18. October 2022

Computer-Controlled Machining

This week’s assignment was to “make something big” (on the order of meters). Having played in the MIT Symphony Orchestra for two years, I decided to make a music stand.

Design

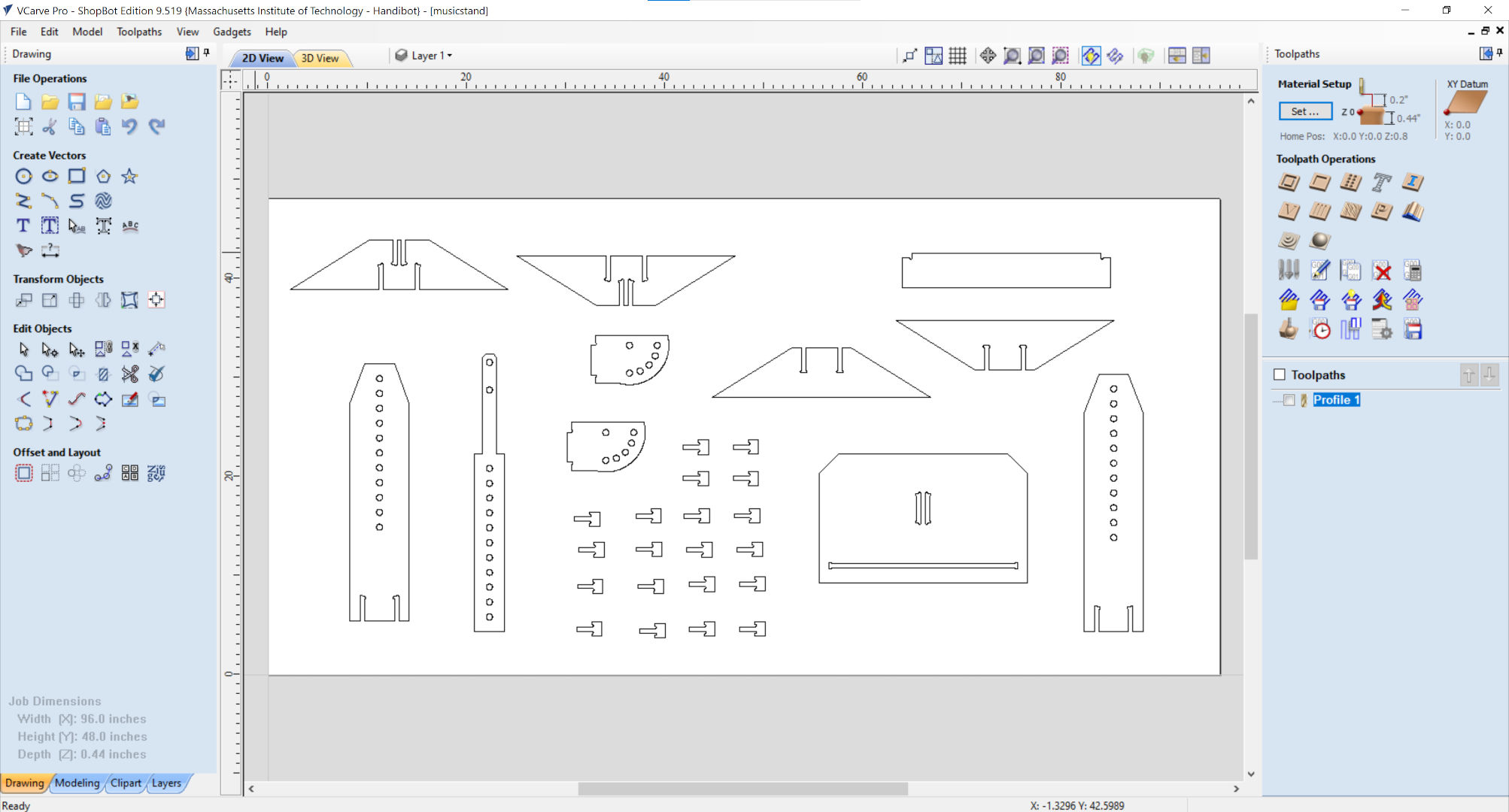

I drew the parts parametrically using Onshape, and outputted a .dxf file, which I then fed into VCarve to draw the tool path. I made sure to include fillets so the Shopbot would cut through the interior right angles.

Machining

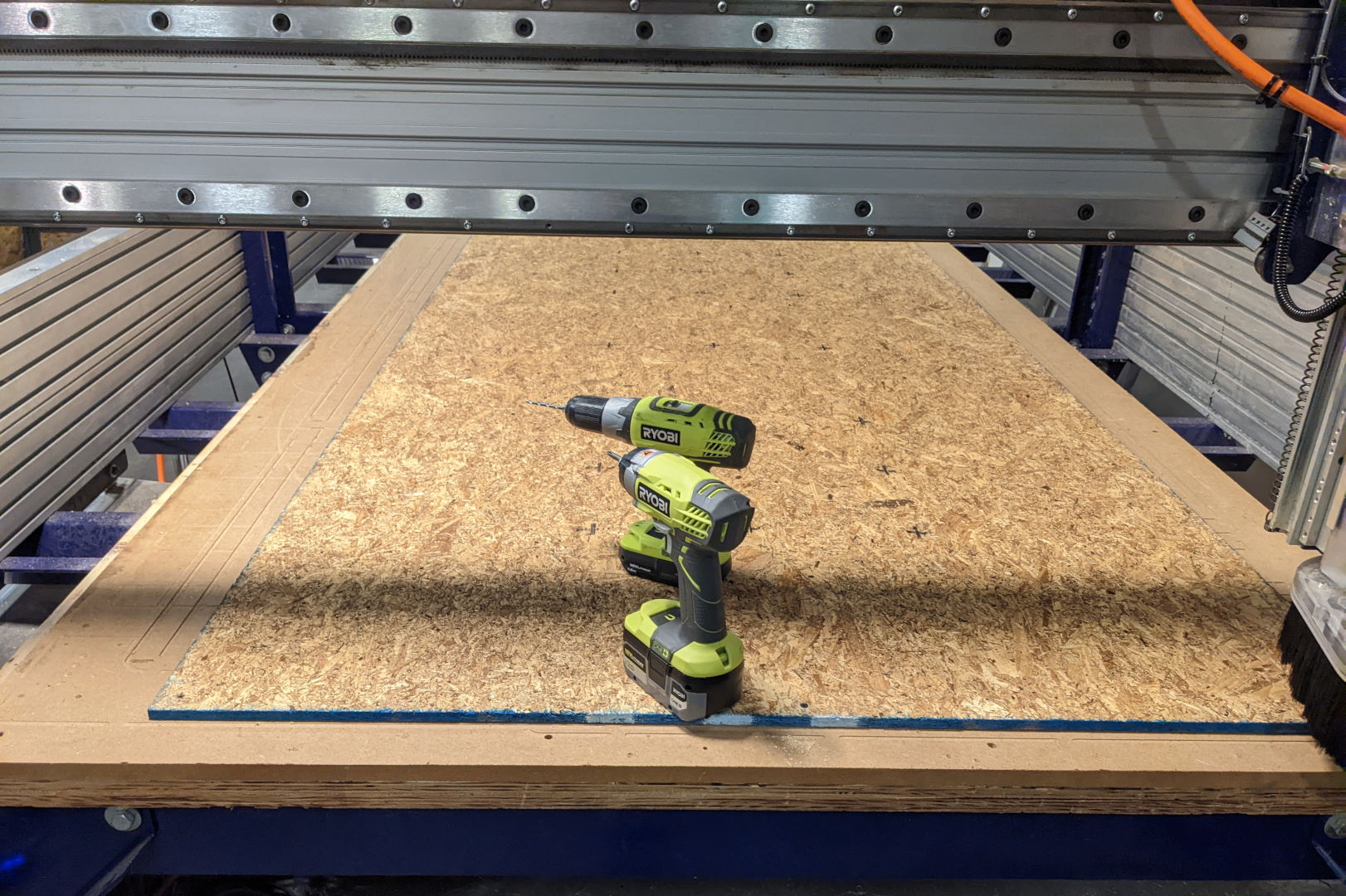

To cut the parts using the Shopbot machine, I first drilled my 8ft x 4ft piece of plywood onto the bed of the machine. I then made sure to zero the axes and follow all safety protocols.

After turning on the machine, I waited for around 30 minutes while the machine cut my pieces. The noise was very loud, but the process was very straightforward.

Assembly

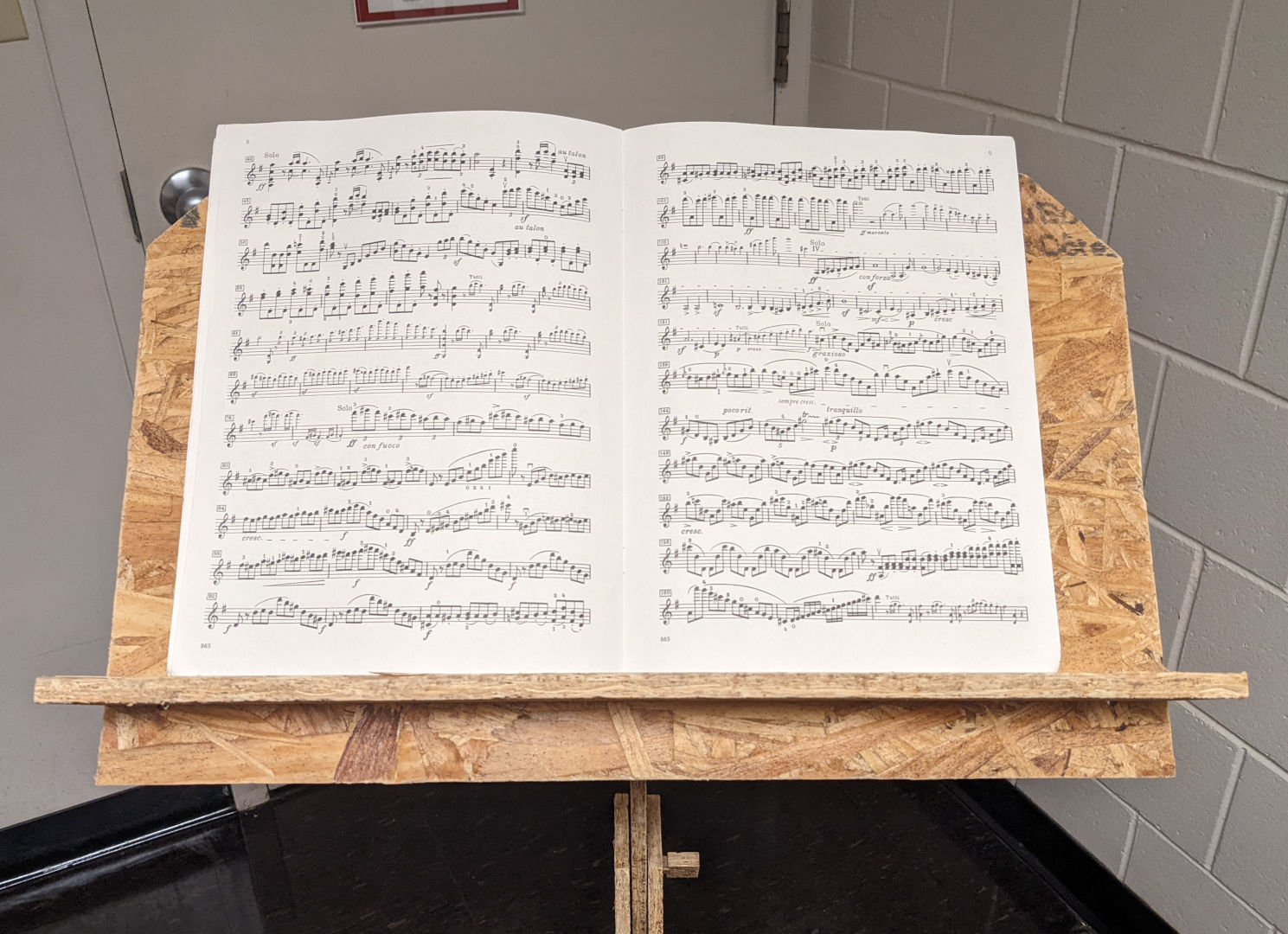

After the parts were cut from the machine, I removed the individual pieces using an electric hand saw. Finally, I assembled my music stand.

It can hold sheet music like I intended it to! The height and angle of the stand is adjustable. If you look carefully, there is one part on the base that is missing; this is because I designed the part incorrectly and it doesn’t quite fit. Nevertheless, I would consider this project to have been quite successful!