Designing

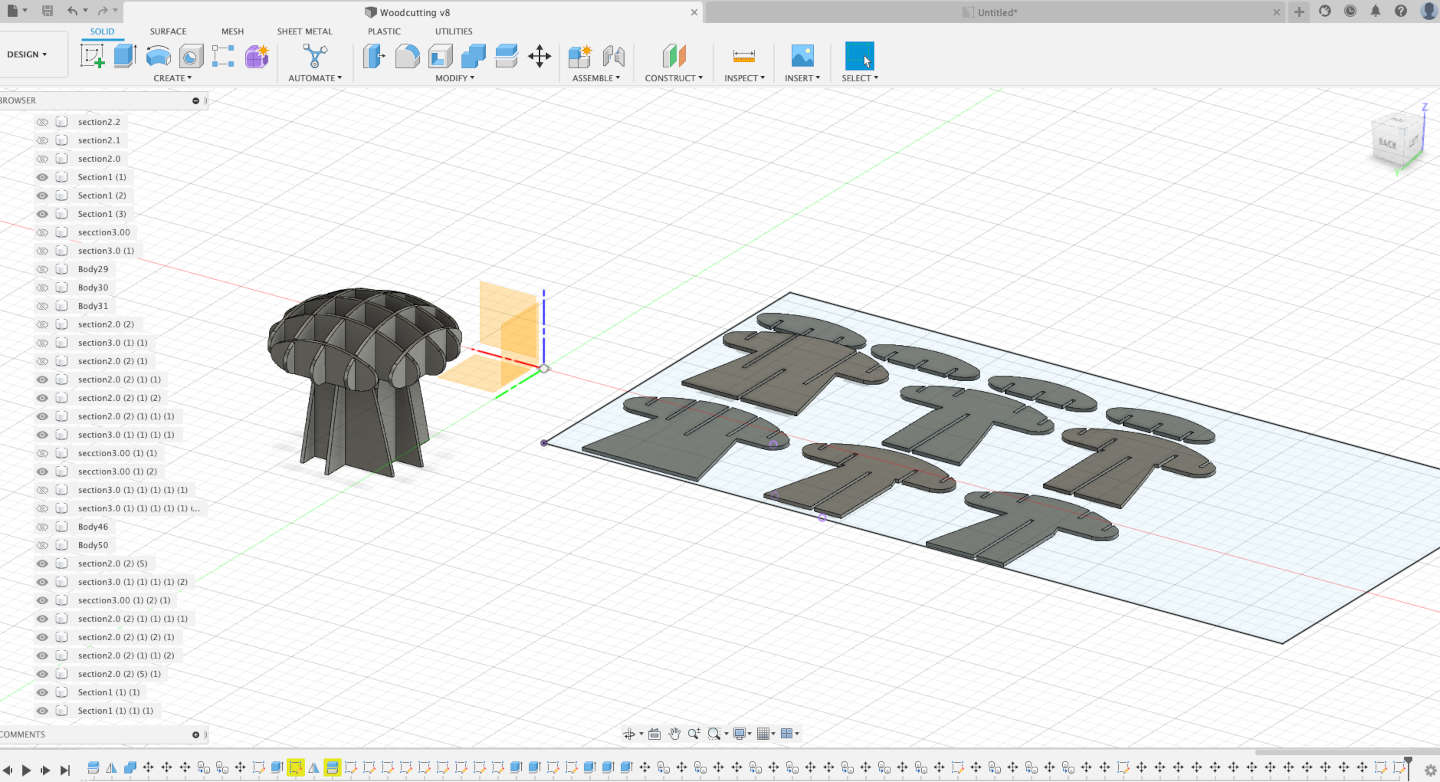

I decided to build a mushroom chair! As a CAD noob, I worked with Alfonso to think through how to design a stable model. It took a lot of work: first creating the smooth 3D parametric model, then slicing it into pieces, then creating the press fit joints, then making sure the geometry actually works out to assemble.

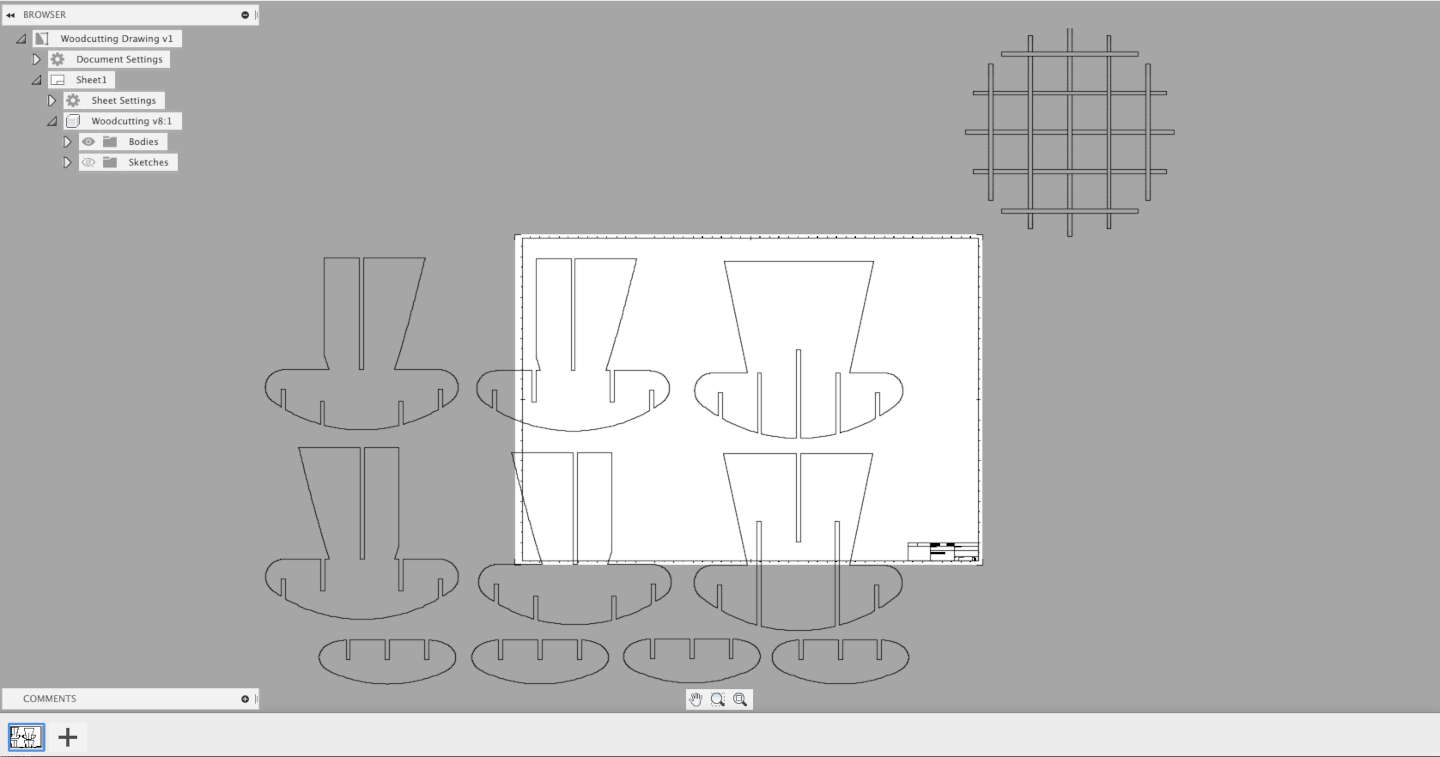

Afterwards, I put each piece onto a flat plane and exported the drawing as a DXF file to Chris Dewart, the woodshop manager for the Architecture section!

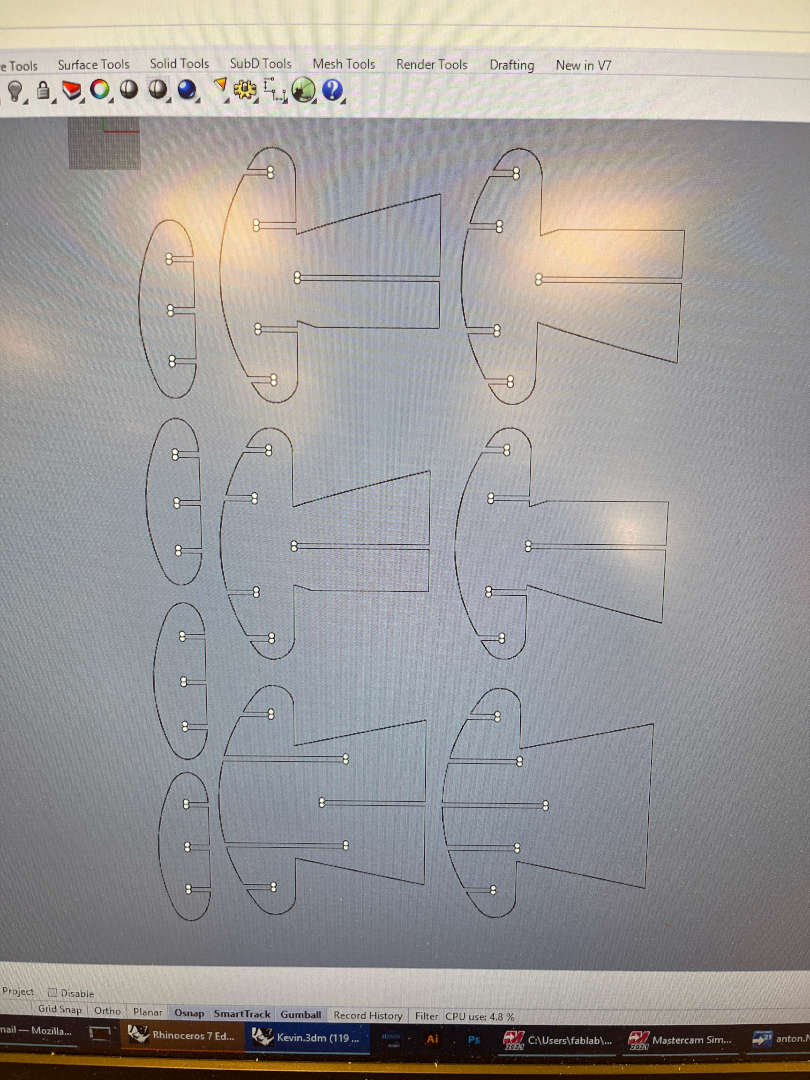

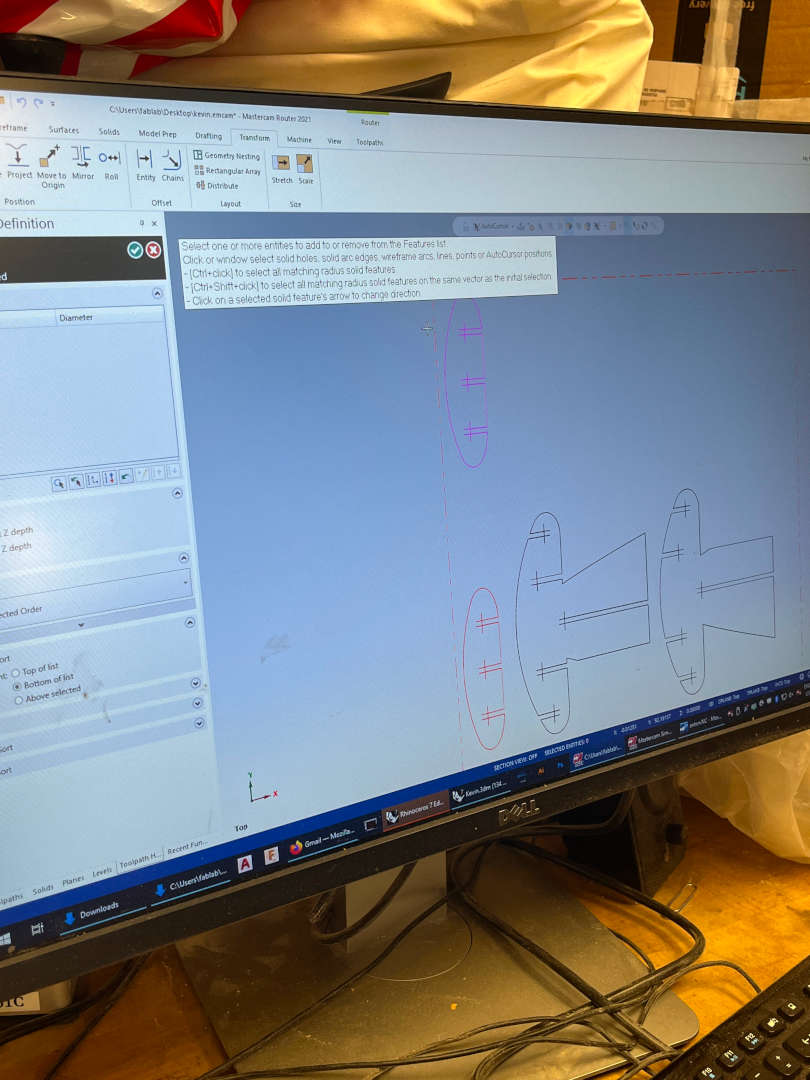

Next, I went into the woodshop to add drill points on Mastercam. Because the CNC Router has circular drills, drill points on each press fit joint are necessary to make the joints fit well together (the CNC Router will use a different drill size to carve it out). A lot of other setup was needed that Chris helped take care of (setting the right drill parameters, equipment, etc.).

Milling

Now, we placed a 4'x8' OSB wood onto the CNC Router and uploaded the file. We did a small test cut to see what thickness the OSB wood was after compression to make sure the joints would fit tightly together. If I remember correctly, we settled for 0.44 inches. After the cut, we got the individual pieces!

Assembling

Finally, we assemble! The joints were actually quite tight, and some parts were difficult to press together. So I had to use a hammer to smash the pieces in place. Additionally, I used a cutter to round out one of the legs because the geometry was preventing it from coming together with the other pieces.

After a bit of work, I assembled the mushroom chair! I used some sand paper to smooth out the edges and make the chair at least able to sit on. Overall, I'm very proud of what I made! I've never made any furniture like this before, so it was super fun to go from 0 to 1 :).