Week 14

WildCard Week

What to Choose

It's really coming down to the wire for final project work and after the success of the prototype pancake printer last week, I was confident that my final project could be done... I just needed more time, or rather to use my time better. So this week I swore that I wouldnot explore fun tangents, but instead do something meaningful and worthwhile for my final project... then I saw the inflatables presentation... here we go again.

Inflatable Design

In the tutorial we learned all about how to use sheet metal/flat pattern and unroll to create sewing patterns in cad. I use fusion so sheet metal tools was my weapon of choice. My idea was to build something big and after the word bouncy castle was thrown around I quickly decided to try that before being told that we did not have the materials for it, we did however have the materials to make something you "could lay very slowly on." Jumping was out of the question, but sitting was not so I decided to go back to make something big week's idea and make a couch, well less a couch and more a bean bag, and less a bean bag than a inflatable pillow thing. The next first idea that popped into my head was to make what I had seen as a Dall-E example, a avocado armchair, but there wasn't enough green so I switched to generating my own Dall-E prompts. I spent a lot of time designing a dinosaur couch after it generated some cool images, but A: I couldn't get sheet metal tools to work perfectly and B: narwhals are cooler. Here are some pictures of my CAD files along with the suggestion Dall-E gave me.

Narwhal Couch Thing

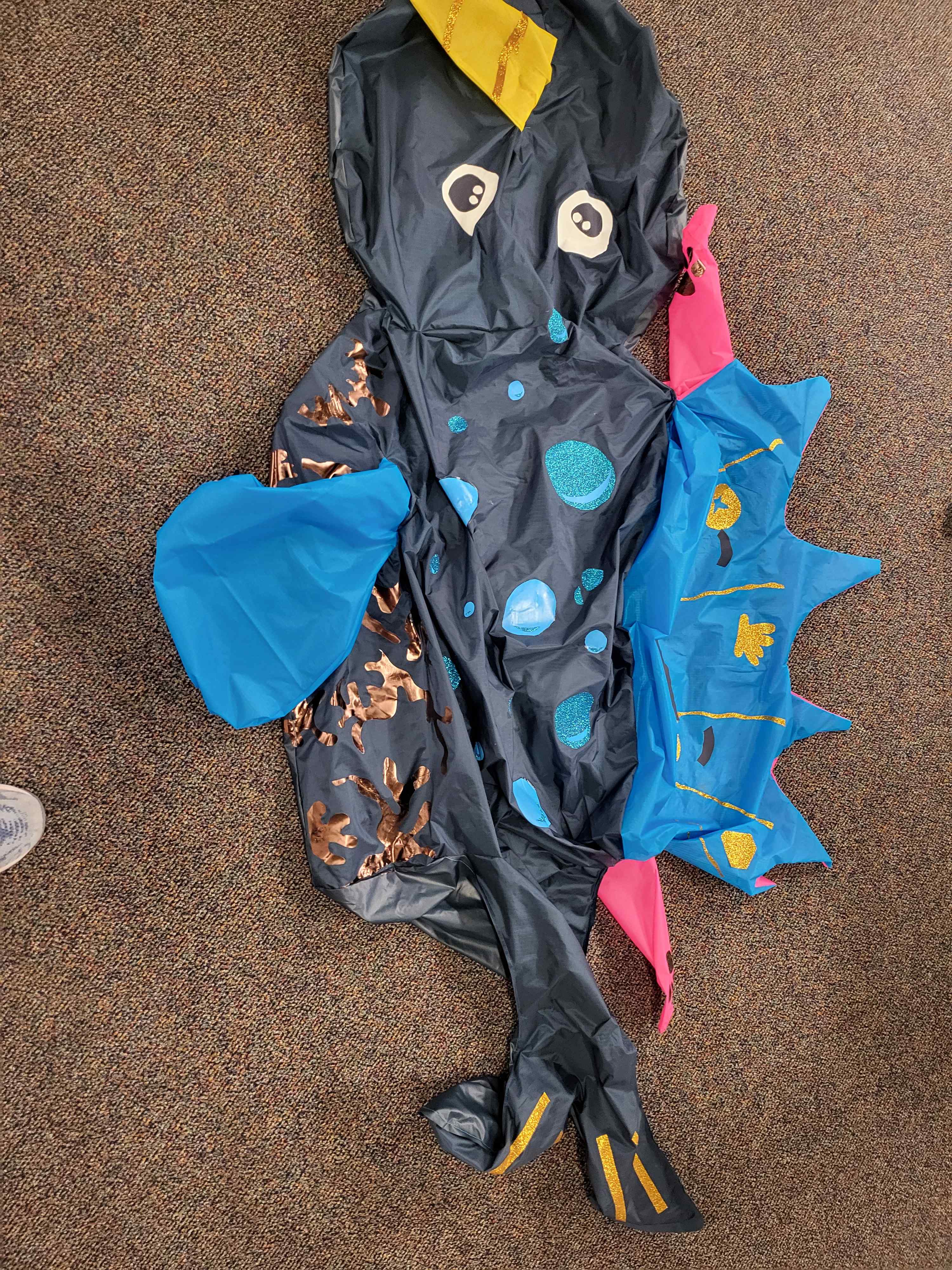

In the end I decided to create a narwhal couch that was supposed to ressemble a narwhal seat with a shell for a back, which was probably not the best decision structurally speaking. I created the couch outline in fusion then switched the arms of the chair for a narwhal head and tail (the fin and horn would be added during post processing), then cut into the back to create a wavy seashell pattern. I tried both starting from a flat pattern and getting fusion to make a flat one through flanges, but found starting in 2D was a whole lot easier. We cut the fabric on the zund and because it was so huge I had to use 3 sheets of material, I also had issues exporting the shell as a DFX as it kept on swapping the shell shape for a small triangle which was really odd, but Alphonso worked some DFX magic to fix it and I got the rest of my projecs cut. I think a combination of weird splines and weird exporting was the culprit. Sewing took forever and thank goodness we were allowed to have holes. I've sewn before for a project for another class (stuffed animals for 2.00B) that I never finished, but this was a lot of sewing and I made plenty of mistakes. The biggest one was when I lined up the edges of my pattern perfectly and proceeded to sew the head to the tail instead of to the the other half of the head. Scissors fixed that mistake and a seam ripper helped to fix several more.Eventually I finished, but it lacked eyes and looked very drab. So I got some iron on vinyl to decorate. First I tested the iron to make sure it wouldn't melt the material, then tested whethe stick on vinyl would stay, then after concluding that the adhesion was terrible I tried the iron-on kind and it worked... So I went a little sparkle crazy, and not with the Roland or any cutting machine, just me and a pair of scissors. I am proud to say that it looks like a kindergartener barfed colorful crayons all over it but we'll see how it looks when blown up.

Conclusion

I haven't inflated it yet, but I think it'll be really cool and I learned a lot about sheet metal tools in Illustrator, how to think 2 to 3 dimensionally, and how to sew/troubleshoot sewing. All in all this week was really fun, but also quite distracting from my final project so I might have to simplify.

Group Project

I went to the tutorial and we learned the basics of CAD and sewing.