Computer-Controlled Machining

Process

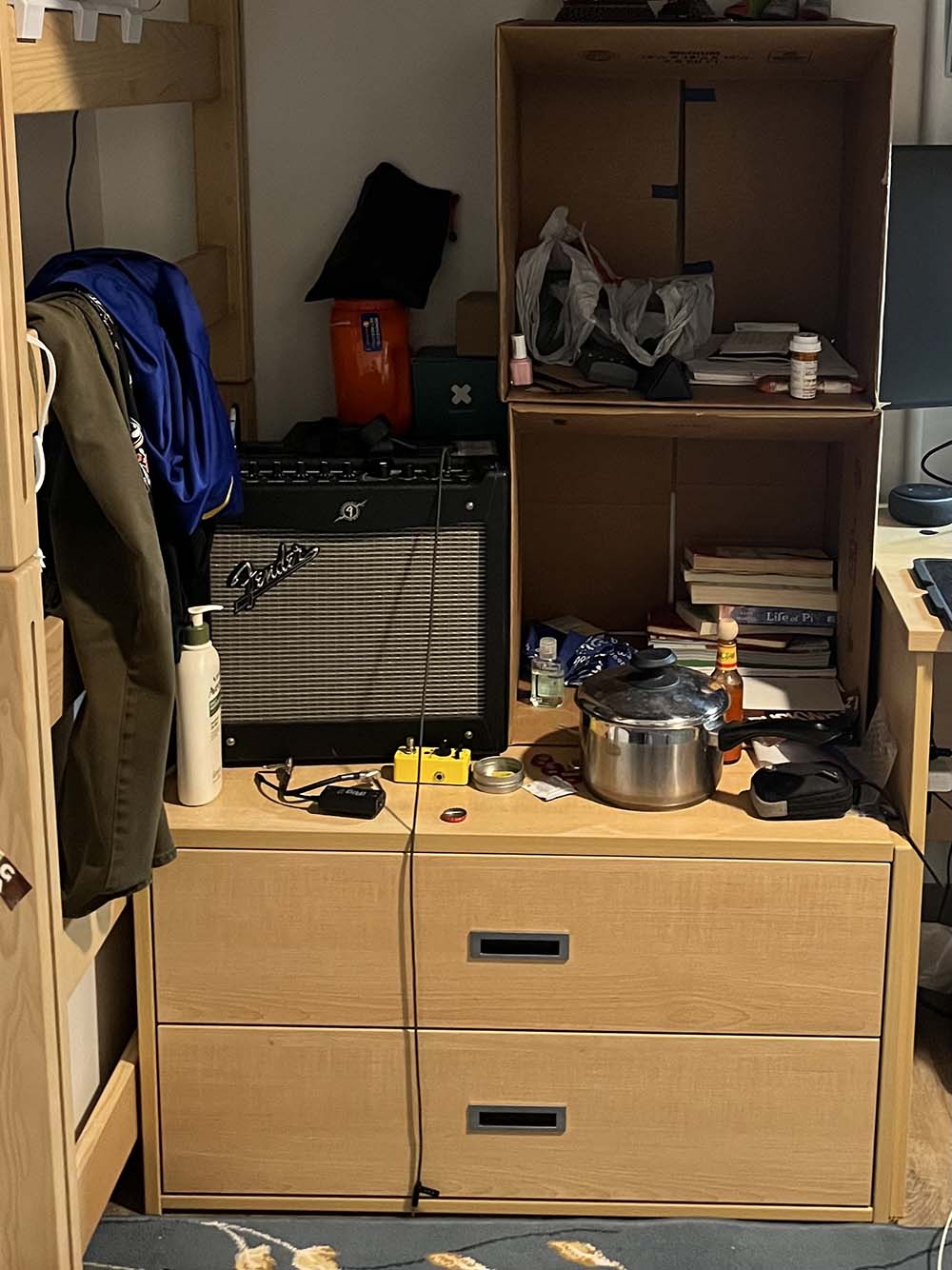

I am currently using these cardboard boxes as shelves in my room. They will eventually fall apart so I want to make more durable shelves that will also use the space more efficiently.

They gave us 4x8 foot OSB boards, which are pretty low quality, but I kinda like the crazy texture they have. After I made my design in Rhino I got help in setting up a MasterCam file which is needed to cut it on the Onsrud, which is this big CNC milling thing:

The Onsrud is really cool because it's super fast and can make really complex cuts that would be really hard with simpler tools/machines. It even changed drill bits automatically for each stage of the cutting process without me having to do anything.

The drill doesn't cut all the way through so it leaves a small layer of "onion skin" that keeps all the pieces attached so they don't fly around dangerously. I cut the pieces out with a knife and sanded off the onion skin that remained attached to the edges.

Then I sanded the surfaces because the OSB is very rough on one side. Finally, I assembled it. I used press-fit joinery so I didn;'t have to use any glue or screws or anything. To figure out how wide to make the slits we had done a group cut earlier to test which width worked the best. I found .42 - .46 inches worked, but chose to use .42 in case the sanding widened the slits or thinned the boards.

Rendered animation of assembly that I made in Blender for fun:

Here's the Rhino file I used to design the shelf.