Week 3: Electronics Production

Assignment

Assignment Details

👯 group assignment:

- characterize the design rules for your in-house PCB production process

- extra credit: send a PCB out to a board house

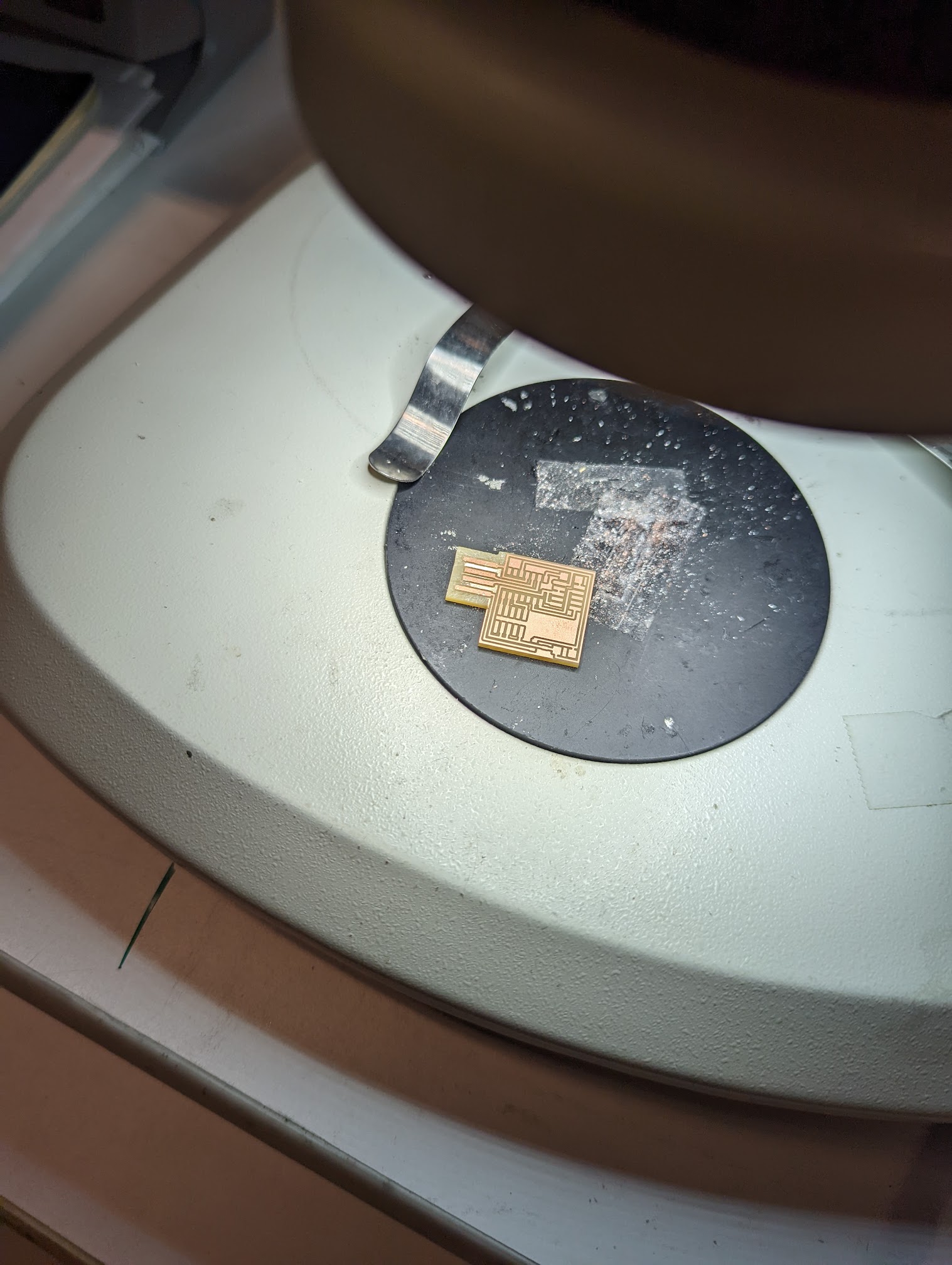

PCB Milling Process

- Clean the inside milling machine and milling platform as necessary

- Place double-sided adhesive to a clean copper plate

- Smooth the tape onto the milling platform until plate is maximally flat against the platform

- Grab the necessary end mill

- Make sure milling machine is powered on

- Open mods

- Gently load the end mill into the milling head until desired depth is reached

- Align milling machine head to home/origin in mods

- Adjust machine settings via mods until the end mill is barely touching the surface of the copper plate

- Start milling process in mod

- Repeat steps 10-12 as necessary

PCB Design Rules for Manufacturing

- Measurements should be in Metric units

- Set solder mask clearance between 0.0508 mm and 0.1016 mm

- Do not allow blind/buried vias

- Do not allow micro vias

- Keep the shortest path between components

- Group related components with test points for probing

🐇 individual assignment:

- make an in-circuit programmer that includes a microcontroller

- mill and stuff the board

- test it to verify that it works

- extra credit: try other PCB processes

🐇

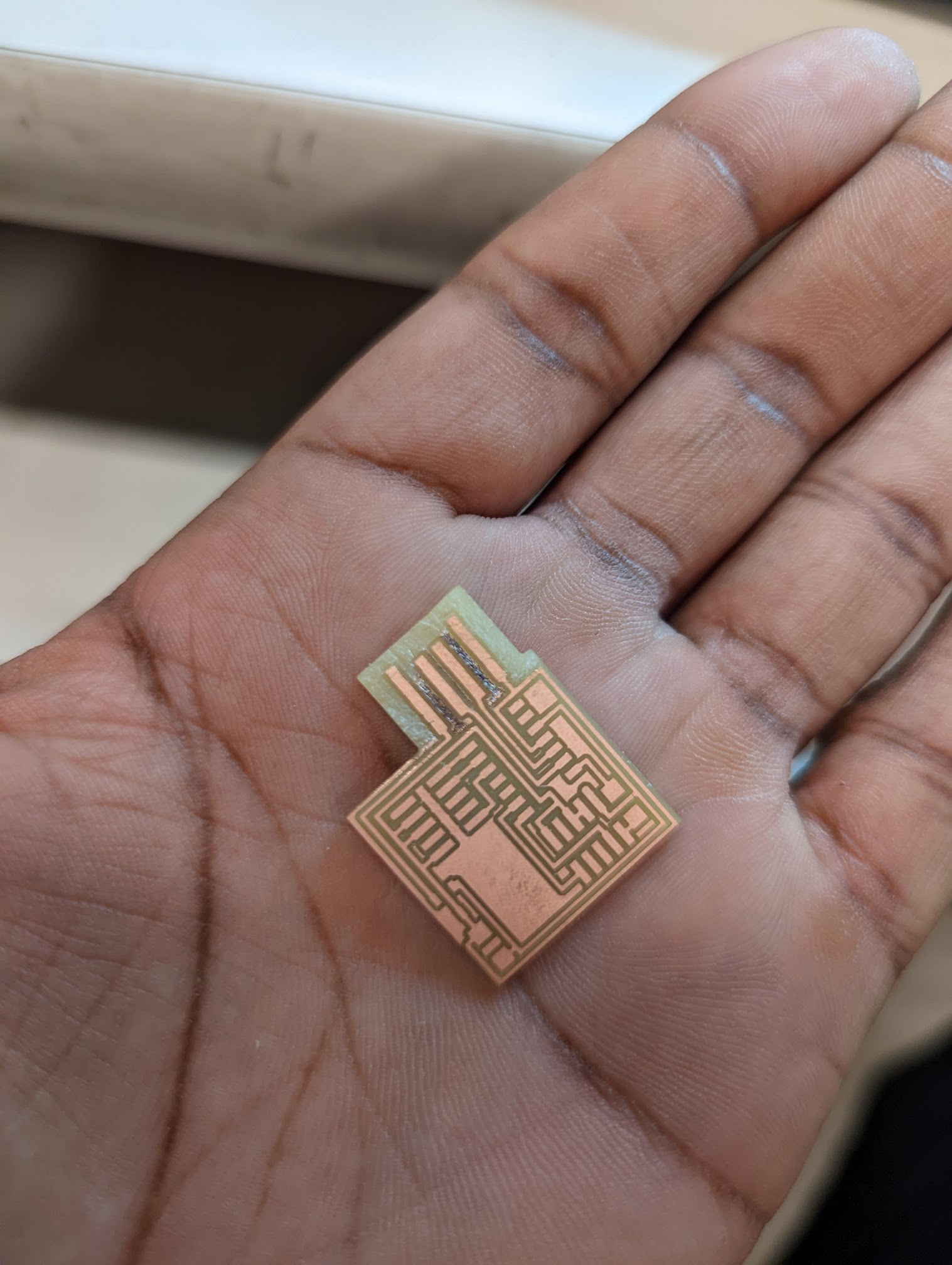

So, I've never milled a pcb before. There was a lot of trial and error obv. I need to get the bit size, trace depth, and position of the substrate

Then there was the removing the copper, which I had never done.

I still have yet to solder the componens, but a hack that another student showed was that one doesn't need to peel all the copper of the substrate

Anyways, I have all my tools to start picking and placing the components on the board.