This week, I explored molding and casting.

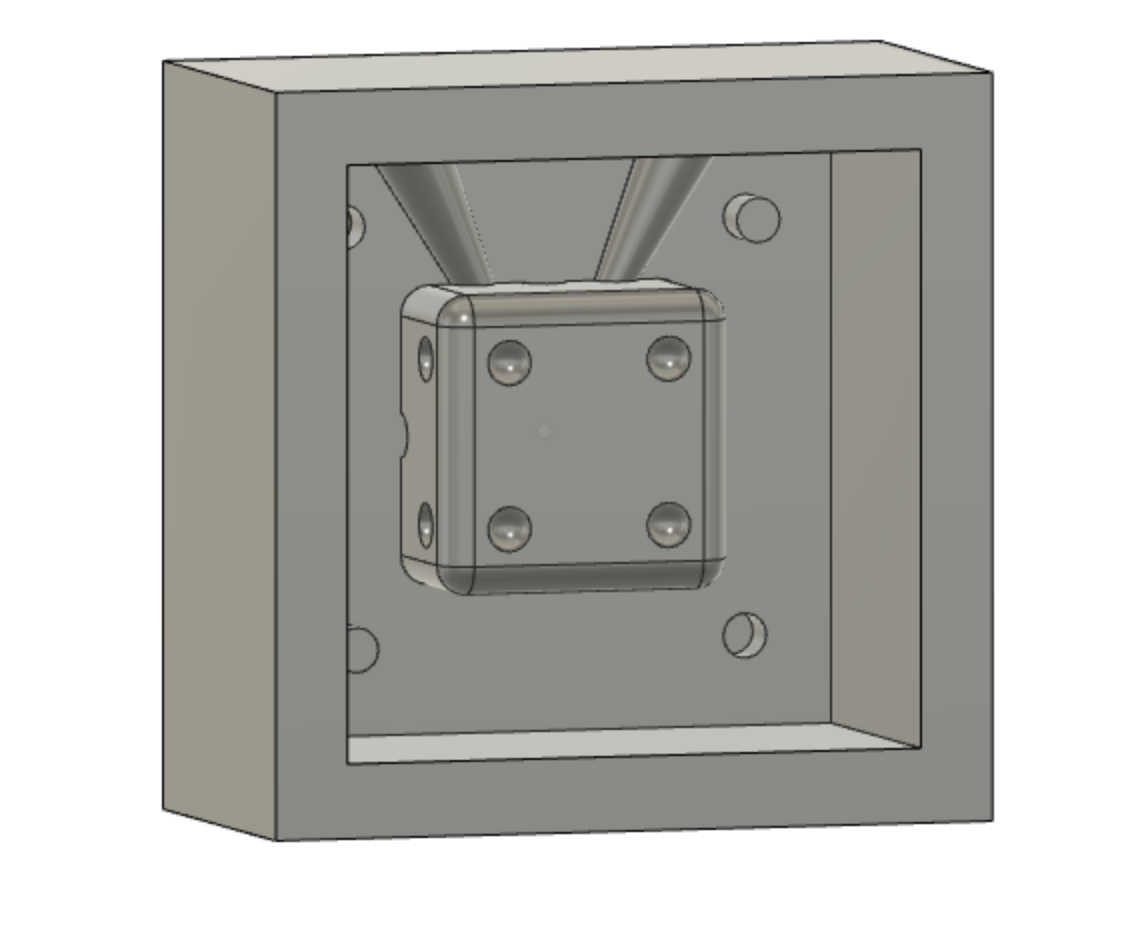

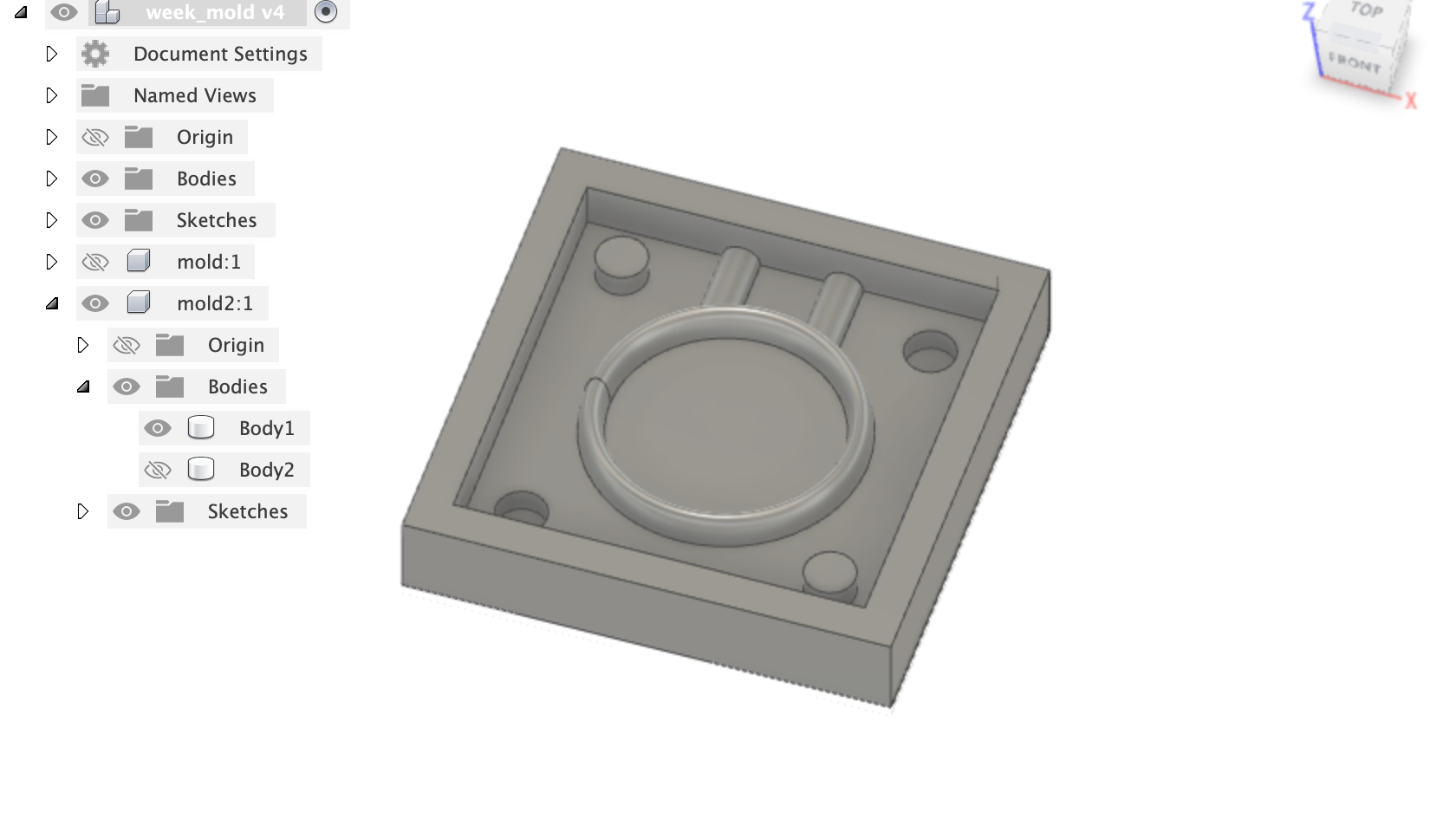

At first, I wanted to make a dice with a skewed expected value depending on the roll axis, i.e. 1 across from 2, etc.

However, after molding the die, I realized that I could not do this with only two mold parts. I decided to go for a simpler design: a ring.

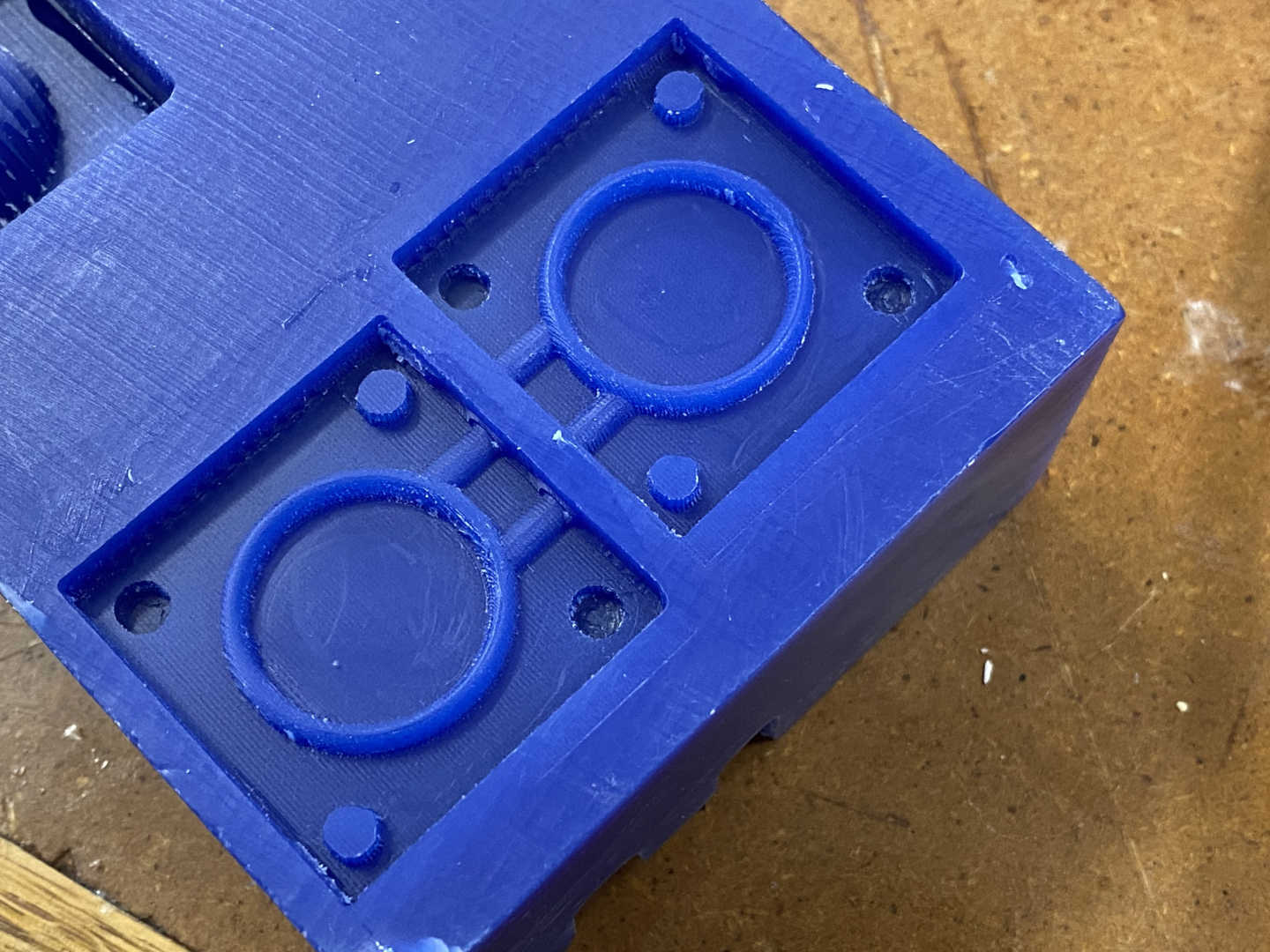

I used the Roland SRM20 to mill a block of wax. The rough cut took about 2 minutes, and the final cut with a 1/64" bit took about 20 minutes. Even though it was a very small design, it took a substantial amount of time because milling is subtractive.

The Oomoo was easy to use, and I did not use measuring cups and instead eyeballed the 1:1 mix ratio. After 75 minutes, the mold was complete and immediately ready for use.

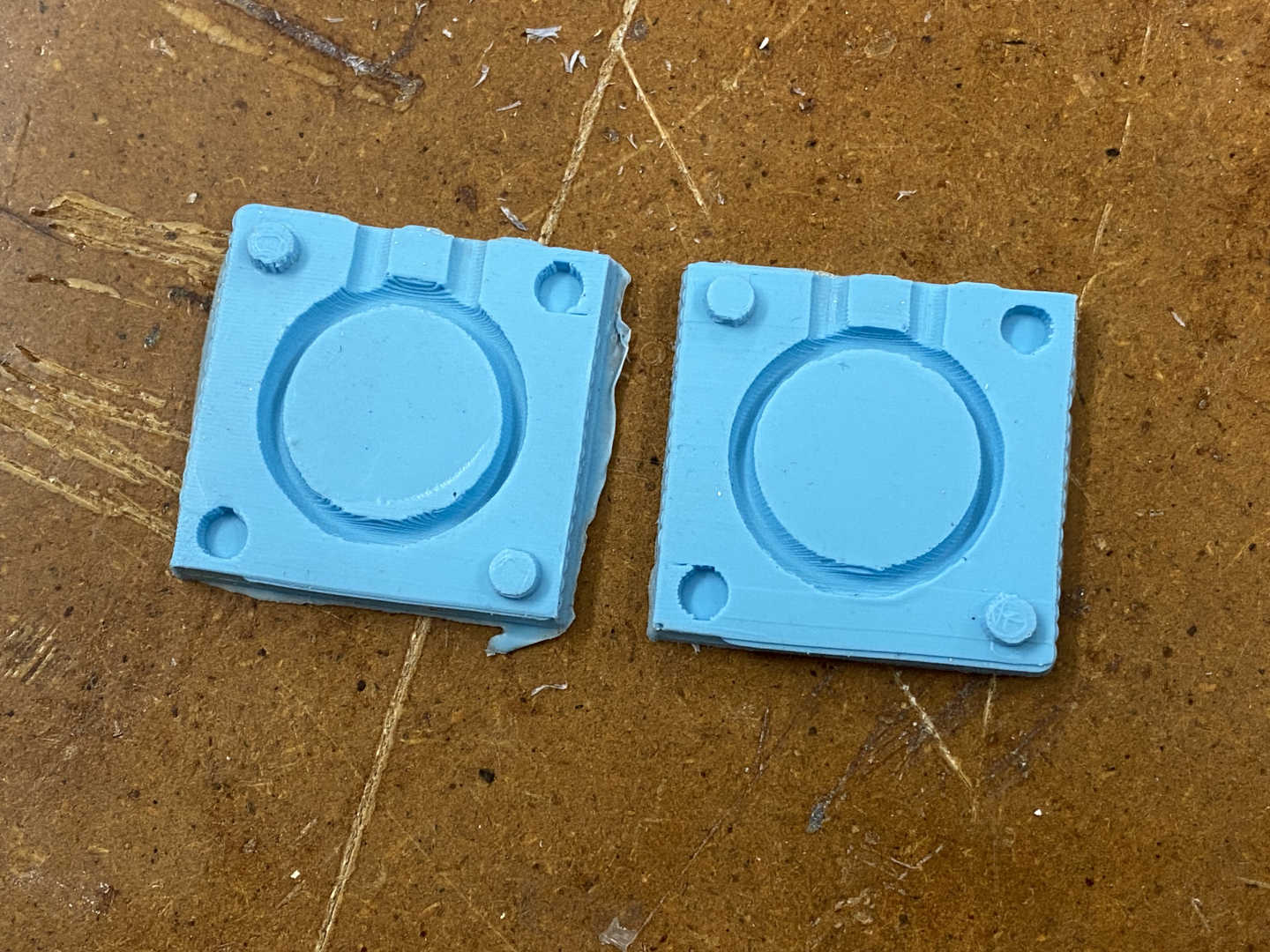

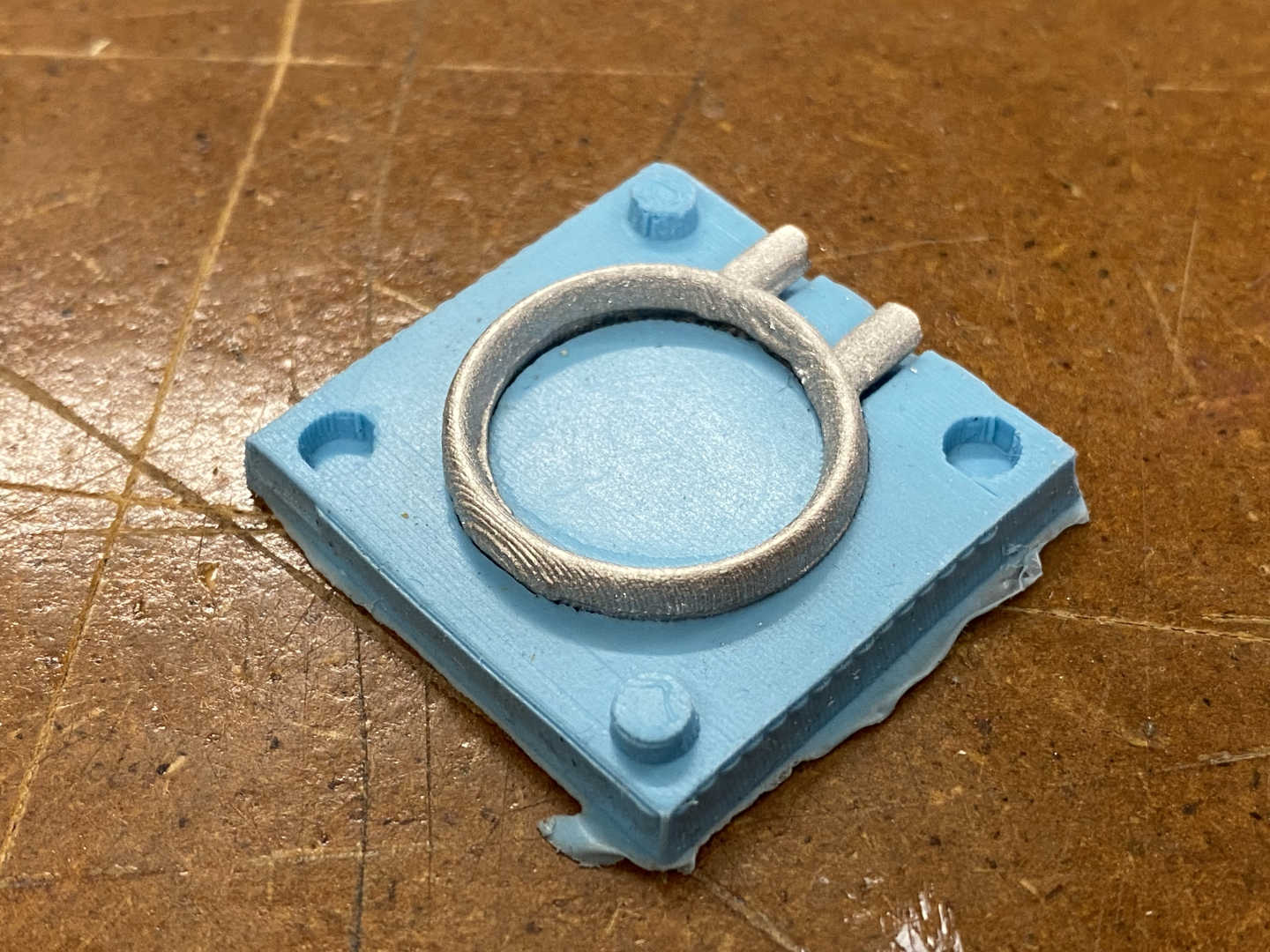

I used a small clamp to hold the parts together and poured a bismuth alloy (melting point ~280F) into it.

I only had to wait one minute and the cast was complete!

I still have to remove the sprue and vent attachments.