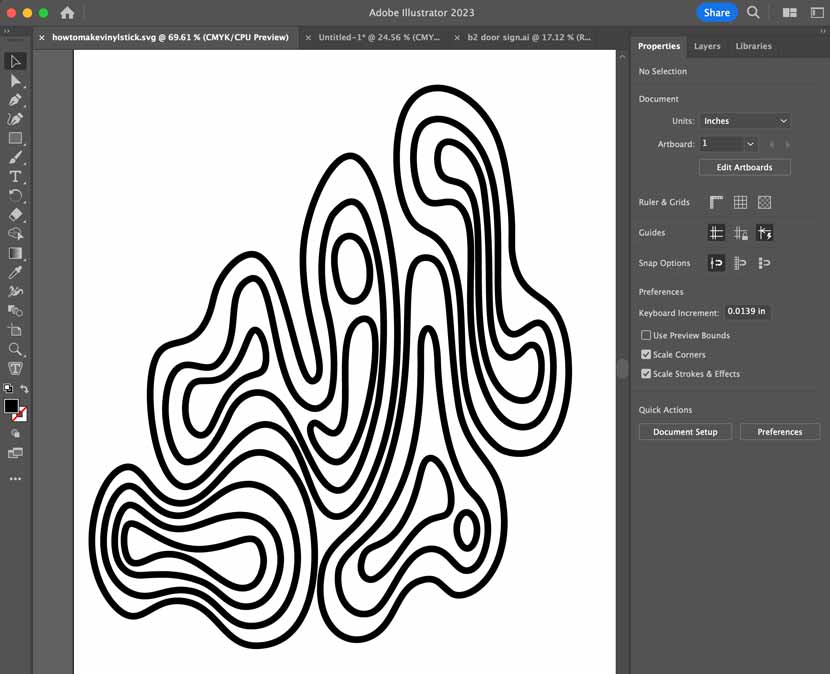

Illustrator File for the Vinyl Sticker

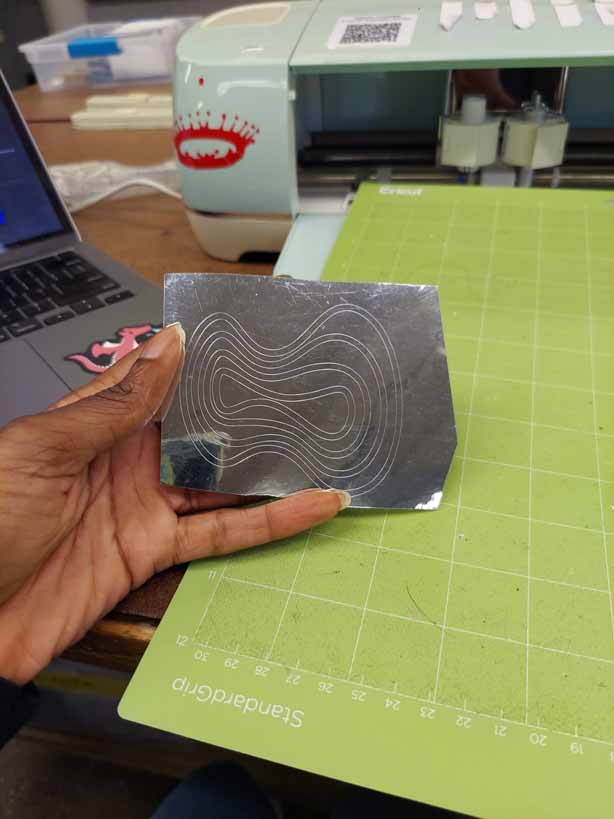

Vinylcutter setup

Cut vinyl

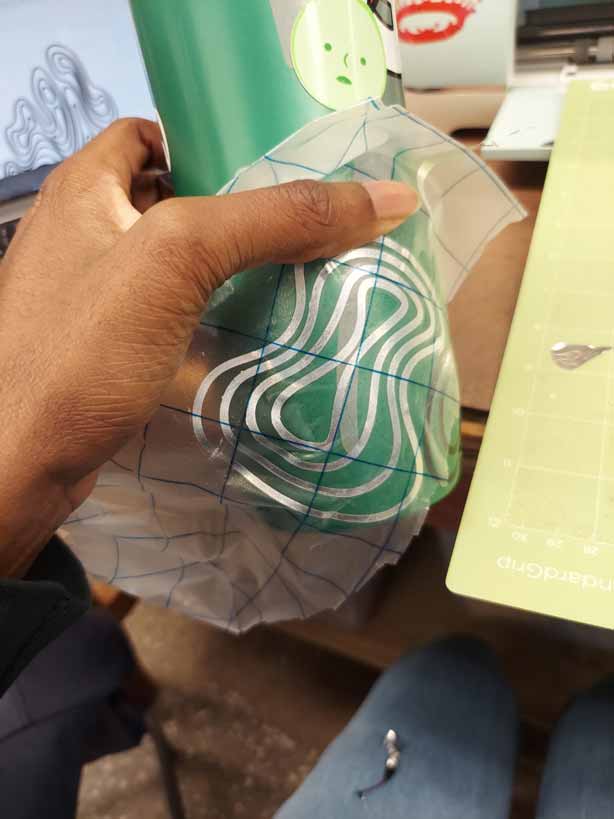

Using transfer paper to transfer the vinyl onto the bottle

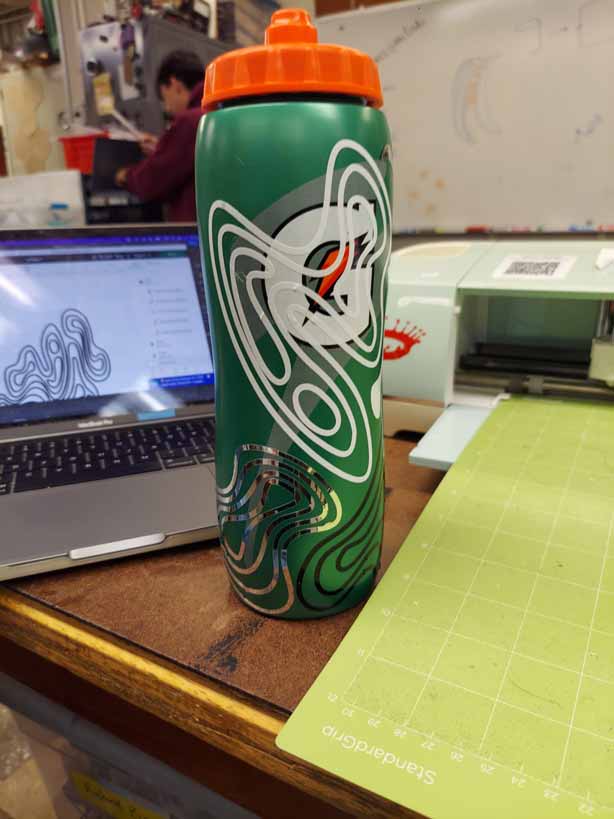

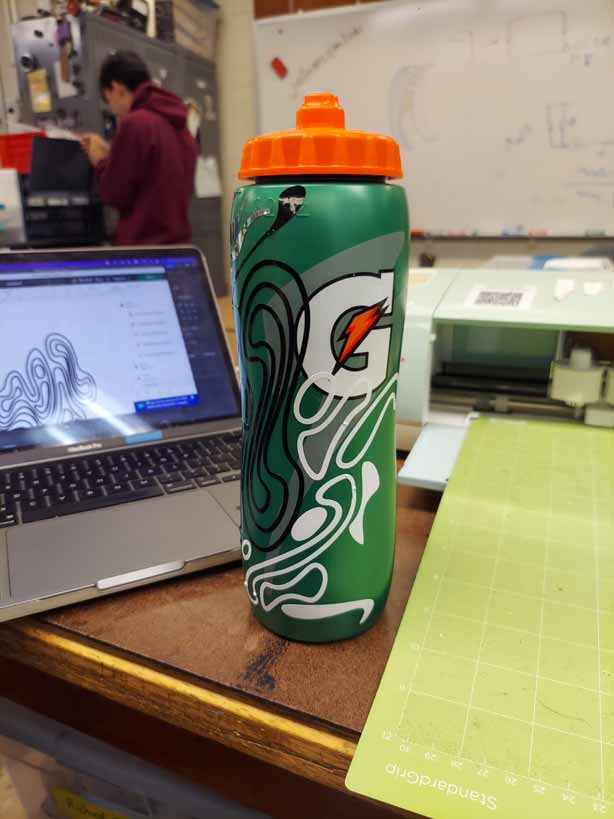

Final vinyl cut water bottle

lasercutting

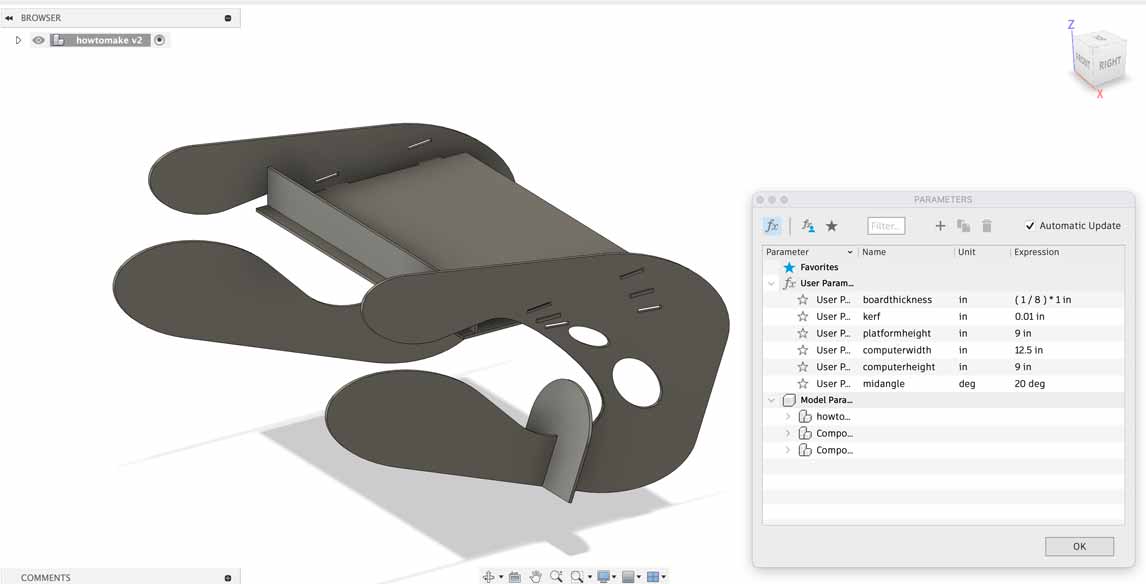

CAD of the laptop stand

Support cut with exacto knife

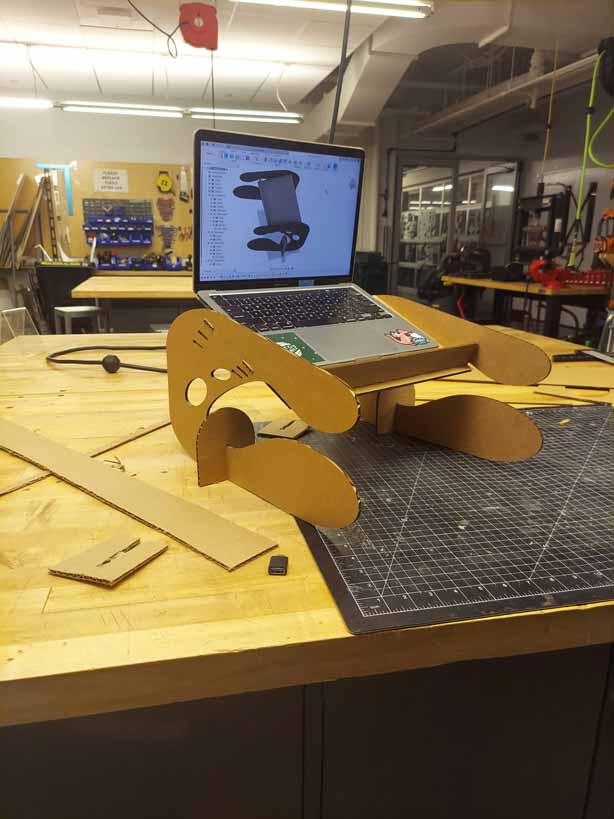

Finished laptop stand