This week’s GROUP assignment was do your lab's safety training and test runout, alignment, fixturing, speeds, feeds, materials, and toolpaths for your machine. This task was to determine the limits joints in our model and the bounds of the bed size and materials we had access to.

Working with the entire Harvard Section, we started by printing incrementing overhangs with our printer, gradually increasing the angle. We determined that a 45-degree angle is the maximum limit for an unsupported overhang. Our test models also decided that geometry thinner than .5 mm had a high risk of breaking and, therefore, could not be trusted. Additionally, the printer can print a sizeable rectangular gap with ease, but curved or rounded forms on the y plane most often require support material.

The most crucial design characteristic is understanding what elements in your model will need support material and if you can remove the material after its production. Some machines can use dissolvable support material, but this can require a decent amount of time. I decided to orient and design my pieces using angles and forms that would require the least amount of material to remove after its printing completion.

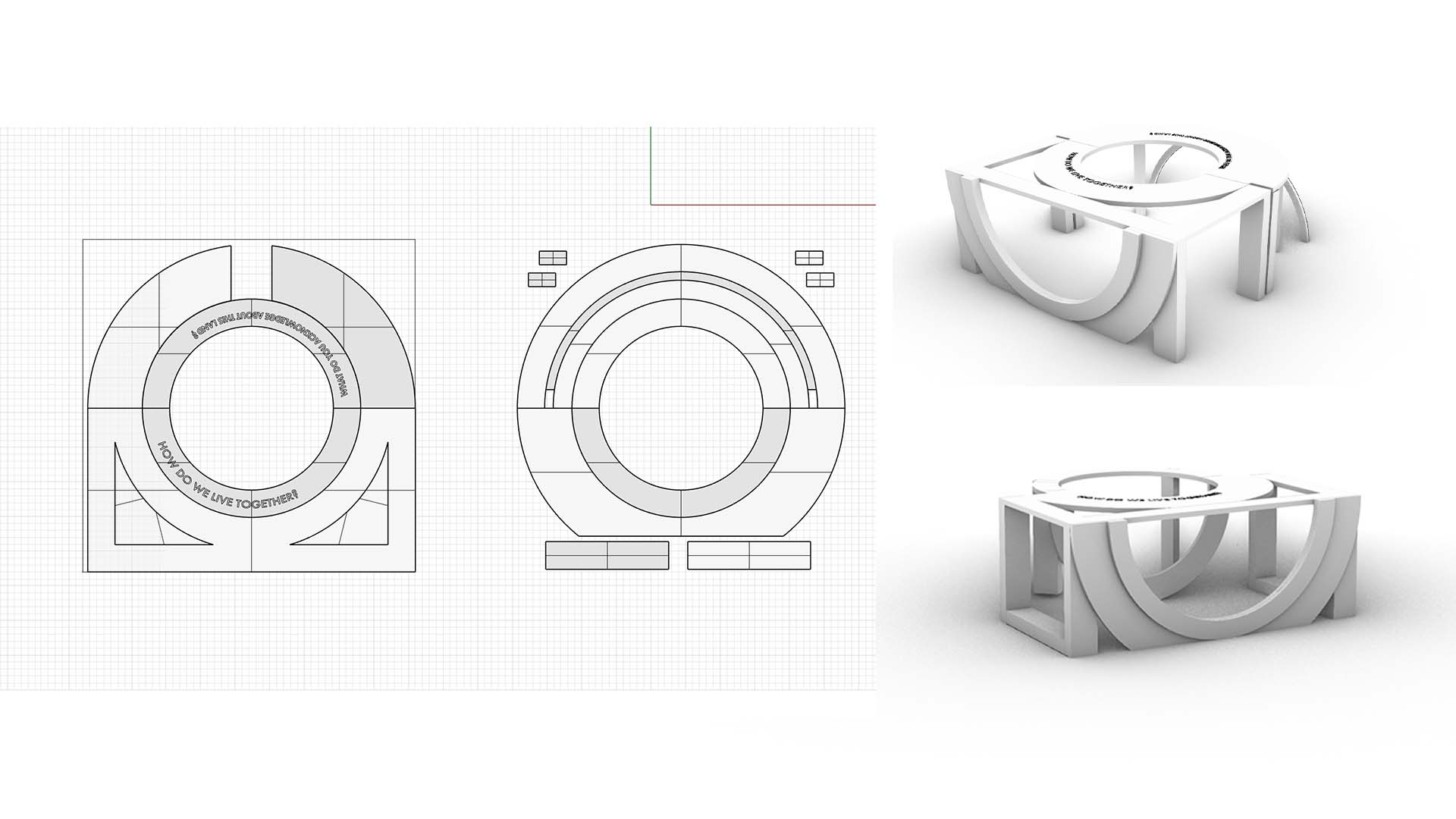

Individually, we were assigned to design and 3D print an object that could not be made subtractively.

I used Rhino to 3D model various items starting with a simple nested message in a literal ‘Easter egg,’ which could not be printed subtractive Ly as it was hidden beneath a solid surface. Can you guess the message? Next, I was practicing my Cad skills and created what I am calling a futuristic napkin holder. Working with the Prusa printer took some love and care. I learned it takes multiple trial efforts to get the setting just right. The most common issue is when the 3D printed object pulls off from the bed and starts moving with the nozzle. I would wait until the first few layers had set without any peeling to leave the lab and return halfway through the printing process. Even if the first layers are successful, there is no guarantee that your future will not hold unforeseeable issues!

Additionally, we were assigned to 3D scan an object (and optionally print it). The subject I chose for the photogrammetry/lidar assignment was organic flora (e.g., flowers and plants). I appreciate the dissonance in creating a digital rendering of organic organisms. Construction of buildings and products in most modern production pipelines starts digitally. Therefore, I aimed to use the photogrammetry/Lidar process to digitally capture what is impossible to render in its natural fidelity. I believe these rendering technologies aim to increase accuracy and create a complete simulation of nature. Inspiration for this study comes from the uncanny valley effect, the glass flowers at the Harvard Museum, and Mandelbrot sets. As you can see from the images, there are numerous digital artifacts in the models, highlighting the constraints of the machines and referencing post-digital theory from writers like Douglas Davis.

Lastly, I wanted to record the difficulties and unpredictability of working with 3D printers. This disaster resulted from my 3D object falling over during the last 10 minutes of a 17-hour print. During its failure, I was away from the lab, but even if I had been on-site, I don’t think I could have salvaged the print during the process. Fortunately, I could remove the Spaghetti residue and still create a usable object since the failure happened during the final stage of the print. This was lucky but resulted in my print not having a smooth finish on one side of the object.

I loved getting to 3D print and Lidar scan as this project was fantastic encouragement to refine my digital modeling skills. I am looking forward to being able to design more household items and creative decorative forms with a 3D printer.

Hopefully, I will get the chance to use other larger machines with varying and potentially flexible material to broaden my possibilites with 3D printing