PROCESS

THIS IS HOW I GOT THERE

↓

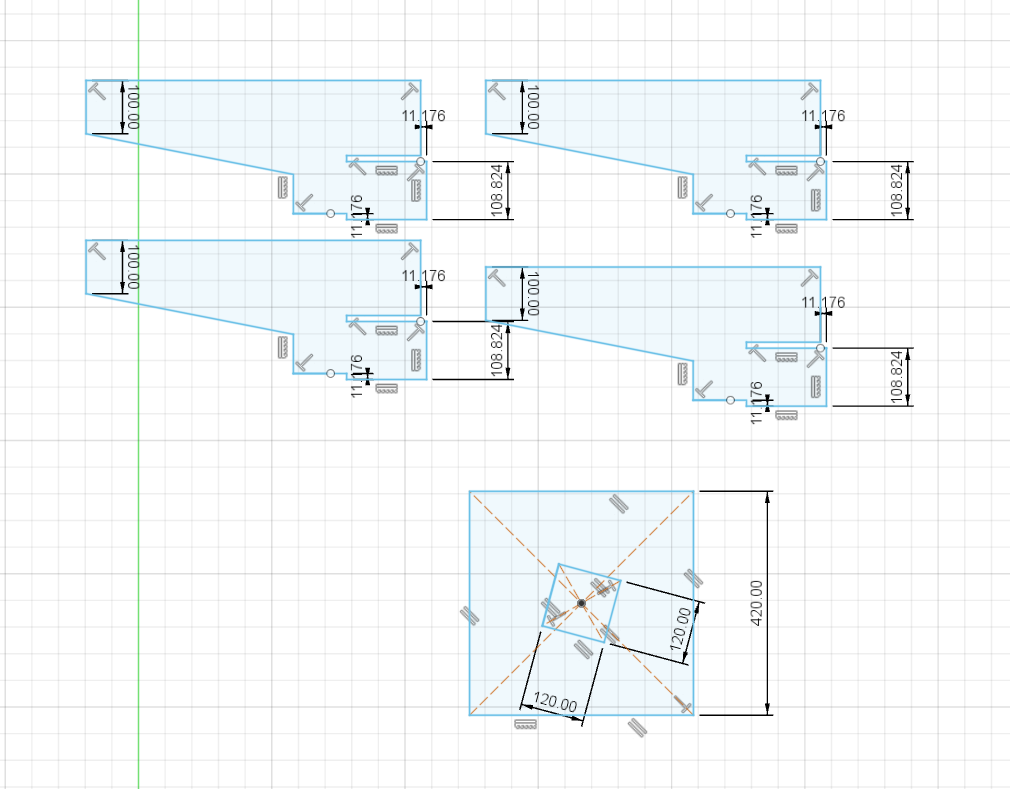

The sketch of pieces.

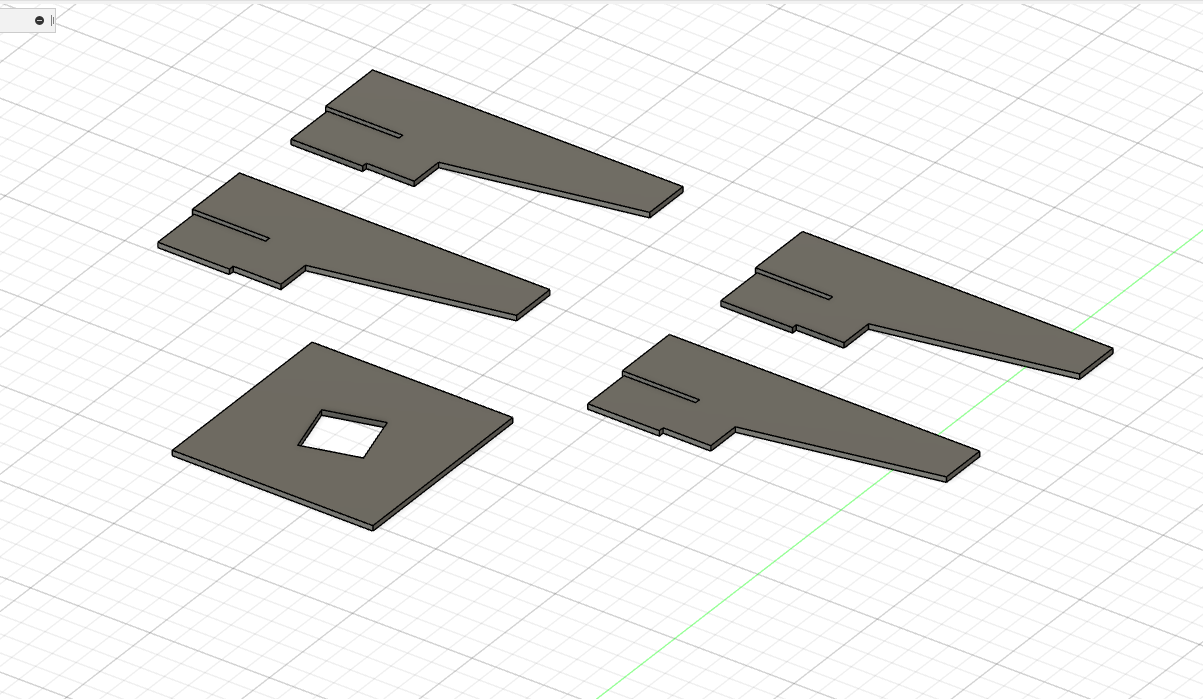

The board.

The assembled chair.

The shopbot working.

Done and ensembled.

It is stable enough for me.