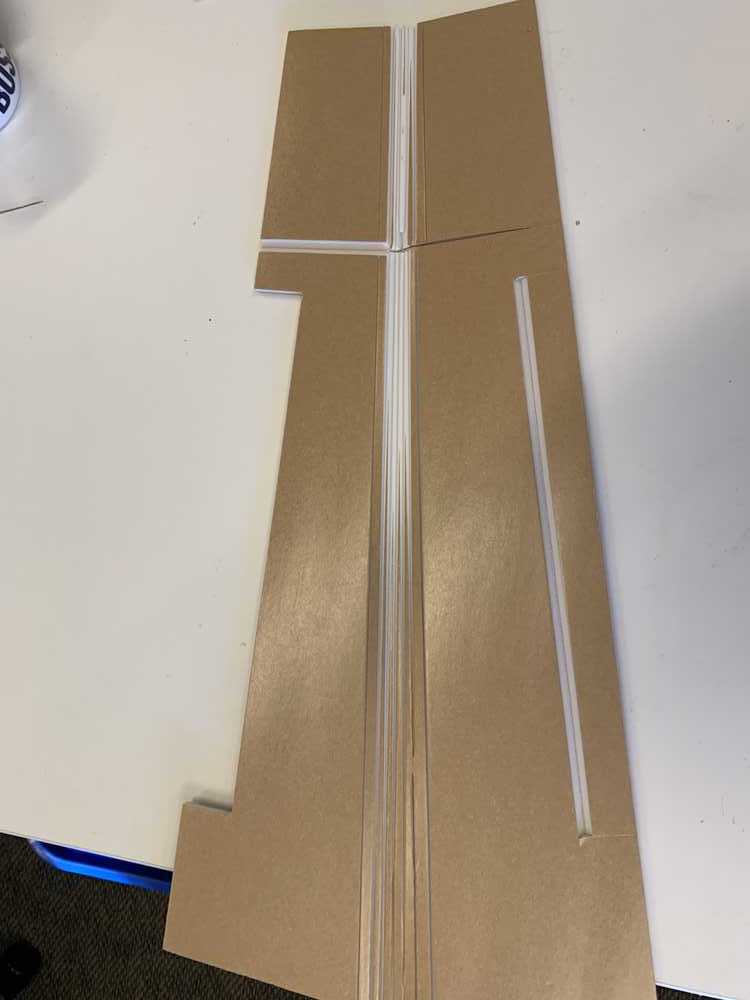

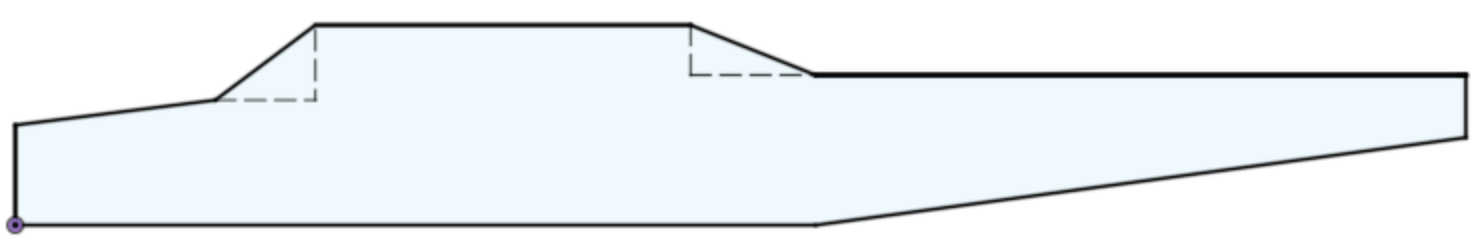

This was wildcard week. In this week we get to choose from a list of several different options for which machines we work with, etc. I decided to work with the Zund G3 L-2500 model, which allows for very precise cuts done by endmills and knives, instead of lasers like the laser cutter. This then provides the capability to cut, score, crease, and mill. As the plane parts that I will need to use for my final project will require some sort of hinge (for the ailerons, rudder, etc.) to be cut it seems very efficient to try and do that here. To demonstrate some of the beautiful things that this machine can cut, Alfonso did a demo cut of a very well-designed plane wing:

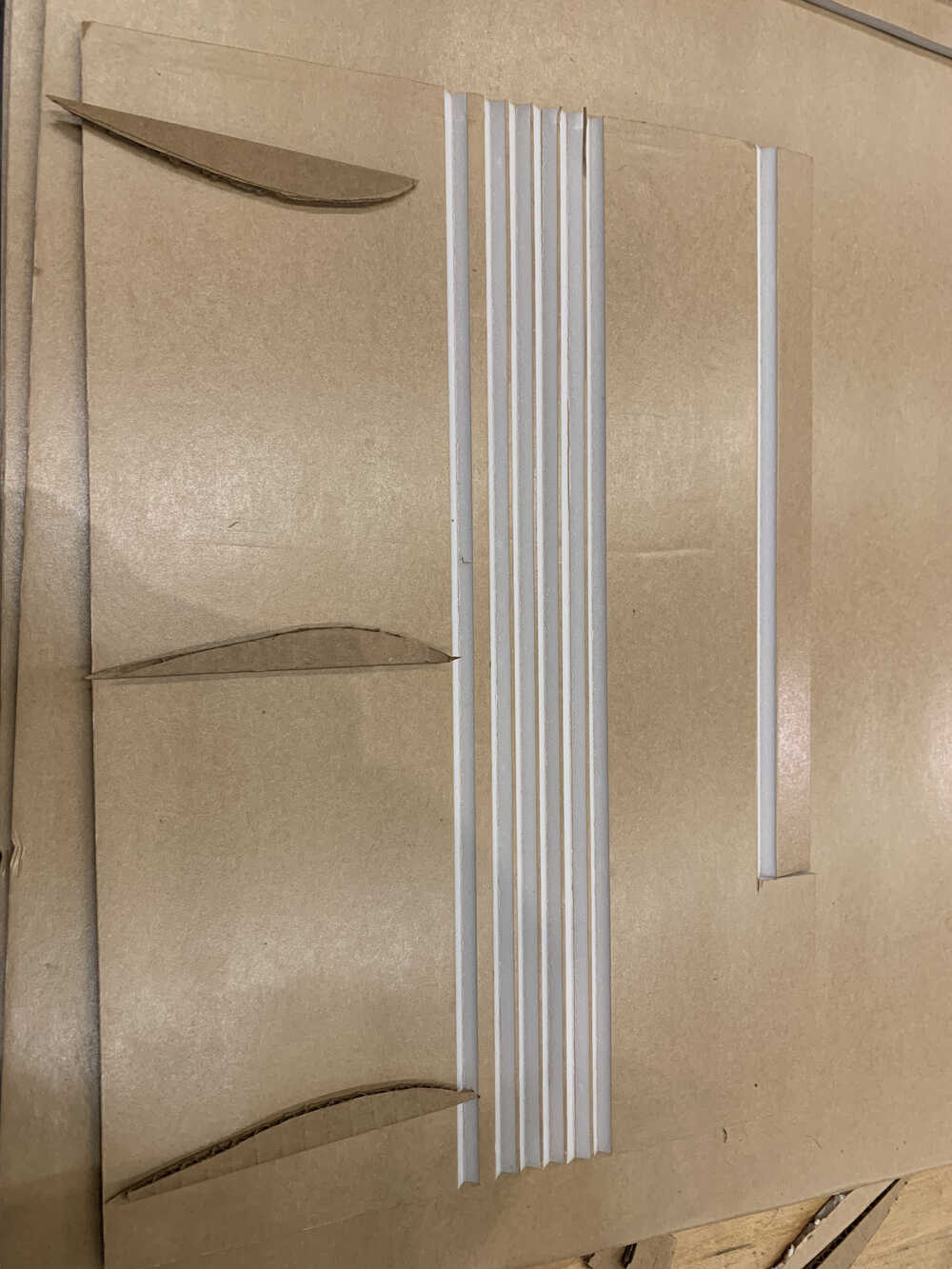

As we can see, the Zund made several different types of cuts. The v-cut for the aileron looks visibly quite different from the cuts that were done to make the wing fold. Furthermore, a nice feature of the way this part was cut is that when folded it takes on the beautiful shape of a real plane wing!

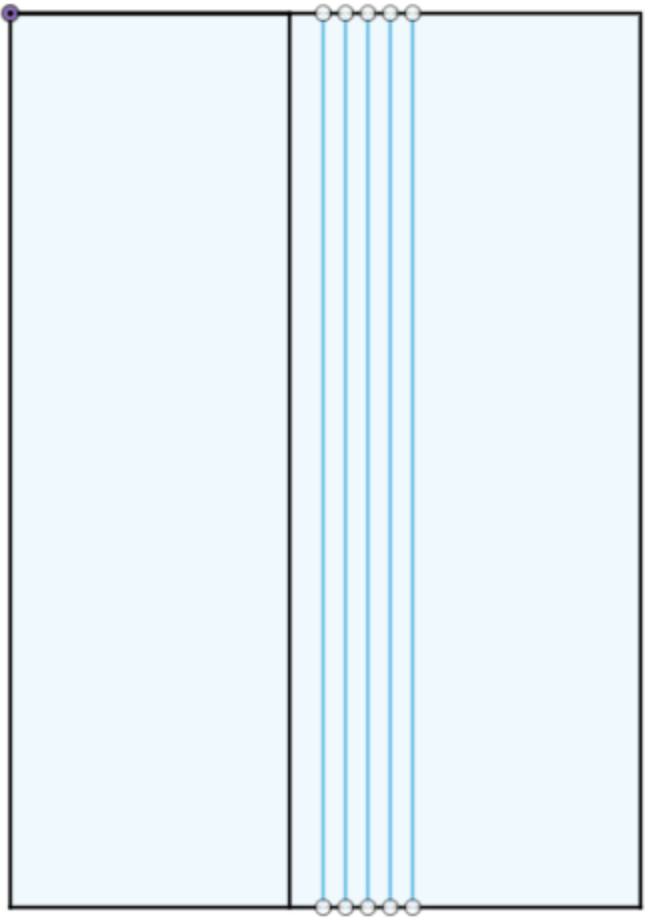

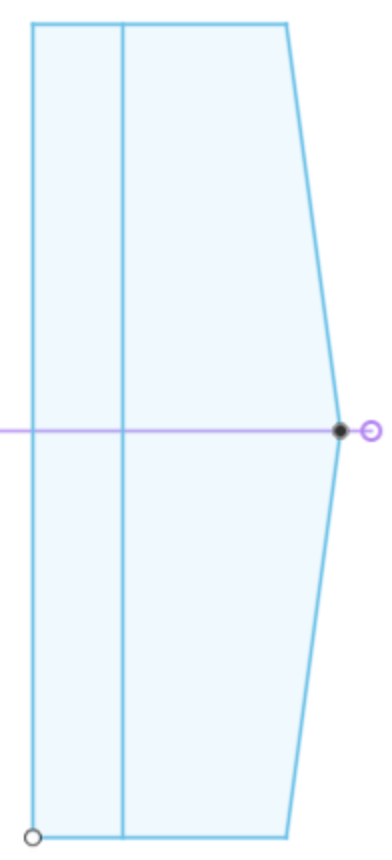

Seeing what this machine can do inspired me to go make my own design. As I am using this to guide my final project designs, I followed the dimensions laid out and did my CAD design in Fusion 360. The design for one of the wings, the elevator, and rudder is shown below:

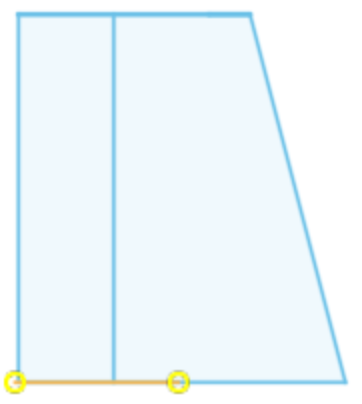

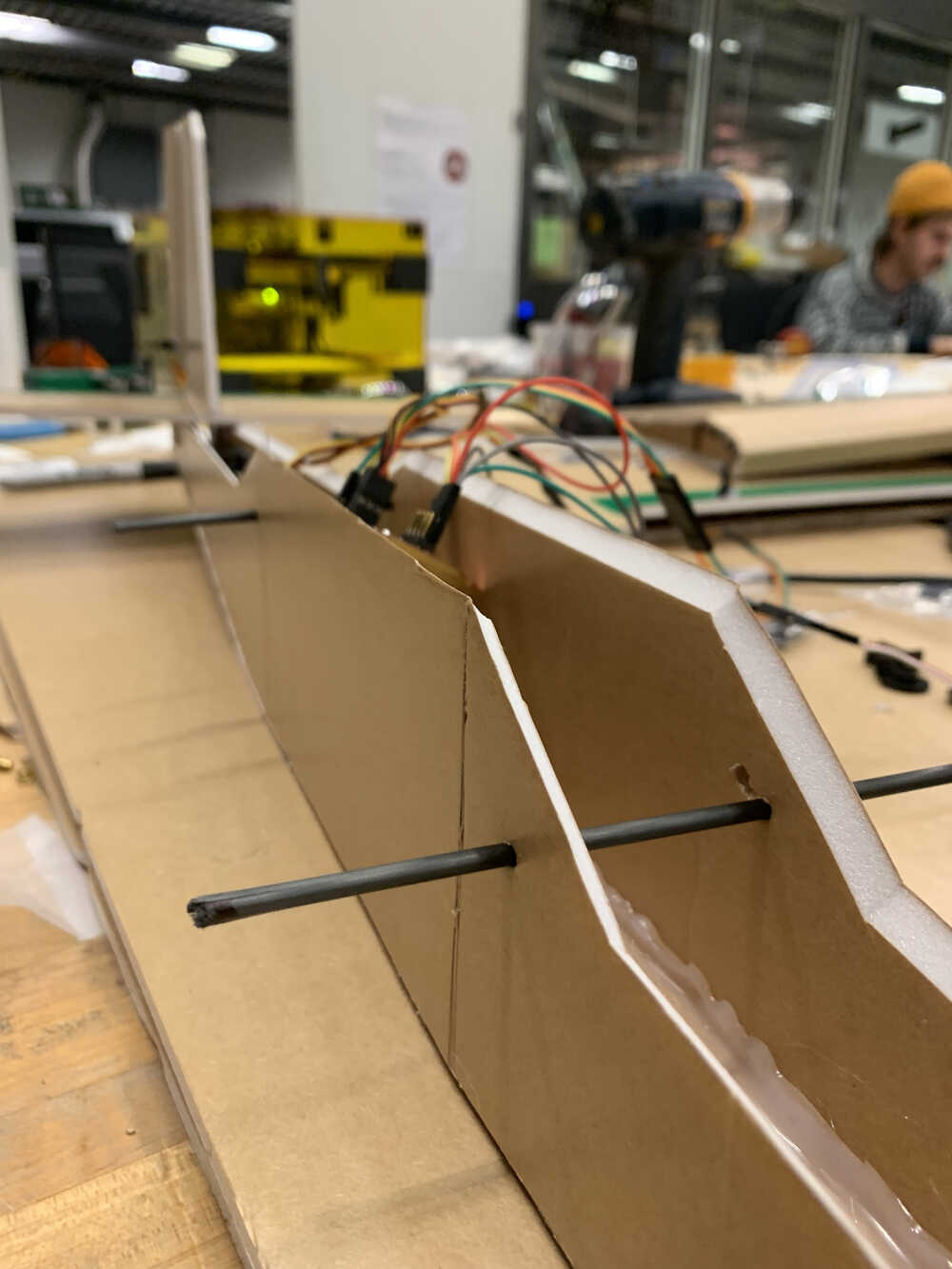

The lines in the middle of each part mark where a v-cut should be made. That actual setting will happen later on (Alfonso did that specification right before sending the file over to the machine). Finally, the design for the base of the fuselage and one of its sides is shown here:

This design does not include all of the cuts that will have to be made in the end (like cutting out

some space for a servo motor on each wing, for example), but it does contain the most important

cuts that will require the kind of fine-tuned detail for which the Zund is great.

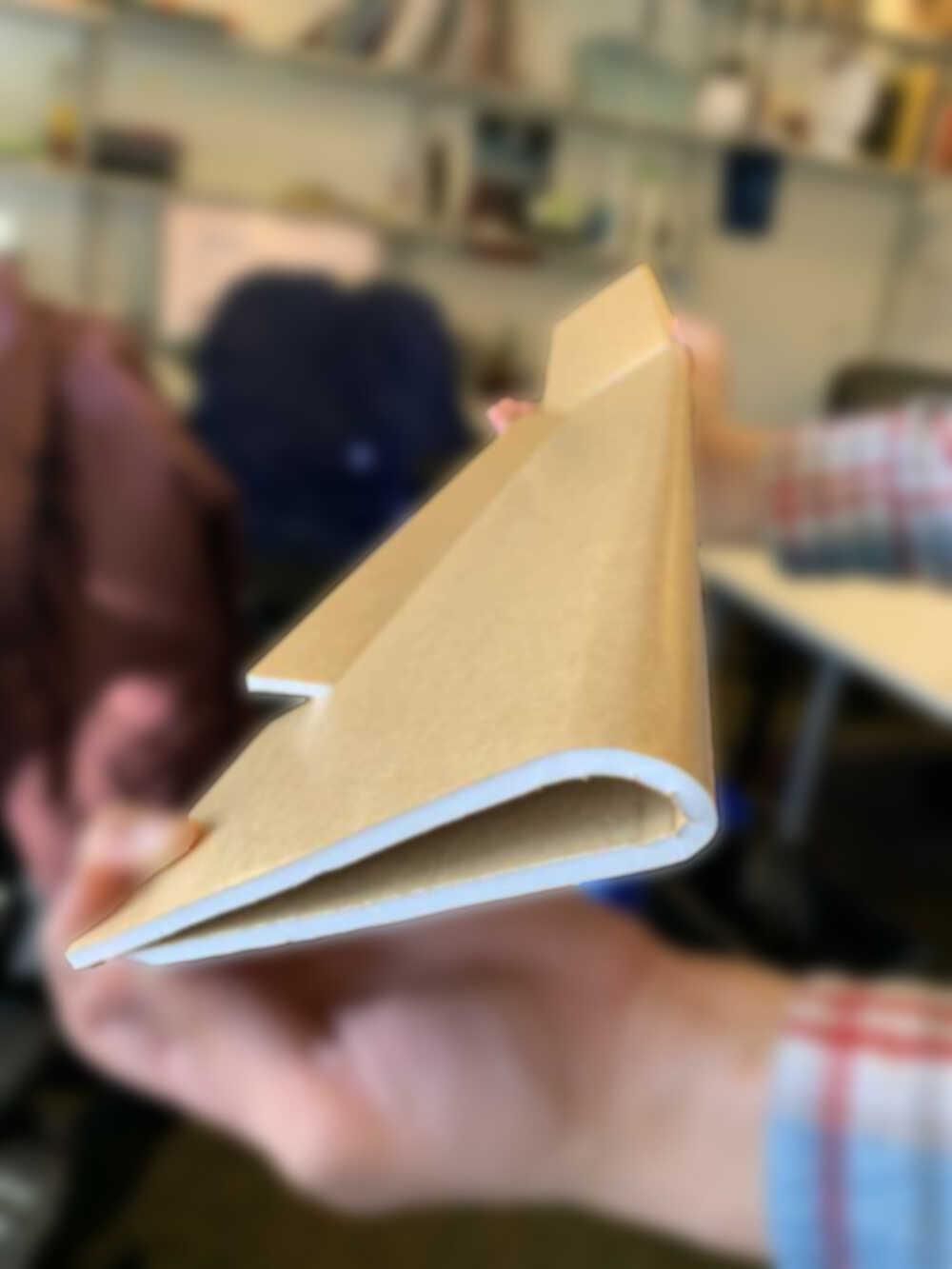

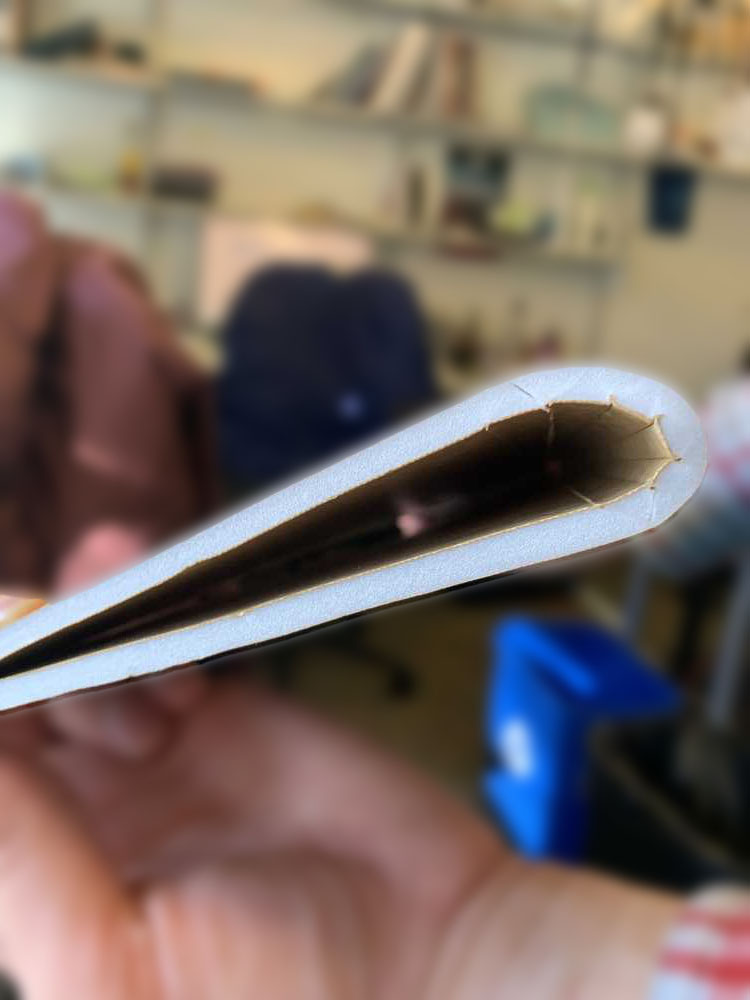

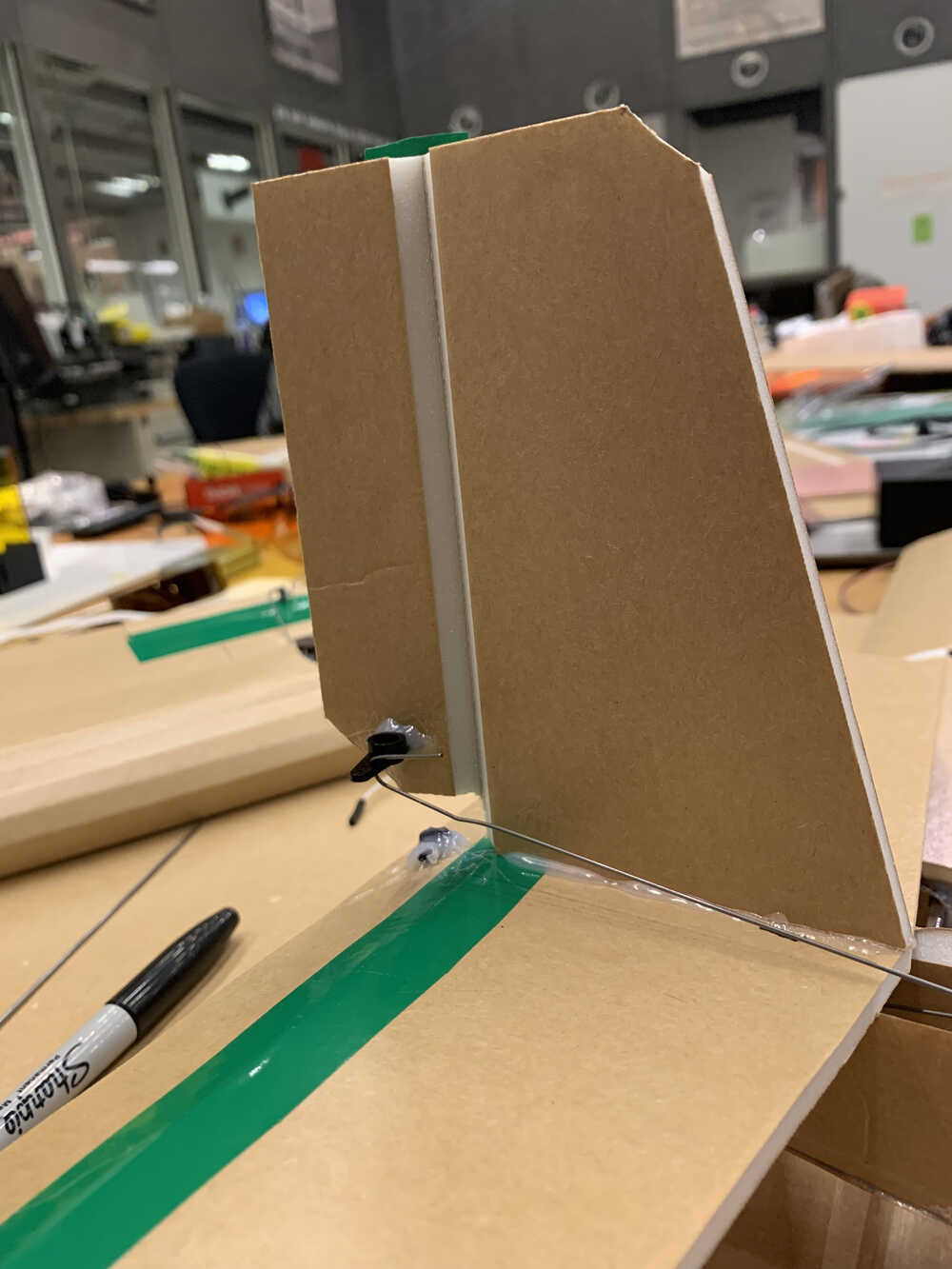

Below we can see some sample cuts that were made by the machine:

We can most clearly see a well-defined v-cut in the second image above which shows the rudder of the plane (after being assembled for the final project). As we can see, the cut is quite well-made with a lot of precision. With a little tape (or vinyl) reinforcement, this kind of cut can make for a rather good hinge joint. A similar cut was done for the aileron on each wing (as shown in the first image), as well as to cut out the actual body of the plane. Though in the latter example this does not create a hinge joint, it is still a beautiful cut.