#Robotic Fabrication #Parametric Design #Modularization #GUI |

|---|

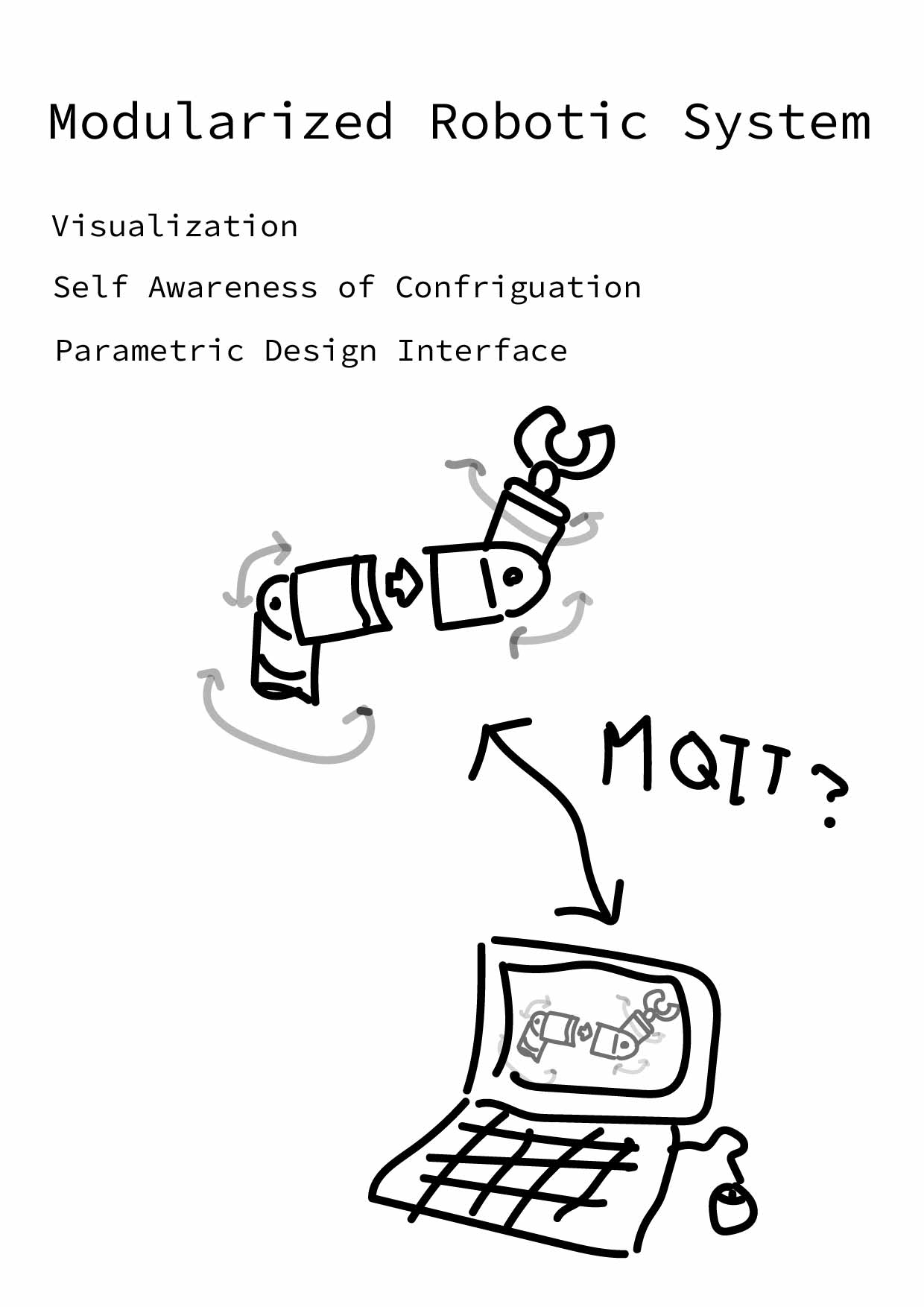

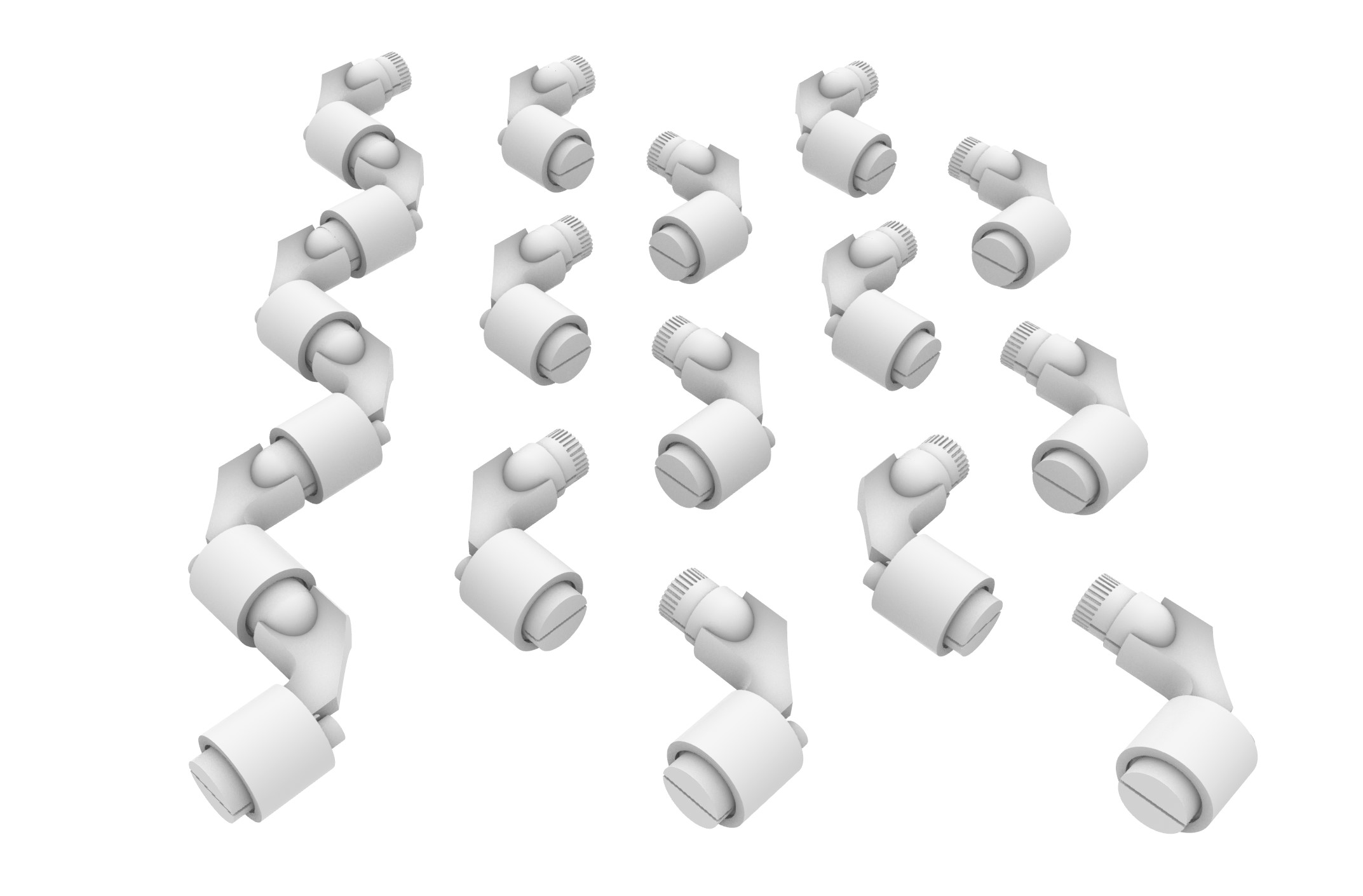

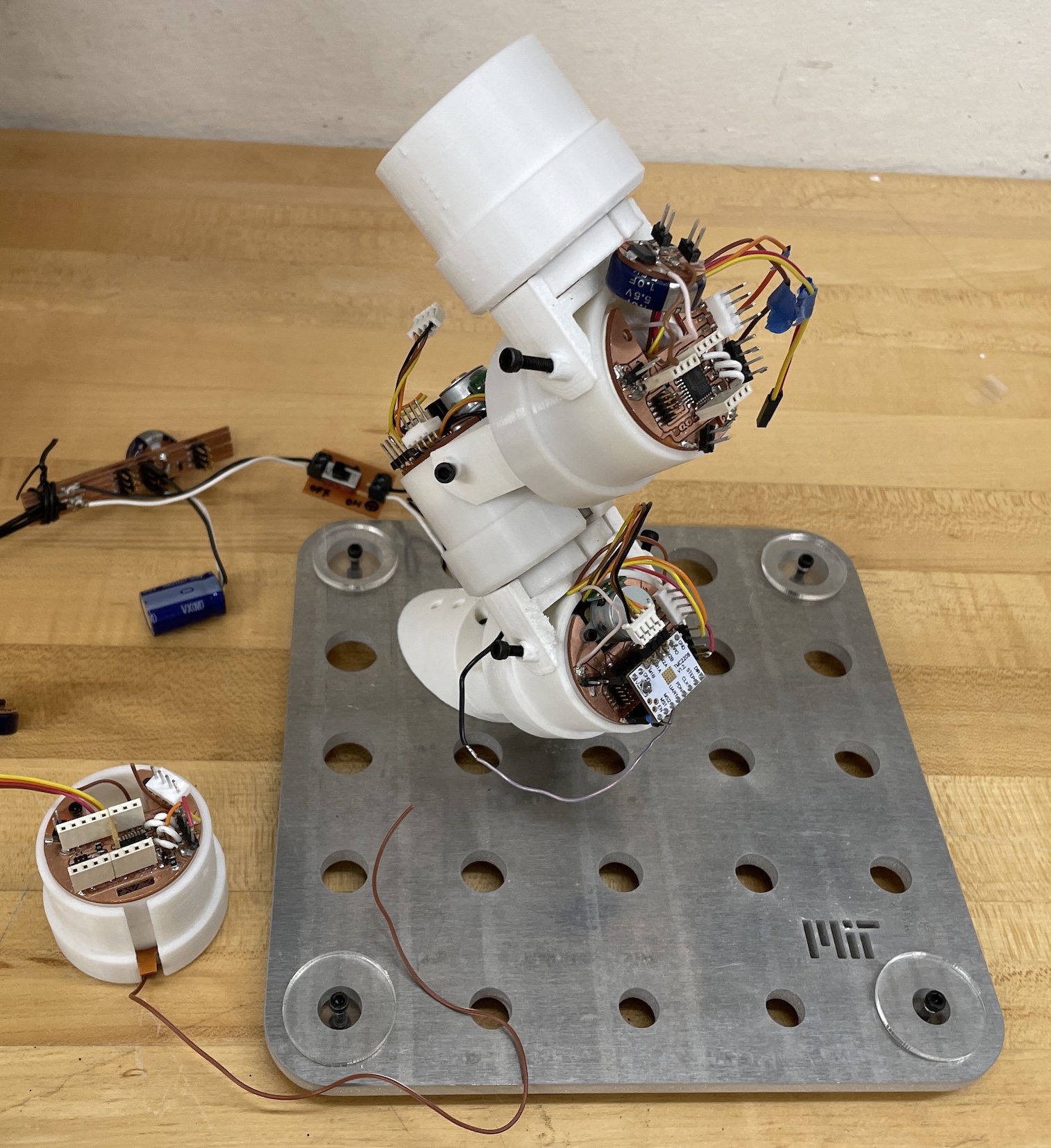

In the design field, designers are looking for a more intuitive way to use robots. In order to meet the need, I decided to develop a modularized versatile robotics system with a parametric design interface and visualization. The robot system may need to be aware of the current configuration when a user assembles some modules. I would use the IoT method to design the robot system; the interface can visualize and control the robot modules in real-time. |

|---|

Furthermore, Users can use these modules as a telepresence robotic system since they can be controlled remotely with MQTT. These parts are the same; therefore, users can easily assemble them, reconfiguring them to meet the needs of different scenarios. |

|---|

Therefore, I design the modular robotic systems including three main features: |

|---|

1.Identical units 2.Plug and Play 3.Wireless Control |

|---|

WHY? |

|---|

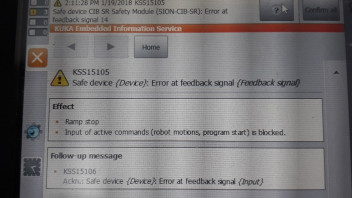

First, current existing industrial robots are difficult to use for creaters. |

|---|

I have some experiences the I was using industrial robots for digital fabrication and art. |

|---|

I need to deal with many issues when using current industrial robot arm all the time. |

|---|

In a confined working space, current industrial robotic systems are useless. |

|---|

In space, a robot system that is compact and easy to carry andmaintain is crucial. |

|---|

It would be handy to carry and repair these versatile and identical parts because they can be designed to be packed efficiently and changed components. |

|---|

Also, when people have a punch of same modules, it is easy to accumulate using experiences; therefore, it is easier to get helps when encountering problems. |

|---|

Wireless control is useful for remote working |

|---|

Additionally, when we meet online and try to solve some problems, a wireless control robots through the interned could help a lot. |

|---|

I believe it can help to convey ideas as well, the robot can be participants' telepresence hands. |

|---|

|

|---|

|

|---|

The interface I created in Grasshopper, which is able to caculate each modular's angle and send to the robotic system through MQTT |

|---|

It will be easy for users to control the robot intuitively |

|---|

|

|---|

|

|---|

|

|---|

#BOM |

|---|

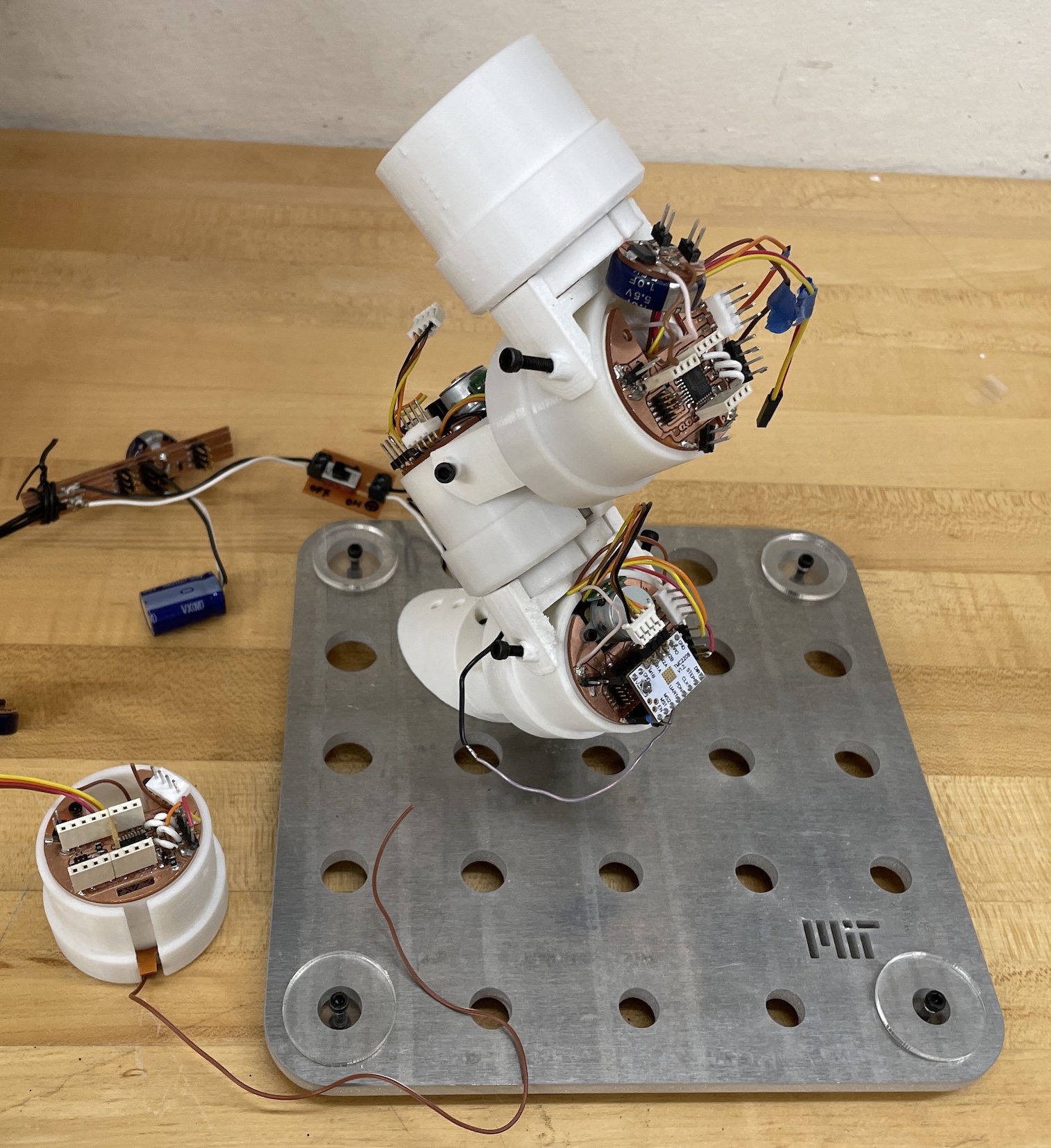

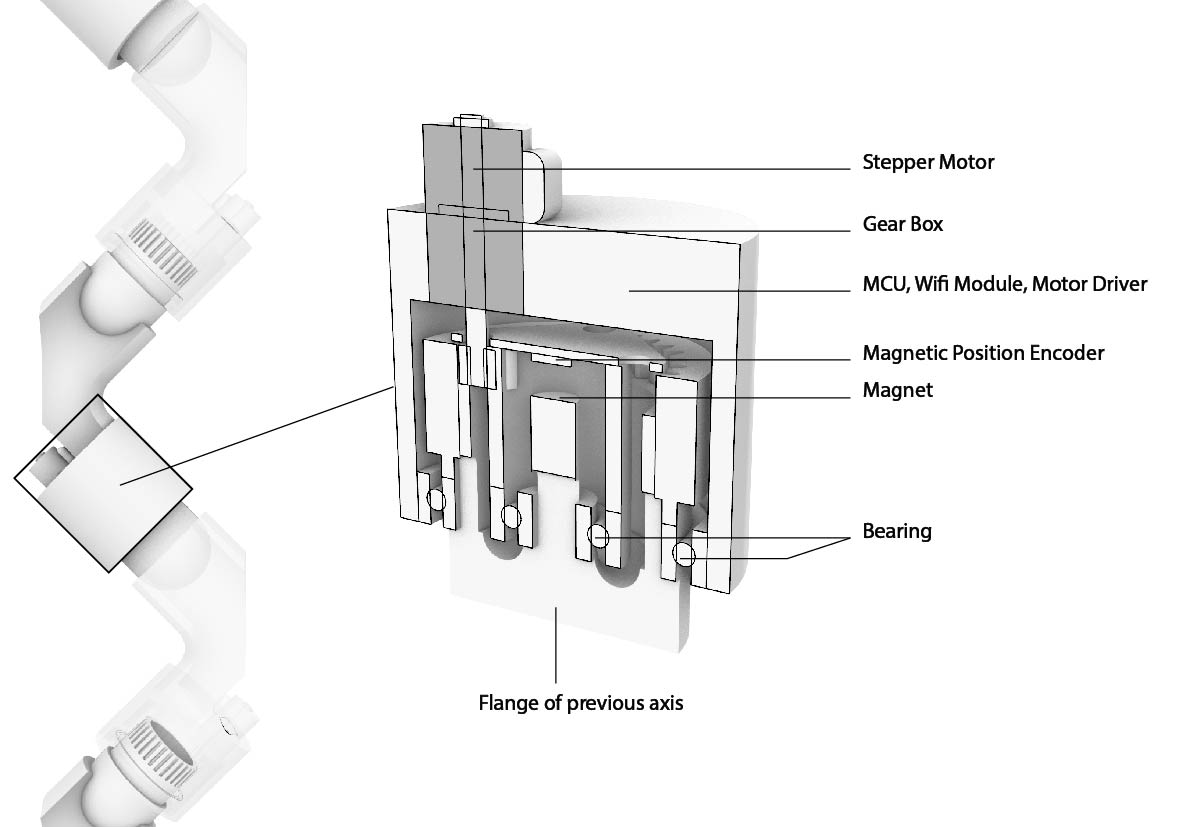

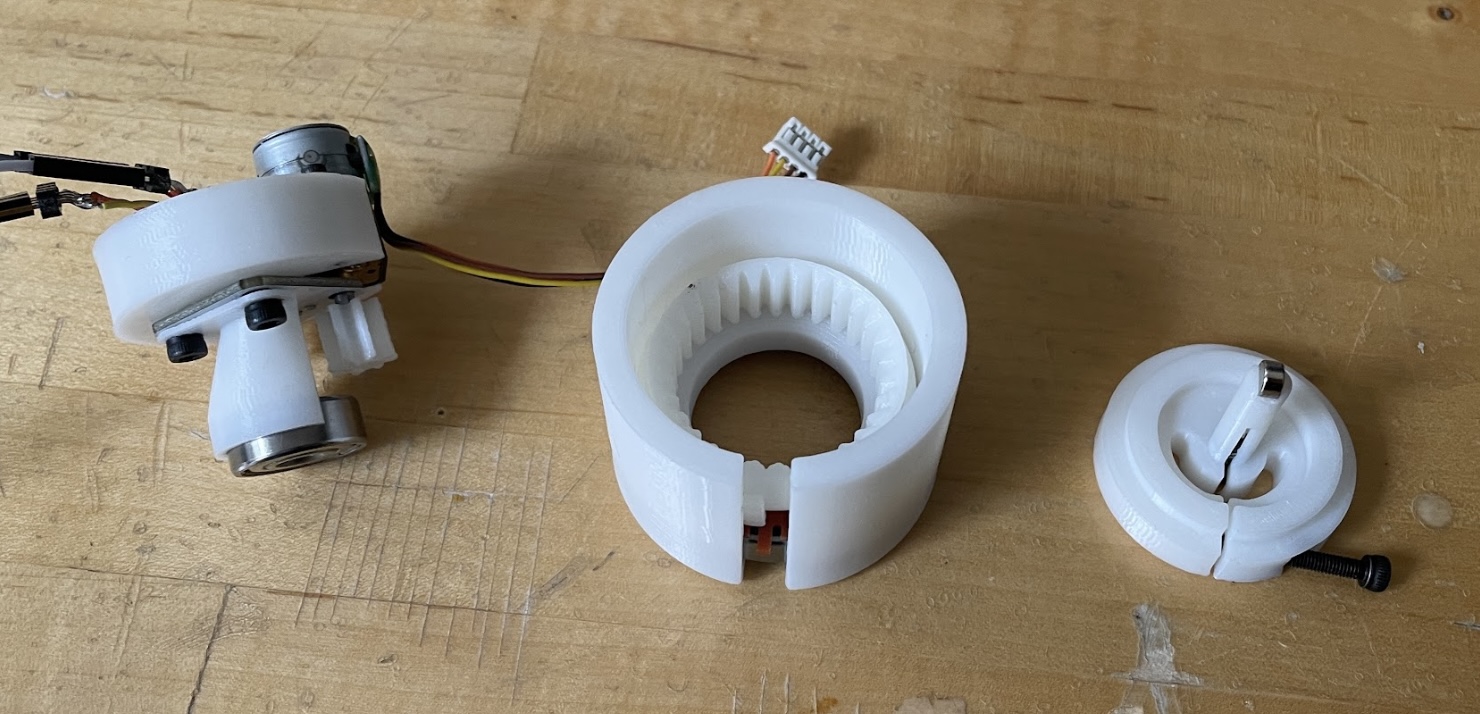

The section of the robot. |

|---|

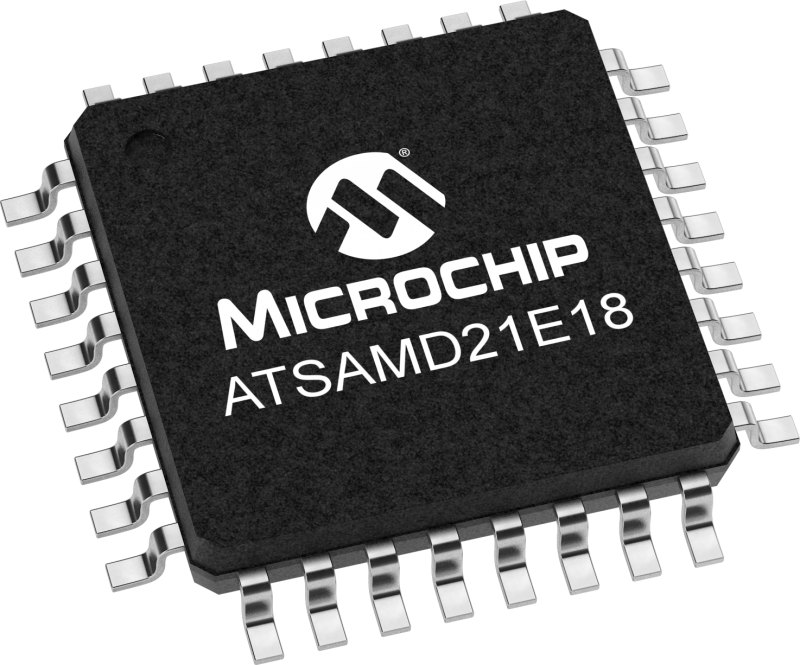

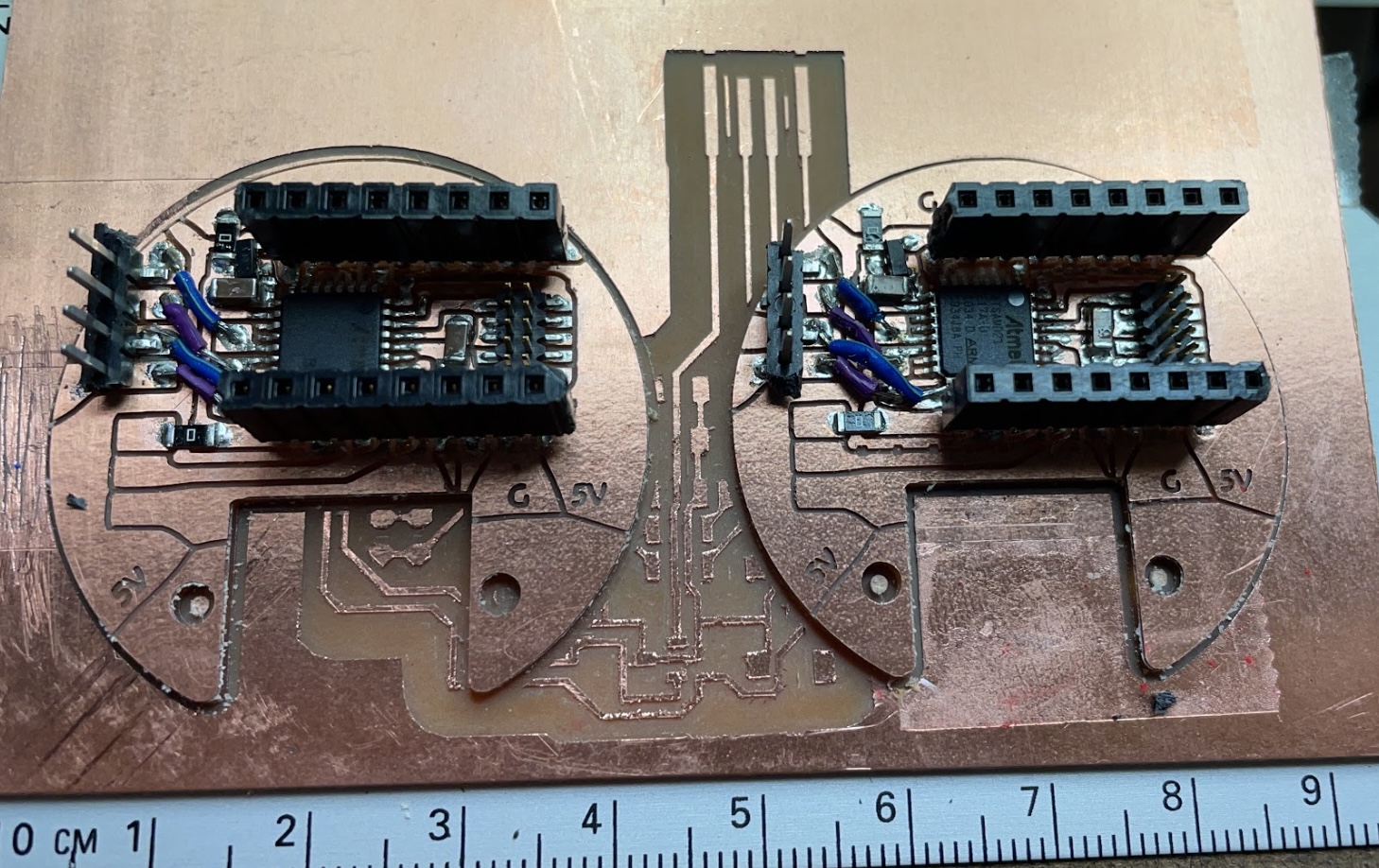

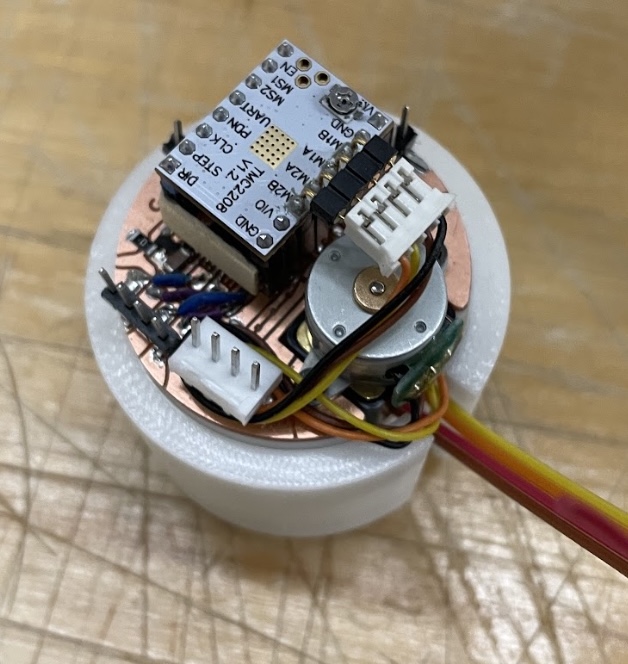

SAMD21E18: MCU with more flash storage to memorize the stepper angle in a non-volatile way |

|---|

TMC2208: Sepper motor driver |

|---|

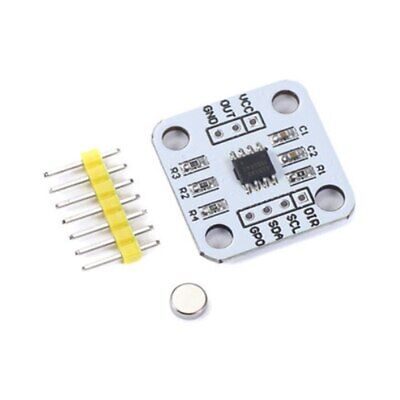

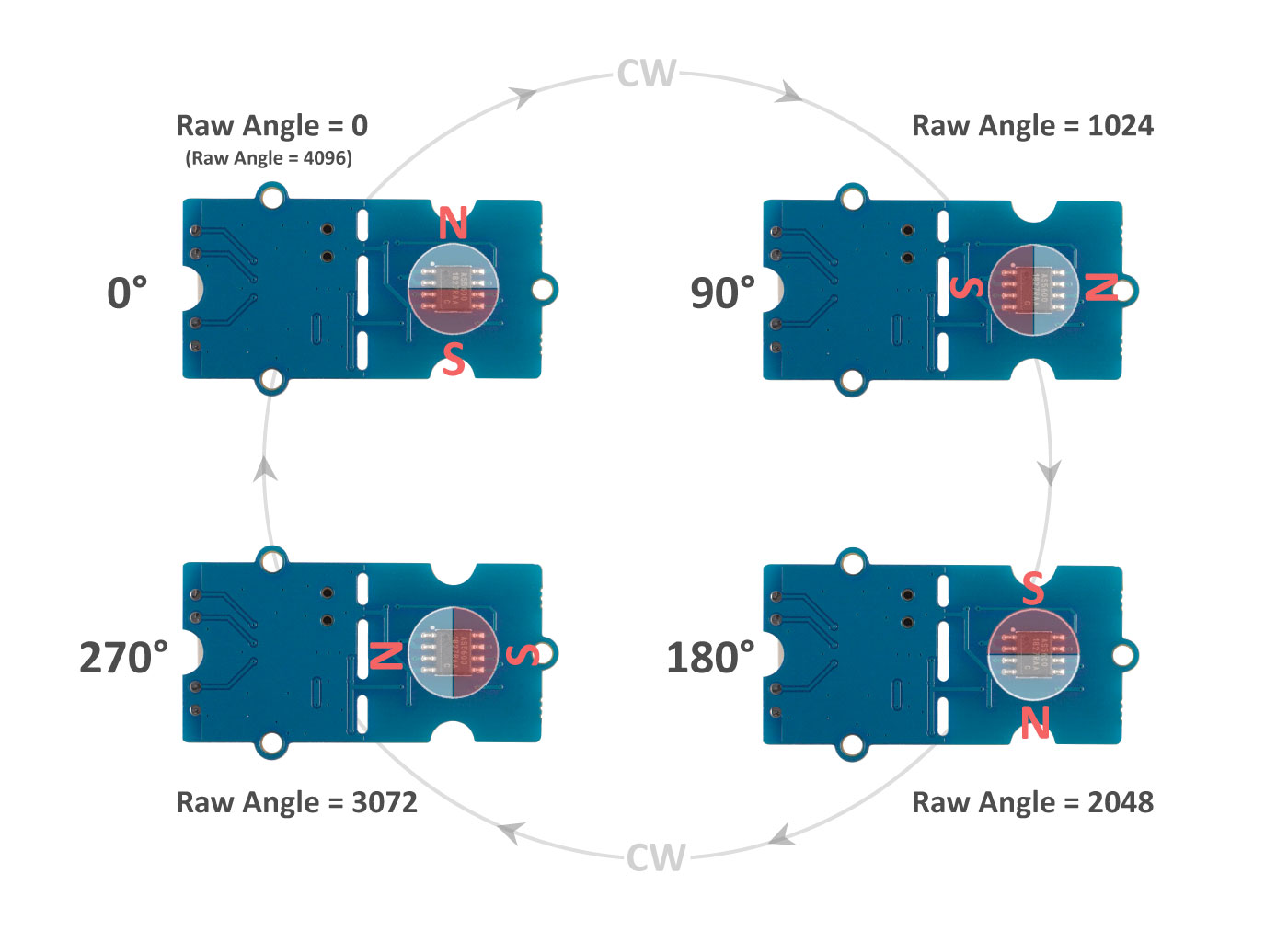

AS5600 is a magnetic encoder magnetic induction angle measurement sensor module, it can output 4096 positions per round |

|---|

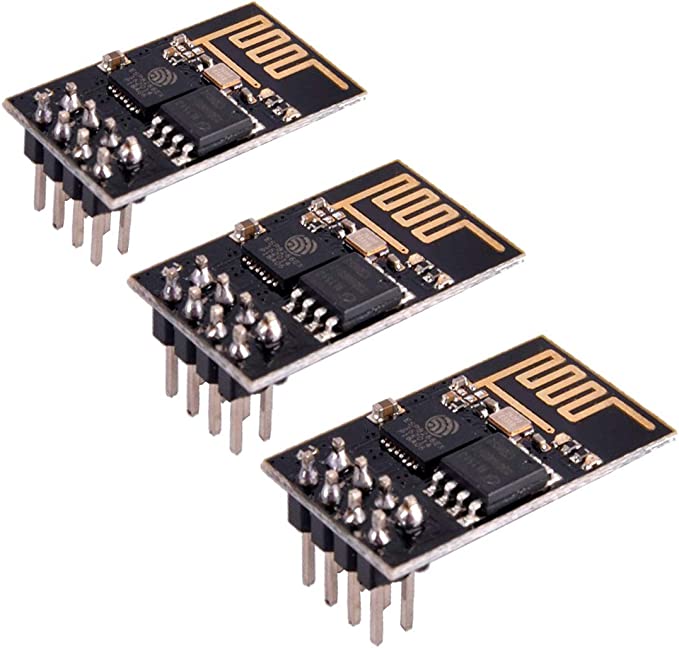

Esp8266: wireless control through MQTT |

|---|

Bearing: in this project, I attempt to make bearings as connectors; therefore, they will be modified to be conductive. |

|---|

DC 5V 2-Phase 4-Wire Micro Stepper Motor |

|---|

|

|---|

working in progress |

|---|

|

|---|

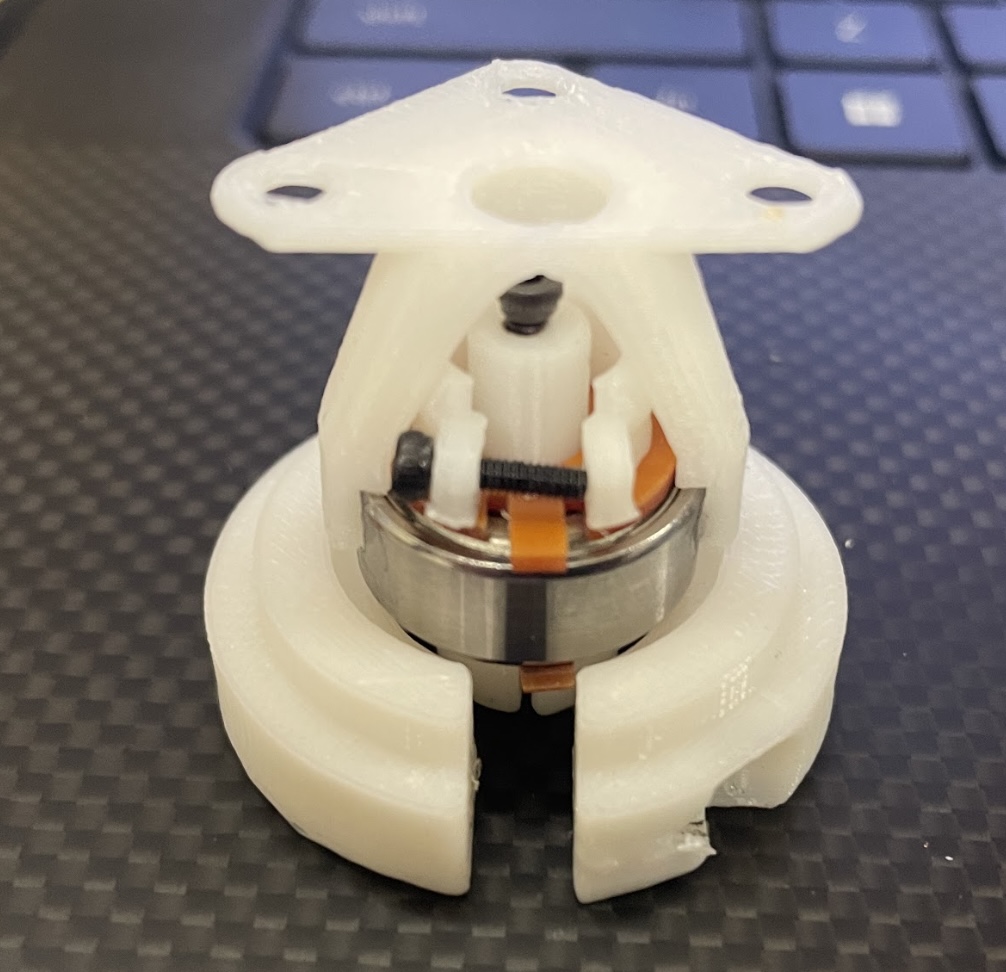

A compact design combines a gearbox, a stepper motor, a rotary encoder, connectors(bearings), Wifi Module, and MCU |

|---|

|

|---|

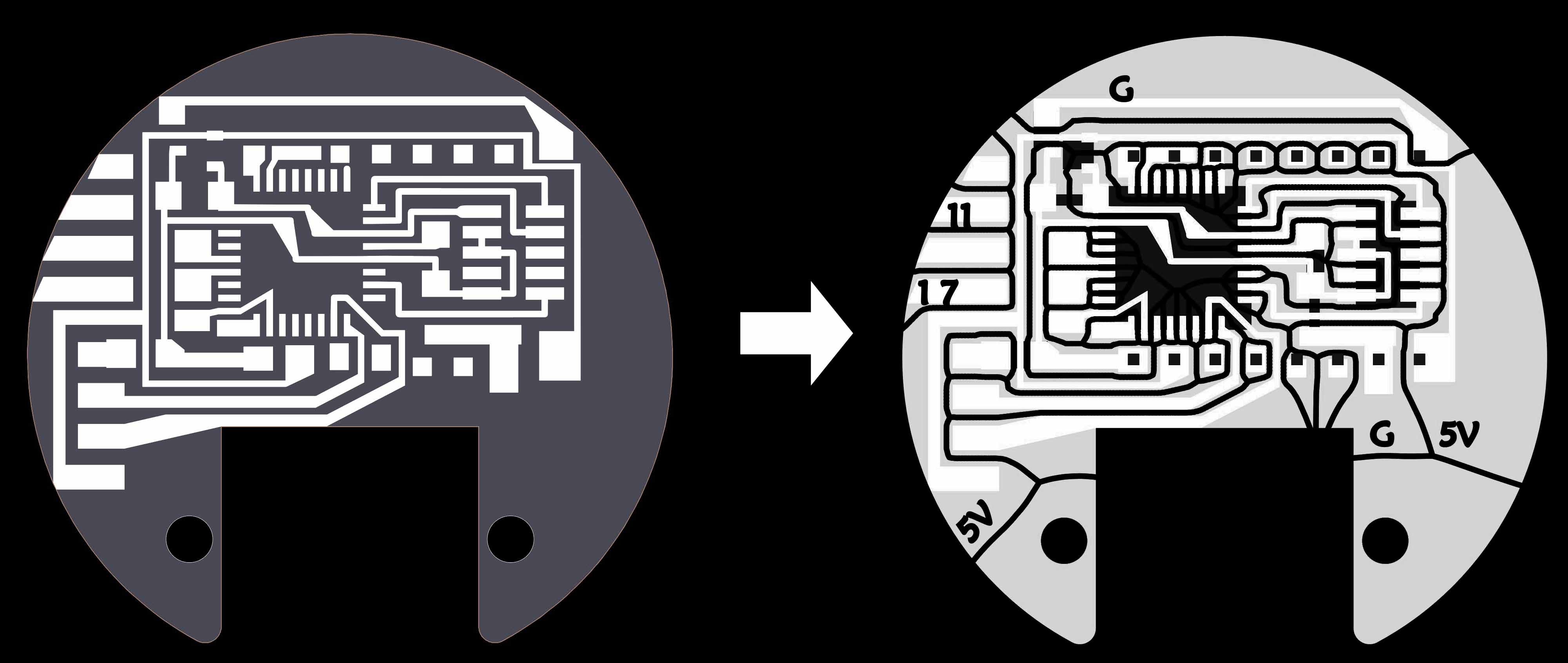

I try to add copper boards to make bearing conductive, using two bearings as GND and 5V to power each system. |

|---|

This mechanism is to press down the copper board to connect inner and outter rings of a bearing. |

|---|

|

|---|

The lubricant in a bearing will make the inner ring and the outer ring insulated; I use a copper-clad PCB to connect them. |

|---|

Rotary encoder test |

|---|

|

|---|

|

|---|

Final Project Video |

|---|

|

|---|

2022 |

|---|