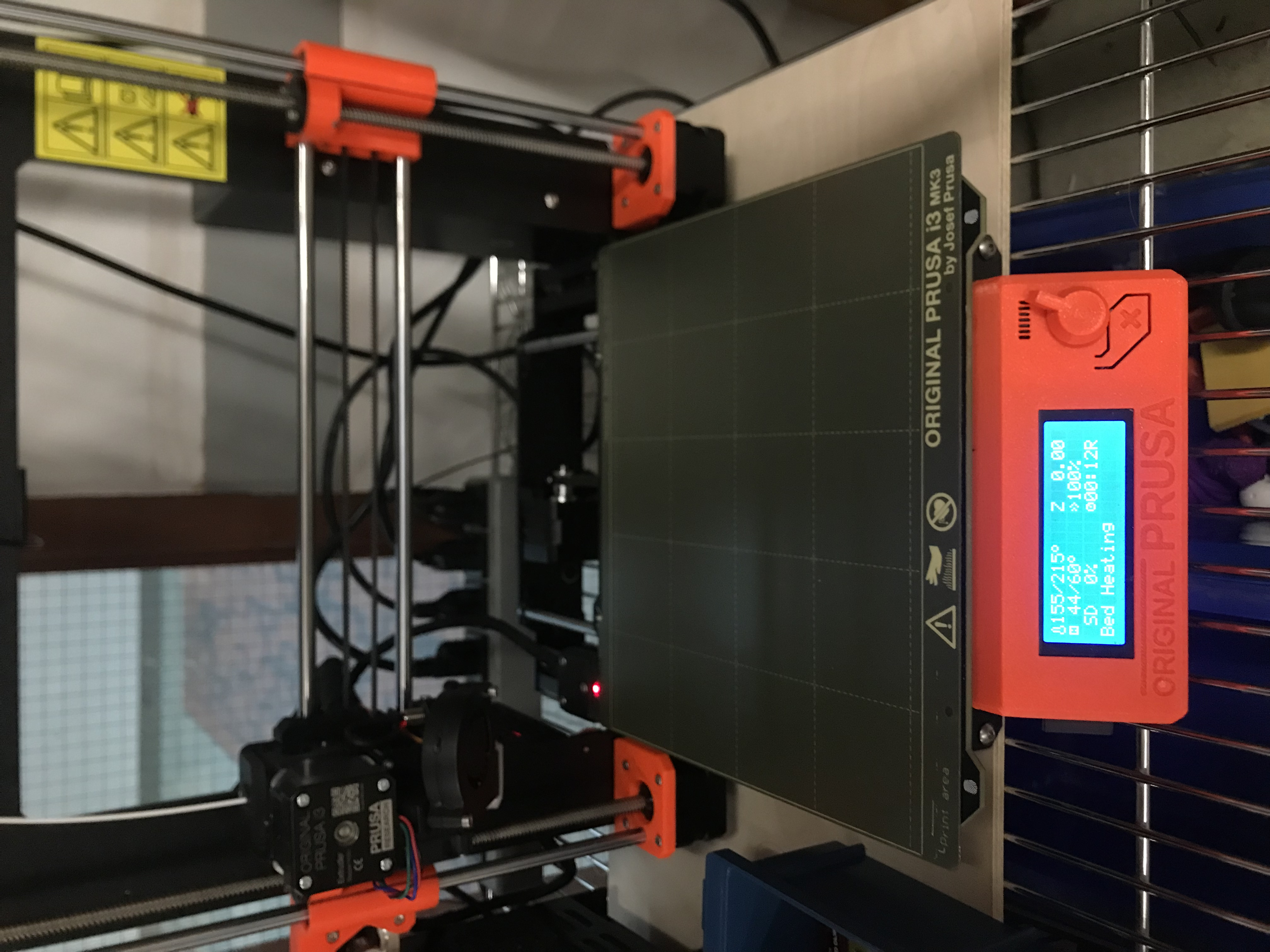

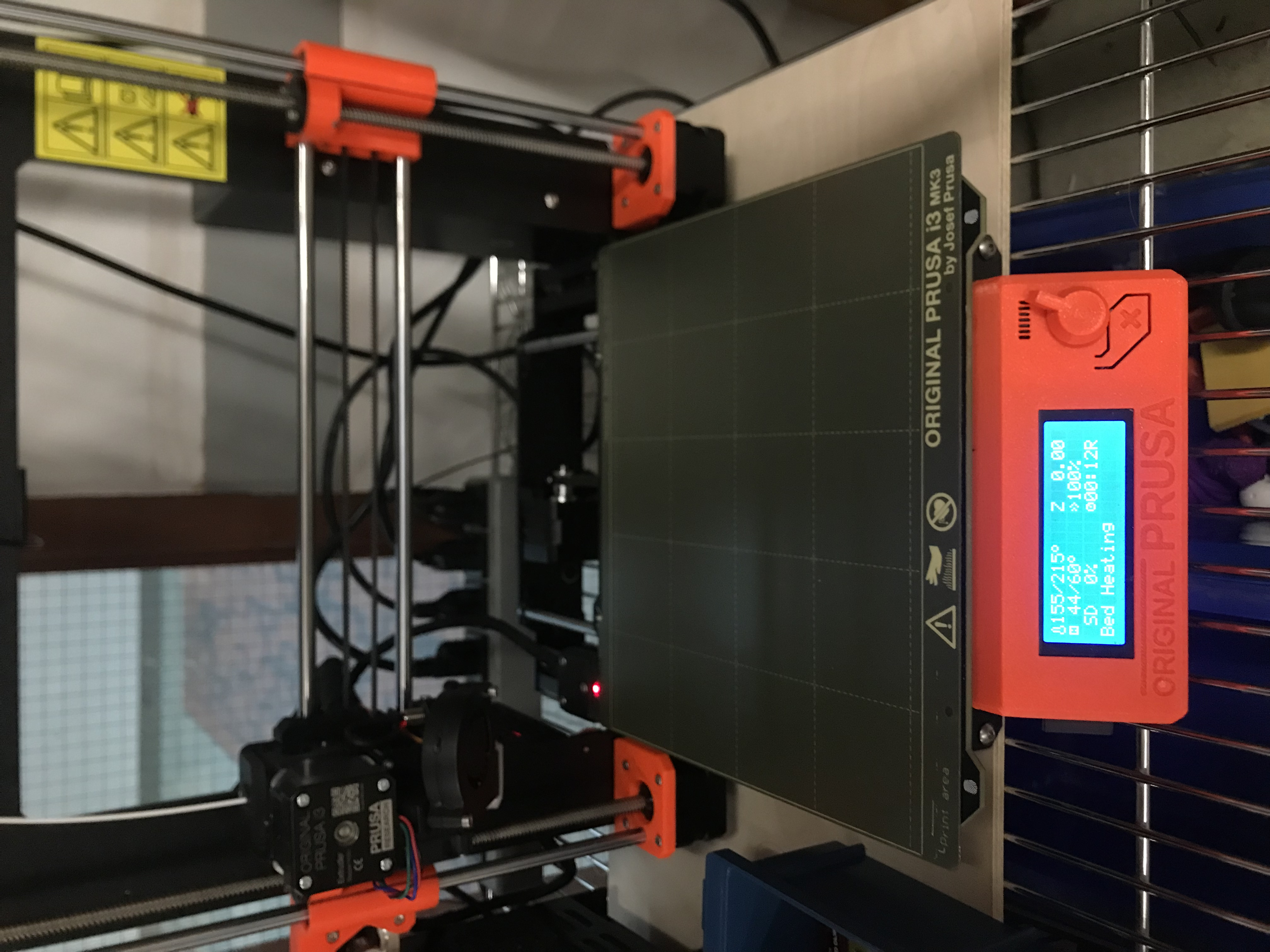

The production story - Complication: I designed a vibey doorstop on CAD (with some help from Joon bcoz I'm still a noob). I whacked it into an STL file, threw it into the PrusaSlicer software, got my G code file and squeezed out some white hot PLA. But it was too small. As my friend John commented, "What is this, a doorstop for ants?!"

Resolution: Make it bigger, duh!