The eighth week we are tasked with learning about casting. We would need to design a wax mold for a silicon mold, and cast plaster (hydrostone) With the silicon mold. Bascially we are mailling out the positive geometry out of the wax block, then using the wax block to cast a silicon negative mold, then to cast the actual positive geometry again.

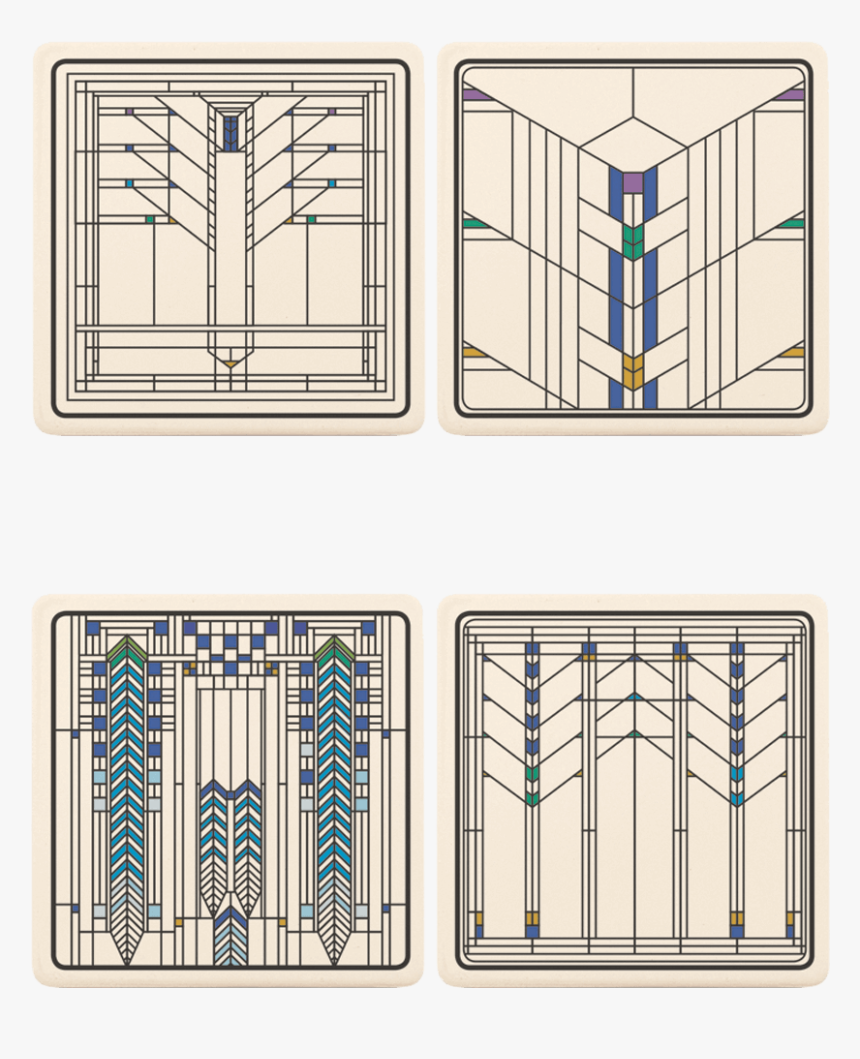

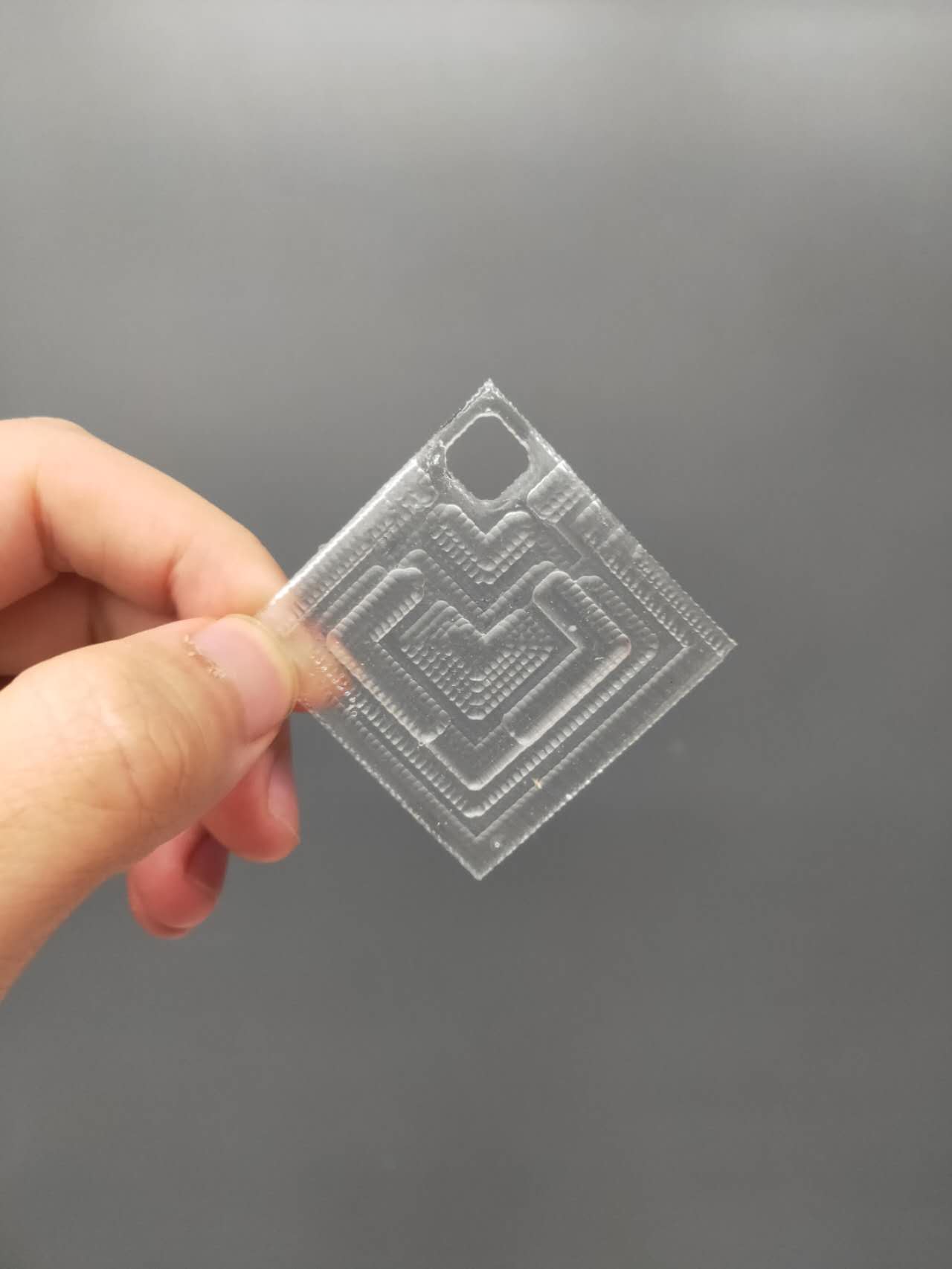

I want to make a Frank Lloyd Wright keychain thing with this week's skillset and tools. Here are some other patterns i've found

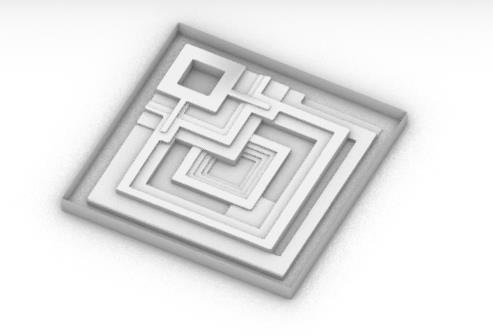

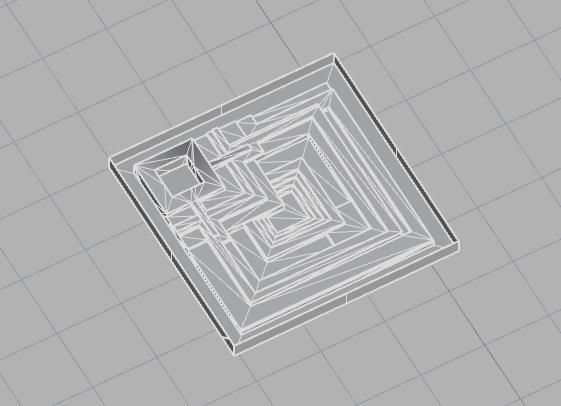

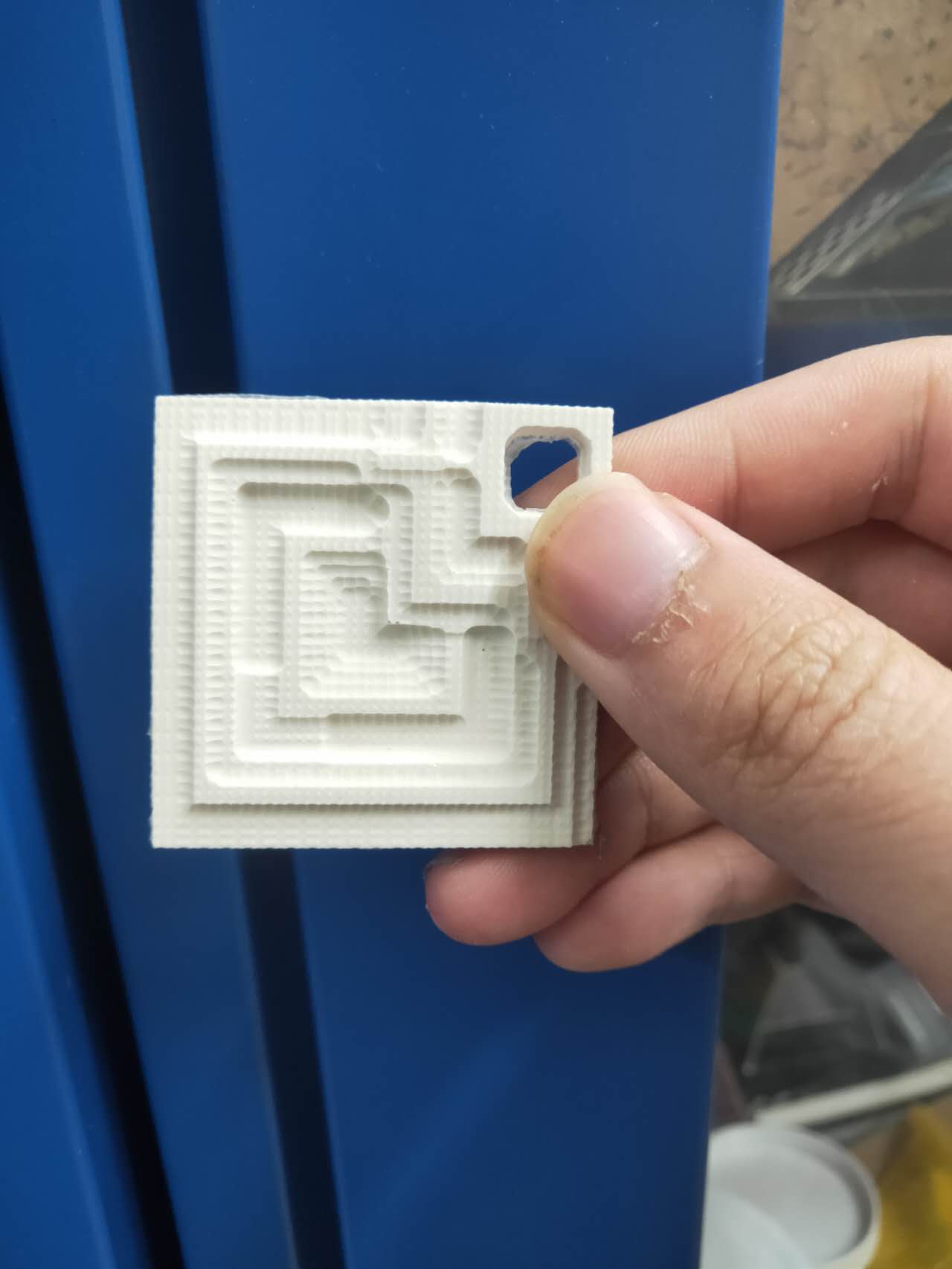

I start off by following a Frank lloyd Wright pattern. More exactly a Wrightian textile block. I download a rough model online and I started to modifing it a bit to make it more complete. My job is also to build a small skirt around it so the entire geometry is now embedded below a surface.

The mailling took a long time, and I made a bad mistake. I used a pointy bit instead of a flat bit. Next time I need to use the flat bit since that's the only way I can get flat surfaces. For now I decide to keep my wax cast because the pointy bits caused a very nice pattern on the surface.

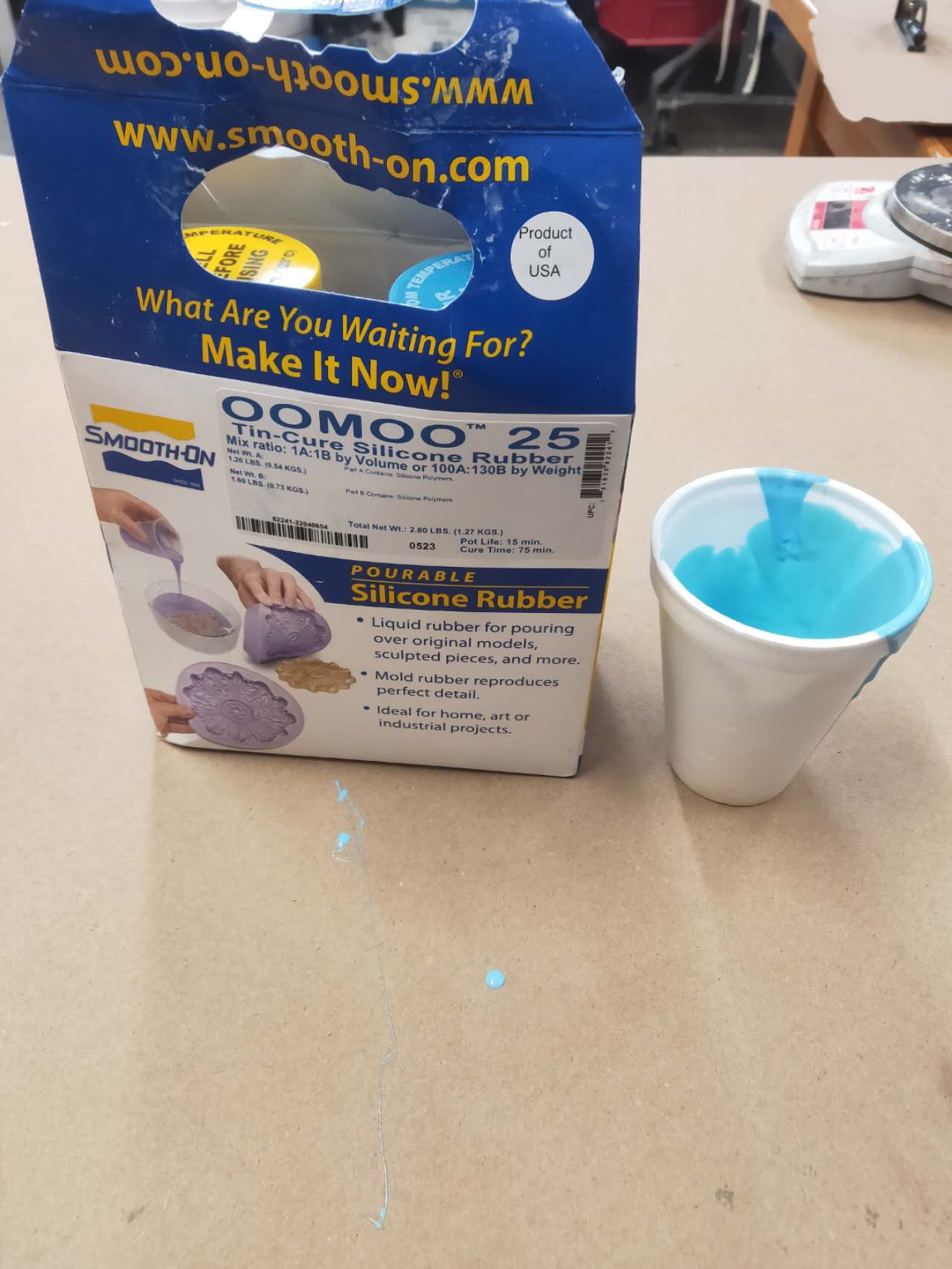

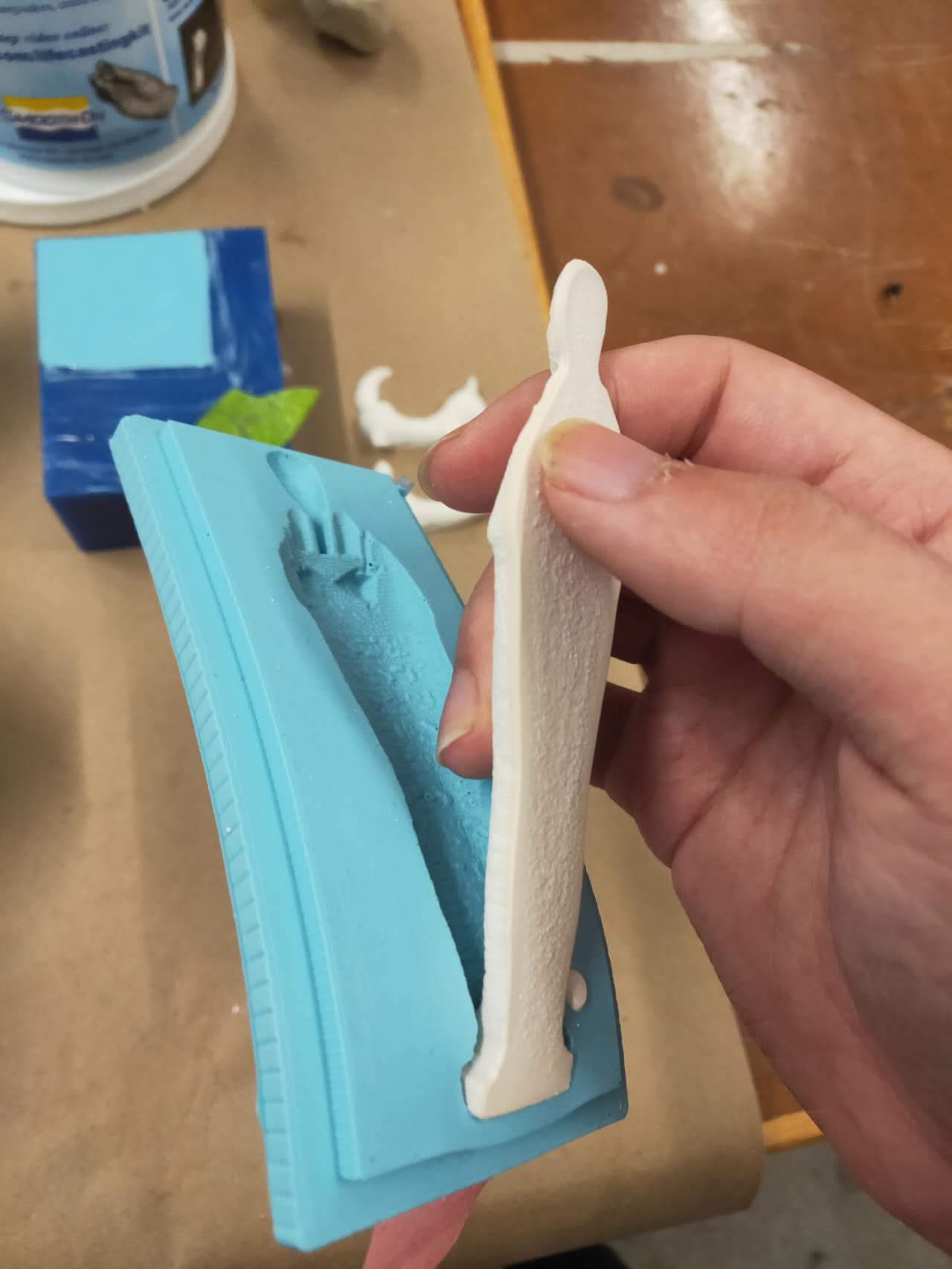

The silicon casting is not hard. I've done it before. You just need to pour half and half of each bottle and mix them very well. Pour in the cast slowly and wait for a few hours. One would need to pour slowly at one location allowing the silicon mixture to spread out slowly in order to make less air bubbles.

After a day of curing I did the casting. We are using hydrostone, which is a kind of plaster. The ratio is about 30 water to 100 powder. I have to really eyeball it and adjust the mixture. You have to pour powder into water, while mixing, not the other way around.

I have a bit of extra mixture so I dig up a recycled mold and cast that too. It is an egyptian mummy.

The results look good!

Here is the link to download the file to make your own cast!

Download Template