This week's task was to design and print a small object that cannot be made subtractively. I wanted to create an earring design. I started with the idea of a chandelier/basket shape. The aspect that made it unable to create subtractively is that the pipes that make up the basket would be hollow in order to be lightweight. I designed the earring in Fusion 360, leveraging the loft and pipe functions. I designed the shape with considerations from the group tasks to characterize the printers we were using. I utilized the Prusa slicer to scale my design down and I tested printing the basket open facing upwards and another print facing downwards. Both failed.

With the initial fail, I thought the problems may be poor bed adhesion and that the size was too small. I wanted the earring to be an inch around or so. For the second attempt, I tried to increase the size x4. The print was okay for the first 25%, but then the bridging began to droop and fall. The pitcures below are from the adjusted and original print size.

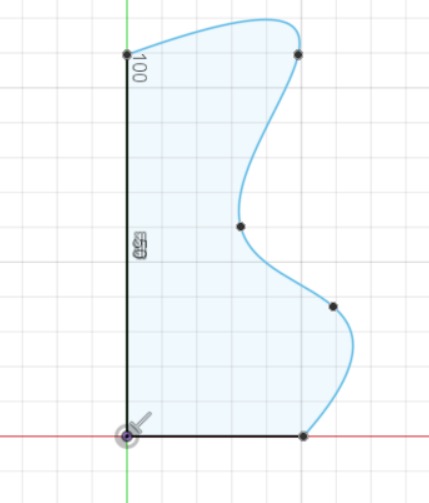

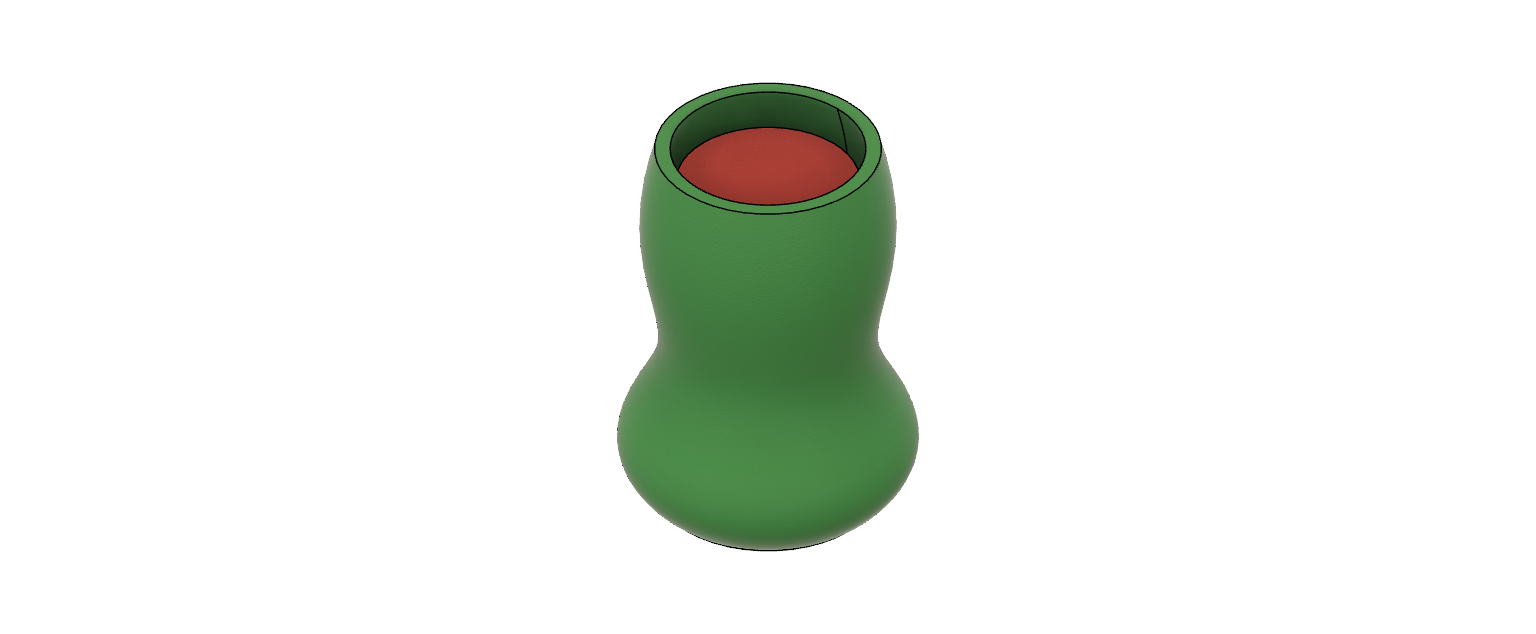

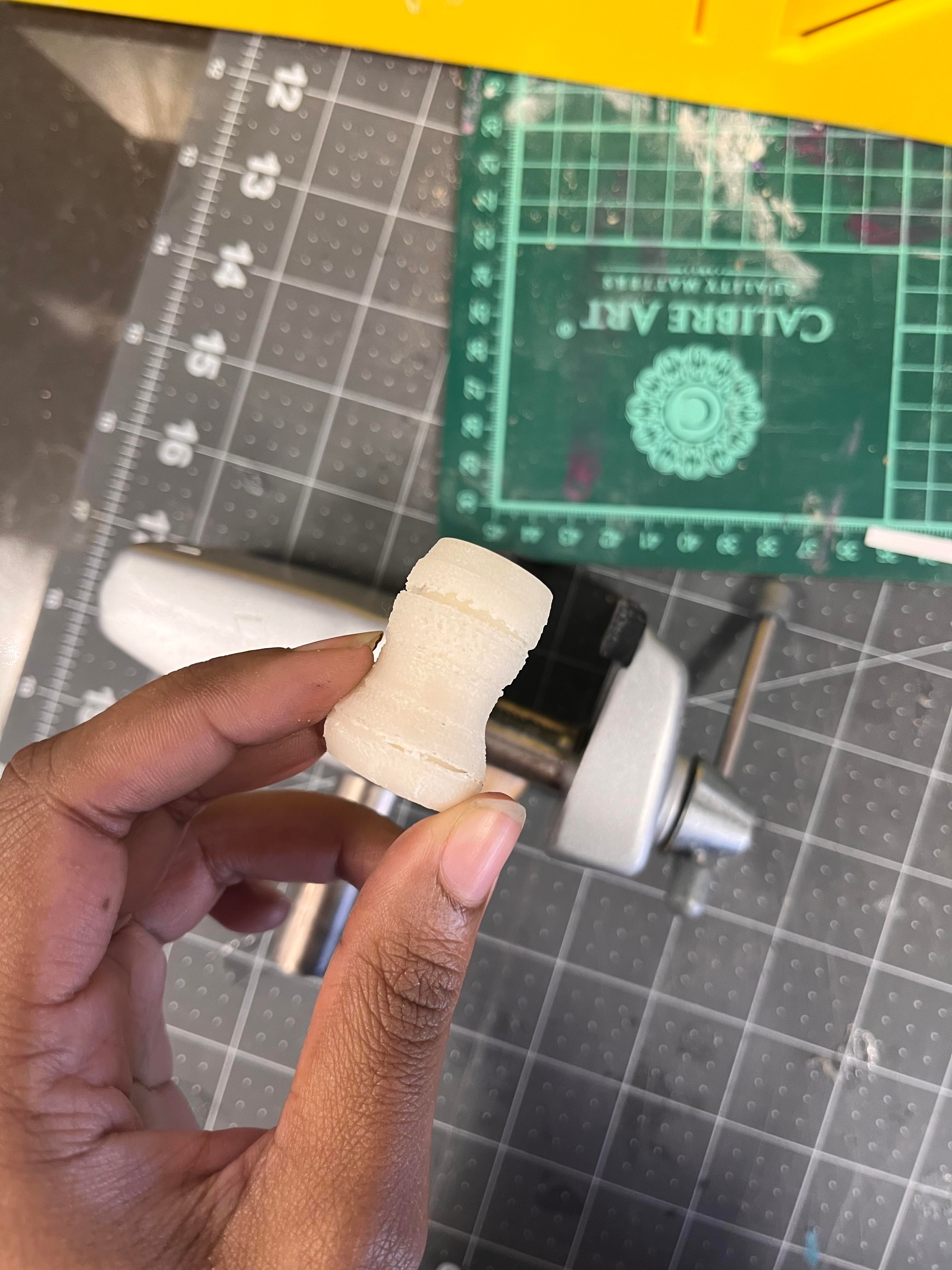

Two other ideas that I designed and tested for this week were a fidget type toy (a smaller curved cylindrical shape with a larger matching cylinder on the outside, leaving just enough room between the two for the outside to spin aorund the inside) and a mini vase with 20% inflil that I used the tessalate function in Fusion 360 to attempt to add texture onto. Both are depicted below.

I had an issue with my print attempts for the fidget spinner. First, the printer paused mid-print when the filament broke, and after I resumed the print, the orientation was off. In my most successful attempt I cut off the bottom layer conjoining the two pieces, and I was able to have the outside layer spin around the inner shape.

For scanning, I tried out various iphone apps including Scandy, Polycam, & Qlone 3D scanner. sing scandy I generated a 3D render of myself. I have used the kinect in the past for 3d scans - both pictured below.