This week, I explored computer computer-controlled machining.

For this week's assignment, I decided to make a small rocking horse, which would be simple yet dynamic.

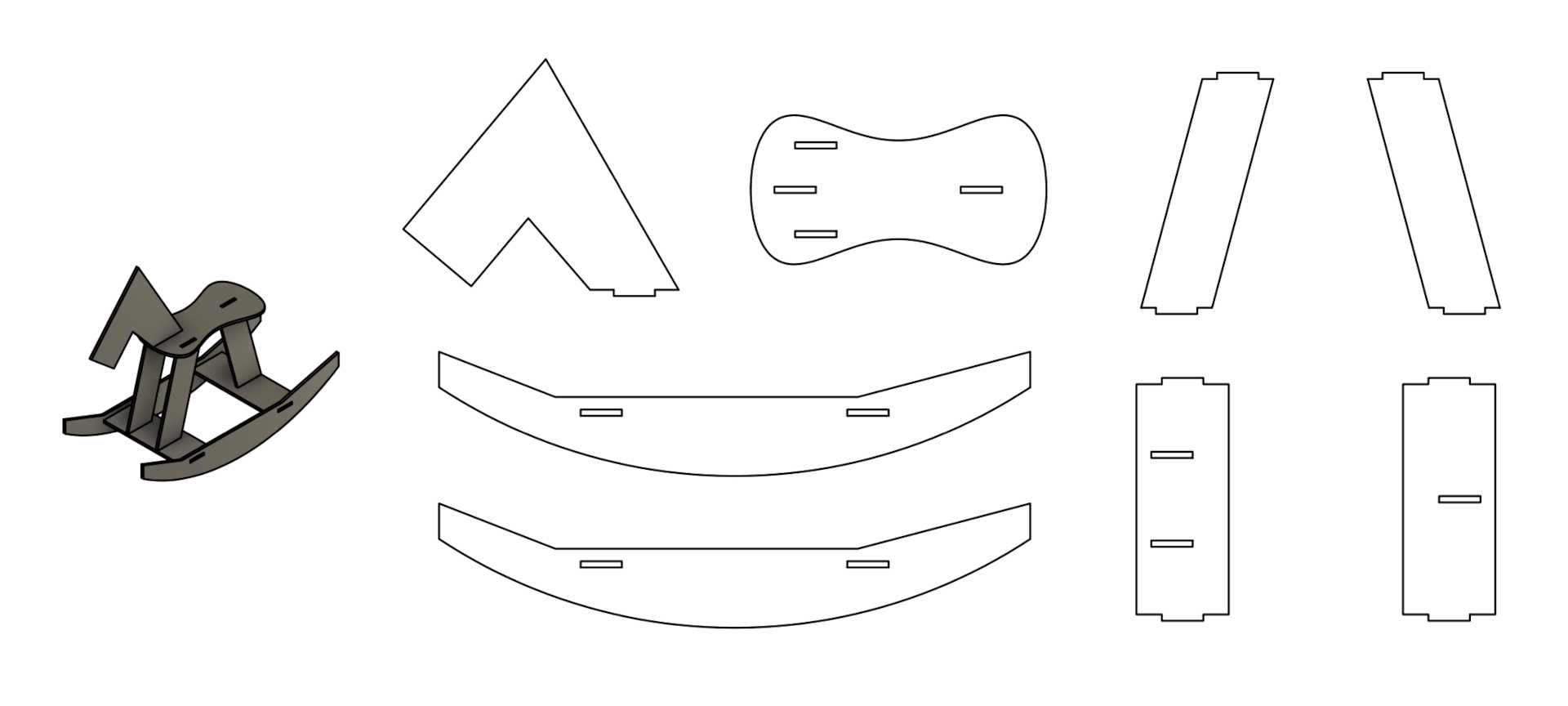

I designed it in Fusion 360 and used the press-fit technique with an estimated thickness of 15/36". In total, there were 9 pieces. These were arranged in Aspire according to Nathan's tutorial and exported as a .sbp file.

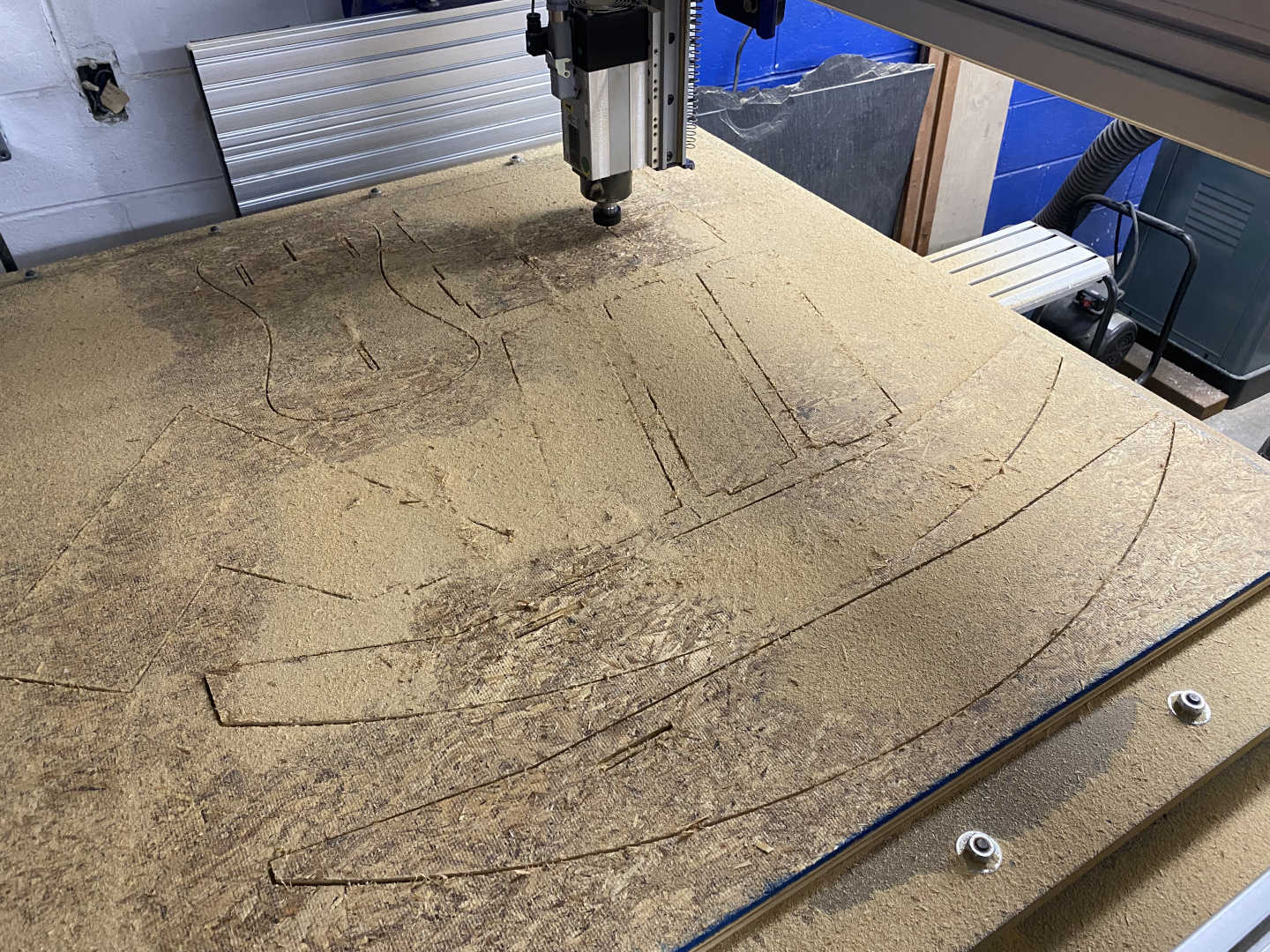

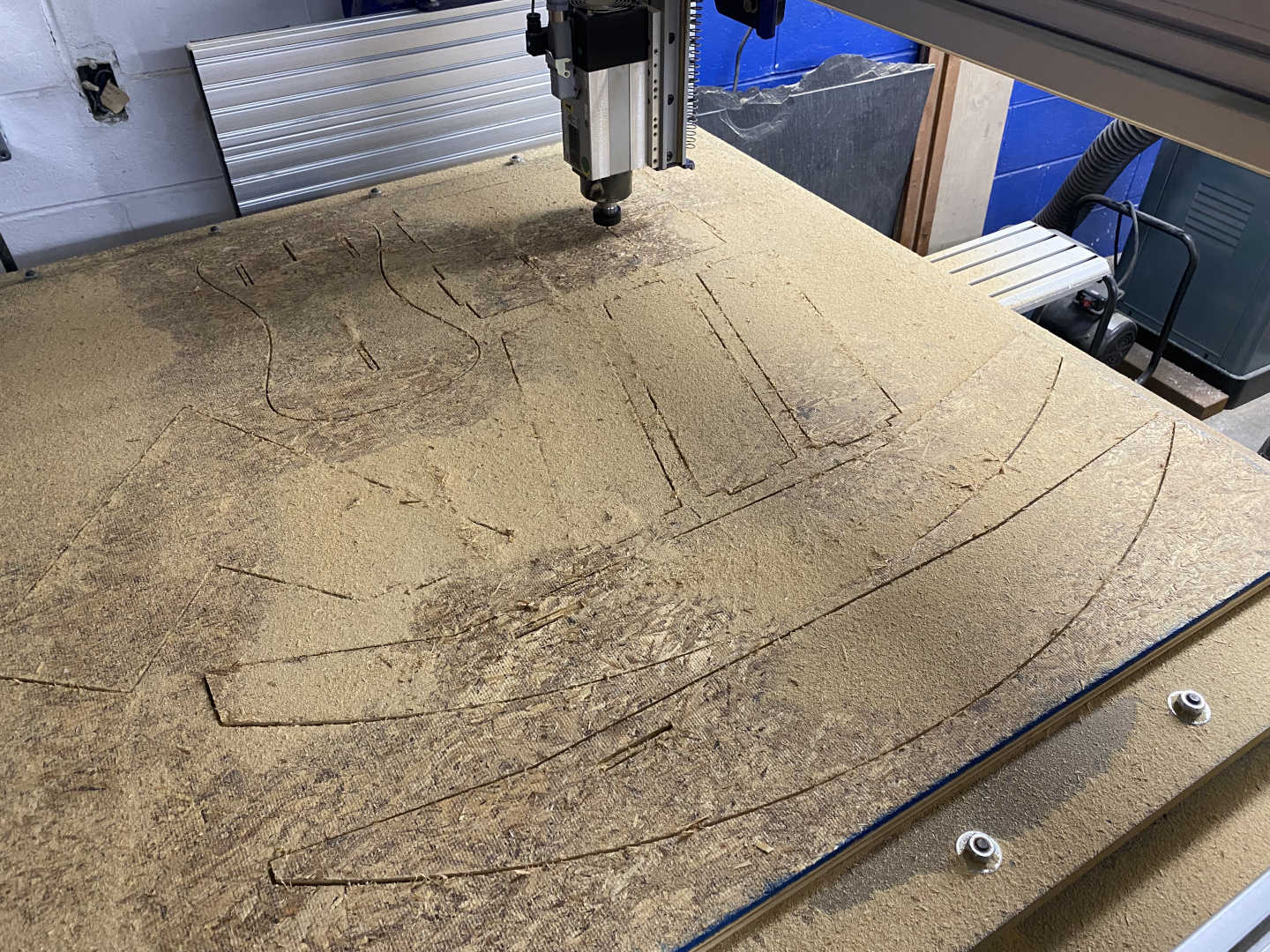

Nathan guided me in using the Shopbot in the basement of the Science Center to cut on a single 48x48" OSB sheet. Assembly consisted of hammering the pieces so that the press-fit joints stayed together.

The finished product!