Molding and Casting

This week was a pretty fun week for me. I enjoyed being able to CAD, cast, and mold whatever I wanted. Since I like to make things

difficult for myself, I decided to make an R2D2 for this week's assignment. This of course meant I couldn't create a simple one or

two part mold this week.

CAD

I started the CAD by making the body of R2D2. I first got images of the side and back view of R2D2 from the internet. Then I imported

them as canvases onto the respective planes. This gave me a great reference to work off of. I used lines, rectangles, and arcs to draw

a 2D version of R2D2's semi-pill shaped body. Then I revolved the pill shape. After, I moved onto the legs. This was where the bulk of the work happened.

I used the side view canvas to create all the details of the legs. I first drew the outline of the leg by following the canvas.

Then I extruded it into the body and out to make the leg connect properly. Then I created planes on the surface of the leg body and

drew on the extra Then I mirrored it to create the other leg.

Manufacturing

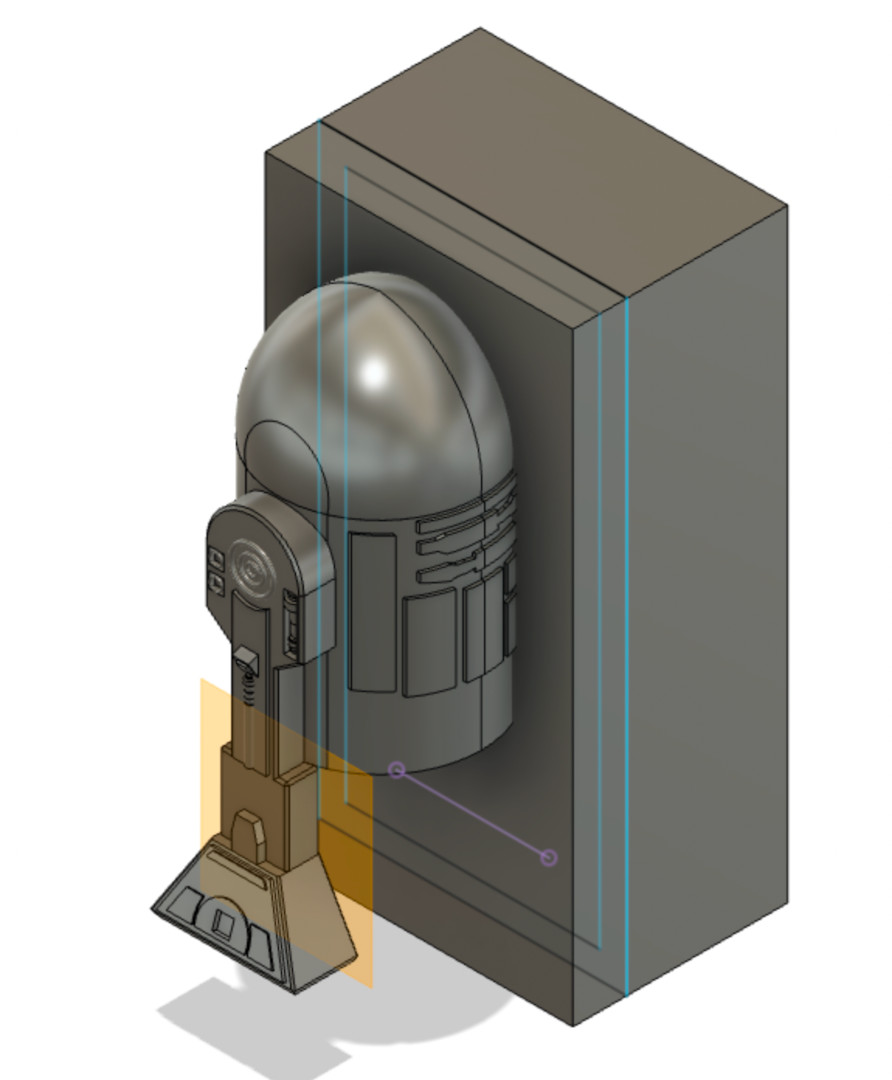

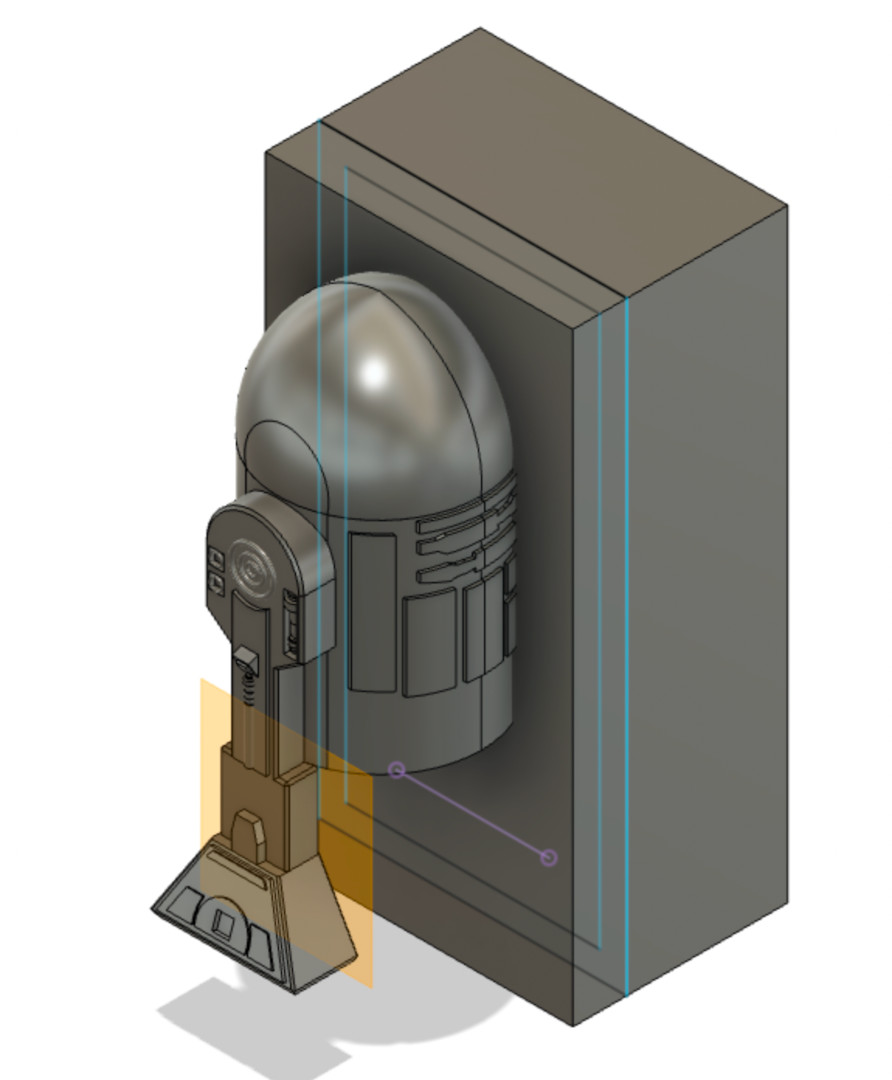

Since my model was really detailed and had overhang, there was no good way to preserve detail and make a good mold. To circumvent this, Anthony suggested a

3 part mold and to create it on the othermill. One mold would be for the leg. I could use the same mold to cast both legs. Then I would make a 2-part mold

that fits together for the body.

Before Wednesday, I was only able to work on the mold for the legs of R2D2. Anthony helped me a lot with deciding how to manufacture it on the othermill. I first

cut off the leg from the body of R2D2 and then built a box around the leg. Then Anthony went through and helped me figure out how to manufacture it on the othermill.

We used one Adaptive pass and then made a Pocket, Parallel, and Pencil pass for the very small details with the 1/32nd endmill. This couldn't protect all the details

in my CAD but it was pretty good.

Creating Mold

I mixed and poured the Uomoo (this may be spelled wrong) into the wax cut out and let it set over night.

Casting

Once the mold was dried, I was able to peel it off the wax pretty easily. Then I made the drystone mixture and poured it into the

mold and let it set over night.