3D Printing/Scanning

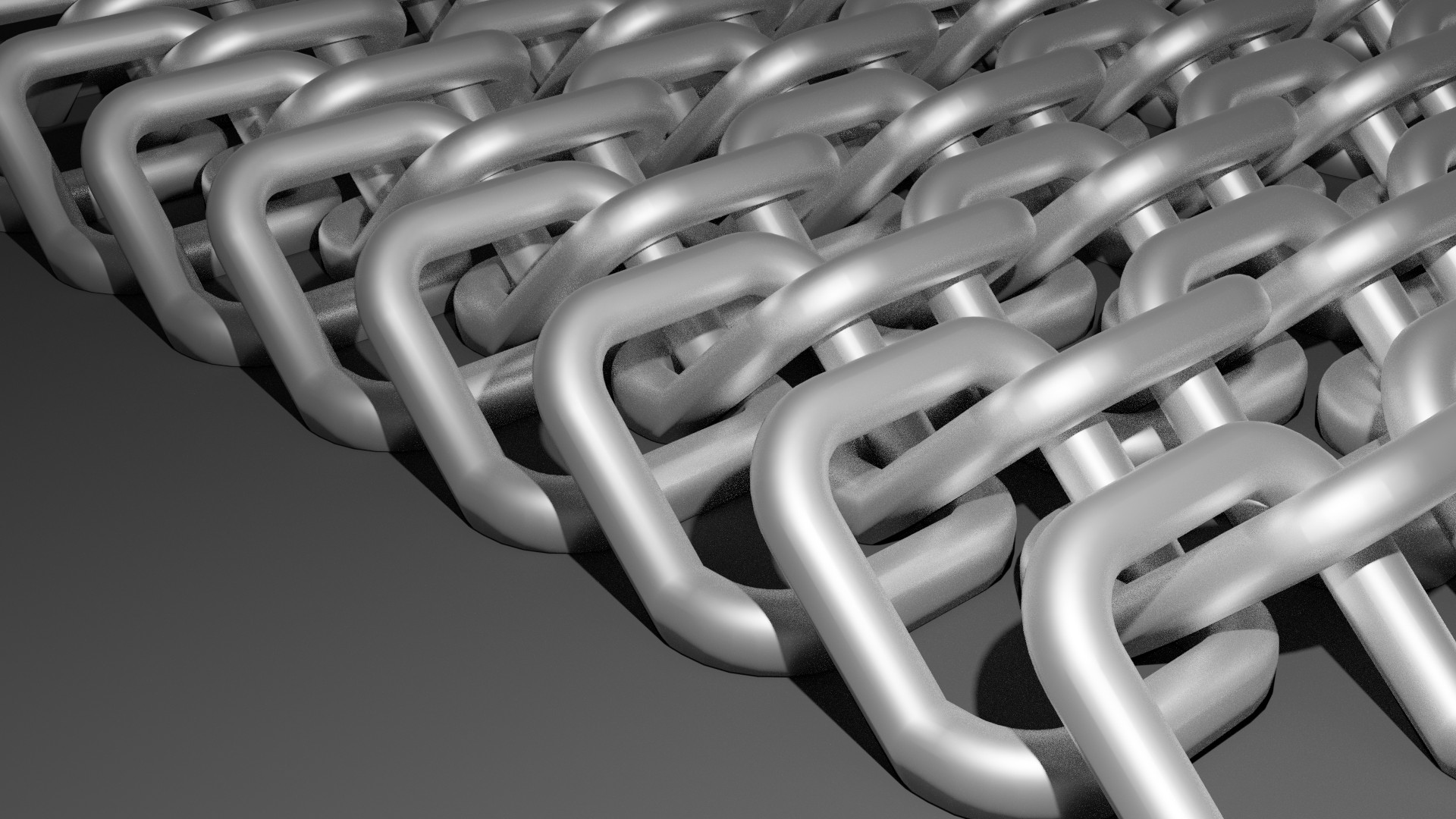

Chainmail is a unique material: matalic, but flexible; hard, but lets some things pass through; bendable in some directions, but not others. The special material properties of chainmail (or just mail) is not just given my the material that it's made of. The shape also plays an important role in how it behaves. Mail consists of numerous rings (called links) that loop around each other in a way that forms a fabric type material. It was often seen in armor centuries ago, and gave the user more flexibility and breathebility, as compared to more rigid designs.

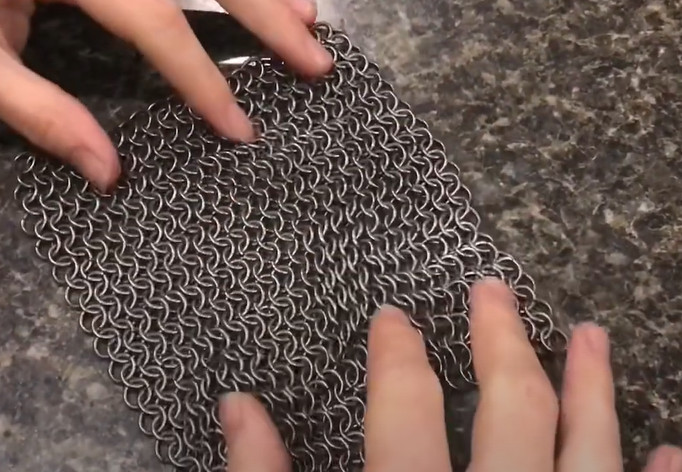

Below is a patch of stainless butted mail I made in the past. This is the style that I am mimicking on the 3D printer. It is a traditional 4-in-1 weave, meaning every link has 4 other links looped into it. Many other weaves exist, but this seemed to me like the most printable type.

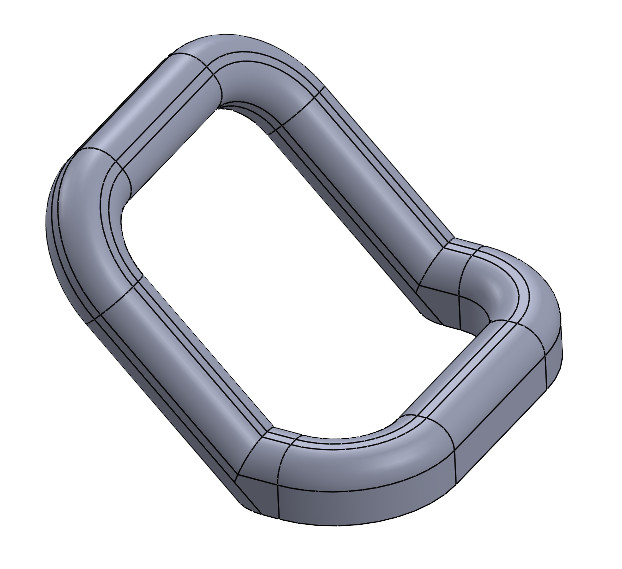

The most difficult design of the printed mail was making sure that the links would not intersect themselves. I could not simply reproduce the round link mail (as in the mail above) because there would be almost no contact between the links and the print bed. Somehow I needed to maximize the contact area with the print bed, but keep the links seperate. Below is the design I created

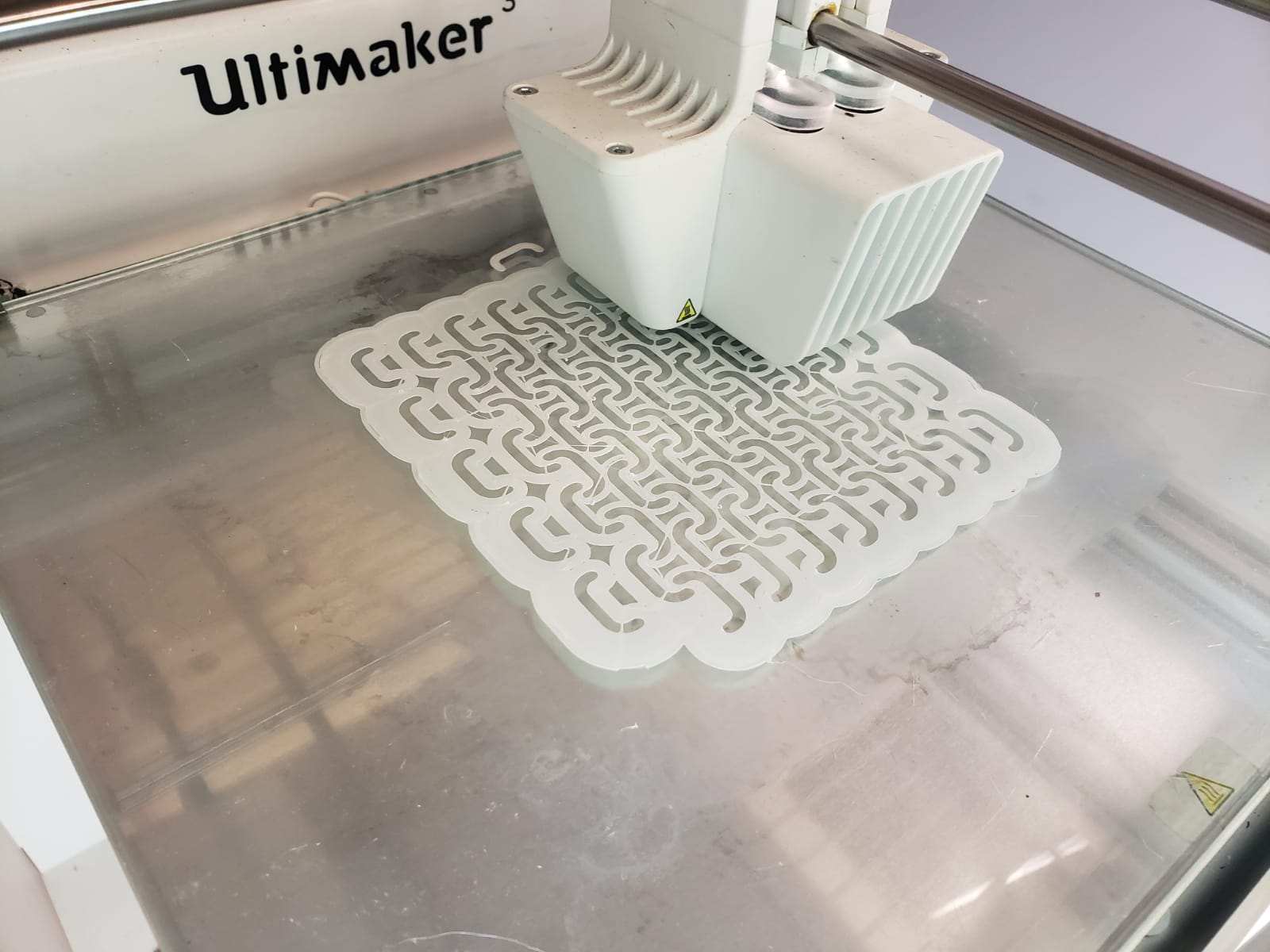

80 of these individual links form the assembly that I printed, giving a total area of about 4"x4". I made them into an assembly in Solidworks, and exported it as an STL to generate the file for the 3D printer. My first print attempt had no brim, so the links easily seperated from the bed, ruining the build. My next attempt had a brim, which helped in 2 ways. First it increased the contact area for each link. Also, it joined each link together on the first layer, making it like 1 large part, instead of many small parts. Below is what the first layer looked like with the brim.

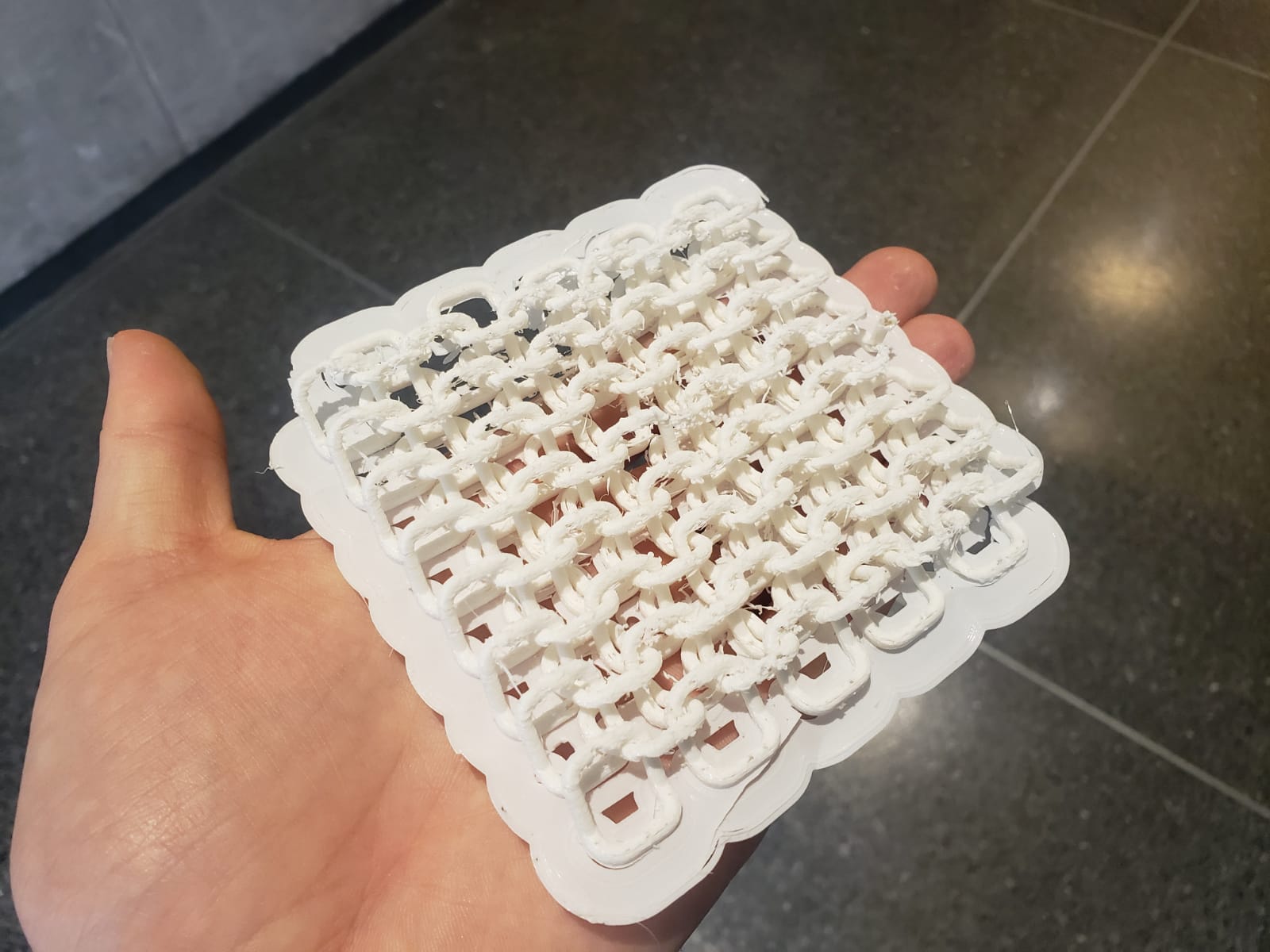

Below is an image of the completed print. It still has the brim (which took a lot of effort to remove). A few links had trouble bridging, and I plan to make some more improvements in future revisions. By arching the top of each link it shouldn't affect the behavior of the mail, but it should stop the messy bridging. I would also want to print the links with close to 100% infill (rather than 10%), because the links feel especially fragile. It wouldn't take an enormous amount of material becasue the links are thin, but I think it would increase the quality of the build.

Overall, I think the most challenging part of this build was the design. It took a lot of guess-and-check style tweaking to get the links to fit together properly.

Scanning with Meshroom

Above is the 3D scan I was able to create of my brass rat using Meshroom. I fed Meshroom over 100 images of my brass rat, and it was able to somewhat recreate a 3D model of one of the shanks. It struggled with the overall shape of the ring, but it was able to put together one of the sides. Below is an image of my actual BrassRat.