PROCESS

THIS IS HOW I GOT THERE

↓

A topographic map from internet.

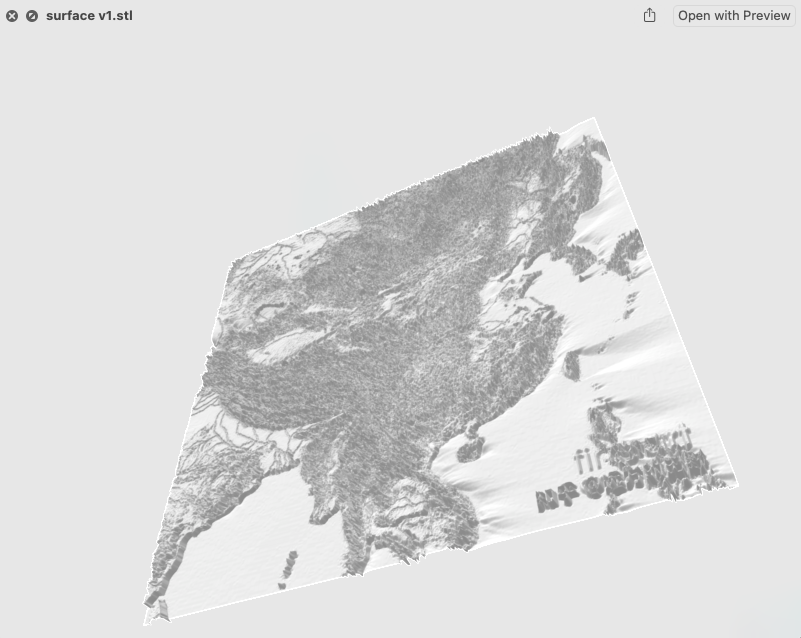

The surface transforme with image2surface.

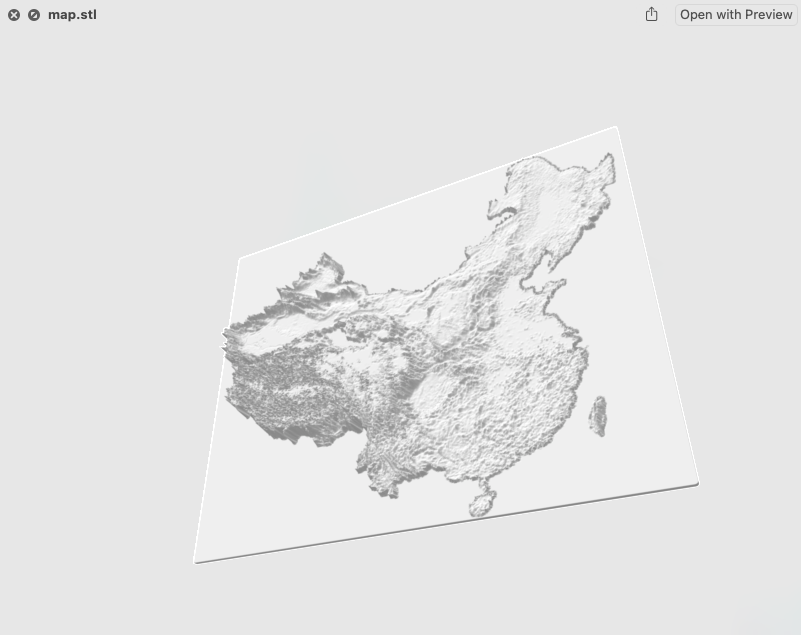

The surface downloaded from internet.

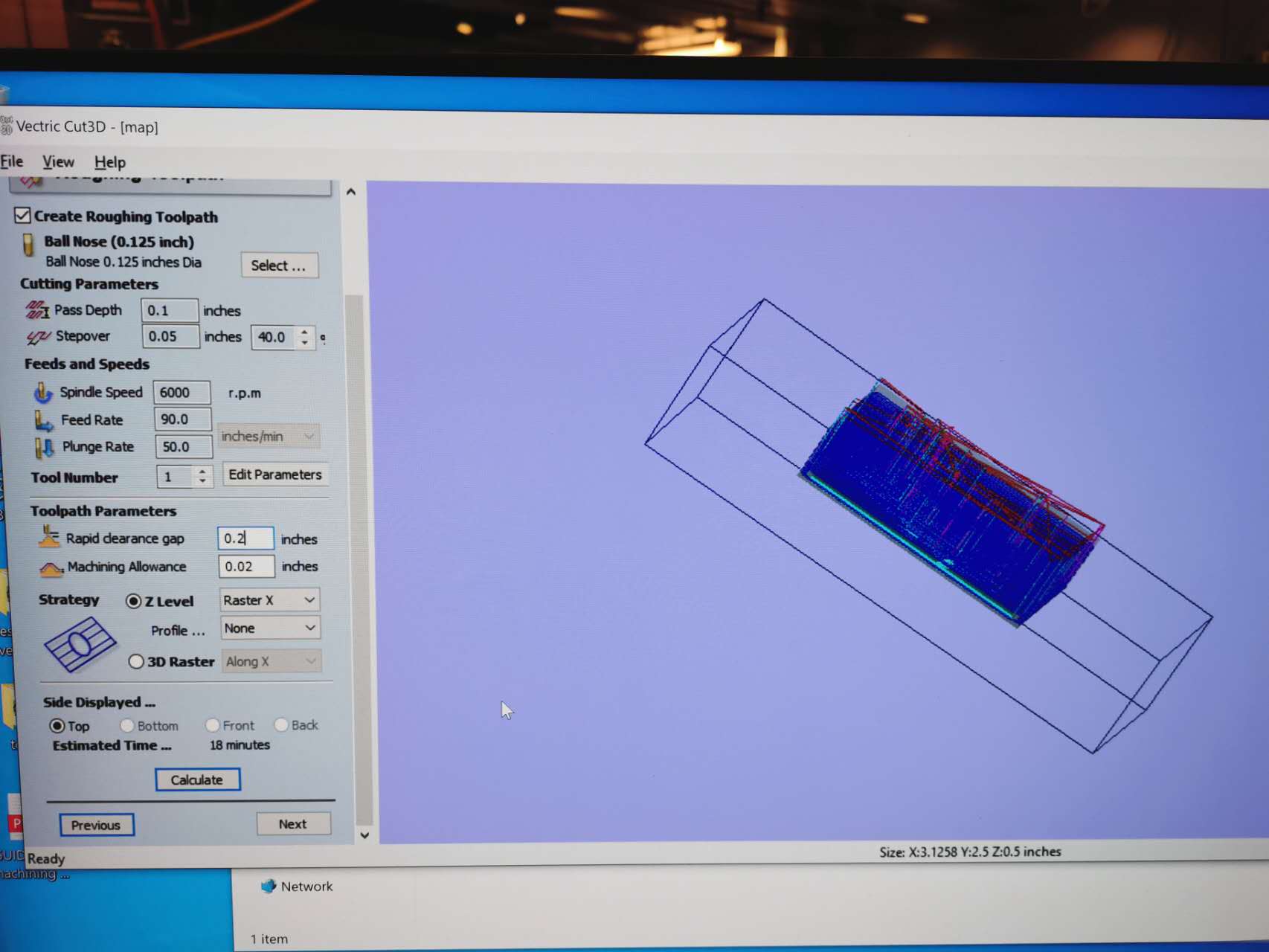

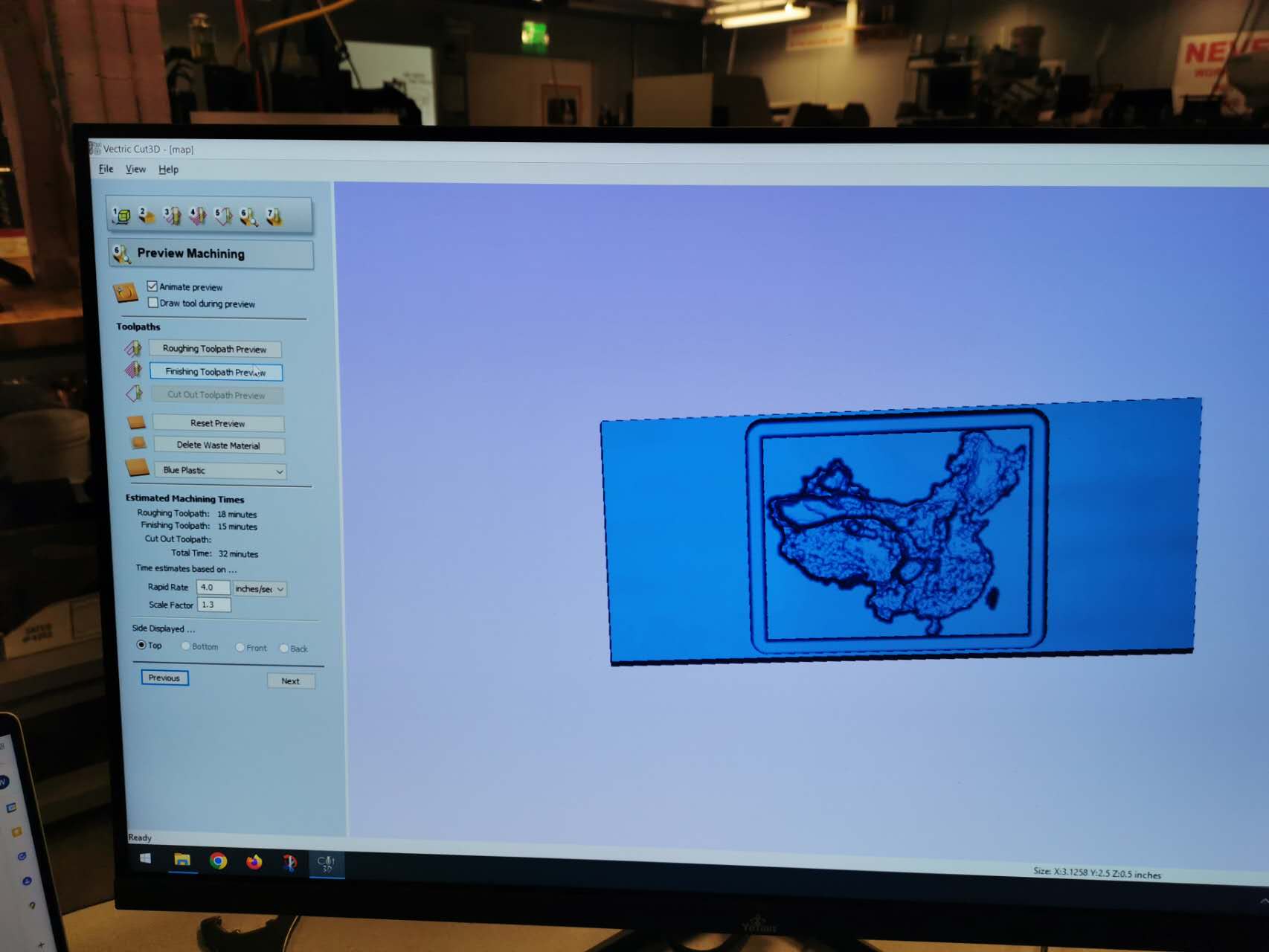

The rough toolpath.

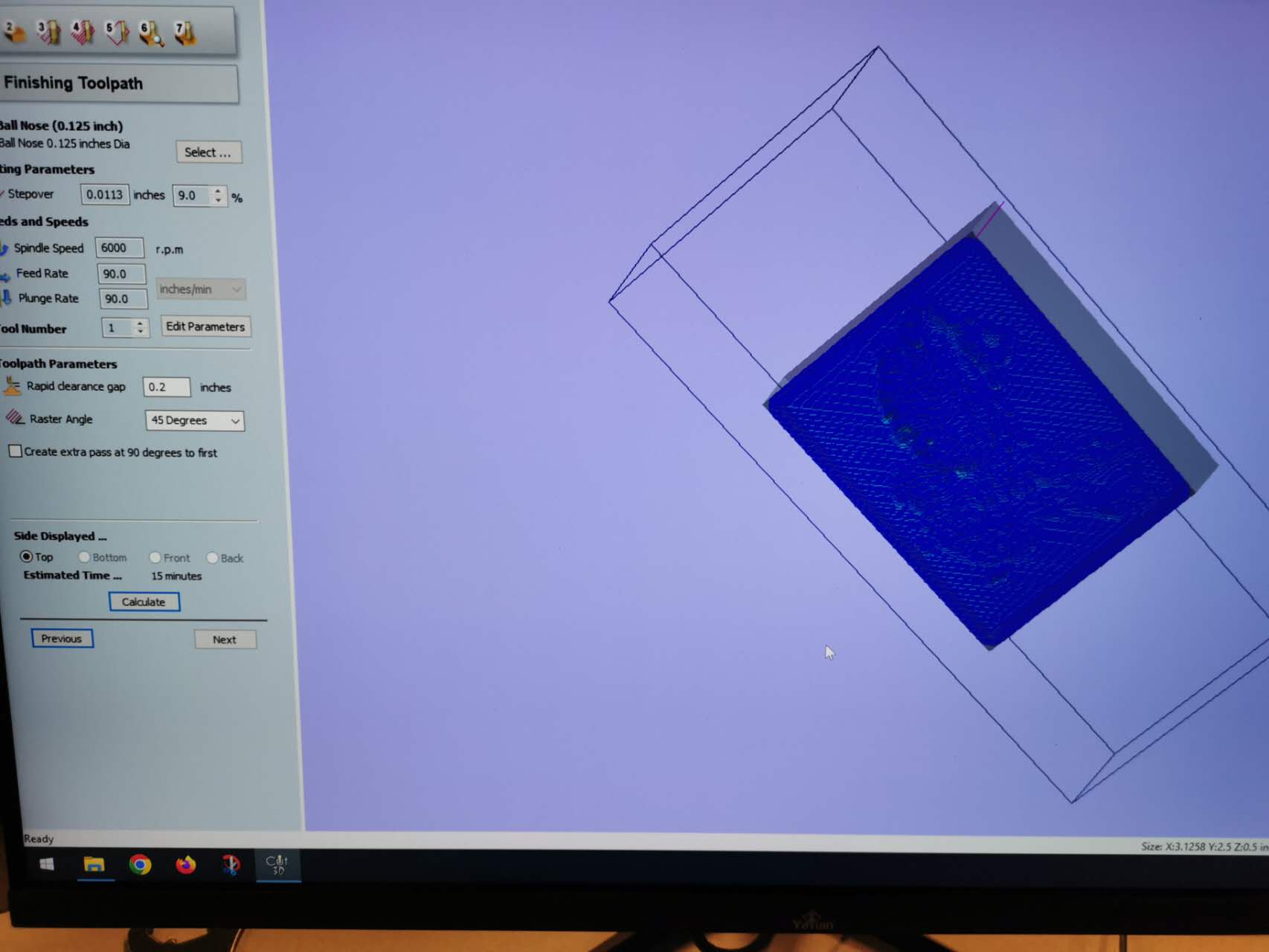

The finishing toolpath.

The preview.

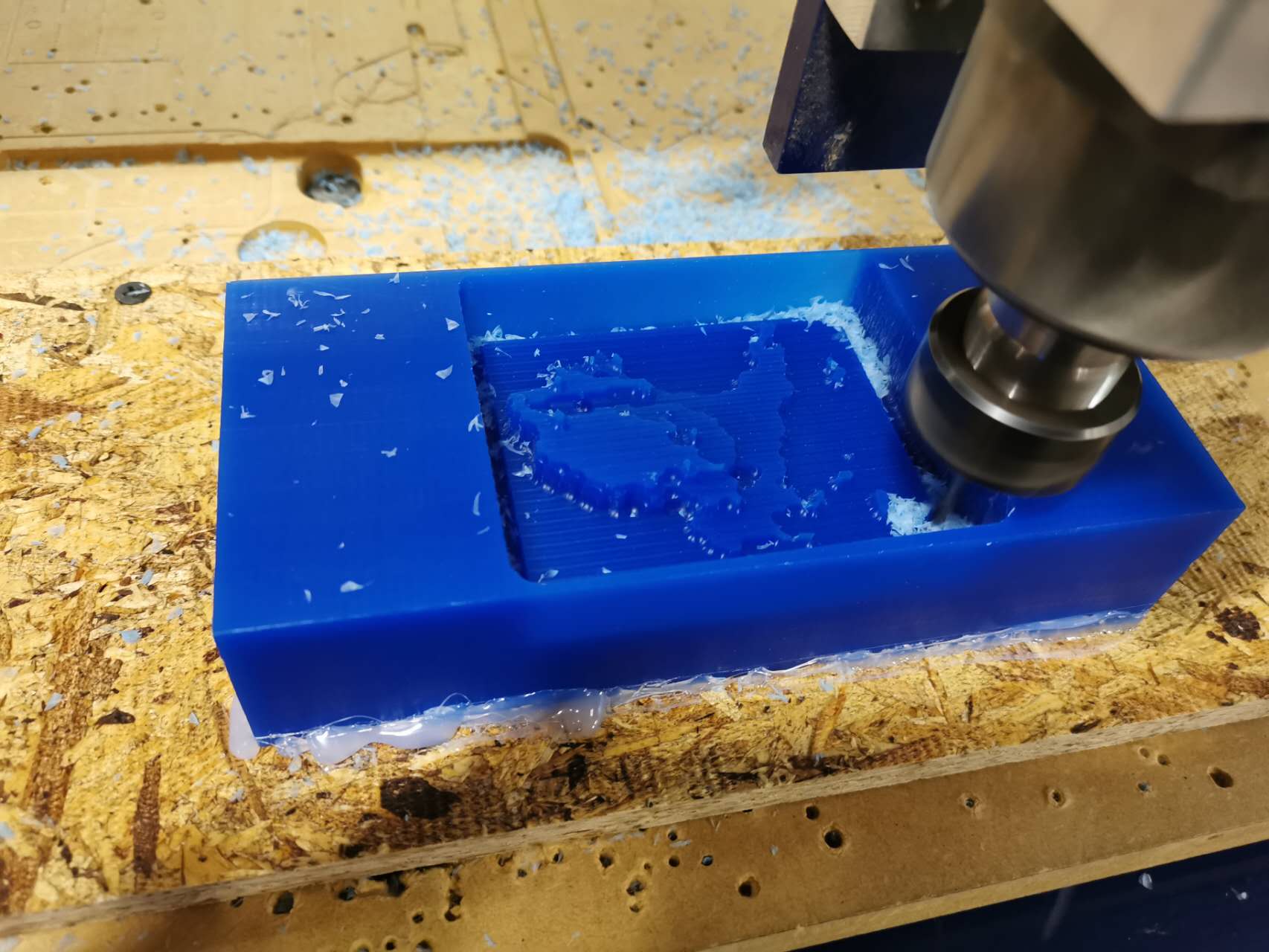

The ongoing rough toolpath.

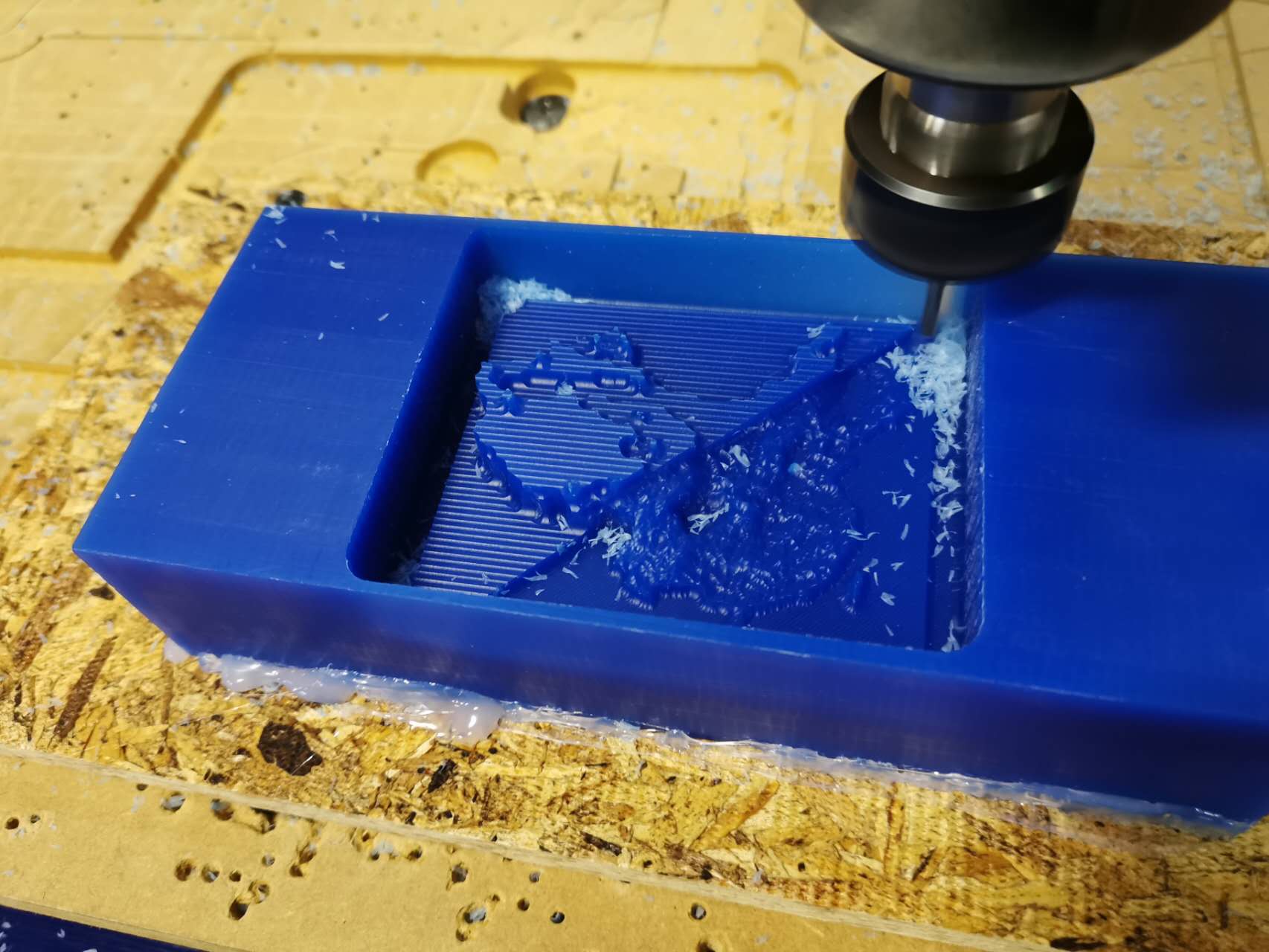

The ongoing finishing toolpath.

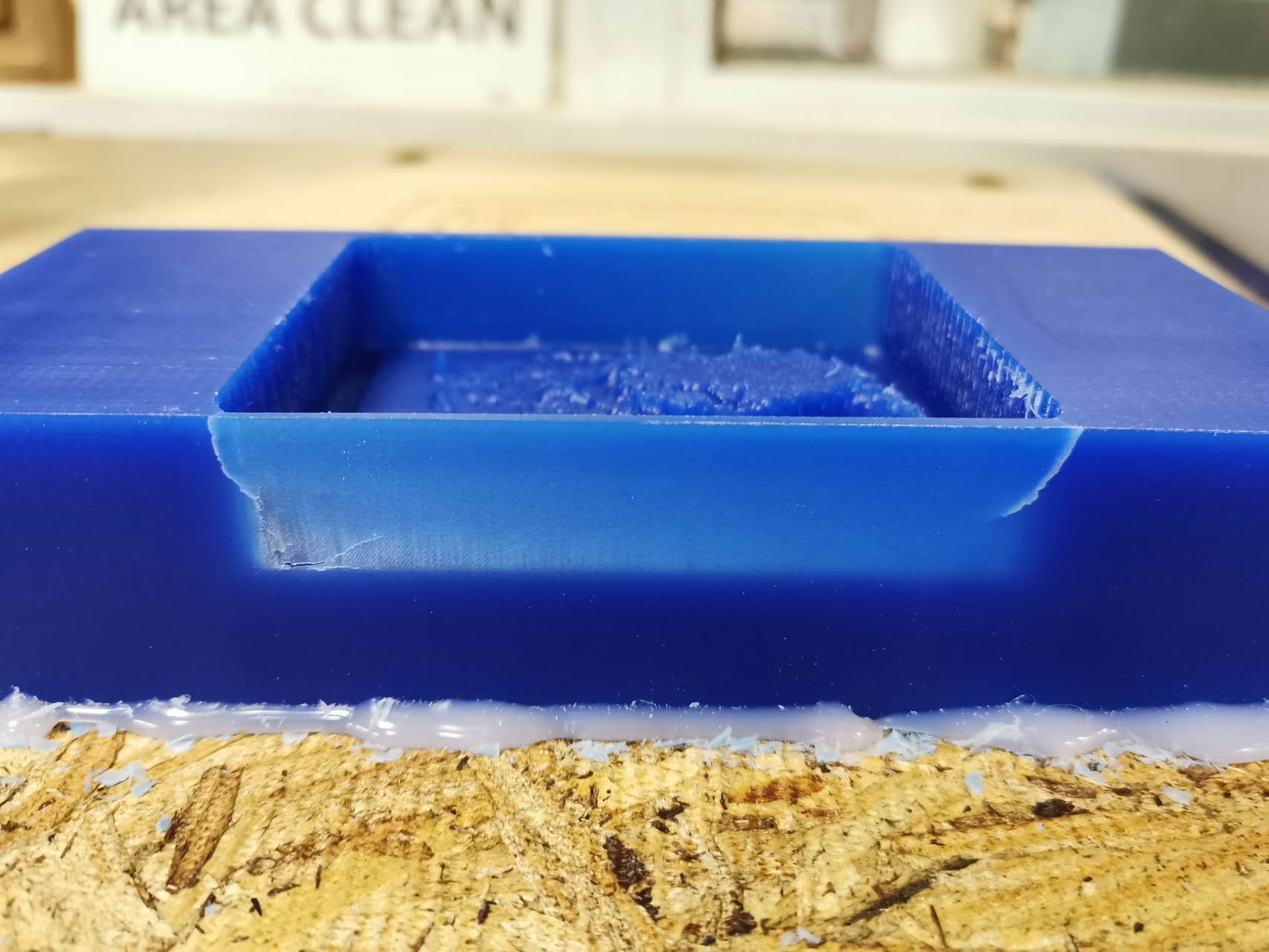

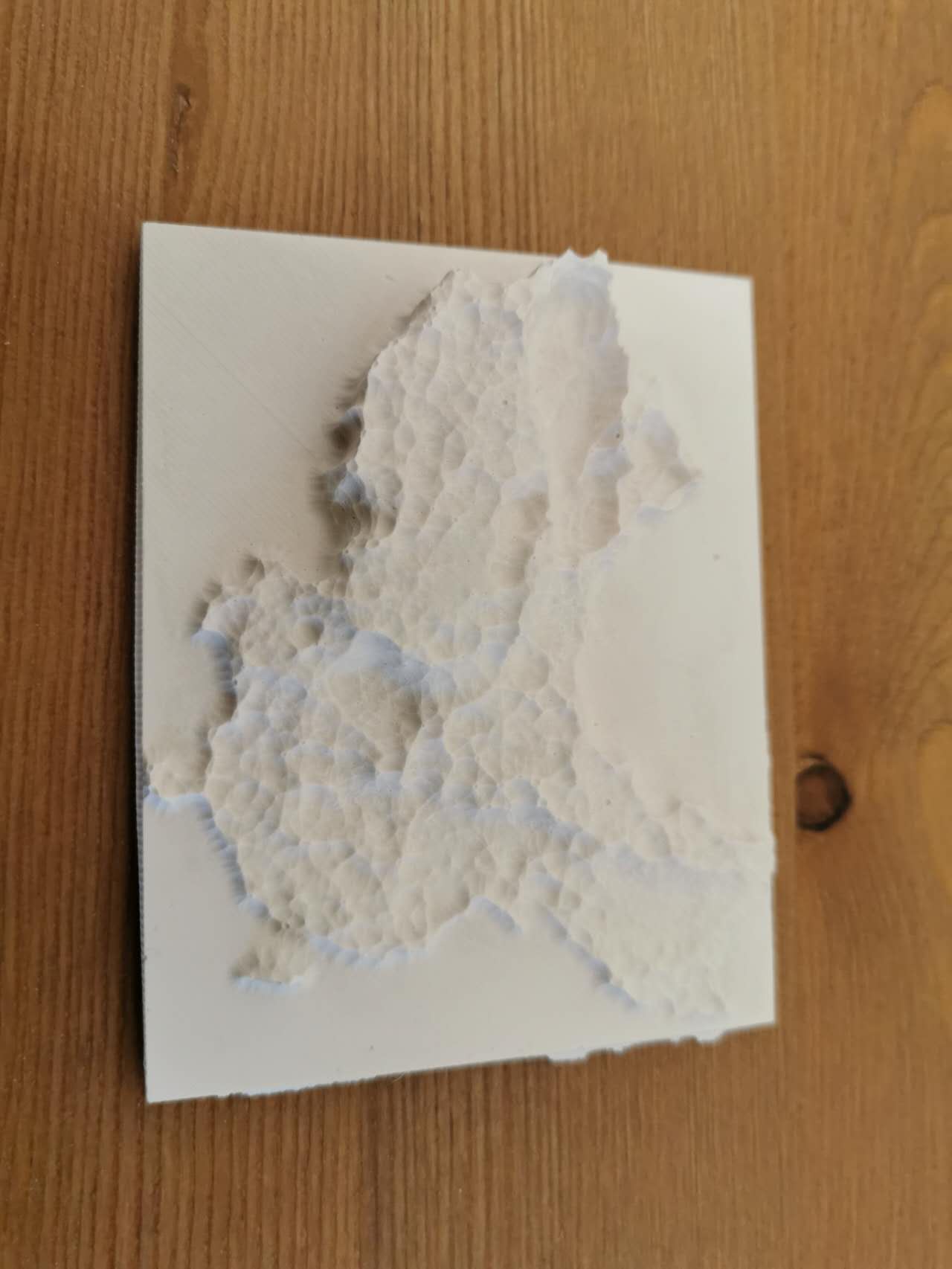

The finished cutting.

The wall problem.

The wood stick to solve the wall problem.

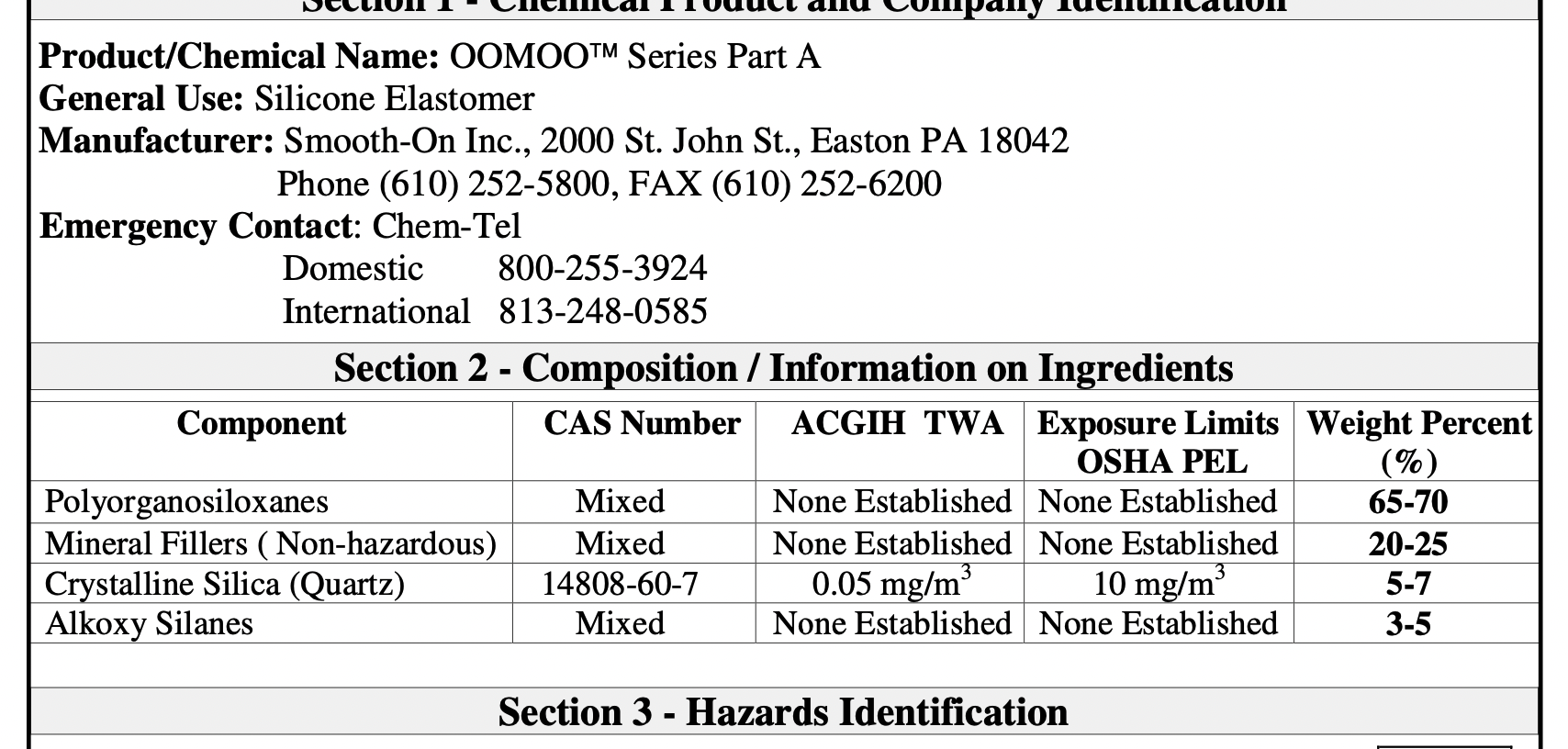

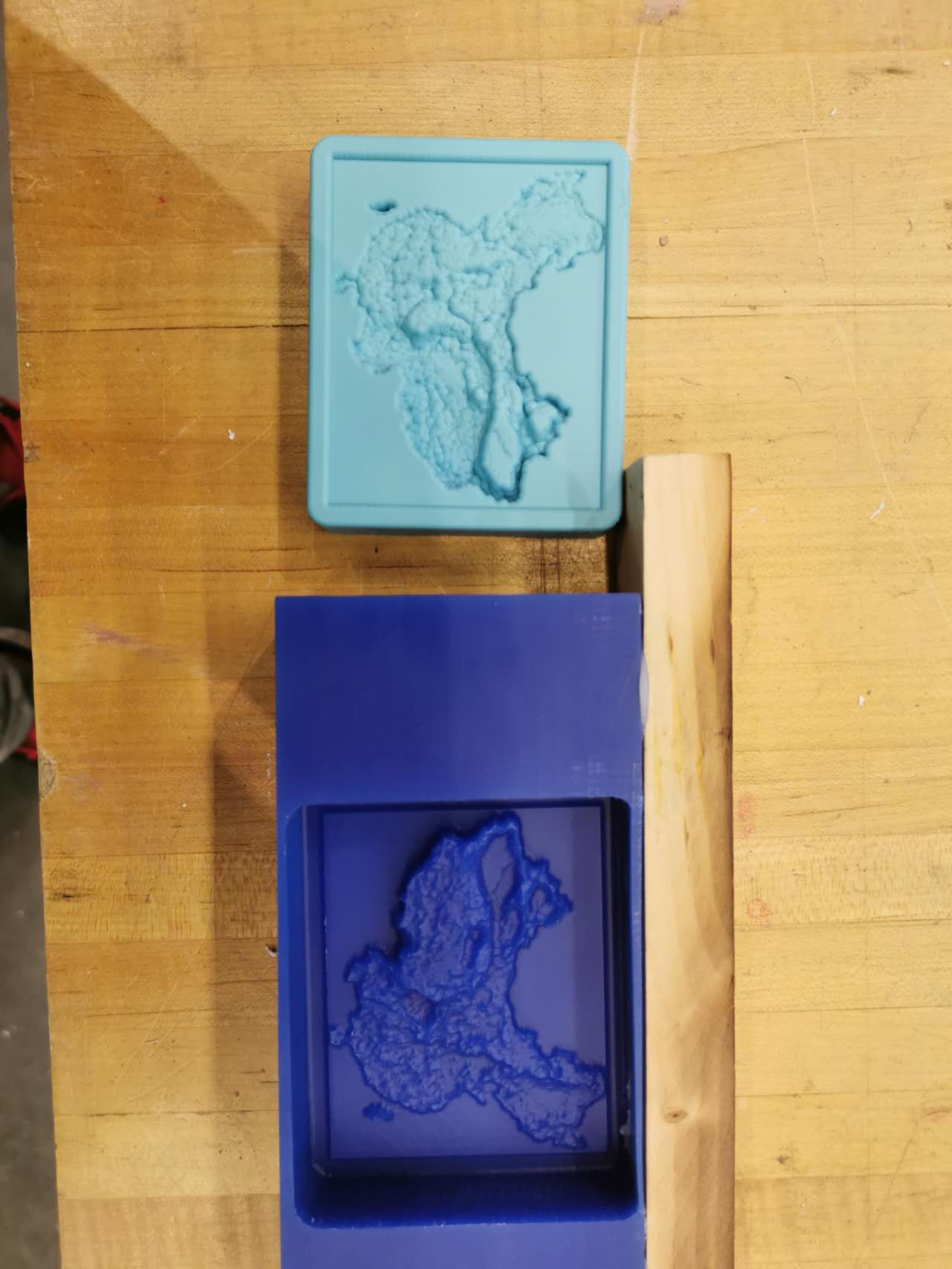

The safety data sheet of OOMOO.

The safety data sheet of OOMOO.

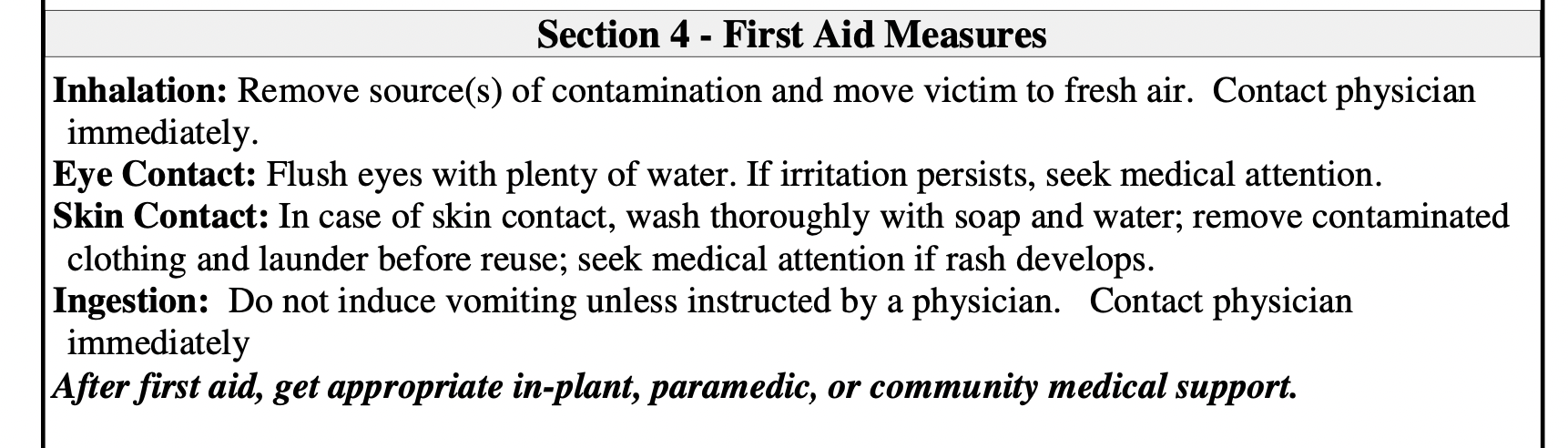

Making OOMOO mold.

Finished OOMOO mold.

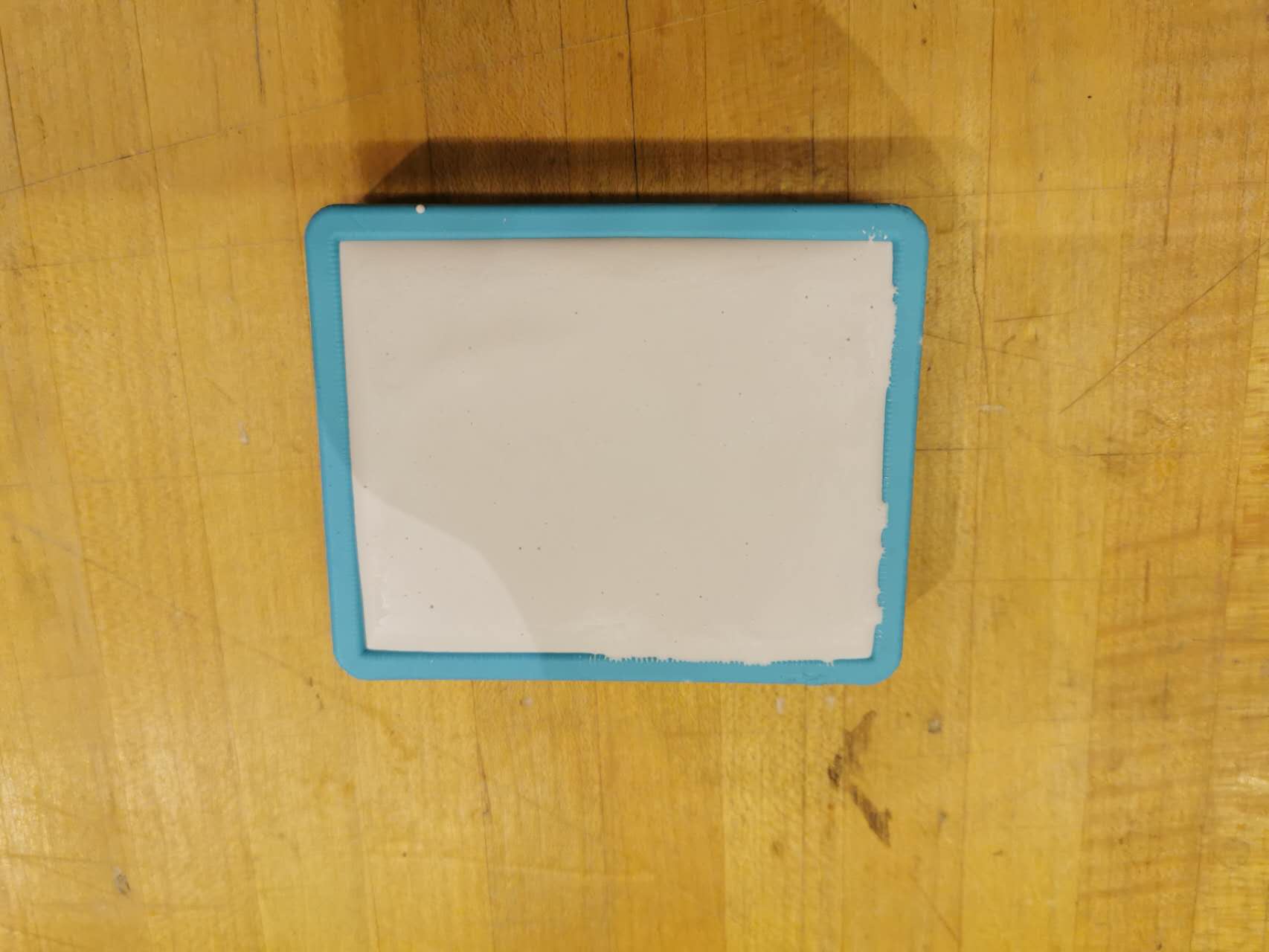

Making hydrocal plaster.

Finished hydrocal plaster.