PROCESS

THIS IS HOW I GOT THERE

↓

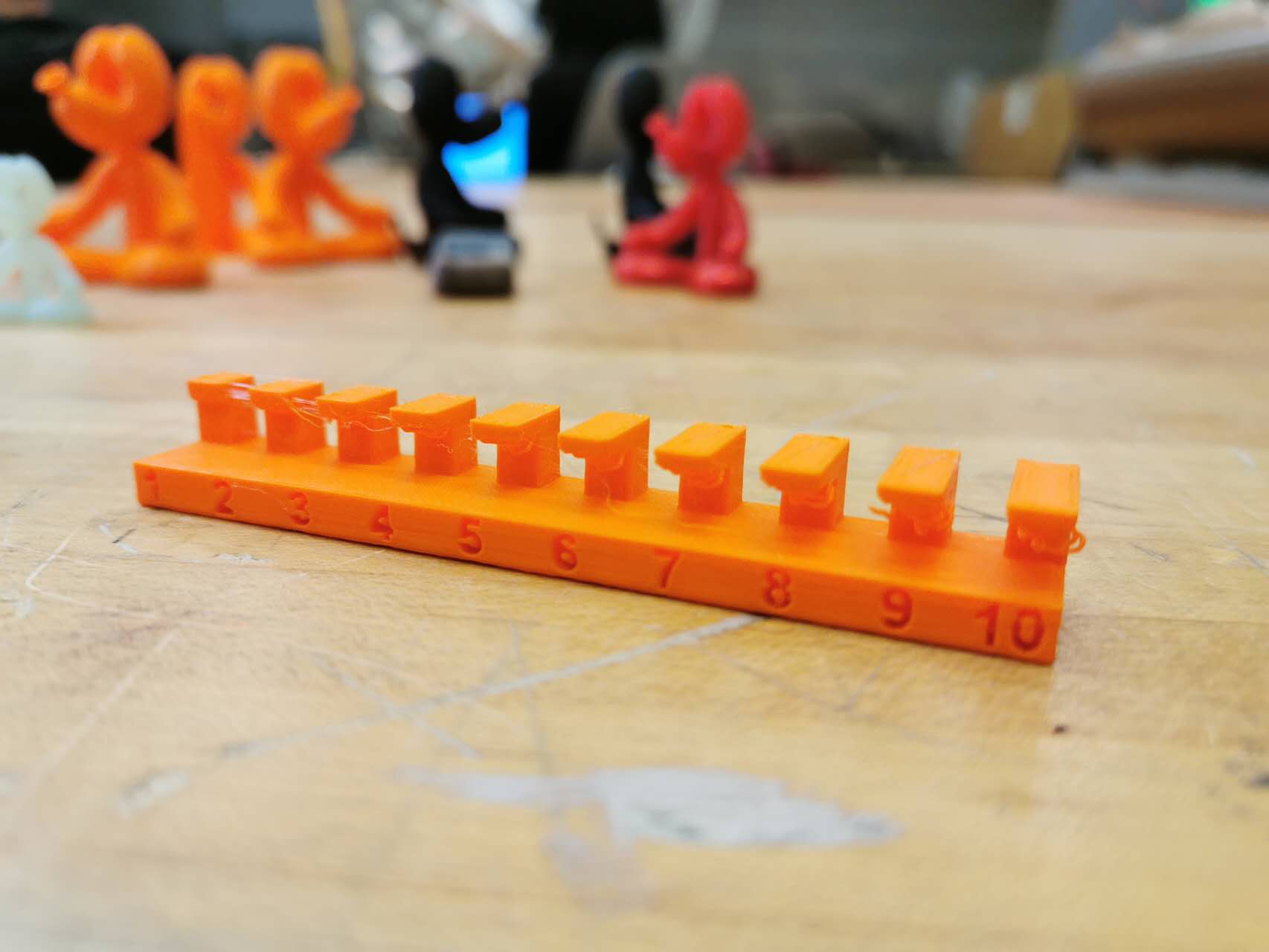

Group assignment: overhang test.

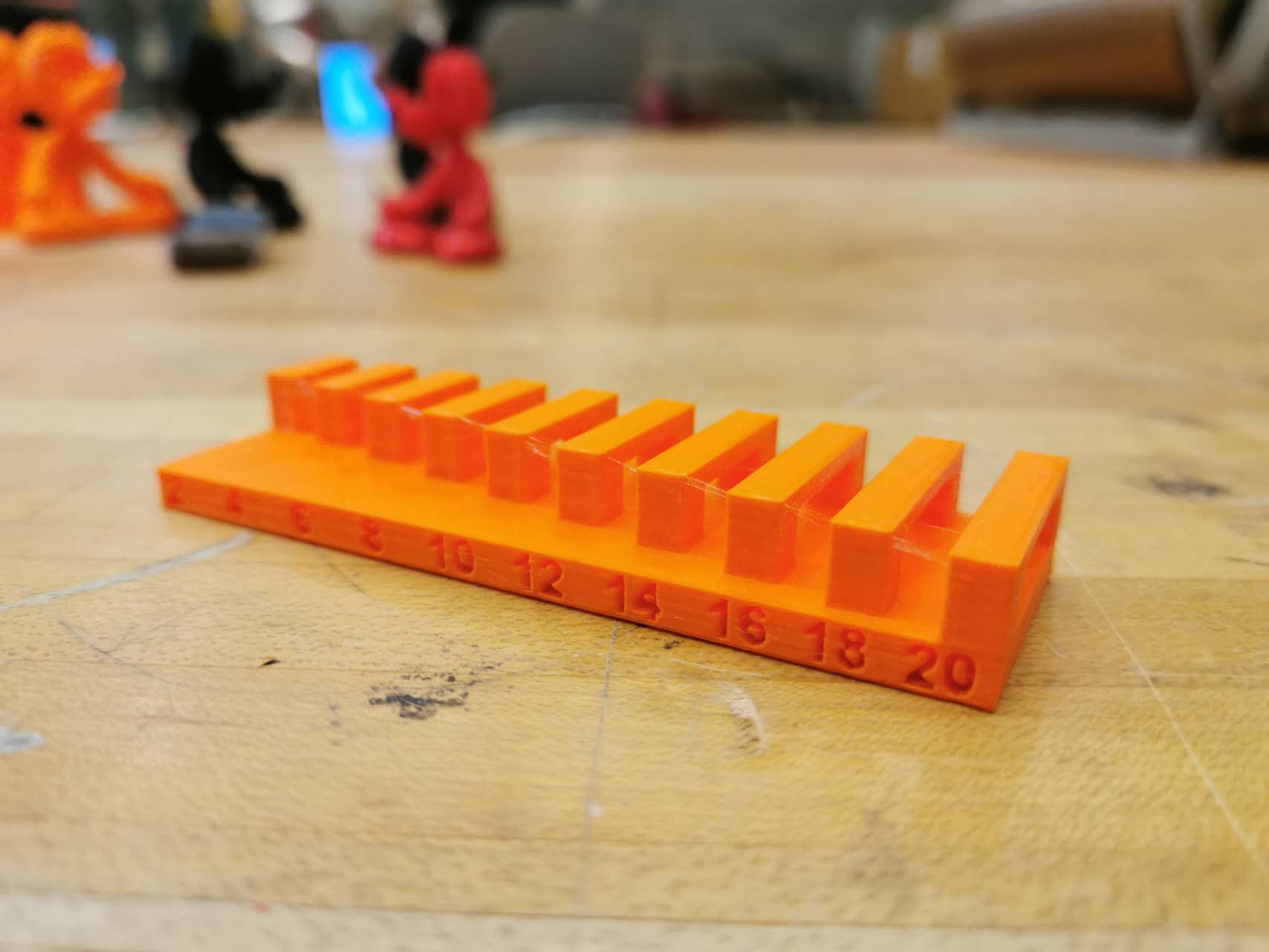

Group assignment: beidges test.

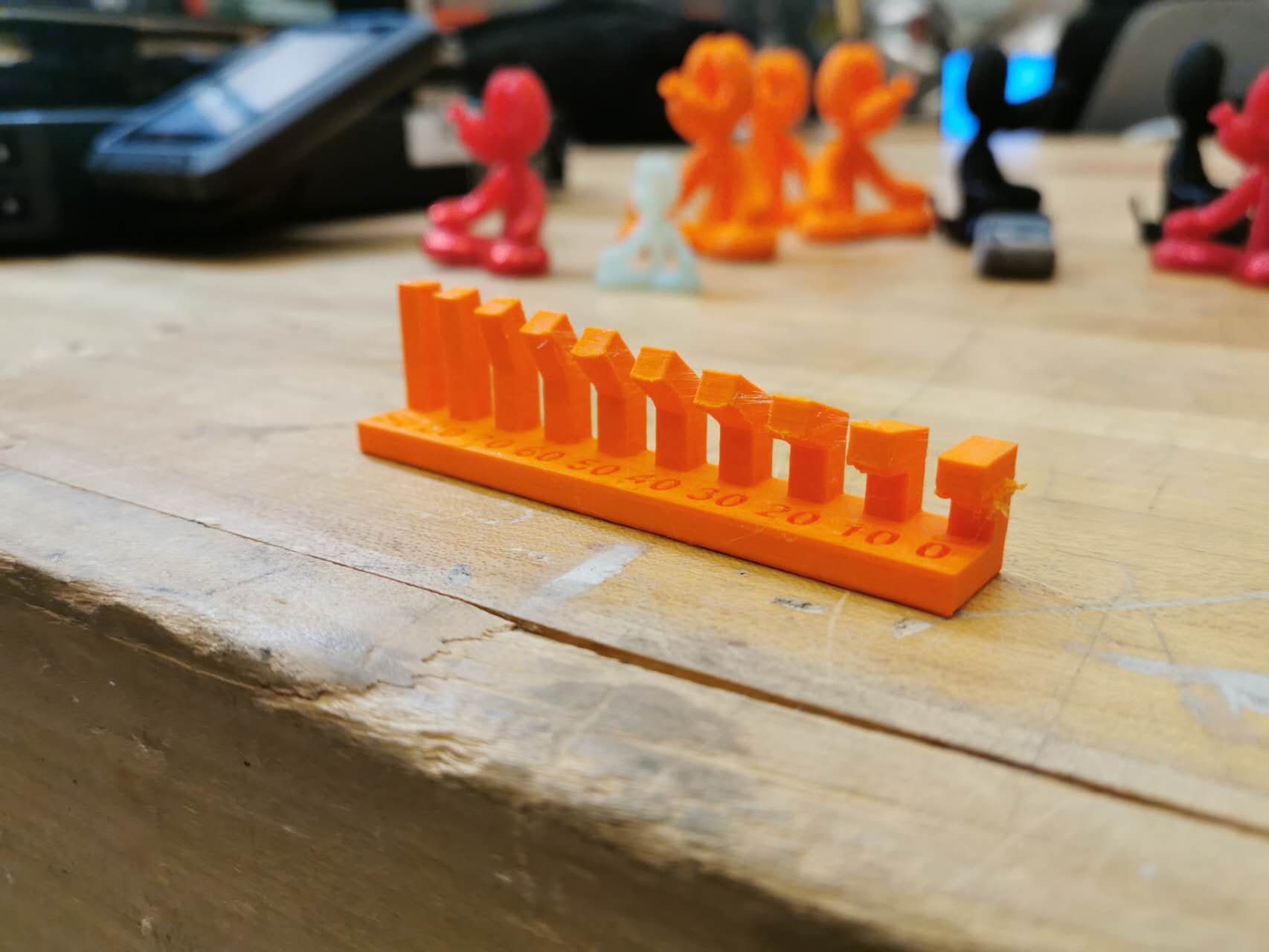

Group assignment: angle test.

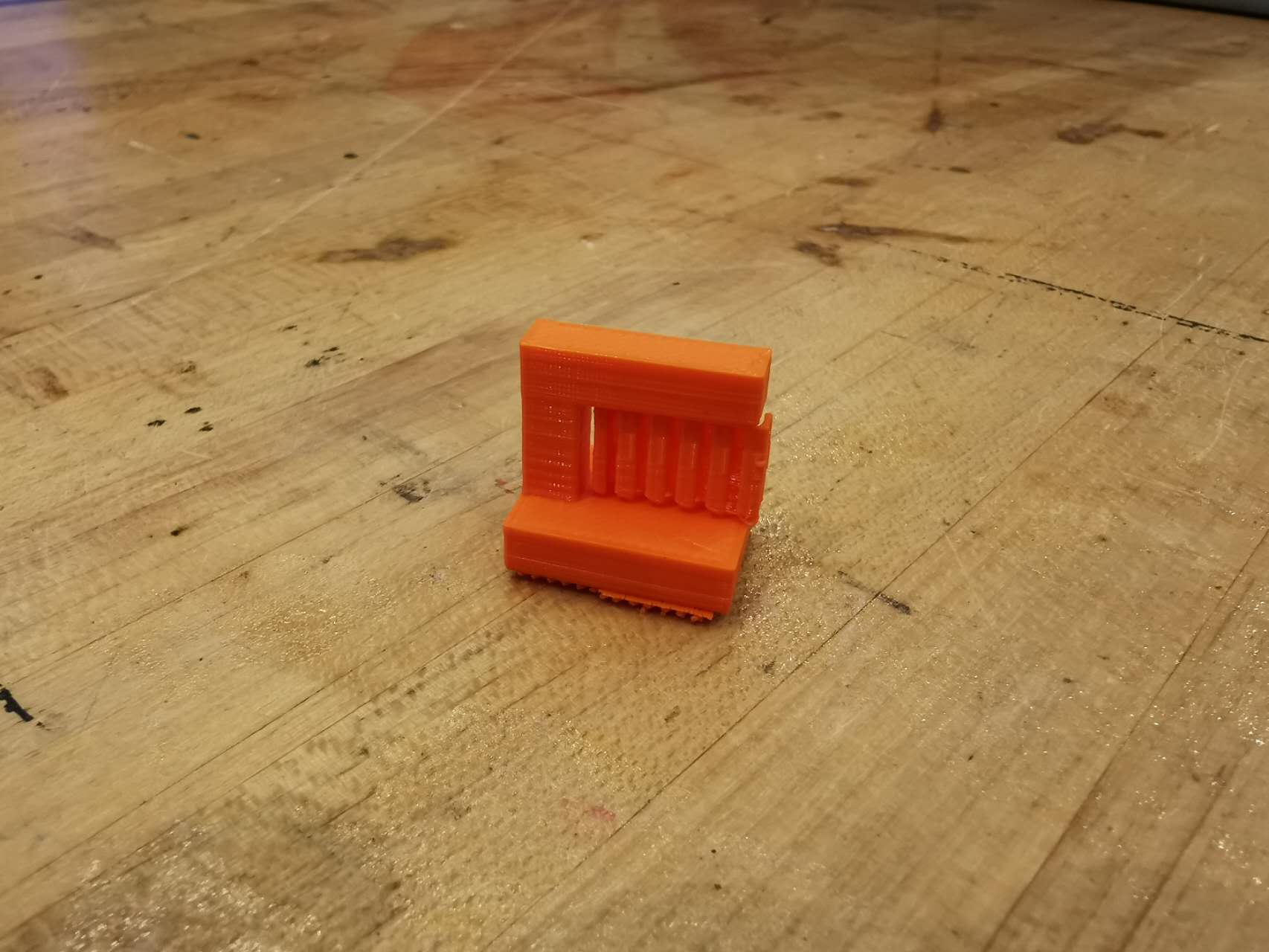

Group assignment: clearance test.

Group assignment: overhang test (failed).

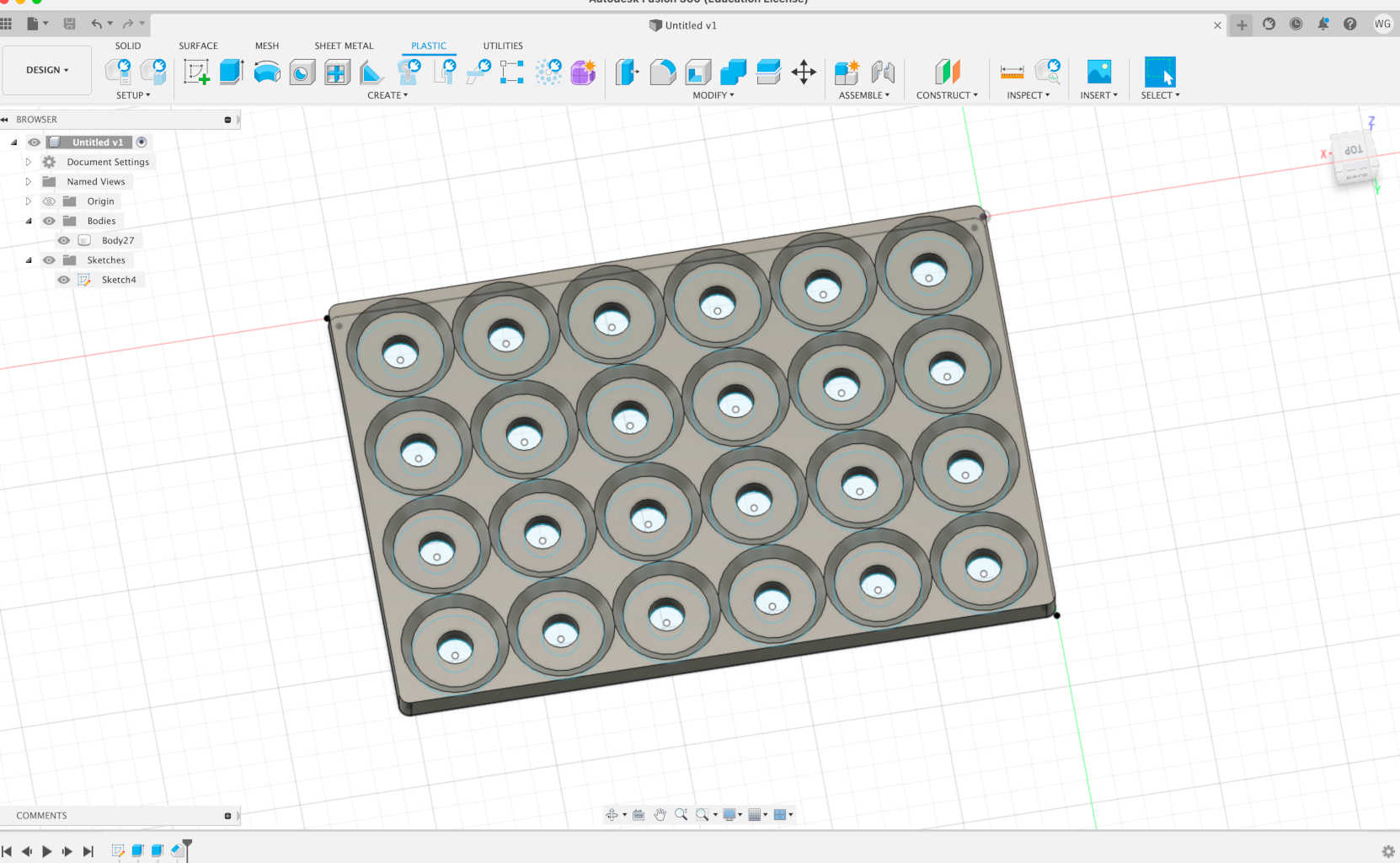

The designed cap mount.

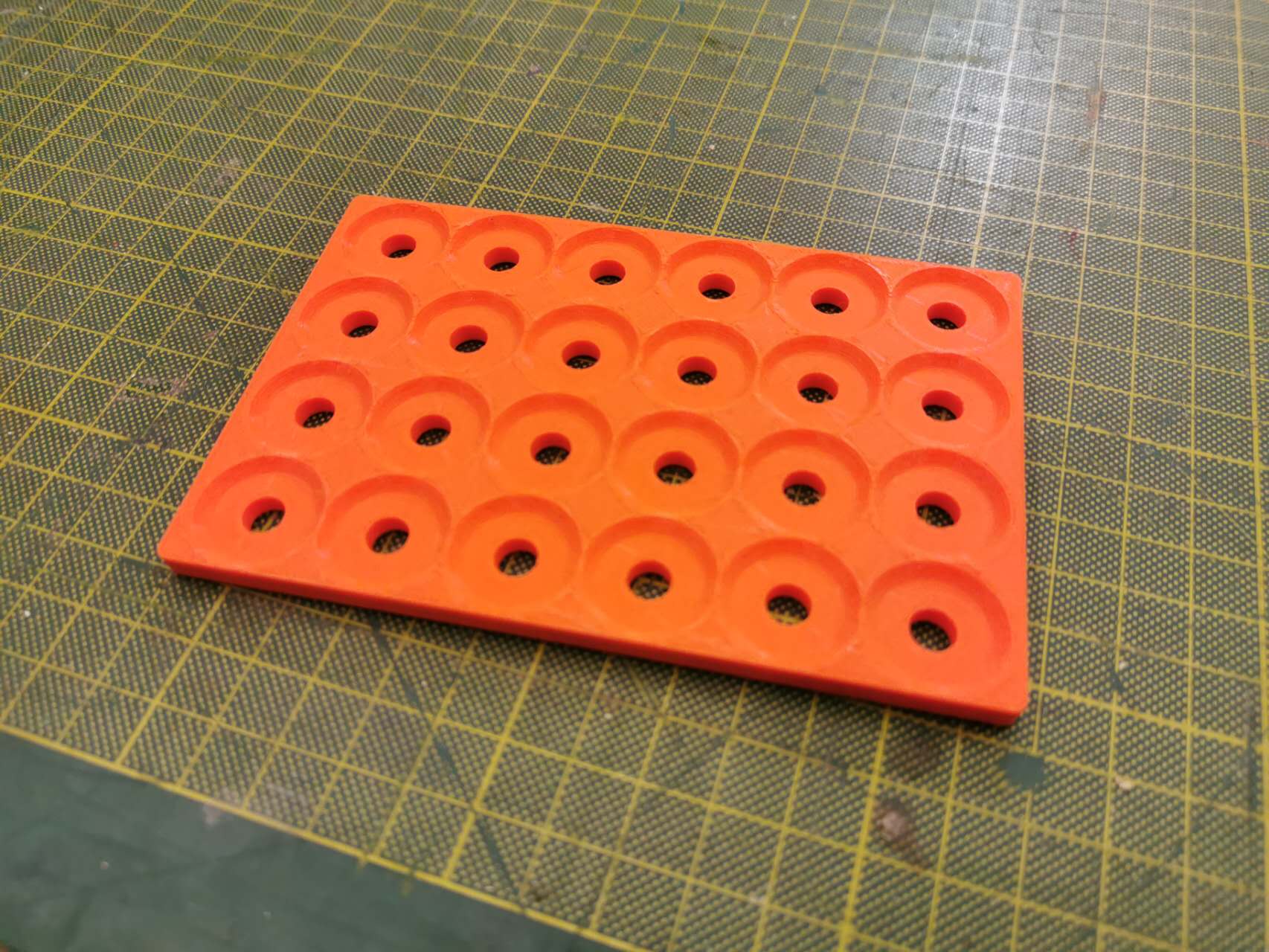

The printed cap mount.

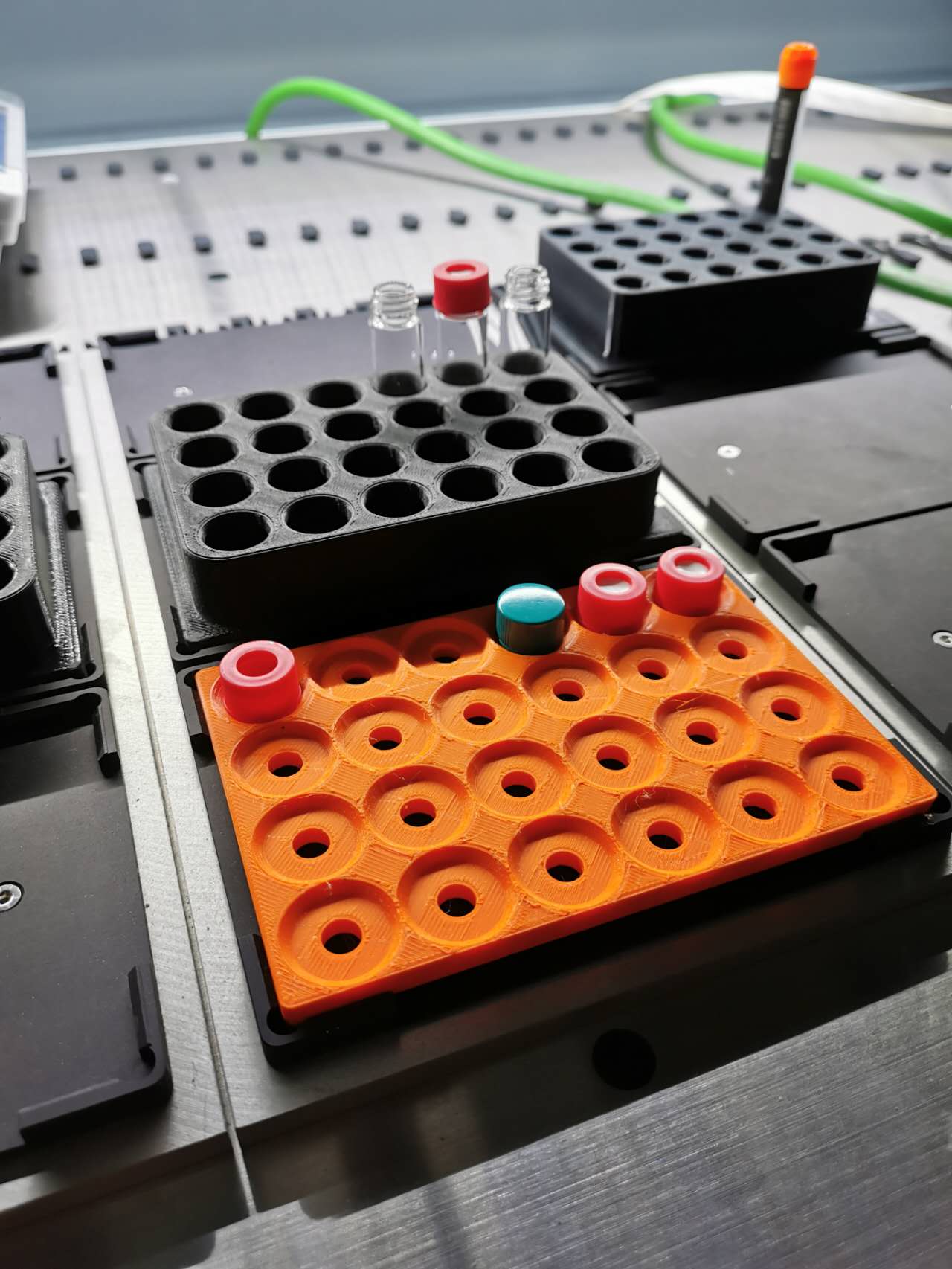

The cap mount in use.

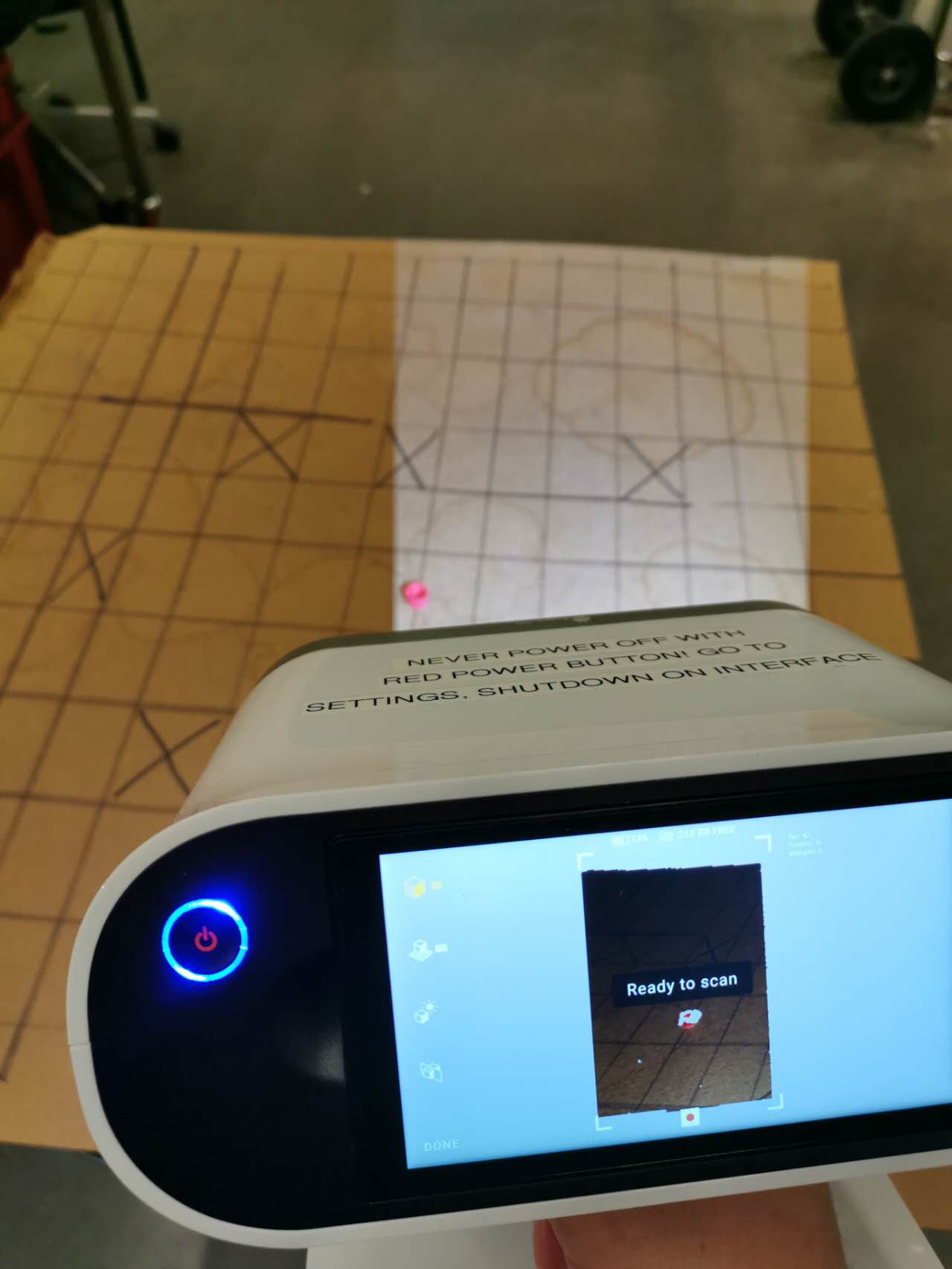

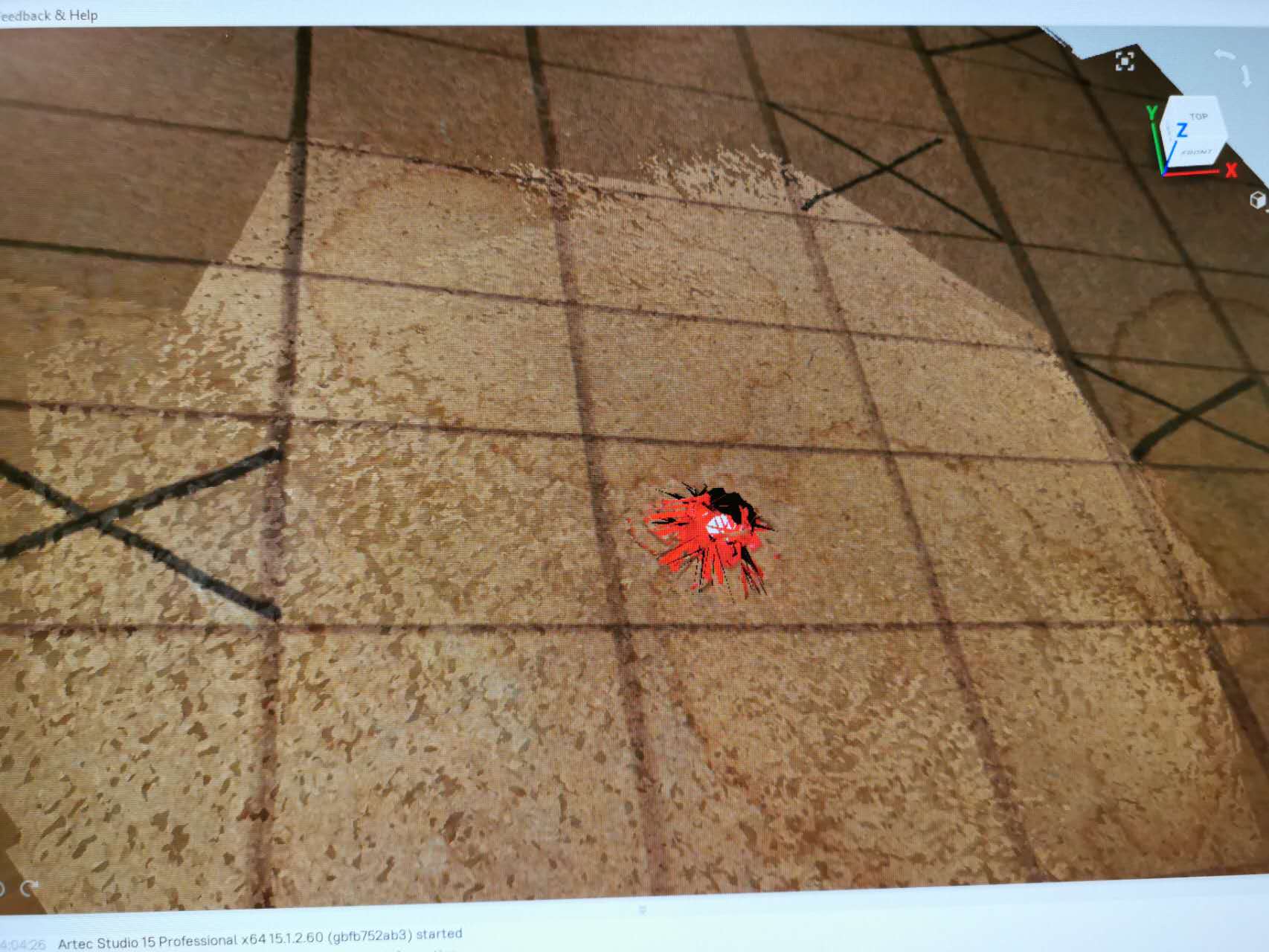

Scanning a cap.

Low resolution.

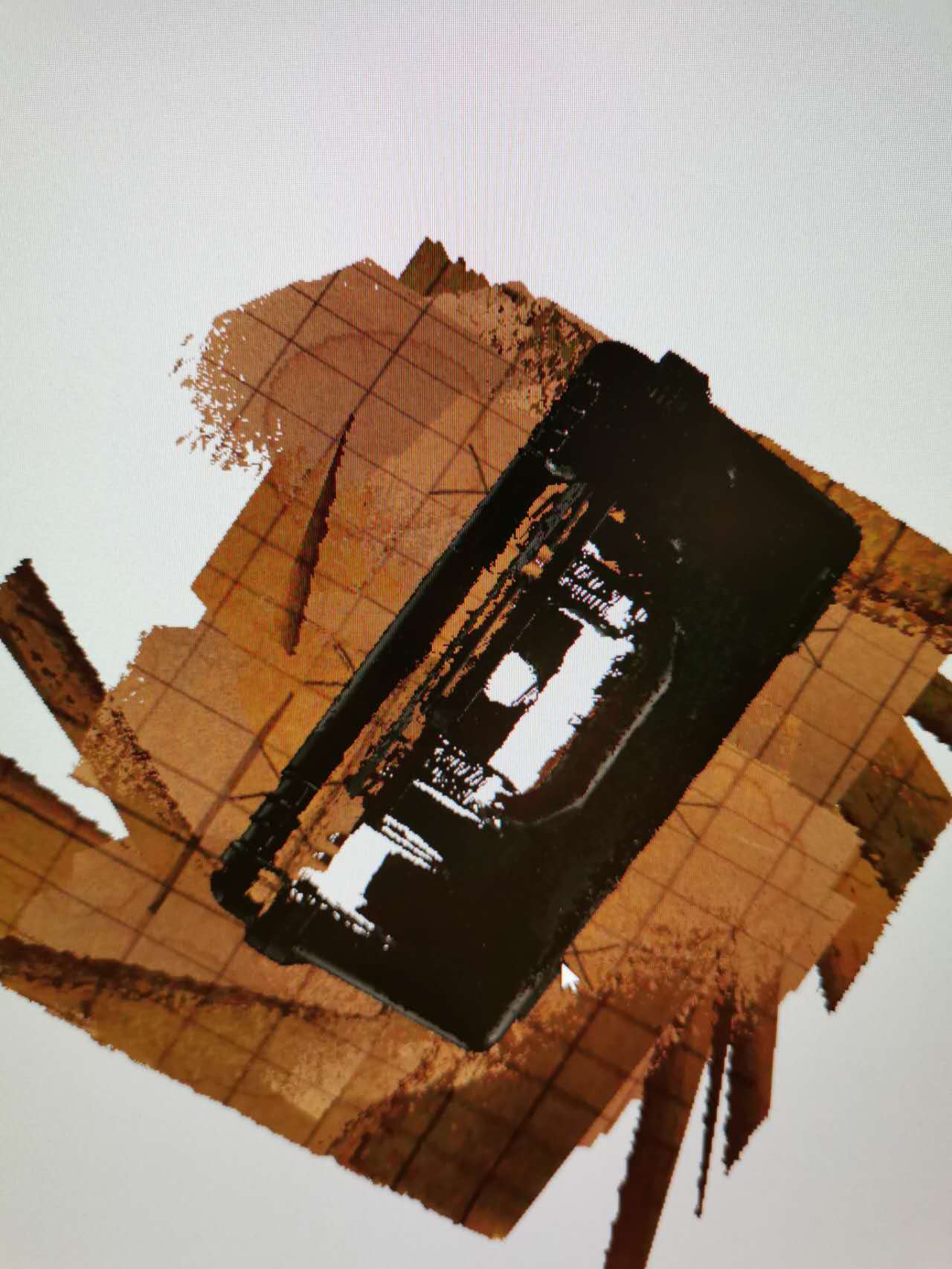

Scanning a bag.

Ok in general, still have holes.