05 Printing something big

This week we were printing something big using CNC.

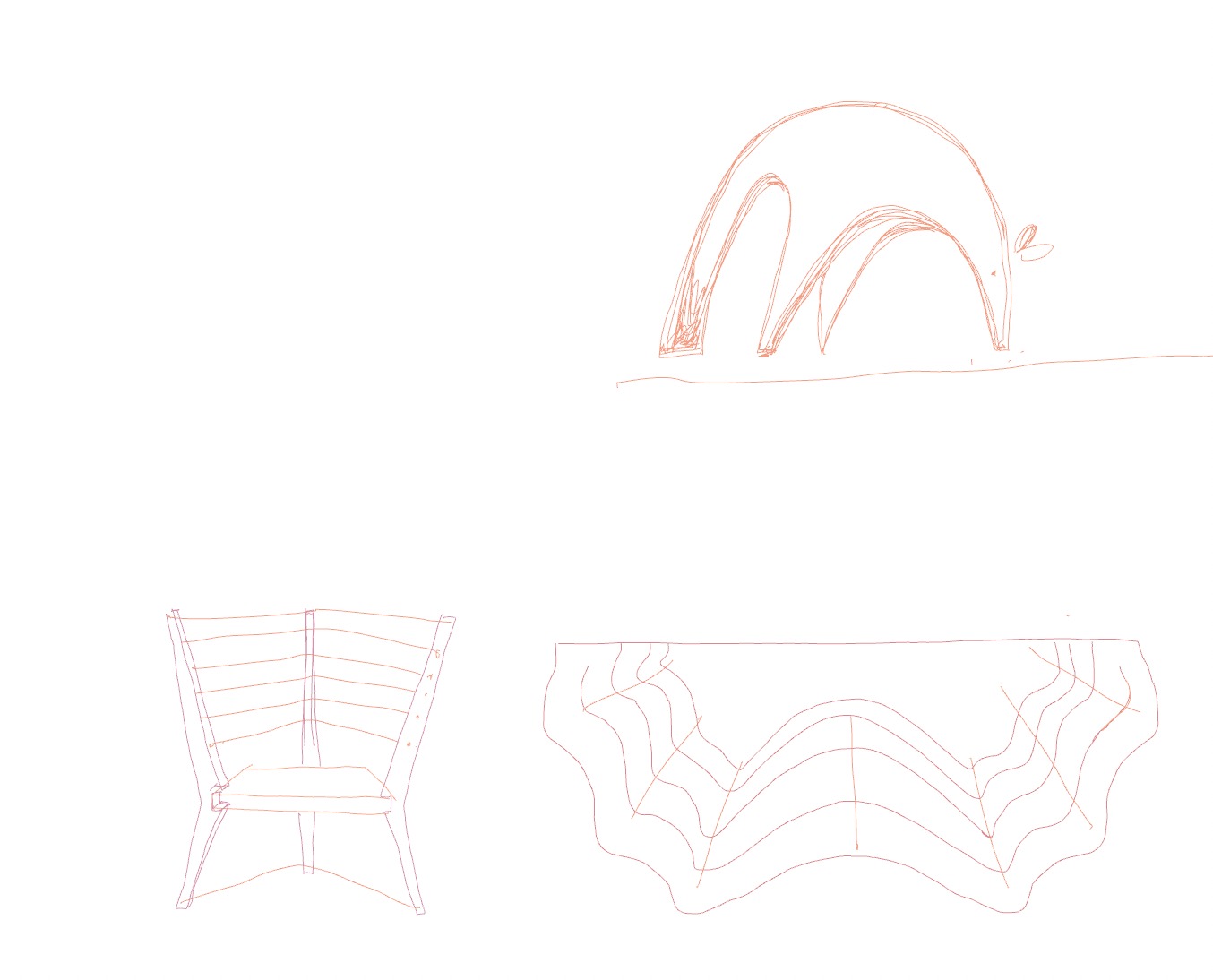

I have designed a small table and chair to use as a dressing table.

My intention was to design it in such a way that the pieces were inside each other and could be extended like an accordion,

so that everything would fit in the piece of material that we were assigned.

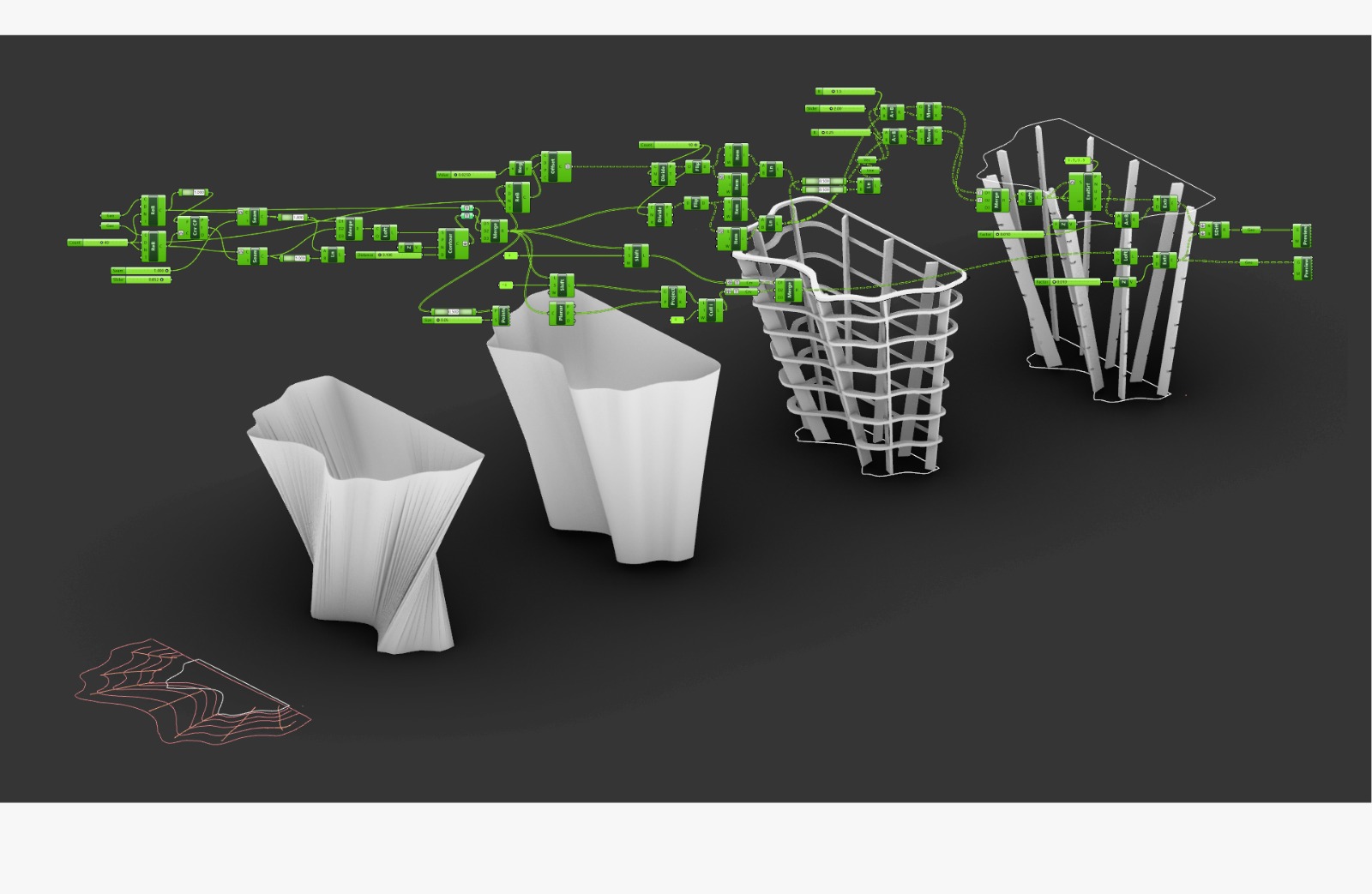

I did the sketches in Concepts, and scripted it in Grasshopper to convert it to 3D and 2D afterwards.

Tools: Concepts, Rhinoceros, Grasshpper, CNC Milling MAchine

Pili, Mili and (almost) a table

I used grasshopper to go from sketch to 3D and back to 2D before printing the pieces. Here you see how the lines are stacked in height, a loft is created around them and then the ribs that will join the horizontal pieces. Same for the chair.

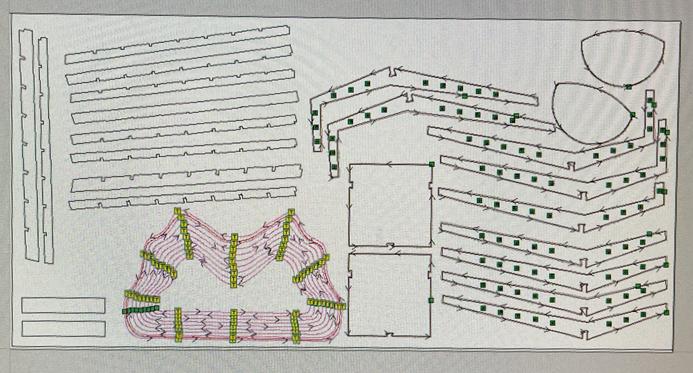

Later in the fablab software, before printing, I added small joints in the pieces so that they would remain stable while they were cut.

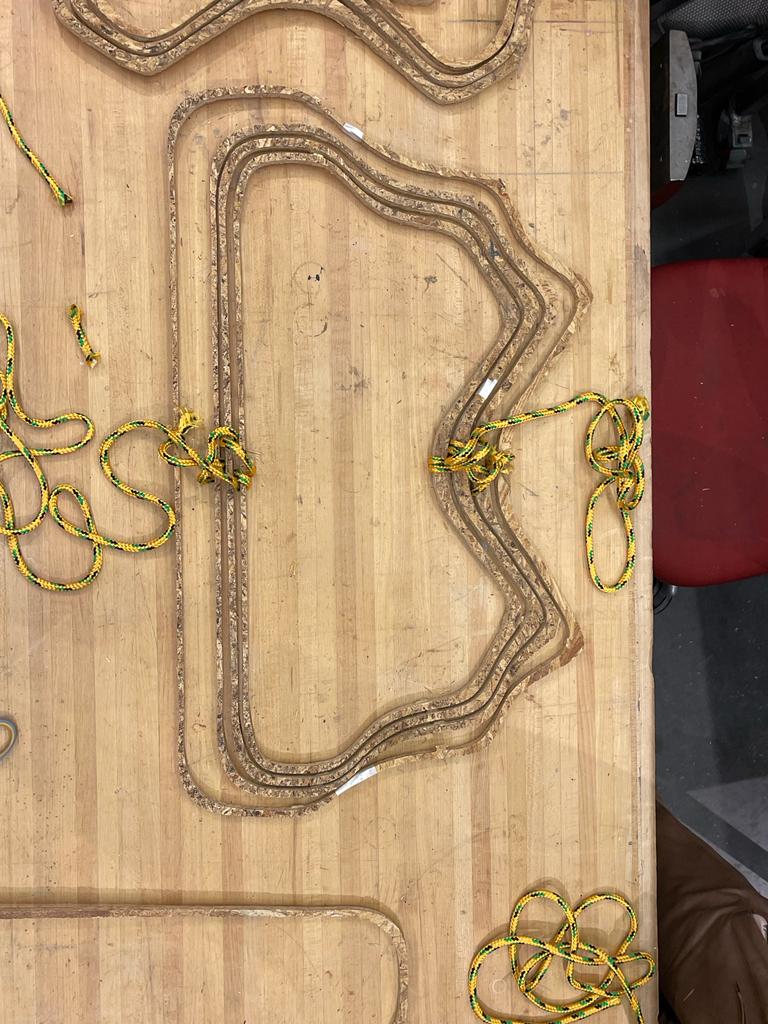

I had a little problem, because everything was cut to .8 of the original scale. As a result, the pieces that were going to form the table were shriveled, and I decided not to assemble it with the ribs. I did a test with some strings that I borrowed from ACT, thanks!

Assembled the chair! As I had left a space in the original table, I drew two circles as the base of another possible one. And here you see the two results, again, Pili and Mili, with our dear visiting student Teresa testing them :)