I start off to measure what thickness is the OSB material. OSB in the shop is cut down from large sheets, so different pieces with different origin will have varying thickness. The thickness range from 117mm to 121 mm, somewhere slightly less than 1 inches. With the thickness in mind, I need to secure the wood so my designed thickness stay consistent. I therefore designed all hinges With this measurement in mind.

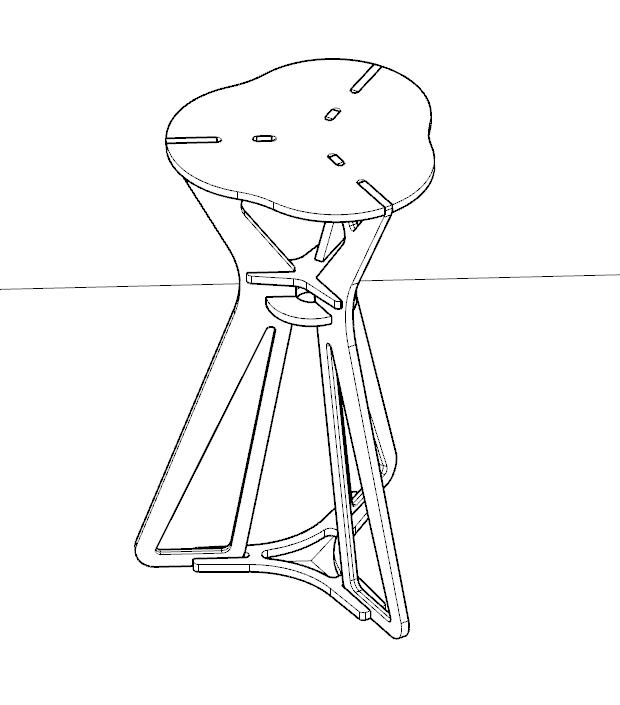

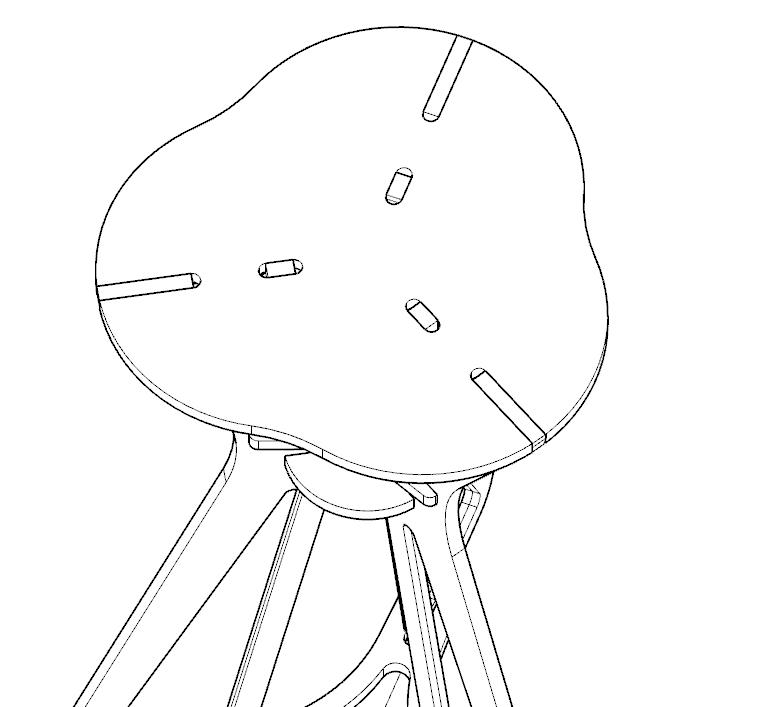

I designed a lily pad looking stool in rhino. The idea is to make the legs feel as light and elegant as possible, like the root of a floating lily. The top surface as a curvy outline, which allow some parts to stick out. I'd imagine they will allow one to adjust themselves upon sitting on the stool.

I learned a lot of CNC plywood furniture design by looking at other designs online. Some interesting joints are formed because cnc cannot cut the inner sharp edges. Hence, to make sure the void can fit a joint, one must over compensate for the corner of a inner rectangle. By doing such, it makes some interesting voids on the constrction.

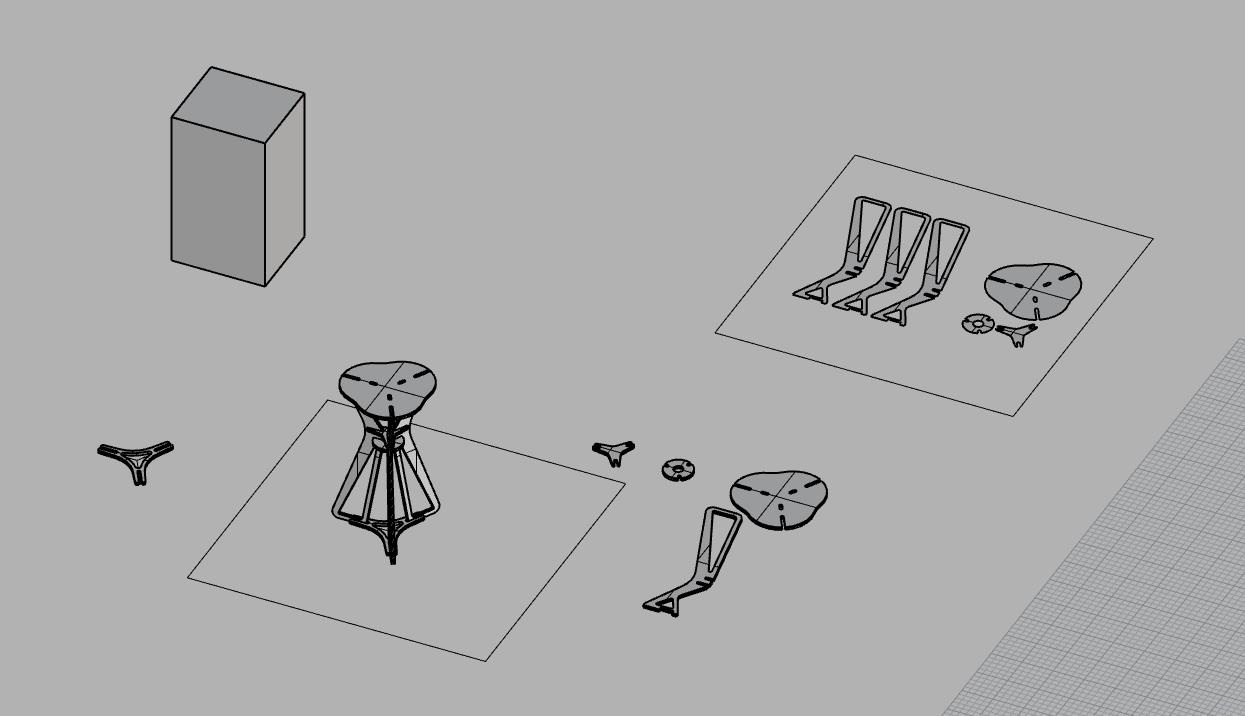

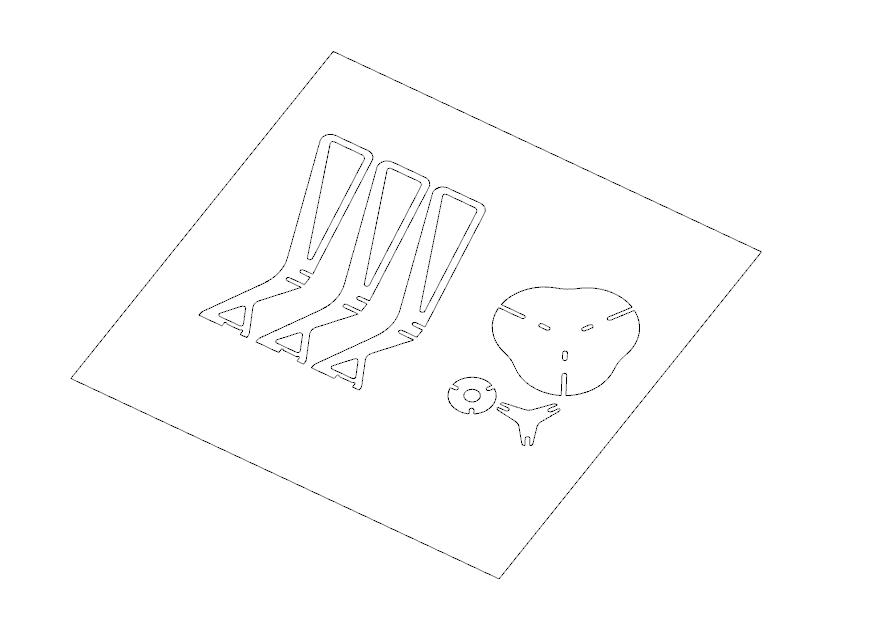

After I finish designing, I arranged all the profiles on a flat surface, and separate inner cut and outer cuts into separate layers.

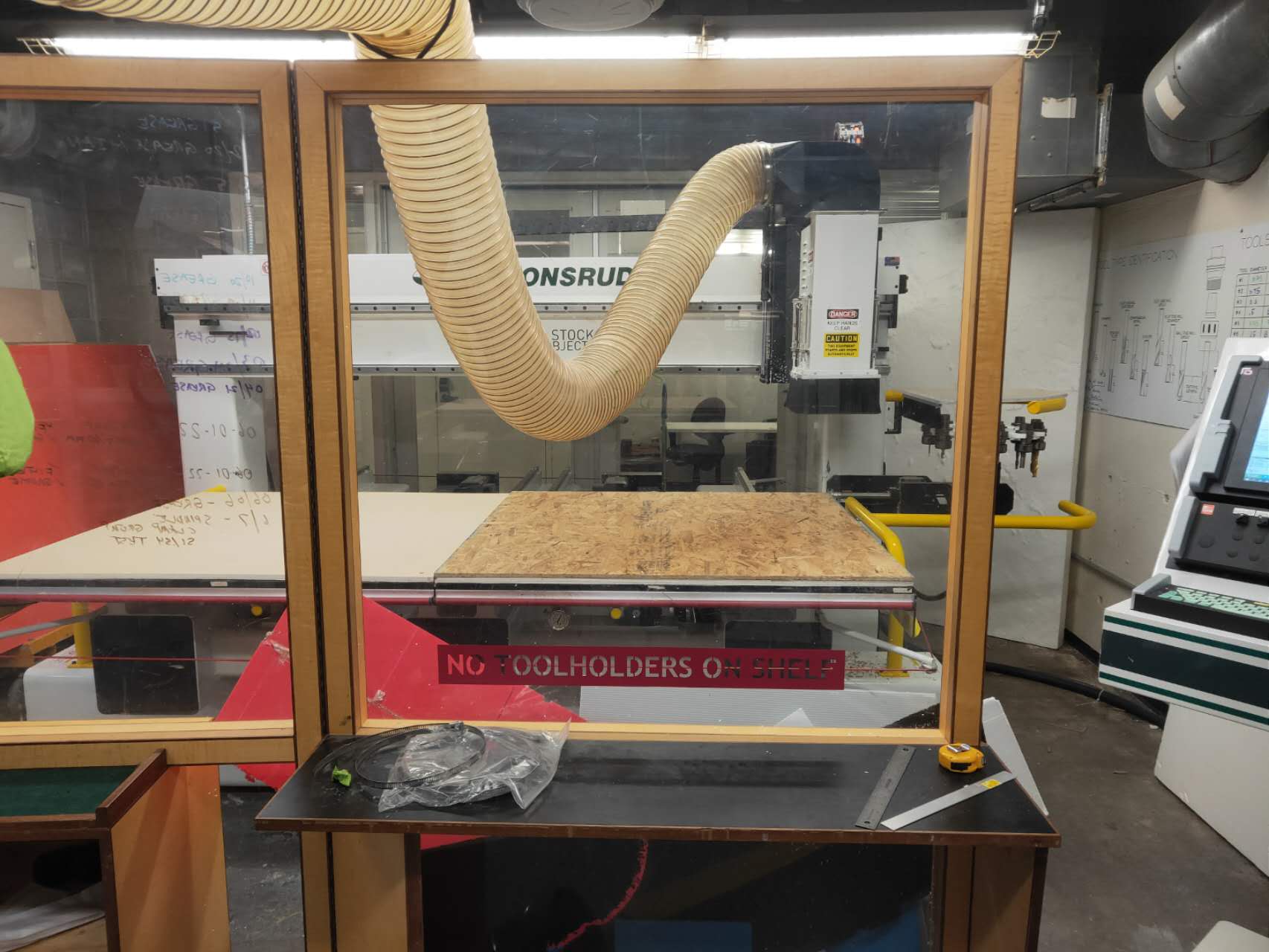

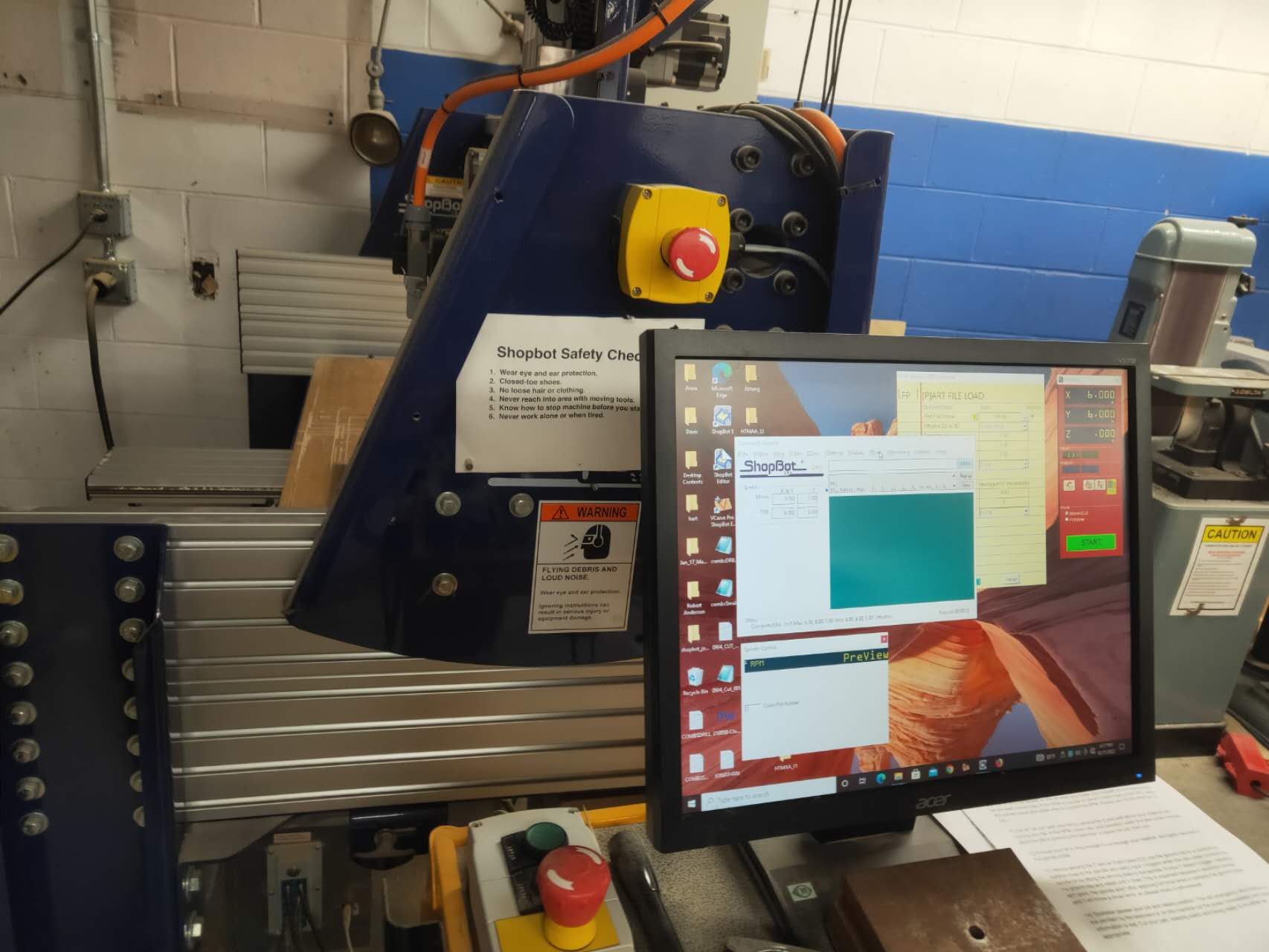

I went to use the GSD CNC which is really high tech. The console use to use an emulator to run Windows XP in order to use the software tho.

The file set up took 2 hours. After it is finally done, I pulled back the glazed protector screen and hid behind it. The cnc will be fully automatic, including changing the bits.

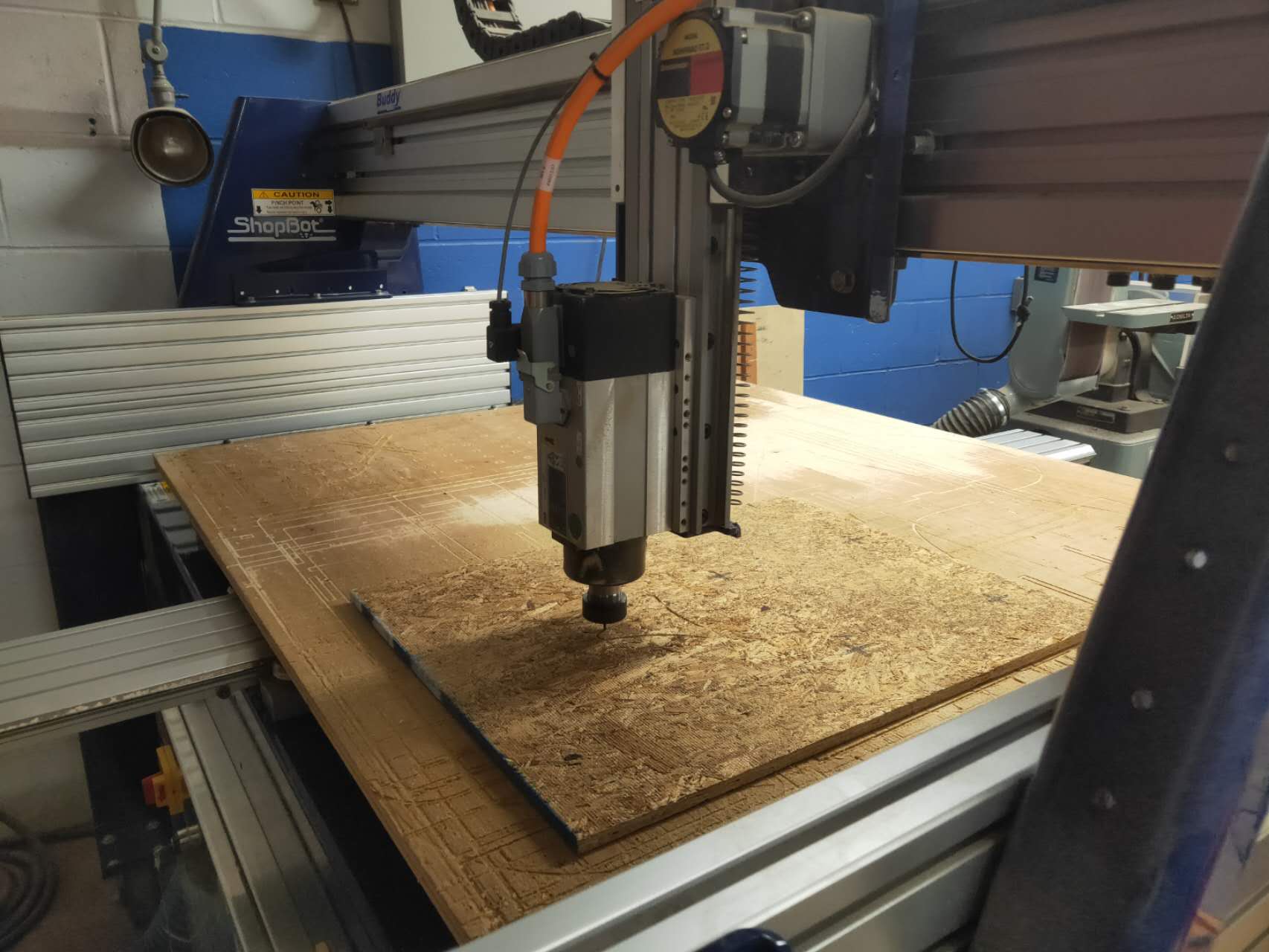

The assembly took 1 hours. The cutting only took 6 mins. The TA used a 0.25 bit for the outline so it was done super quick. I use a hack knife to remove the tabs. Then, I sand the edges to make the finish bearable. When I sit on it, it amazingly can support my weight but it wobbles too much. So I have to add a base plate to secure it.

I went to the Harvard basement shop to use the cnc down there. It is a much simpler machine, but the important thing is it works. many things are manual. Over all it took 40 mins for a small piece.

Here it is finished furniture stool! So much to learn

Here is the link to download the file to make your own stool!

Download furniture Template