week 13: wildcard week

learning about inflatables.

This week is wildcard week so several trainings are being held on different kinds of fabrication. I chose to join the inflatables group because of inflatable's relation to soft robotics. Here are my notes from the session:

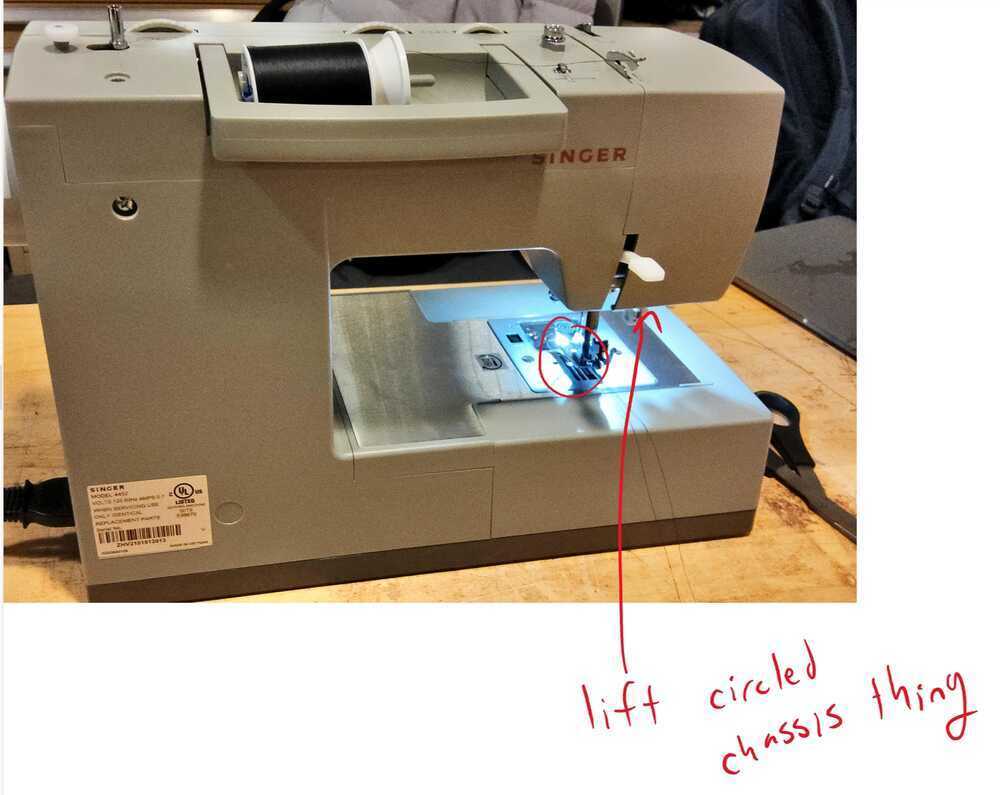

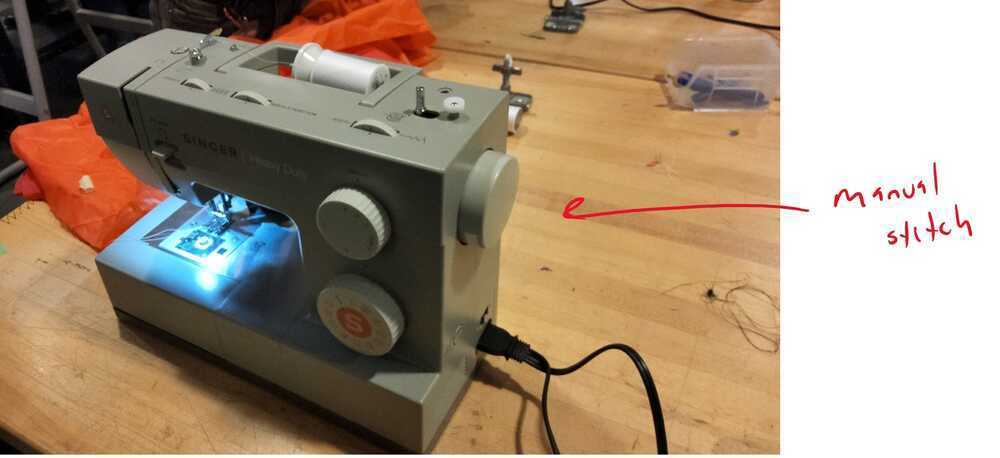

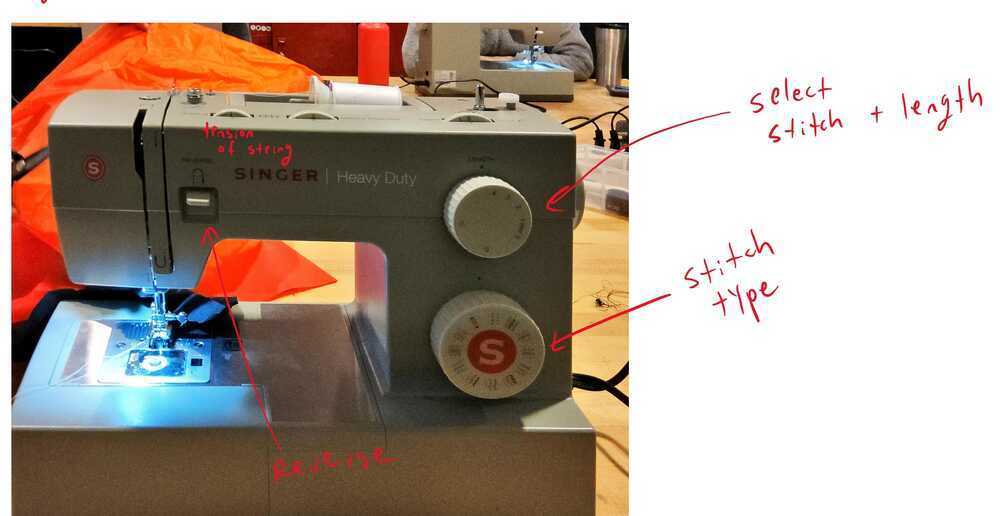

On the sewing machines:

To start and end a stitch:

- [1] Run the machine forward over fabric

- [2] Run it in reverse over what you just did

- [3] Run it back forward

To thread the machine:

- [1] Loop the thread in the catch above the needle

- [2] Bring the thread beneath the catch above the needle

- [3] Thread the needle

- [4] Run the machine for 1 revolution

- [5] Make sure there is a string coming from the bottom and the top of the sewing area and push them away from you

We also had a small training on how to use Fusion to design for inflatables. It was recommended that we use sheet metal tools and the corresponding manipulation functions like flange (rather than extrude). It was important to remember to make an offset to make your cut larger to account for the edges that fold into the inflatable after being sewn. When talking to training leaders, they told us about how it was possible to place copper under the inflatable surface in order to create capacitive sense sensors. I'll definitely have to try that in the future.

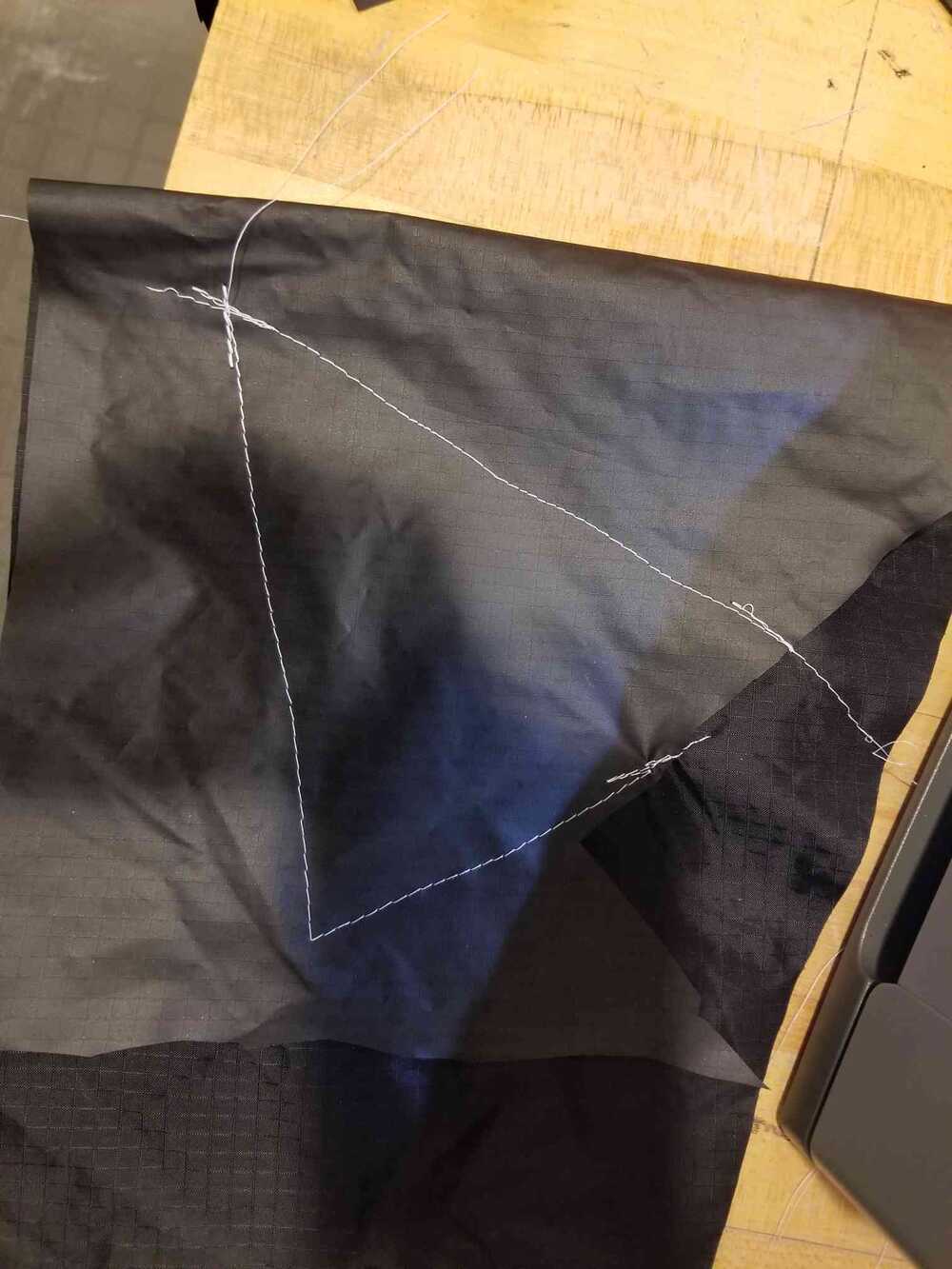

Here is my first basic inflatable design:

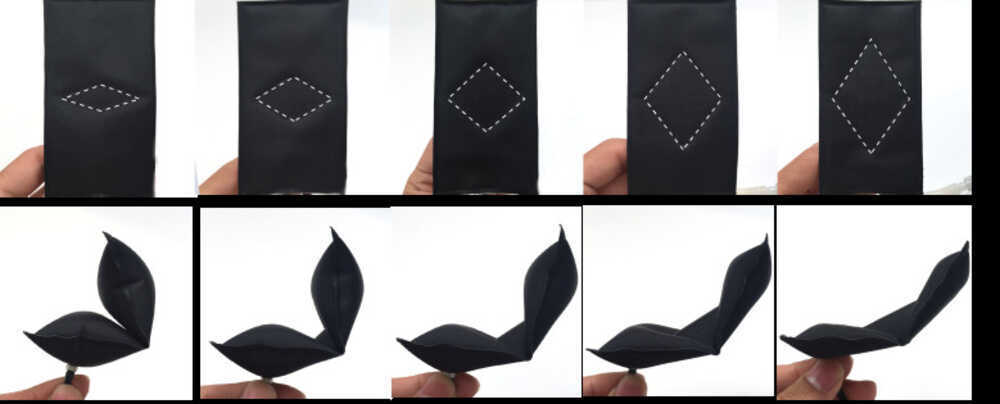

I found out about a type of inflatable on the MIT media lab site called aeroMorphs. Basically, they are a type of inflatable with shapes cut into them to enable bending upon inflation:

I decided to make a starfish with these properties. I wanted the legs to stand up when I blew into them.

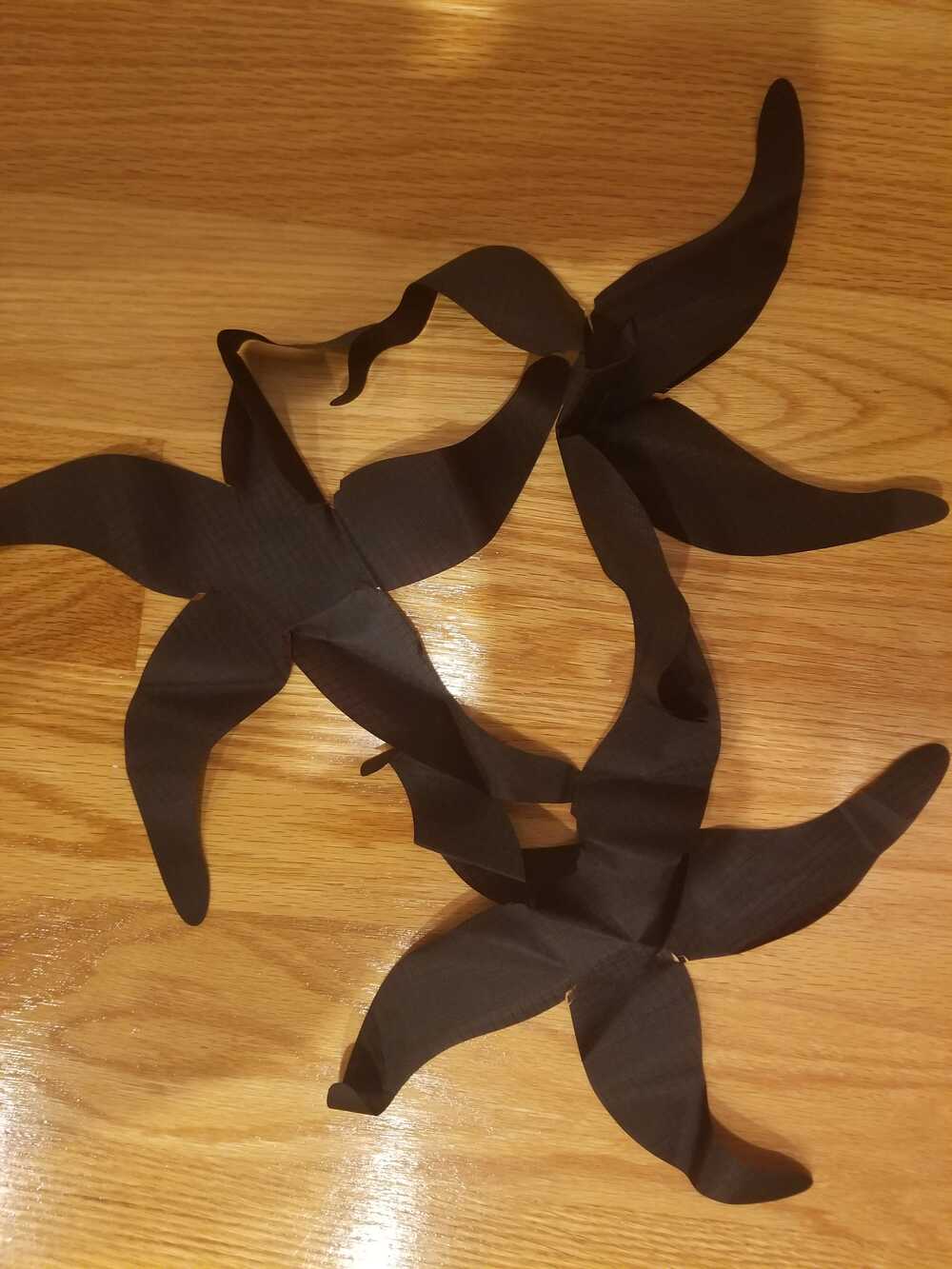

I made a second copy of the design with a hole in the center wide enough for a straw. I got it cut in the Media Lab:

I printed several in case I destroyed one. Being directly before the final project week, I did not have much time to commit to hand sewing every leg of the starfish. I decided to sew one leg and see the aeroMorph action based on that leg. Unfortunately for me, manual sewing really deteriorated the aeroMorph effect; regardless, it was still kind of there:

There were some obstacles, but I was satisfied with my aeroMorph action!

My main design

trying out aeroMorphs!

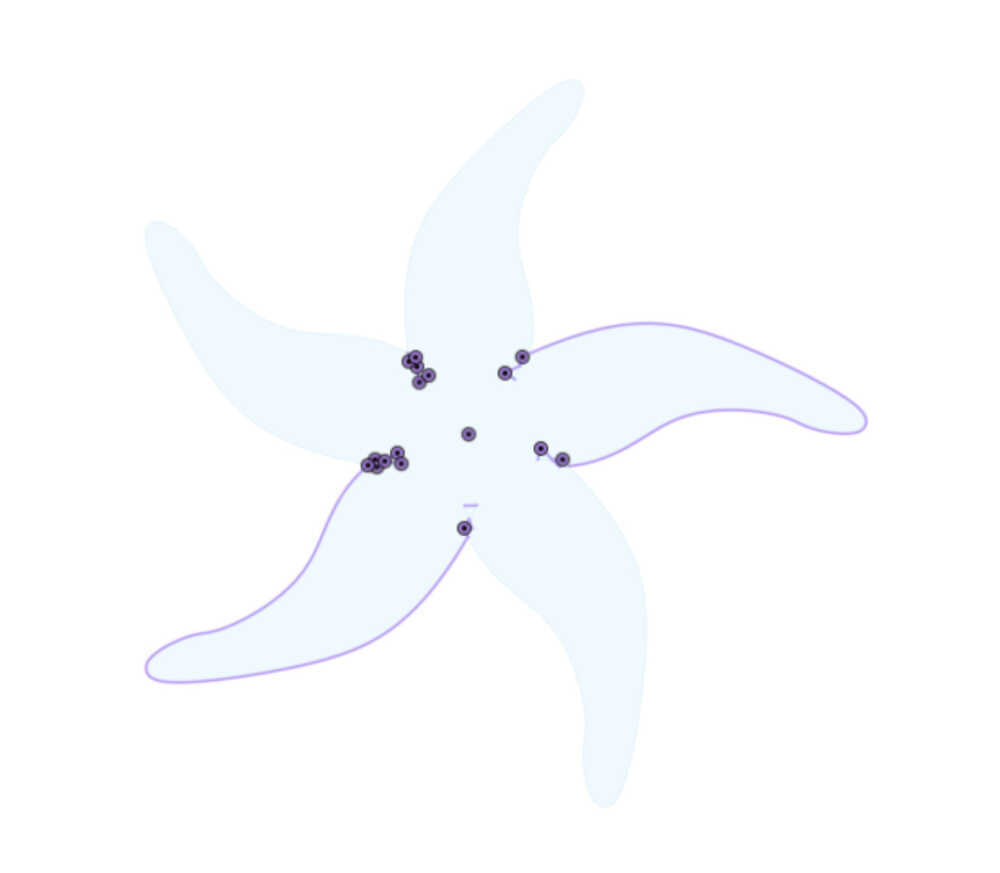

I made a star shape using the sheet metal settings in fusion:

I brought my starfish to the sewing machines and discovered that the material I was using in addition the the width of the design made it un-sewable. The machine would just suck the material right into the bottom of the machine.

After several attempts, I decided to do the sewing by hand: