Week 12: Mechanical, Machine Design

For this week, my section decided to making a drawing machine.

All of the machine's documentation can be found here: EECS Drawing Machine

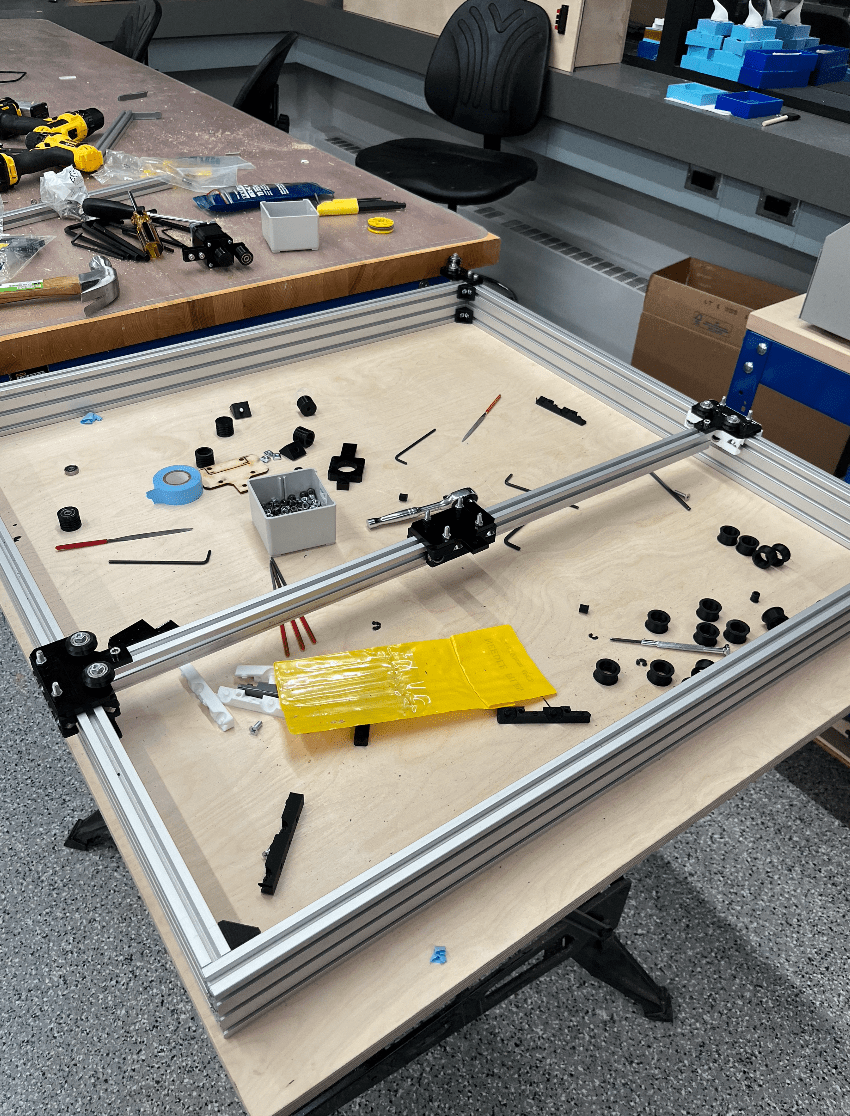

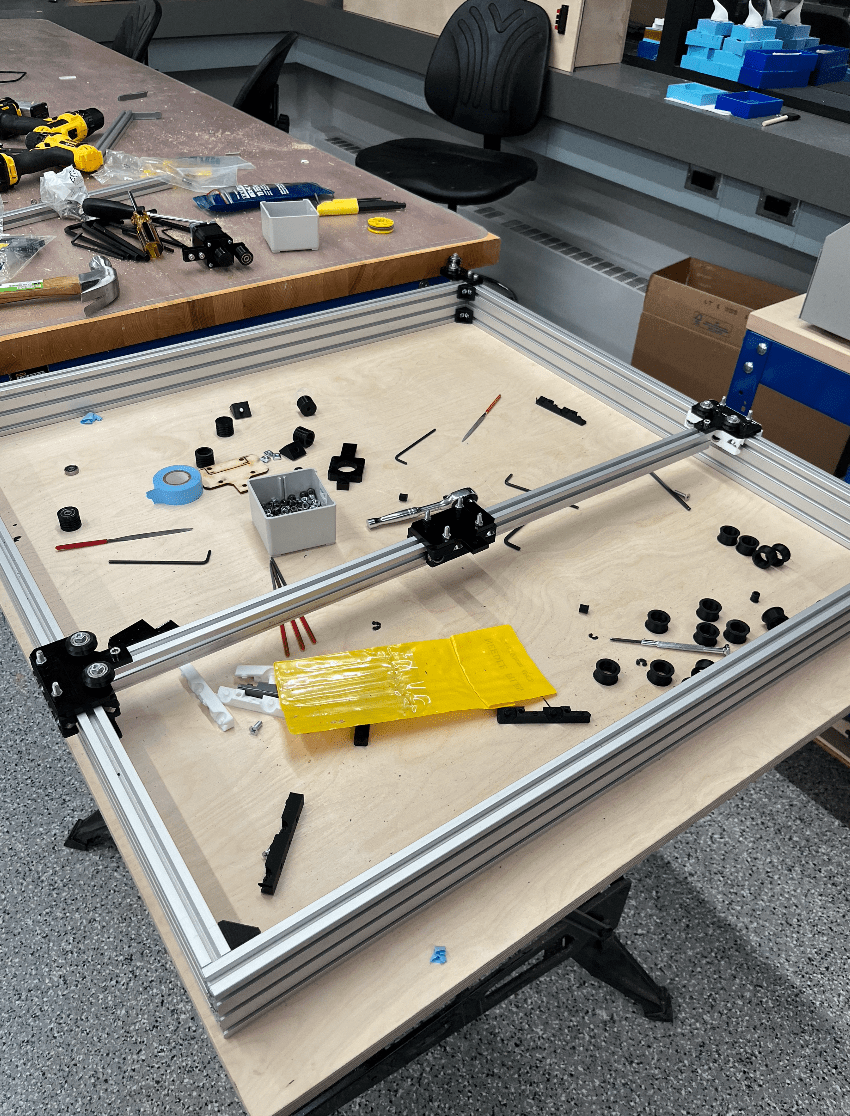

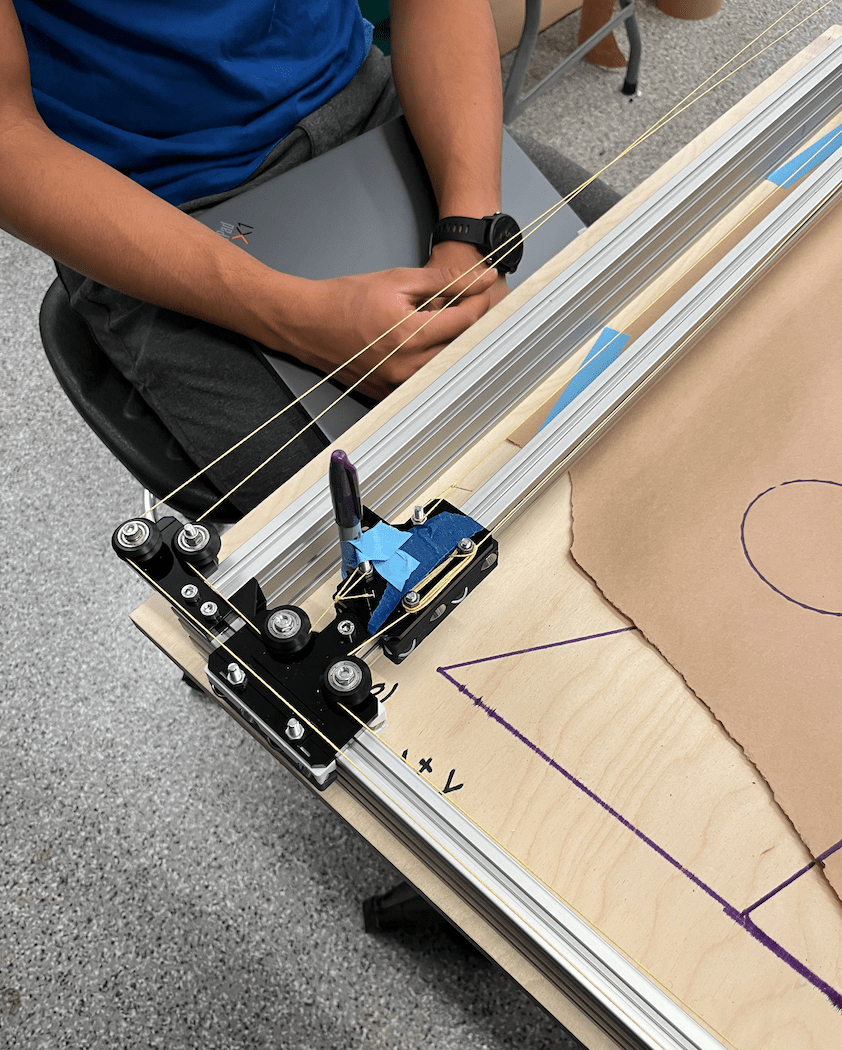

For my specific contributions, one thing I did was help build the main frame of the machine. One trouble we ran into was that the parts on the sides that slid with the bearings didn't fit perfectly, so some of the bearings wouldn't turn when we tried to slide the part along the rail. After A LOT of sanding, we finally managed to get it so that all the bearings turned and it was all quite smooth.

Another problem we ran into was that when we slid the part along the middle beam of the frame, the bearings didn't all turn. We were quite confused, because when not attached to the beam, all of the bearings were able to turn. We decided to test what was wrong by putting the part on one of the side beams to see if it also had problems, and it ended up being to slide much smoother. We realized that it was probably an issue with the middle beam being warped in some way, but it ended up not being a big problem.

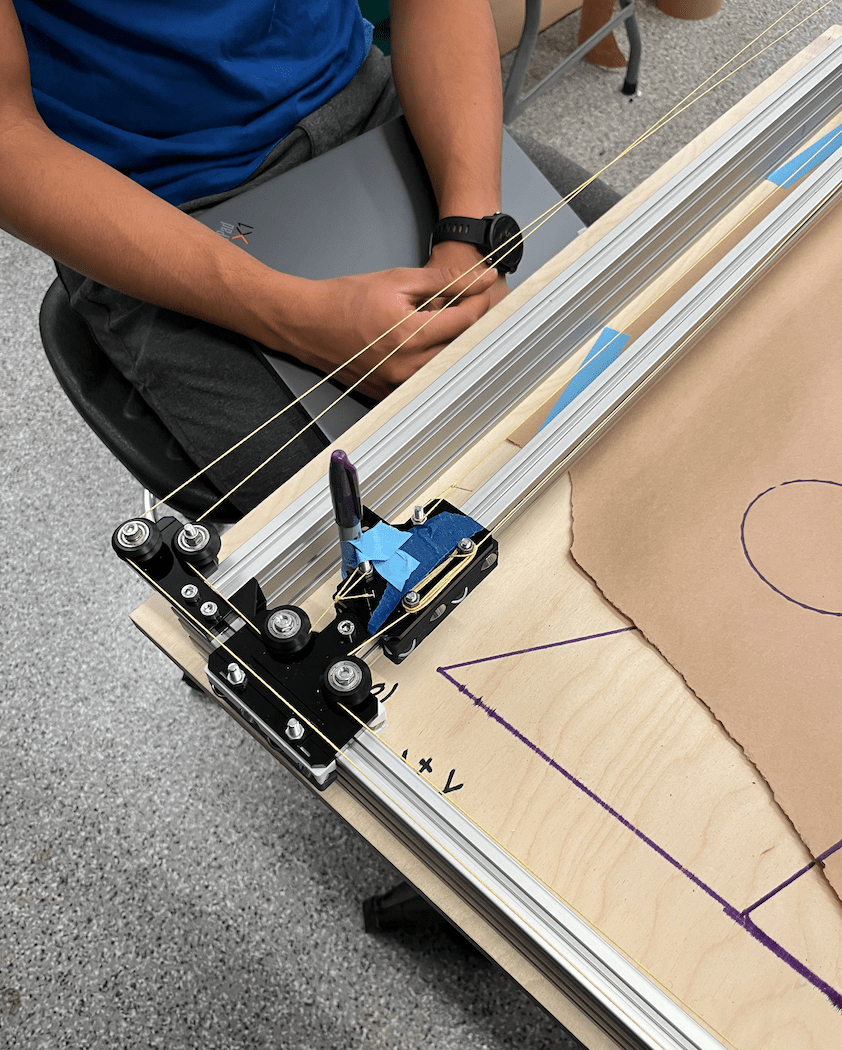

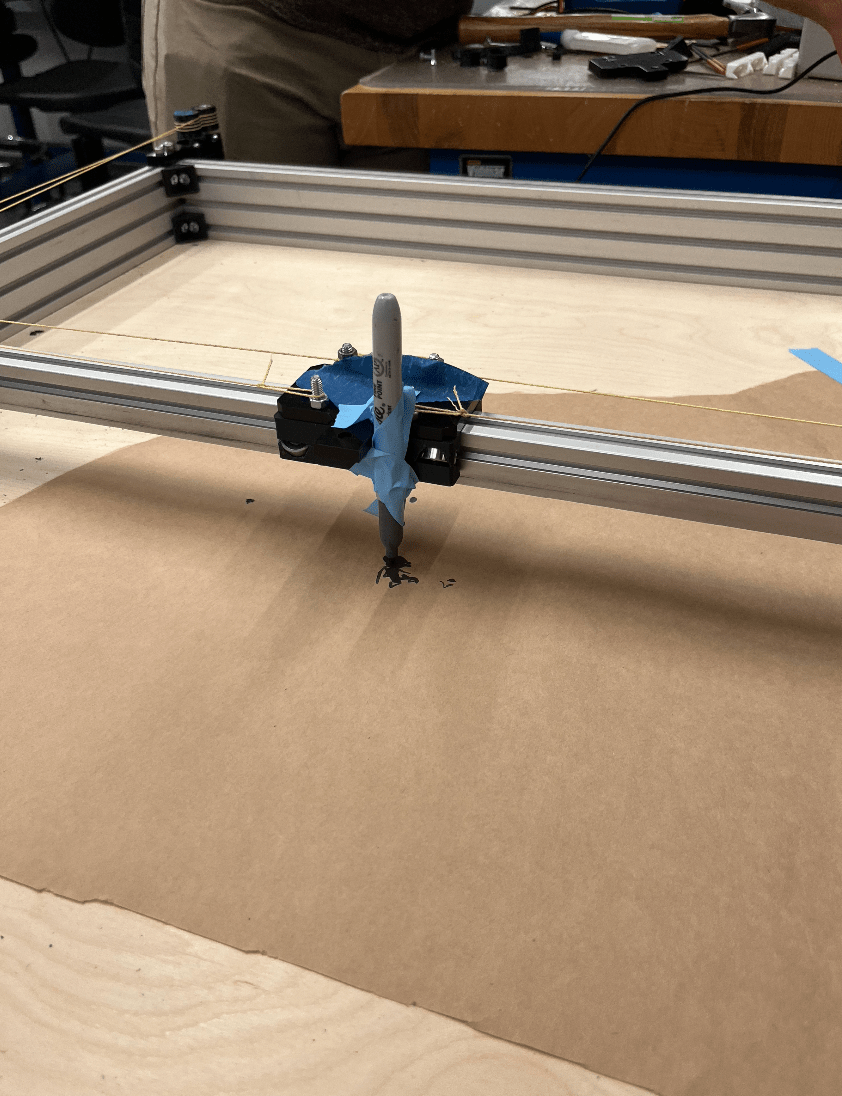

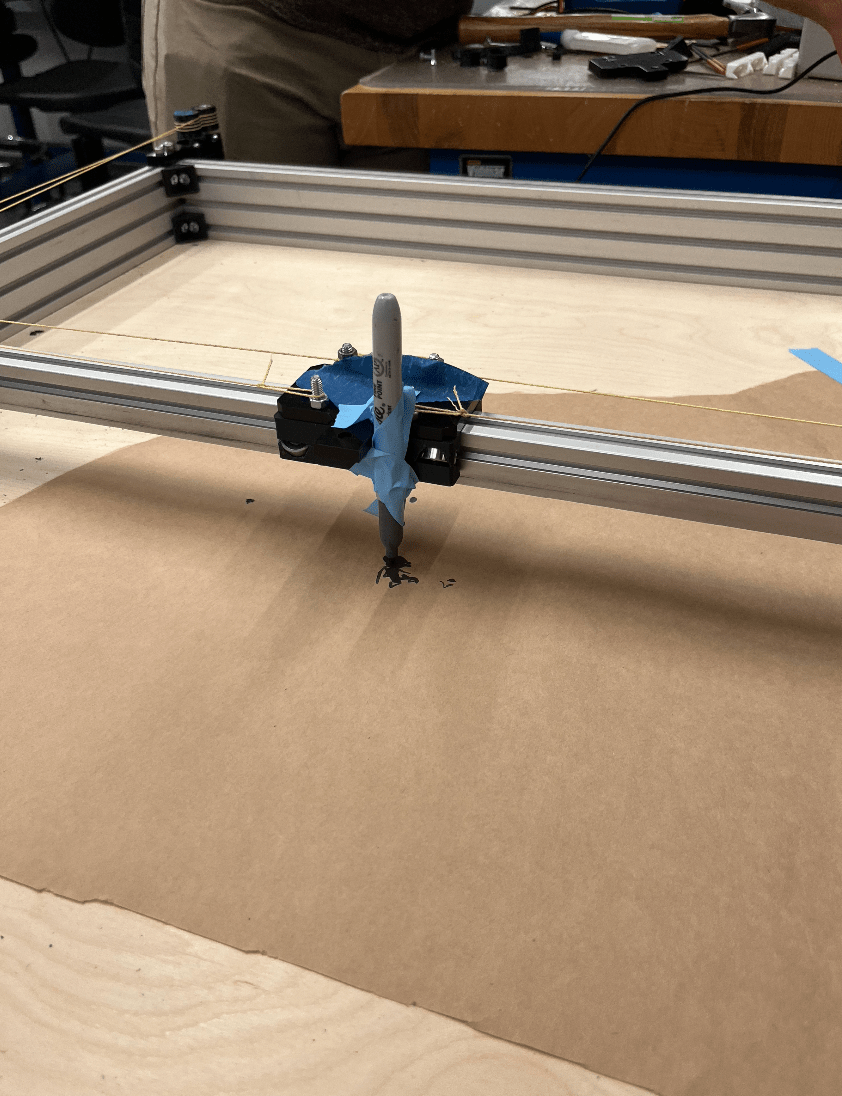

Once we had the frame set up and the parts all attached, we started doing some preliminary testing and simple drawings. One of the things we implemented in the beginning was to have the machine zero by running into the sides of the bottom left corner. Later on, we ended up changing the zeroing process to use a button instead. For this part, I also helped brainstorm how we would be able to code the machine to move when given coordinate values, using the CoreXY equations to determine how much to move each stepper.

During this initial testing, we didn't have the thing to hold the marker yet, so we had to just tap it down. It worked well though, and we got some pretty good initial drawings!

In terms of programming, I also helped a bit with setting up the stepper motors, getting the bootloaders on and figuring out how to use the modular things interface.