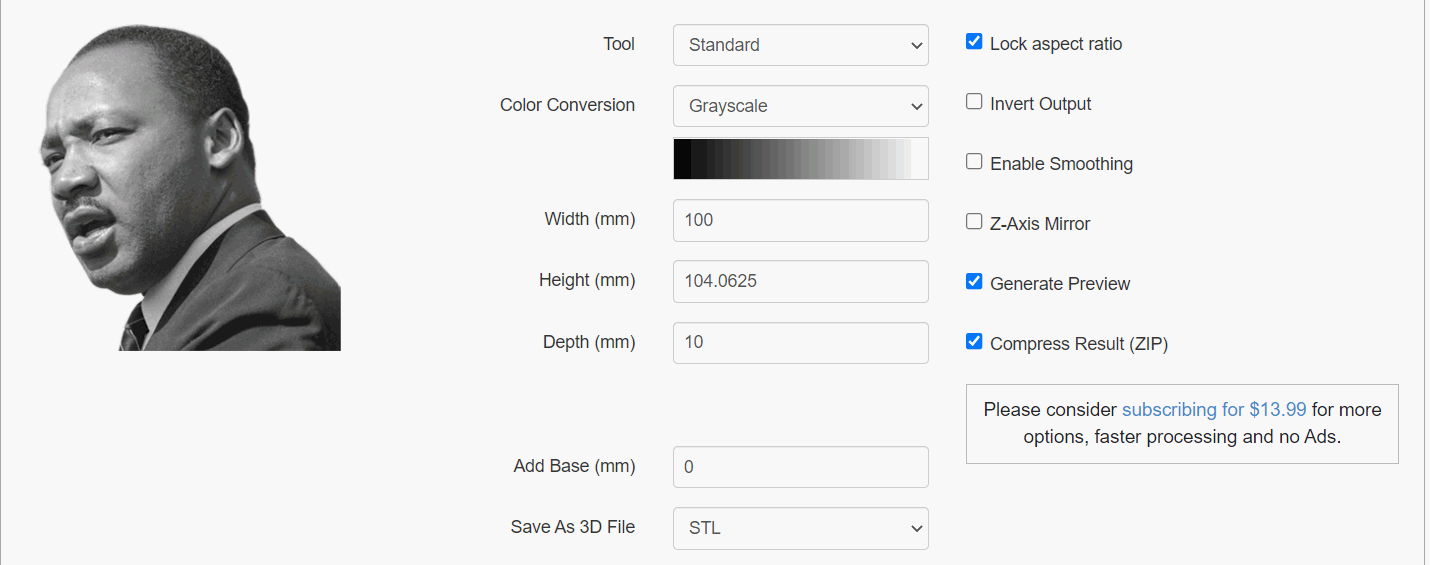

This week I wanted to make a coin with MLK Jr on it. I used imagetostl.com to covert a transparent image into an stl.

This week I wanted to make a coin with MLK Jr on it. I used imagetostl.com to covert a transparent image into an stl.

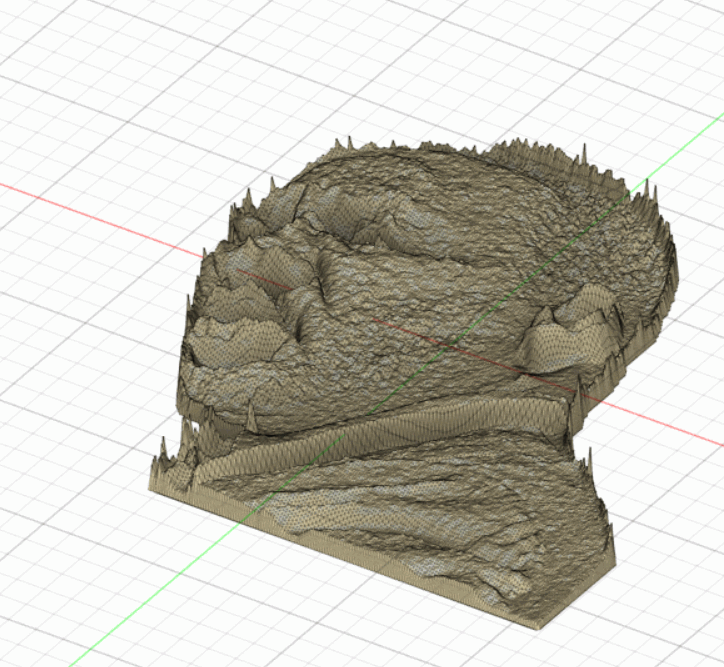

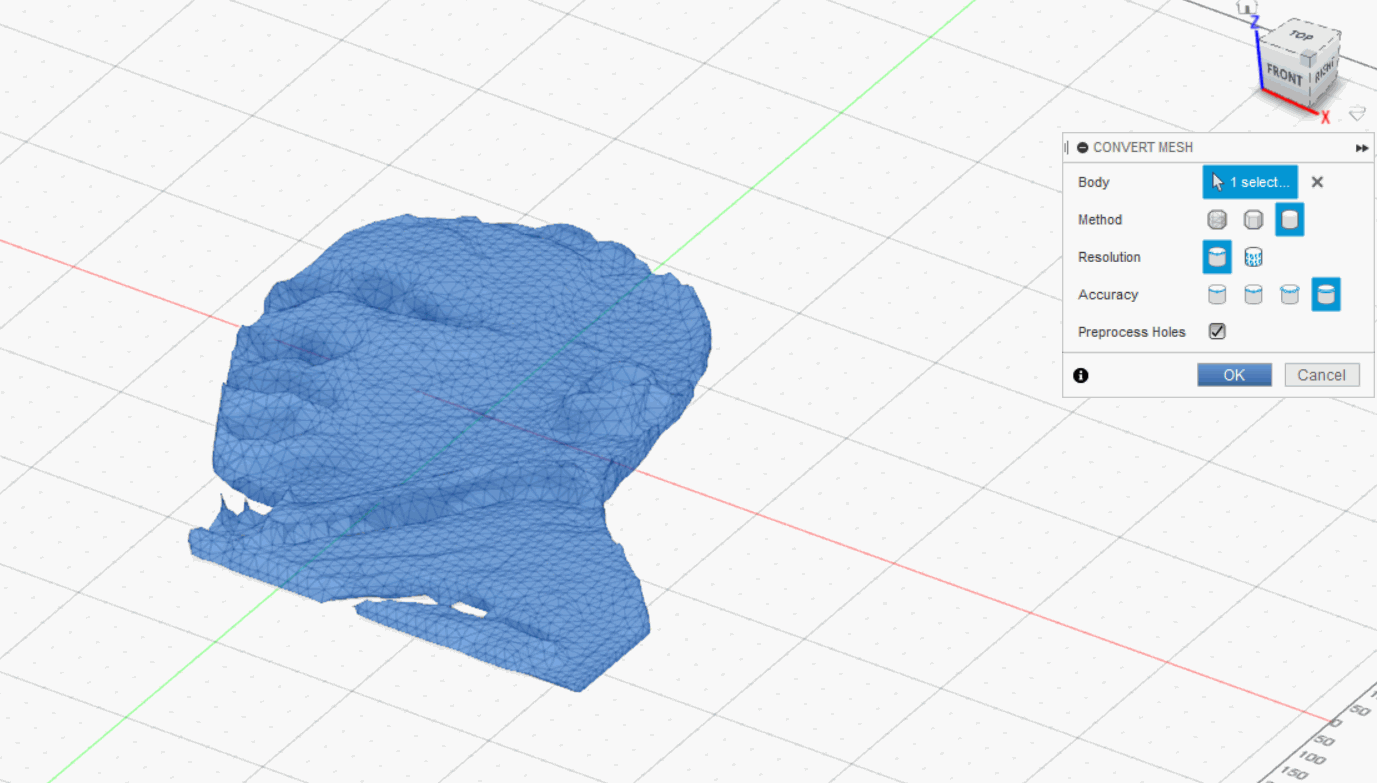

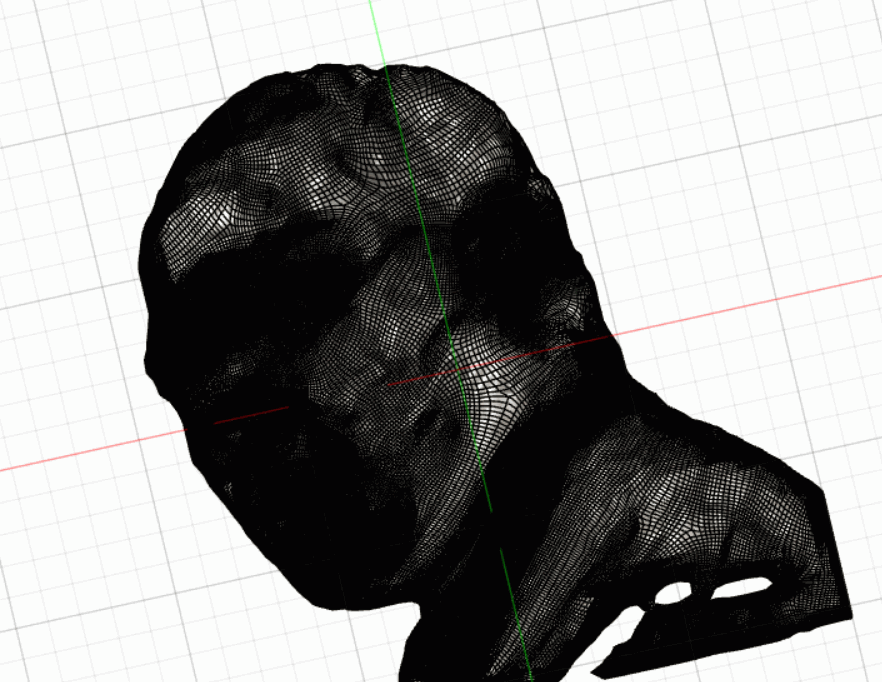

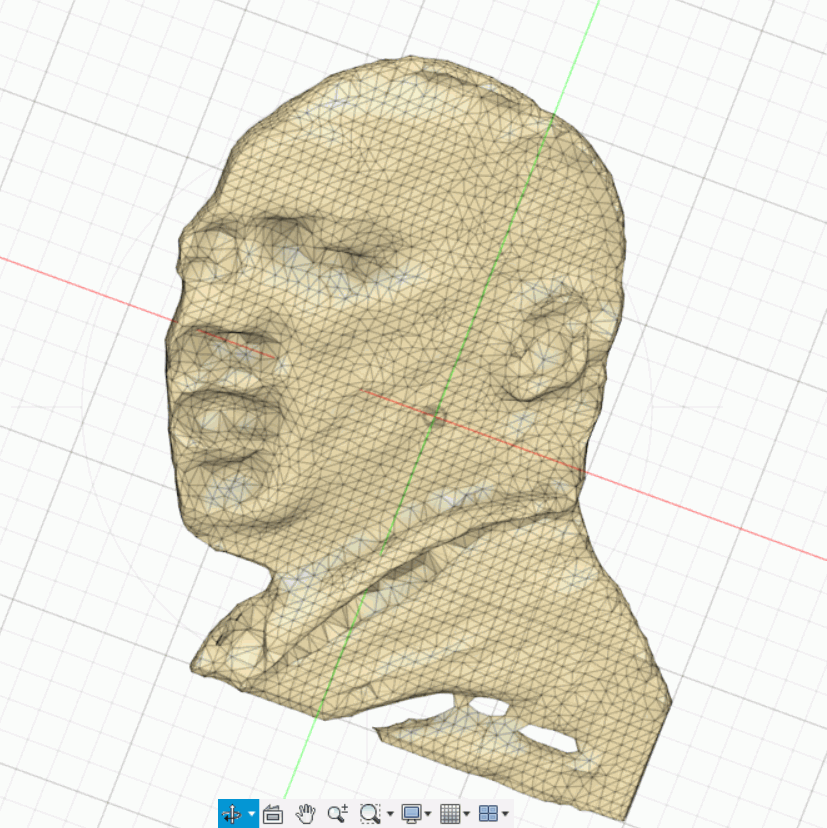

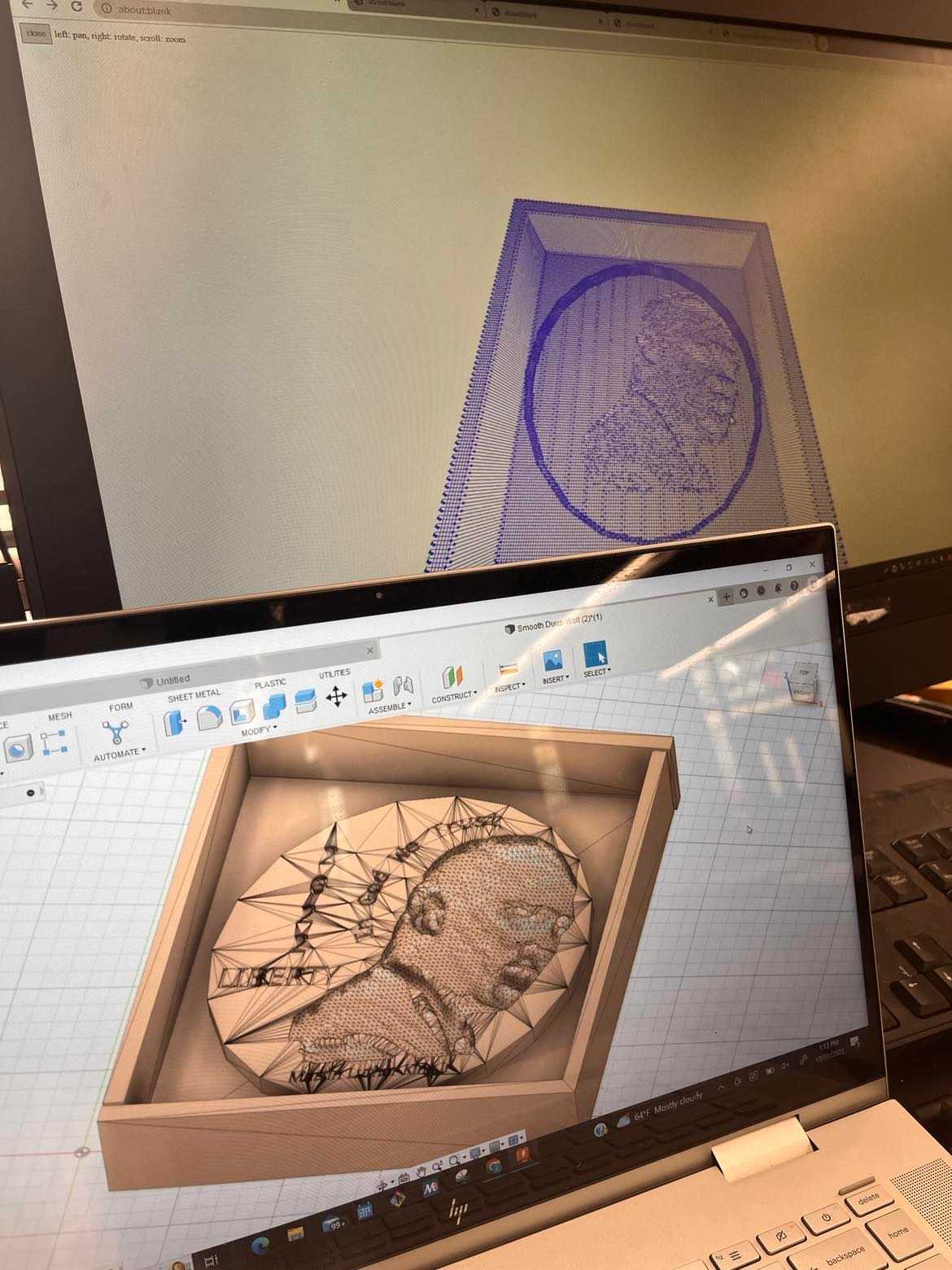

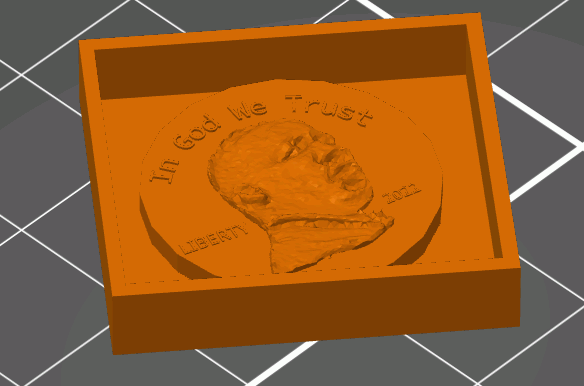

I used imagetostl.com to covert a transparent image into an stl. The generated stl was very jagged and uneven. I used the smooth, repair, and covert tools within Fusion 360 to fix the model. Once the head was ready to go, I added it to a cylinder base and built a box around it. I also added text, similar to a US coin face.

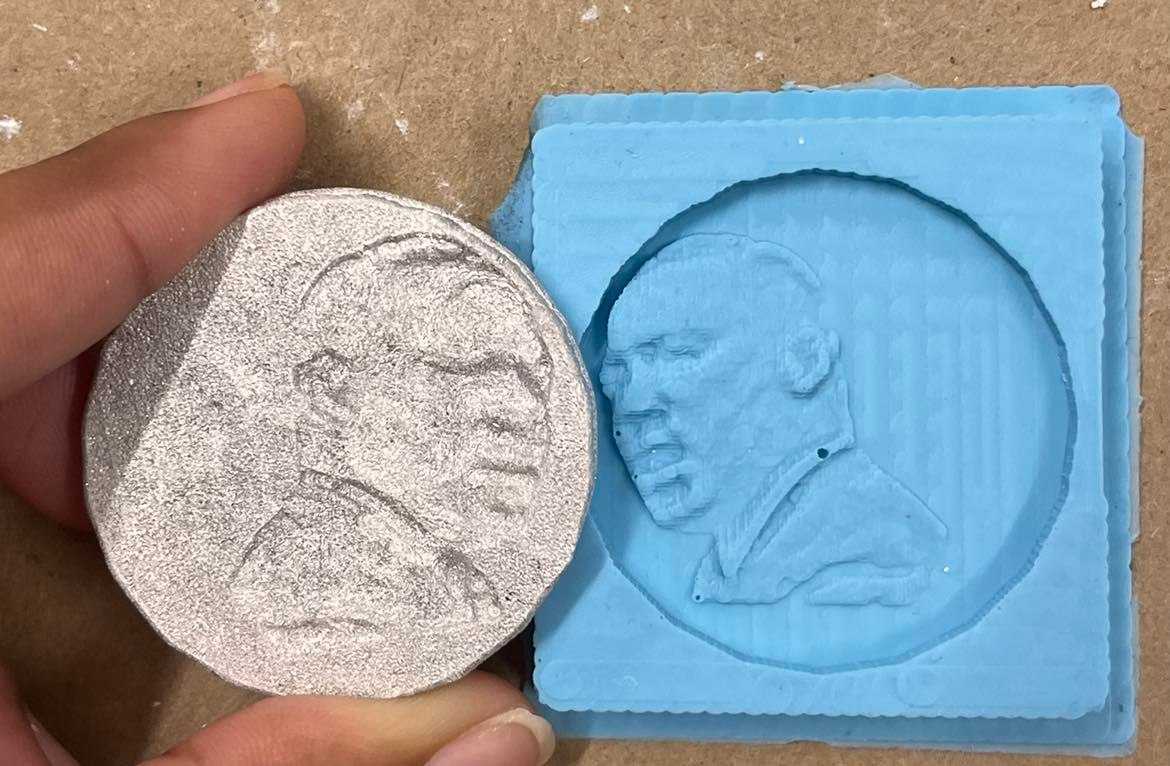

I milled the wax mold in the SRM-20 CNC machine, and the face came out well. The text was too small to be milled out.

I reviewed the safety materials. Then, I used OOMOO-25 to create a silicon mold and casted by melting the metal in the lab (bismuth, I think). I realized that I should’ve designed my wax mold to be raised in order for my silicon mold to be the way I initially desired.

I redesigned the model and resized it, so that I can mill it again in the future. I printed the new model on 2 3D printers, (purple - Prusa, grey - Dremel) just to see how they would come out.

Other casting I did was of my hand. I used an alginate mold to make the cast and plaster to cast. Then, I spray painted it a copper metallic color. It made for nice apartment decor.