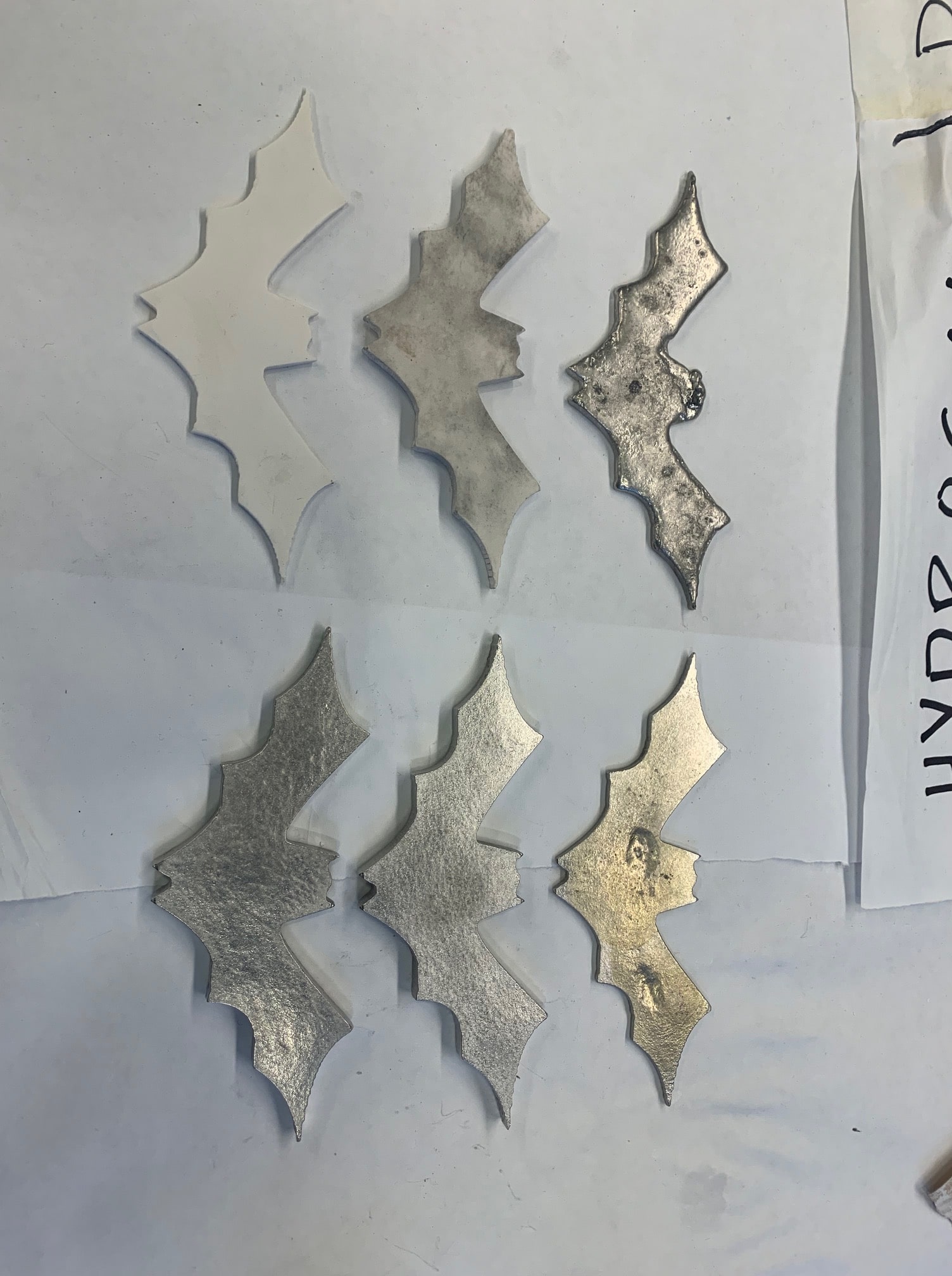

In the spirit of flying things and Halloween, I decided to make batarangs. The results were actually quite exciting:

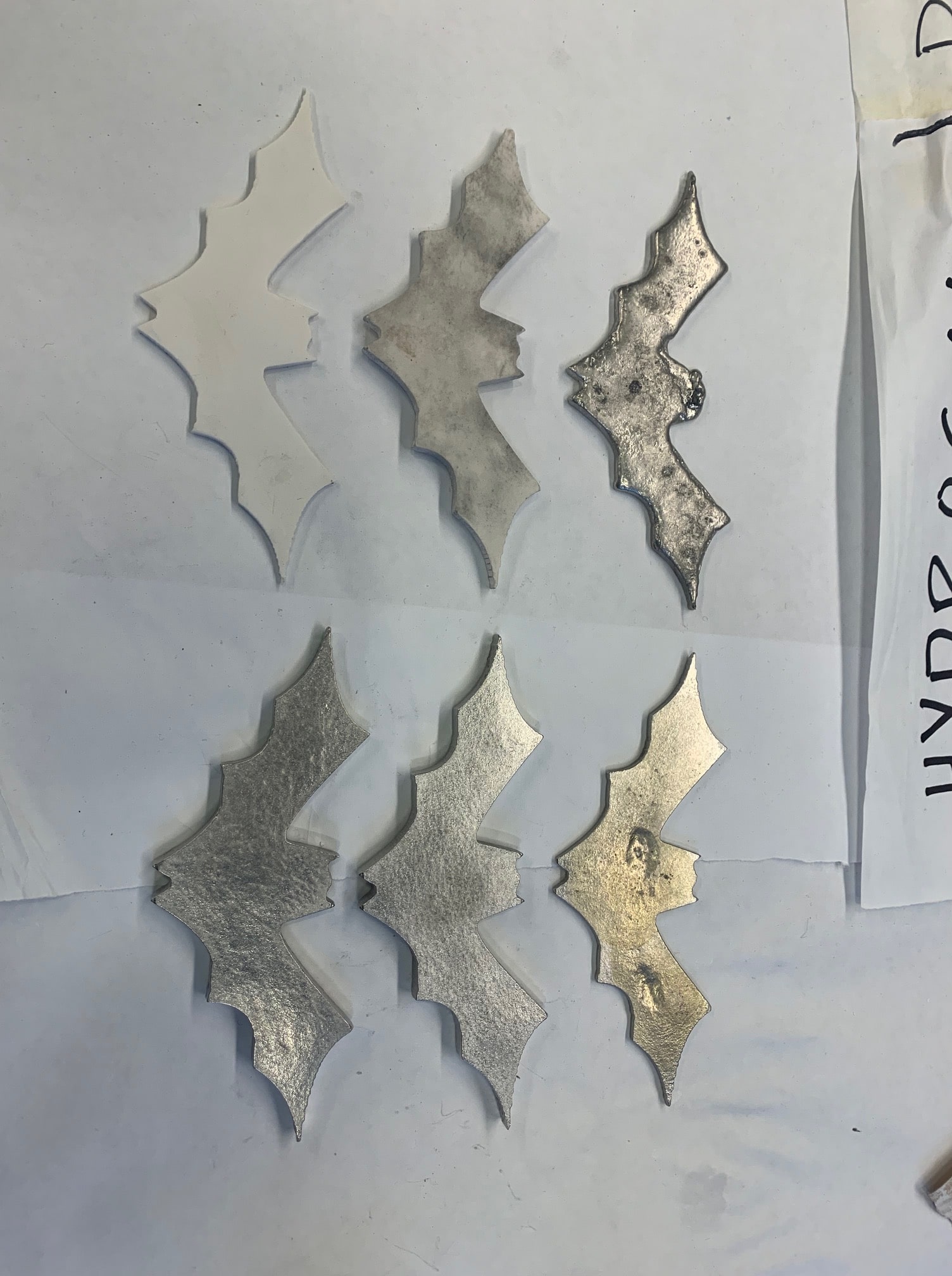

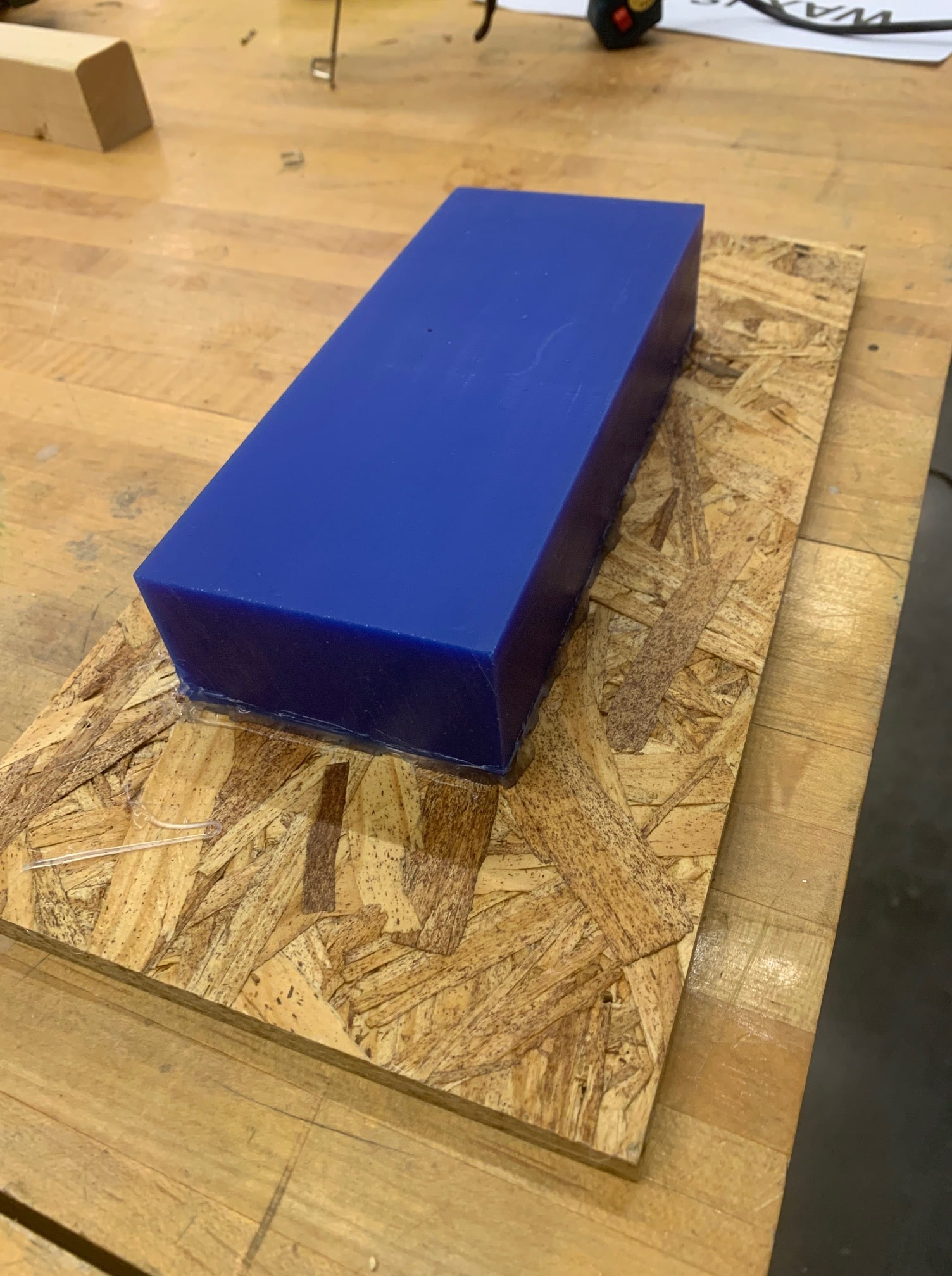

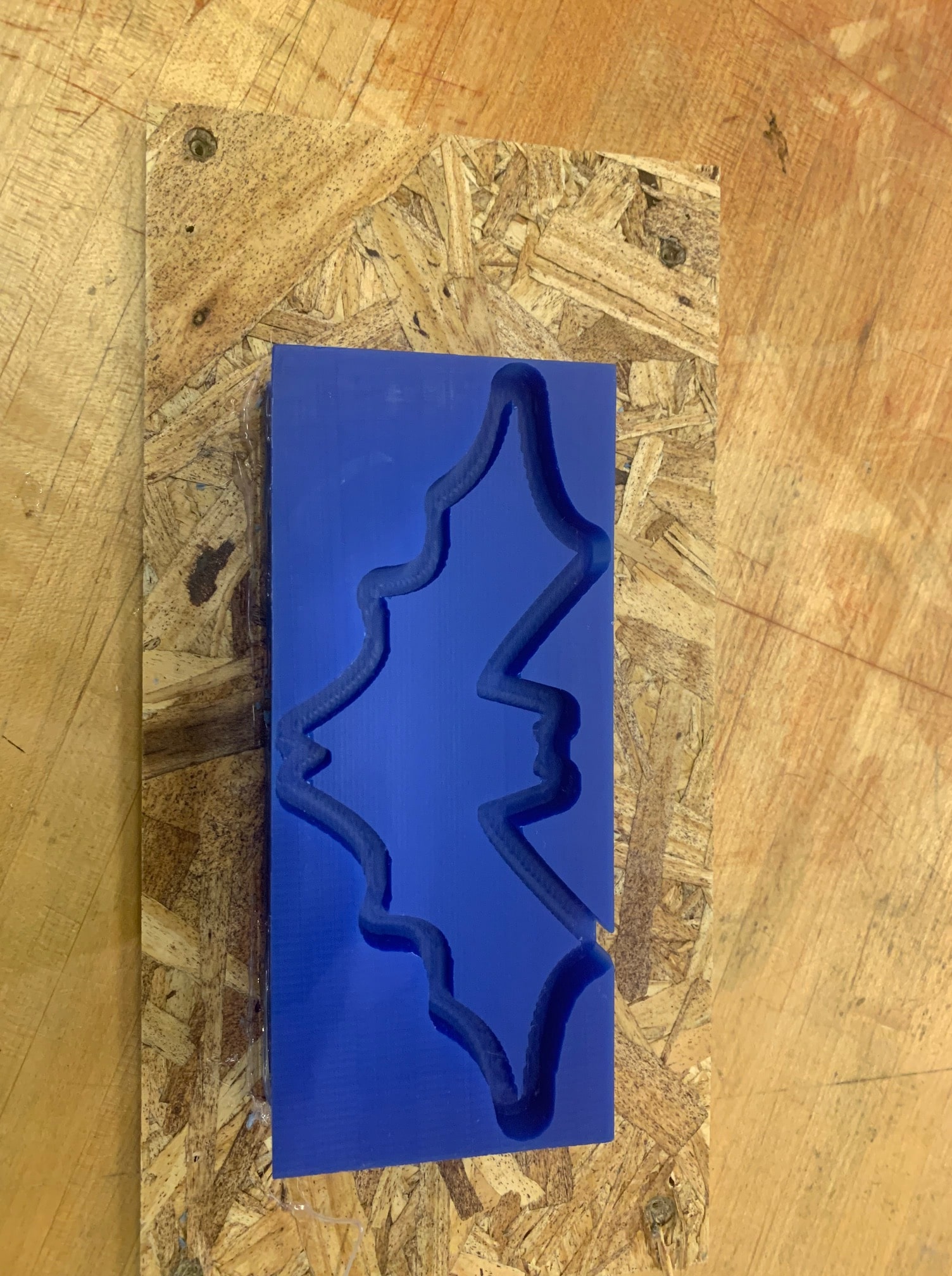

For our design this week we used Fusion 360 and referenced this video as a tutorial. The design is not very sophisticated so a one-part mold was sufficient, however, in retrospect a two-part model might have created a more uniform surface finish across both sides of the object. Here is the .stl file. For the actual machining we used ShopBot VCarve Pro to turn this:

into this:

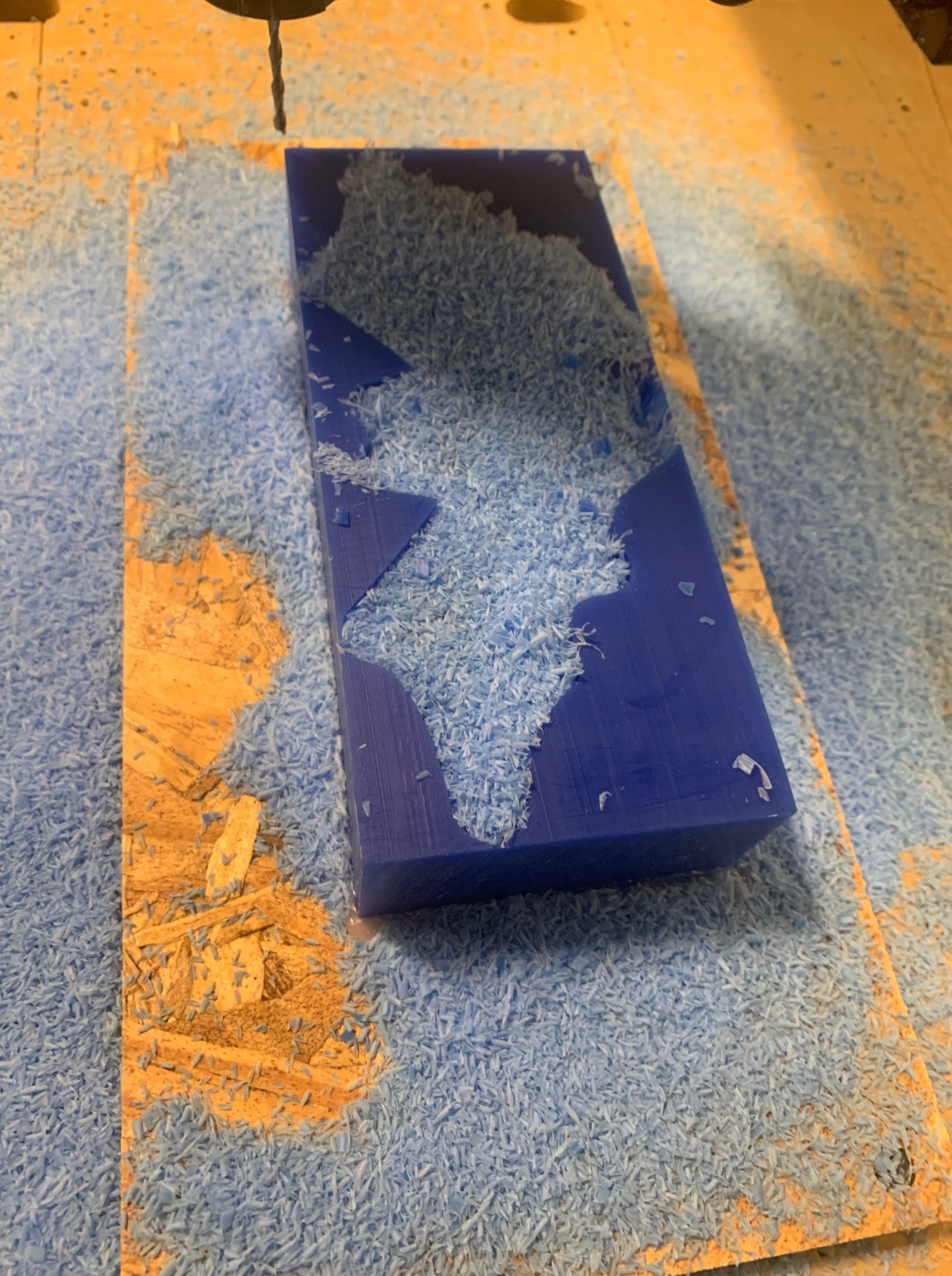

Now that we have cut our wax into the shape we want, it is time to make the mold out of silicone. Using the Oomoo material is quite simple though a little messy. After getting the proper viscosity in the liquid, we can pour it into the wax while being mindful of bubble formation. The trick is to pour it out slowly as if it is cake batter. Just remember that this is very much not edible! Though food-safe molding materials do exist. The wait is officially around 75 minutes, though we gave it a couple of hours to cure. Here is a before and after:

As we can see there is no clear difference. It is hard to tell just by looking at it

whether or not the mold has cured properly. If you touch it with something and it looks

liquid, then it needs more time. The color of the mixture should look like something in

the images above, however.

Now that we have our mold, we can make some fun casts. For this week we experimented with

drystone,

hydro-stone, as well as

cerrotru metal

, which is a low-temp metal alloy containing

Bismuth. Perhaps somewhat

surprisingly, the silicone material we are working with has pretty high

heat resistance

. To melt the metal, we use a very hot

hot pot.

One thing to note though is that the mold needs to be coated with talk or baby powder

in order to have a more polished metal cast.

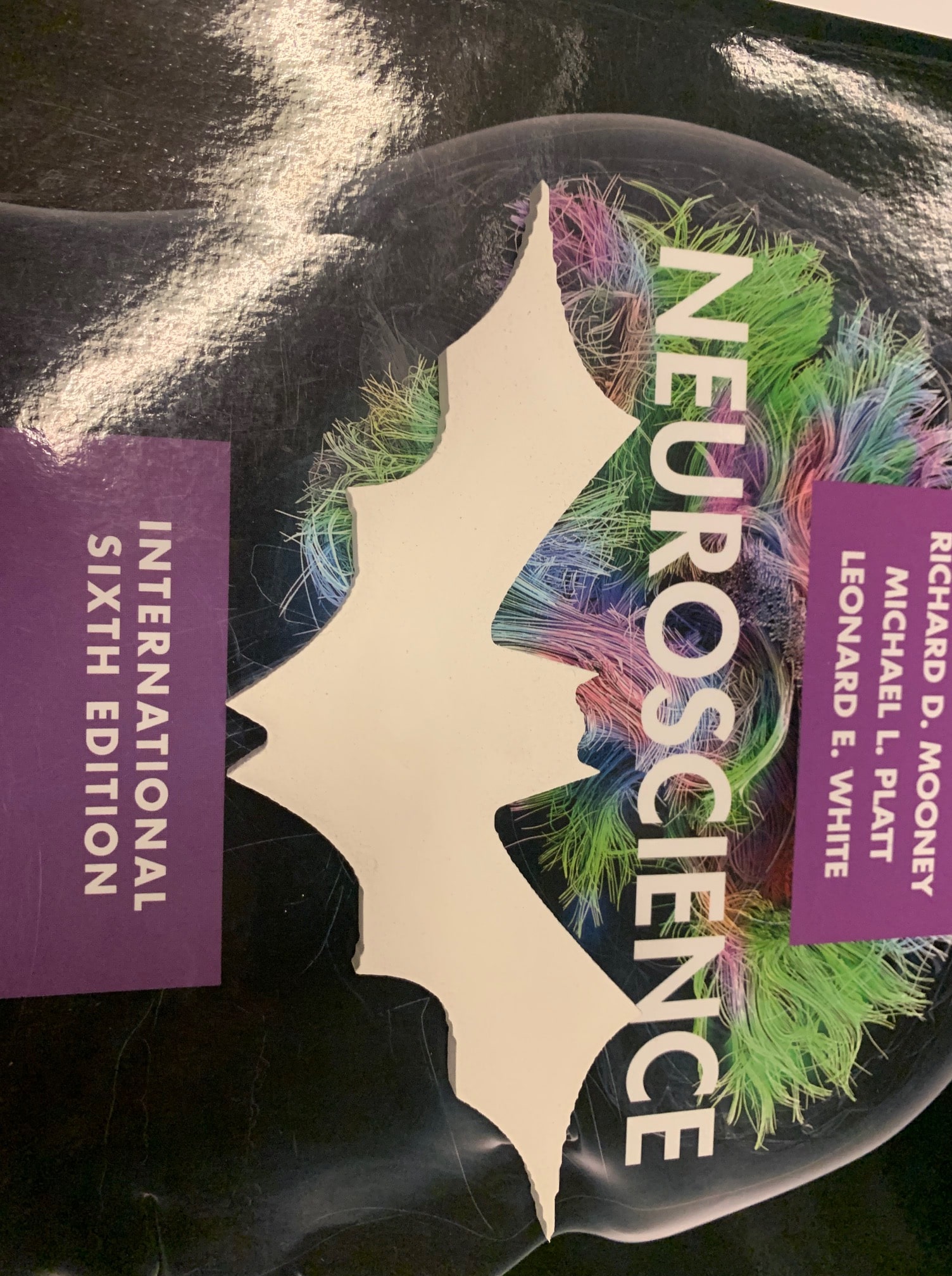

Below we have pictured the hydro-stone and drystone castings (ignore the

Neuroscience

background):

As the name might suggest, the hydro-stone (darker bat) takes much longer to dry even after it cures.

The cast may be ready after around 30 minutes, but it will still be moist. The drystone (lighter bat)

dries a lot faster though. Be careful of the powder-to-water ratios. We produced

some failed casts the first few times as a result of incorrect measurings. Also note that

this plaster is very fragile. An initial iteration of the hydro-stone cracked into many pieces

from being squeezed too hard.

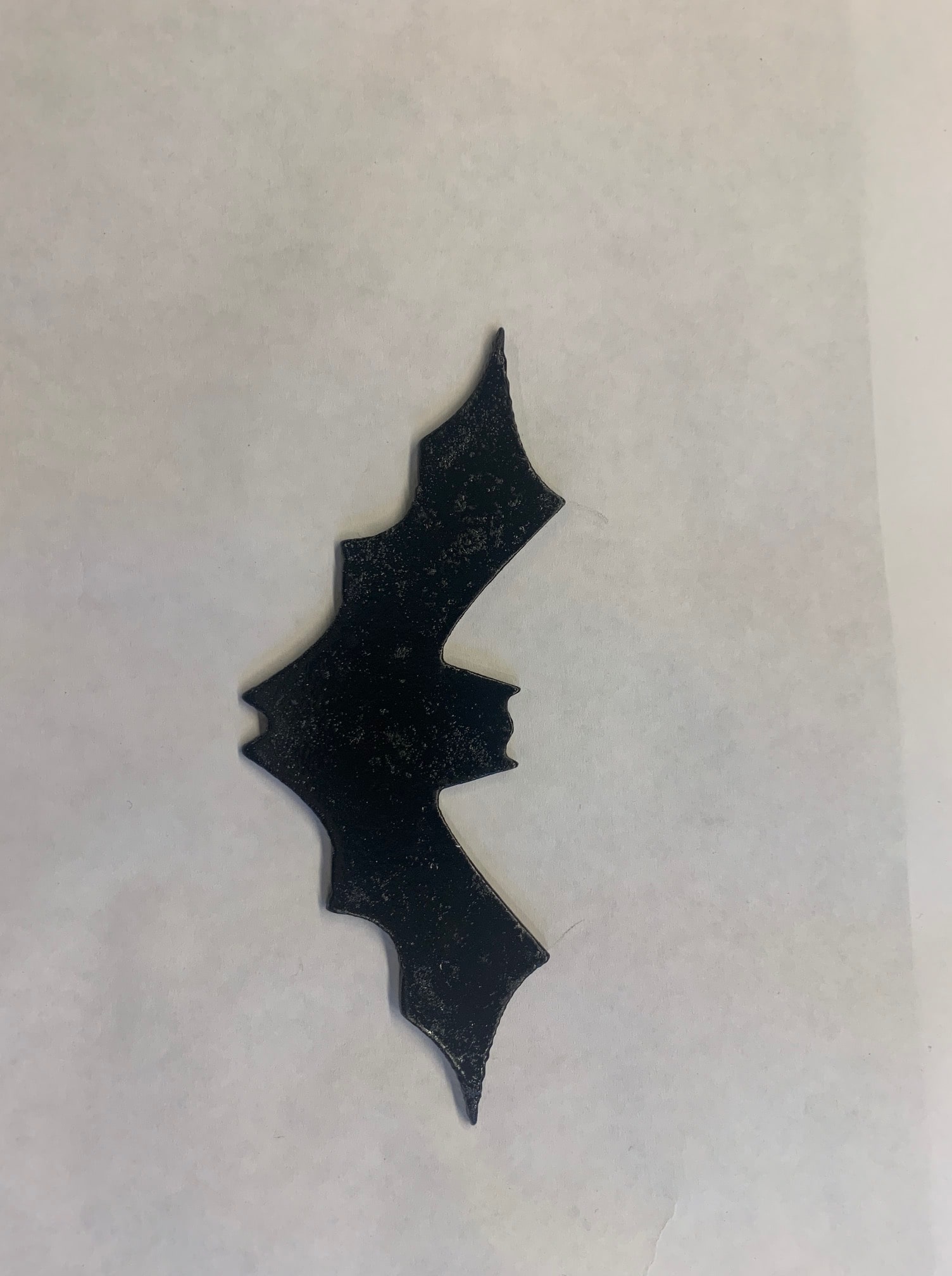

This is what the metal casting looks like:

We can of course spray-paint the metal batarangs black to make them a bit more realistic:

Finally, as it turns out we can also make an oomoo cast out of an oomoo mold. We just need

to use a

release agent

to allow the two oomoo materials to separate after the cast cures.

Here is a final version of an oomoo-cast batarang, along with a silver-painted metal batarang:

This was a rather fun week overall. We experimented quite a bit with different casting materials and made some fun things. Of course, this is probably not quite as exciting as the real thing, but a fun time nonetheless.