Shelf Attempt

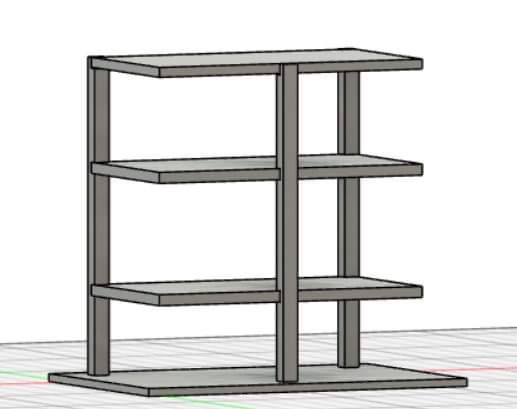

Design

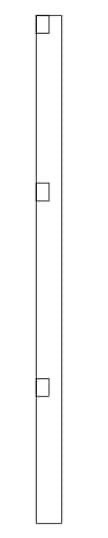

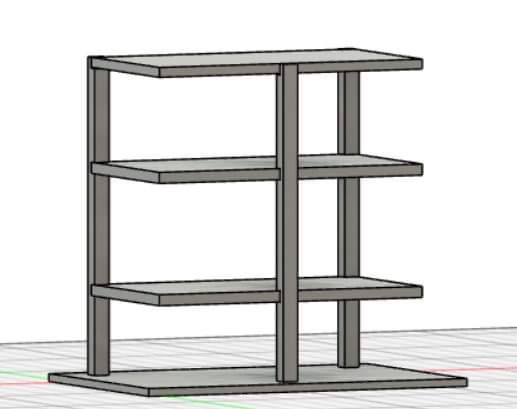

This week I wanted to design a shoe rack. The idea for the design was to cut out upright stands with rectangle slots for shelves to slide into. I used Fusion 360 to design the shelf. A helpful part of choosing to use Fusion was the ability to assemble the shelf and make sure that the pieces would be able to fit together.

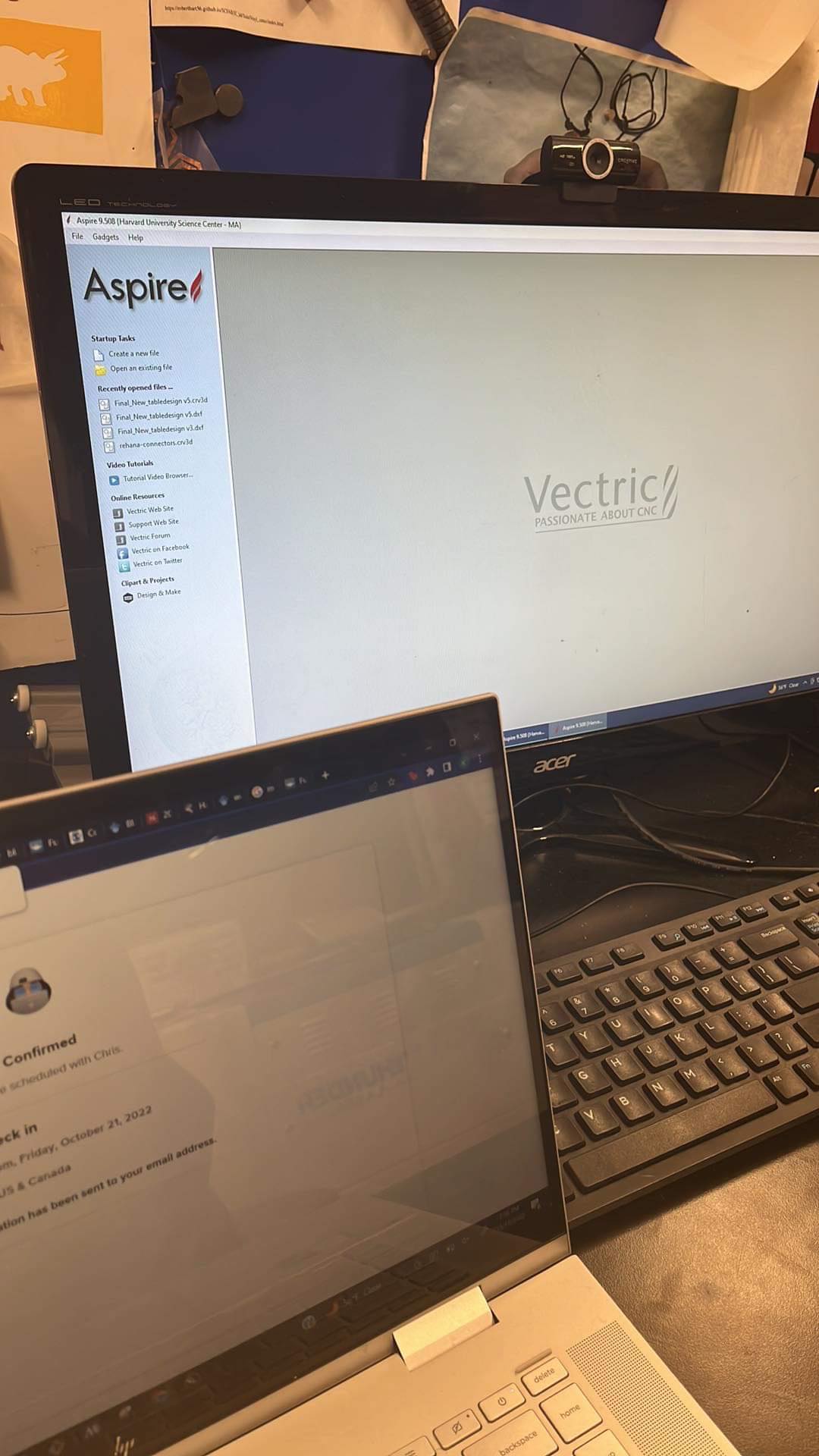

After designing the shelf, the next step was to move to Aspire. I followed the directions from the training and brought my file to the CNC for cutting. I designed the shelf to fit on the smaller 24x18 bed as the shelf did not need to be very large. I received help from a TA who let me know that my cuts would result in weak posts due to the thickness of the OSB and the depth of my cuts into the stands. Based on this, I quickly attempted to create a stool template, went through the same steps and moved to cutting. When it was time to run the file after setting up the machine (drilling down the material I was planning to cut, positioning the cutting head, securing the shield, and turning the key that allows the milling head to run), I was faced with an error of the milling head moving to the back right corner which was way off from the desired position. I checked my units to see if the difference was being in inches or metric, but I was not able to find any issues.

Aspire - Realizing the design wouldn't work

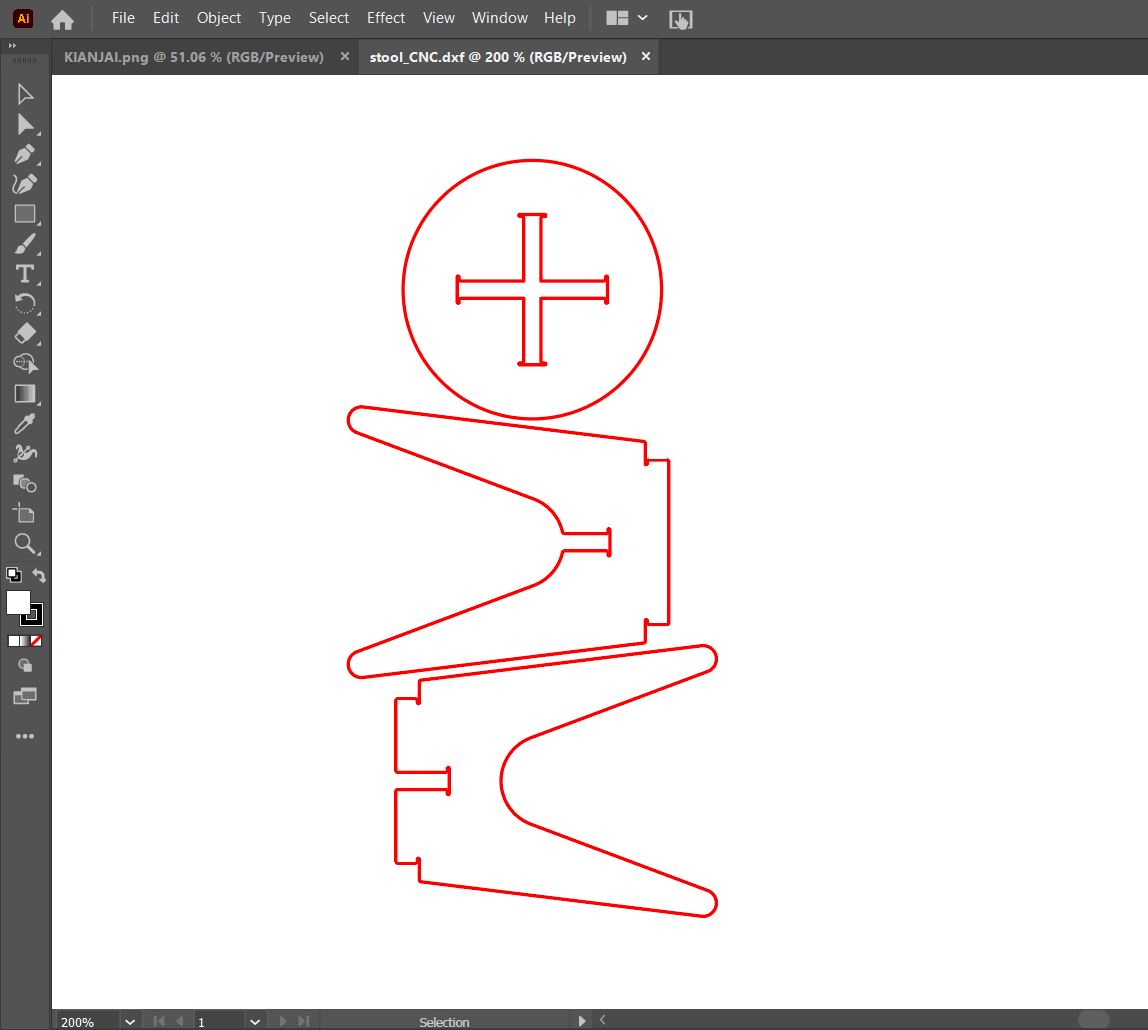

After I prepped the file on Aspire, and recieved feedback from Leo that the design wouldn't work. I quickly tried to design a stool in Adobe illustrator. I chose a stool since it was simple and only 3 pieces. I prepped the file in Aspire and tried it on the ShopBot. I think there was a misalignment in tthe meaurements because the cutting hea on the shop bot went to the back left corner each time that I ran it. My goal is to adjust this and create the stool.

Fail safe: Stool Design