## Lecture 9/27

3D scanning and printing notes:

- additive is less wastage since you are only adding material rather than wasting it

- 3dbenchy is a good print test

- takes a long time - hours and days

- commercial machine are expensive

- PLA is a common polymer material - absorb moisture - hurts their printing properties (store in a dry place)

- print with or without supports (overhangs need support) - you want to design as much without support as possible ~30 degrees is fine without support, but horizontal gives you a spagetti

- You can also bridge the thing so it has structural integrity

- min wall thickness have a few units of the print unit - never make sharp corner

- strength of the object - for gaps or infills

- the gap between the filament and the bed is sensitive - you want to make sure there is good adhesion.

- electroplating - metal coat

- shapeways - all kinds of printers, one of every kind

- stereolithography - messy but wins over resolution

- fused deposition modling - most common process

- print with metal wires - inkjet binder

- PolyJet - wins for color

- laser sintering

- Rep Rap - self replication - a printer that could print other parts of the printer.

- Prusa - open source printer - buy it as a kit

- Design for manufacturing

- Sain smart map for bed curvature - few hundred dollars

- Bambu Lab - favorite 3d printer, sealed environment and meaures flow rate and characterizes the printing proces. Fine for 2 colors, slow for more

- Formlabs - they make stereolithography

- Print the legend (Netflix movie)

- Stopmotion film (Chase Me - a 3D printed film)

- Formlab lets you create nylon pieces

- J55 - favorite printer - 100,000 - multimaterial printing and multicolor - state of the art

- wood fill fibres

## Group Assignment: Test the design rules of your 3D printer

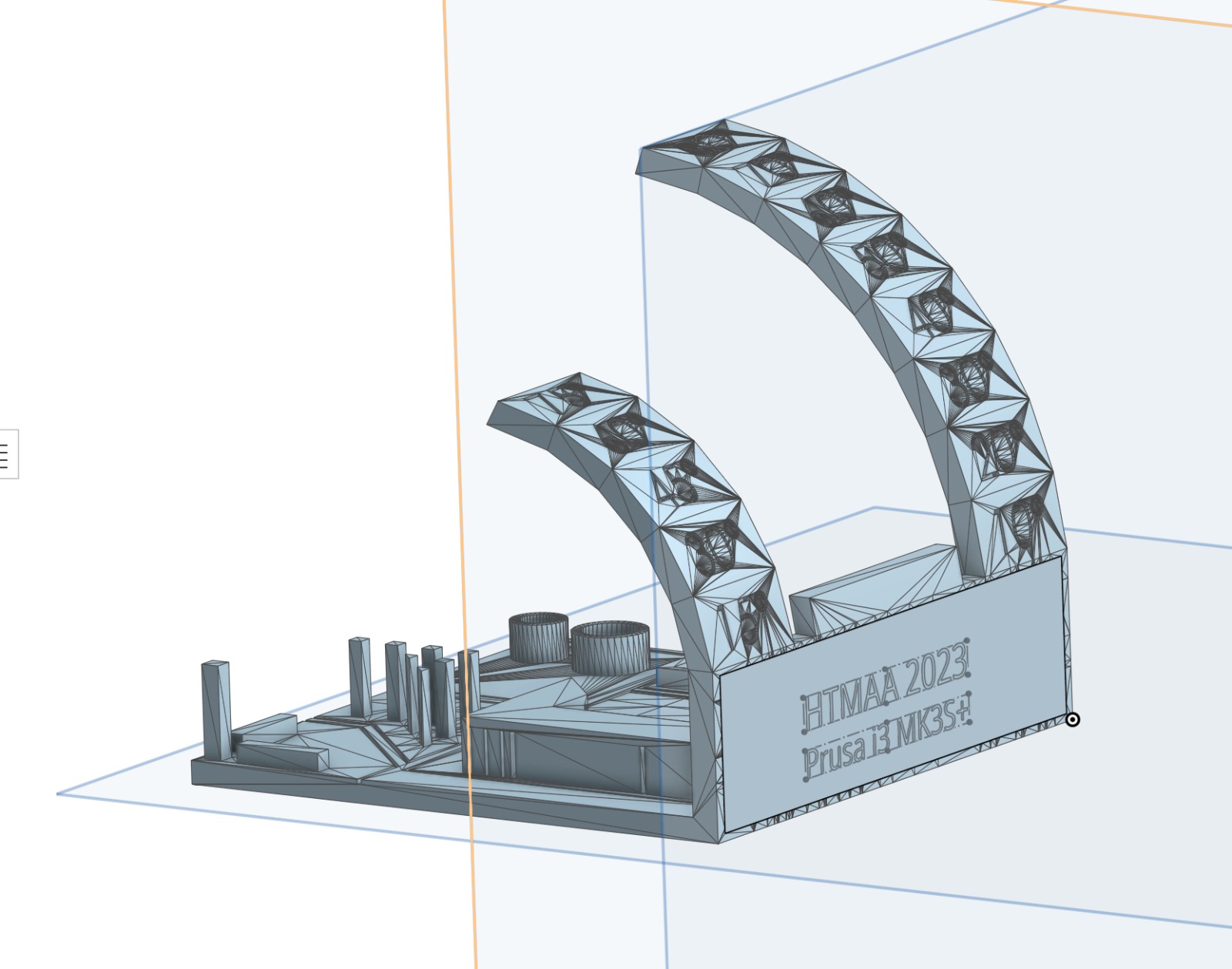

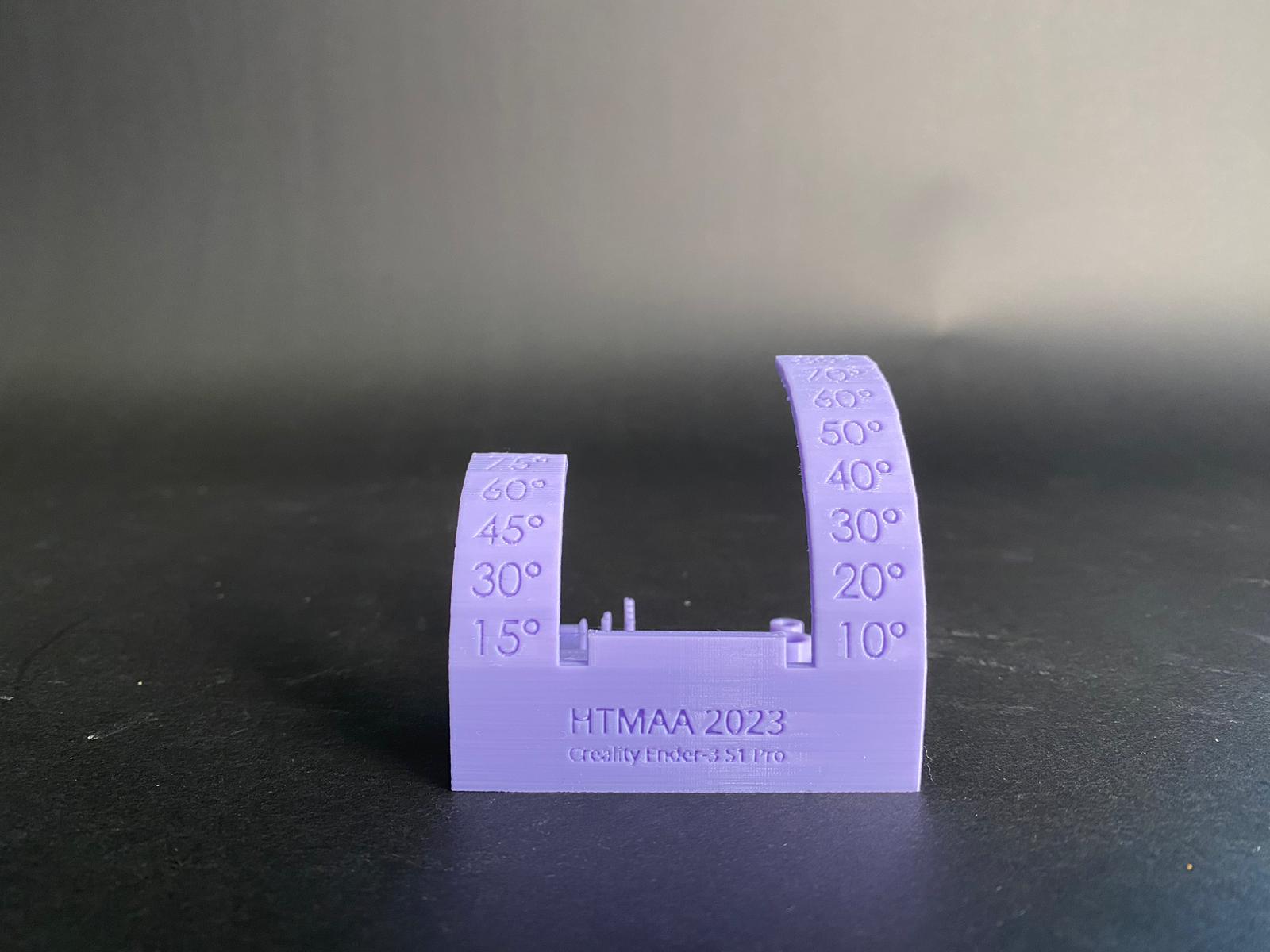

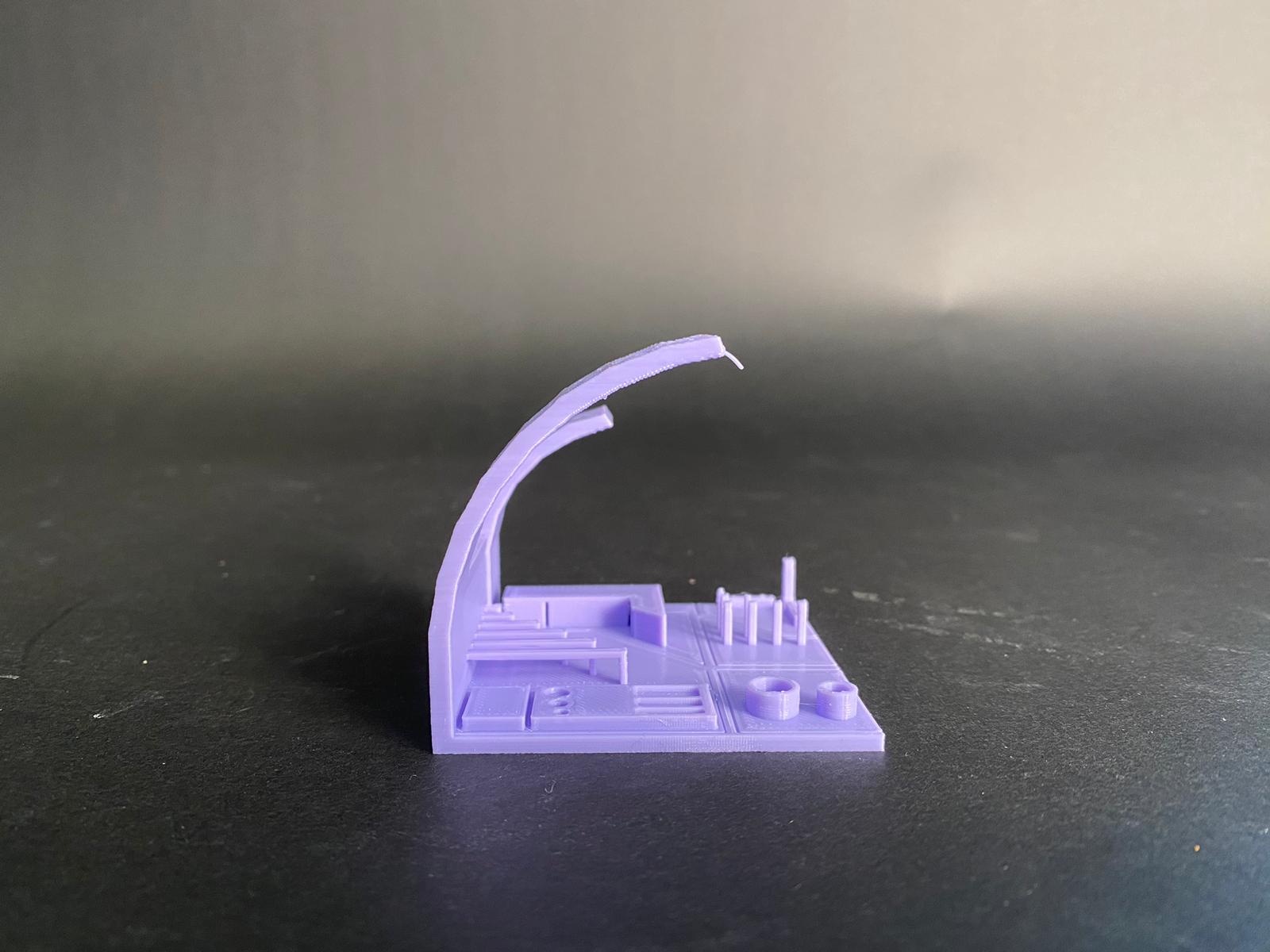

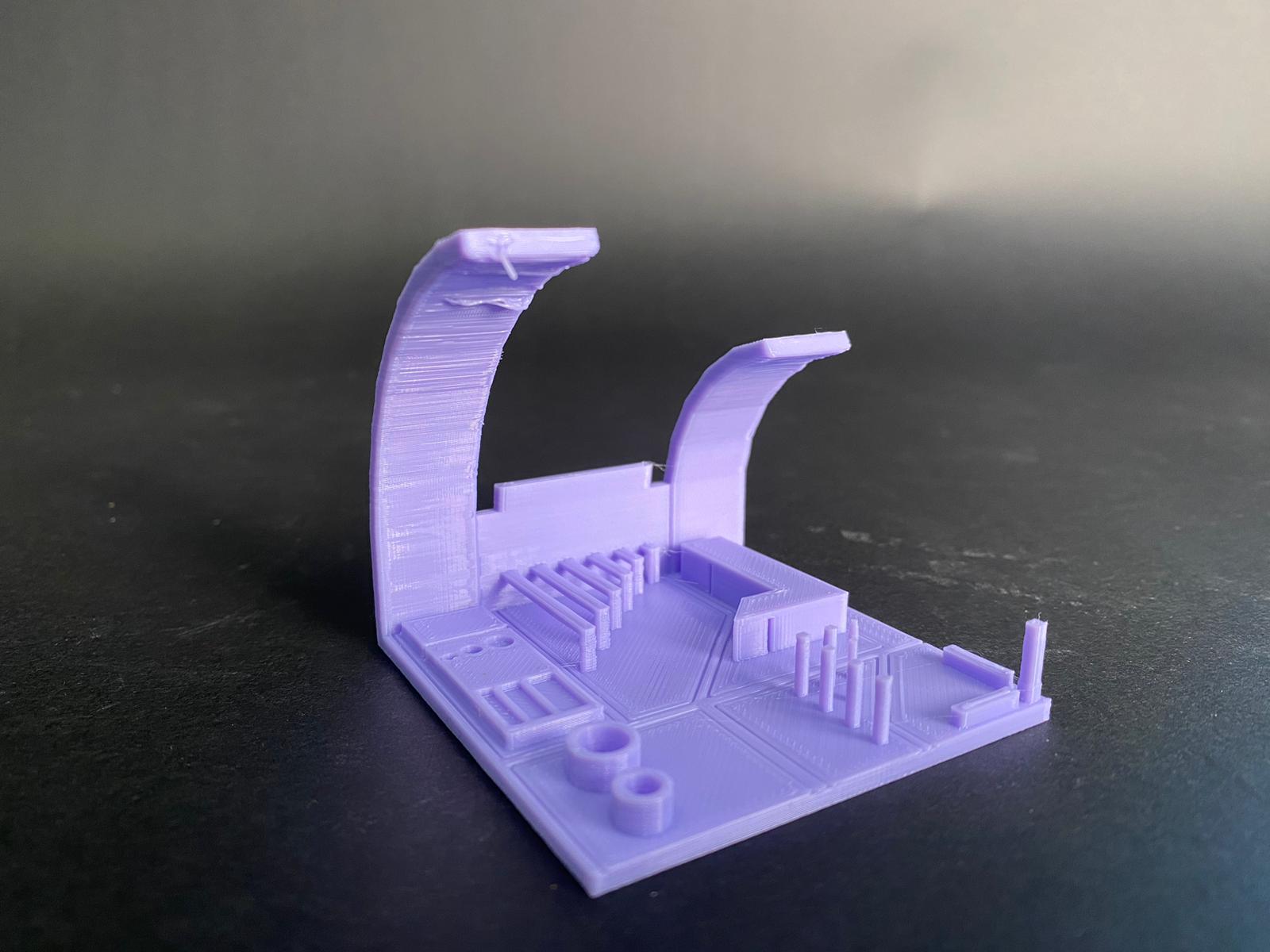

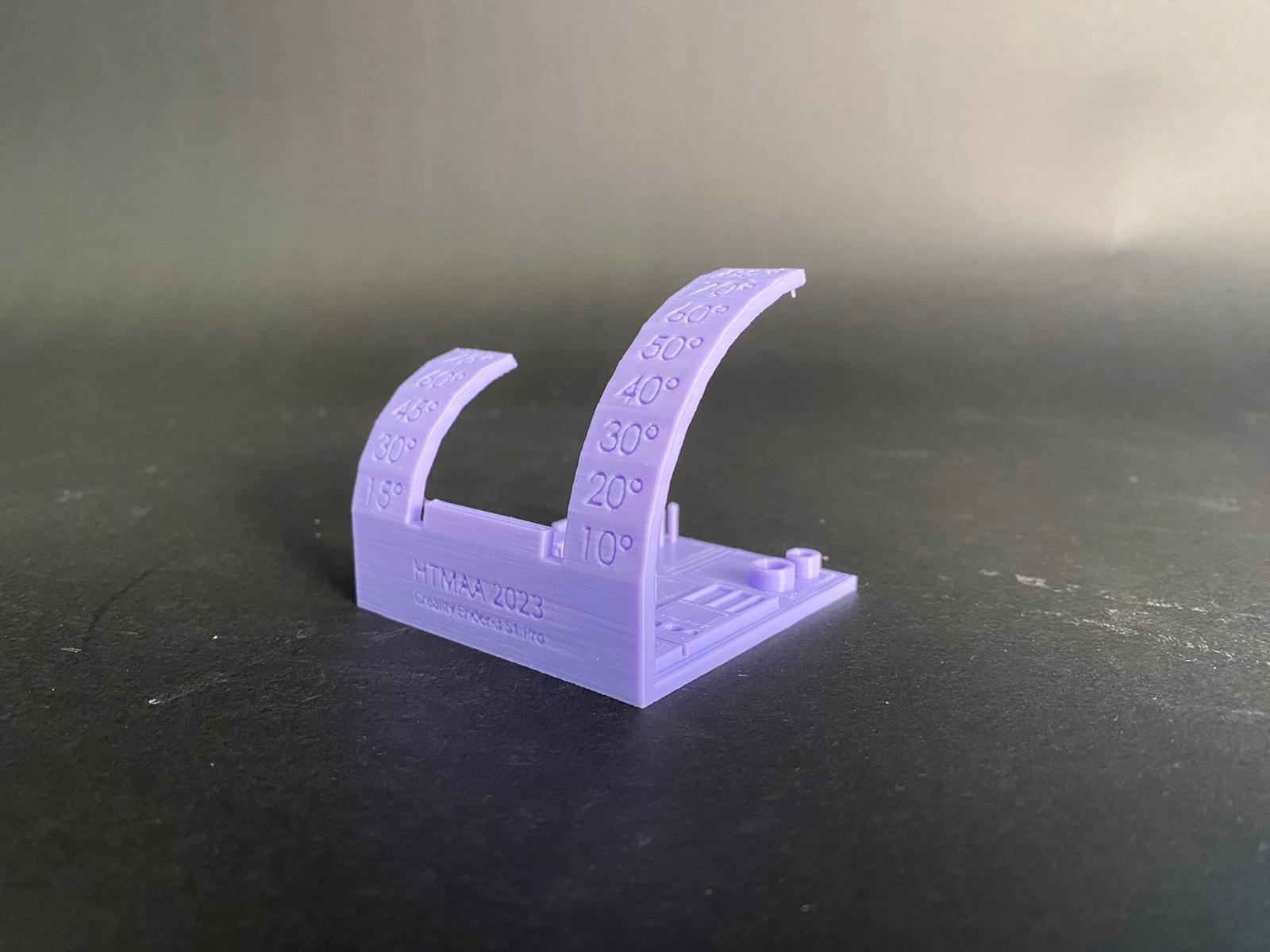

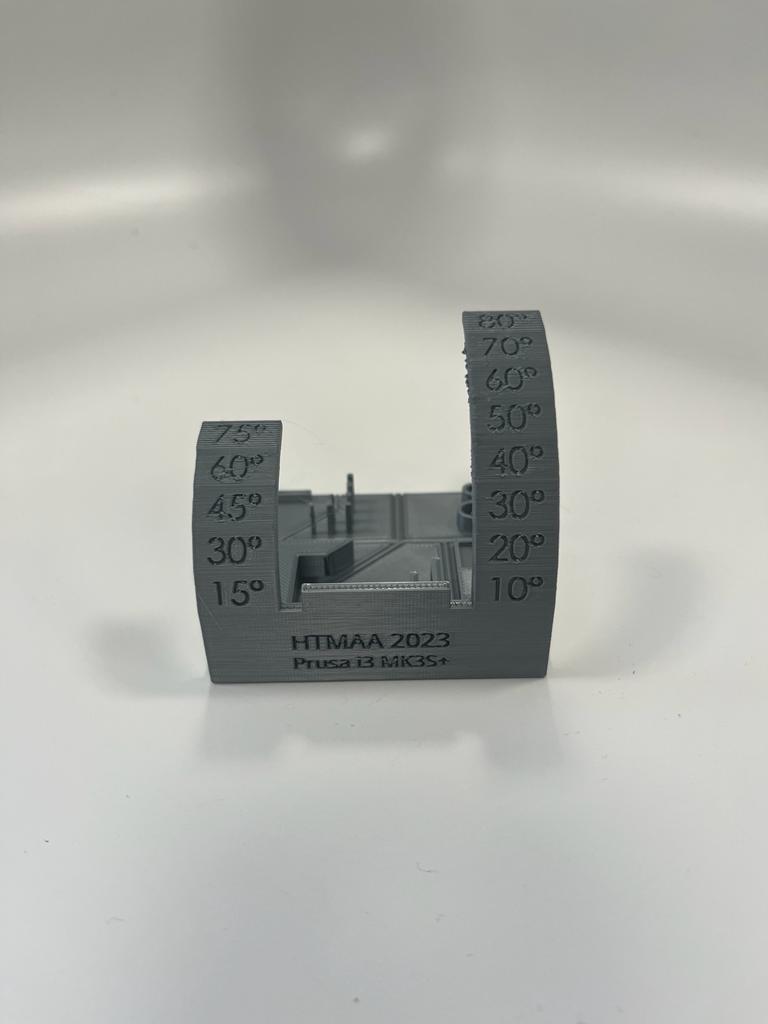

In a group with Vincy, Lucy and Alan - we ran the following test file in both the Ender-3 S1 Pro and Prusa i3 MK3S printers.

On the Ender-3 S1:

On the Prusa:

## 3D scanning

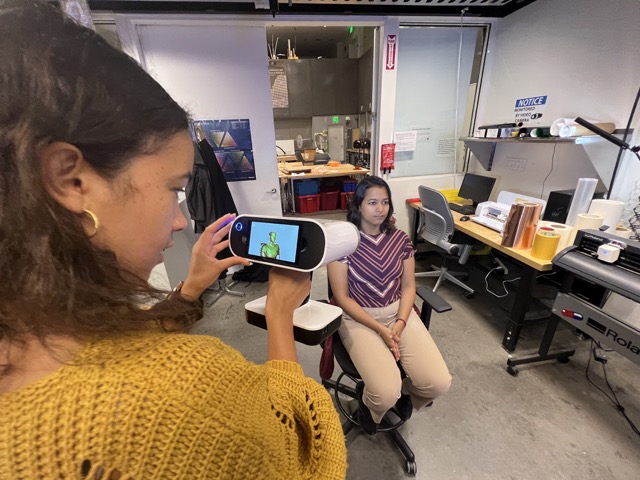

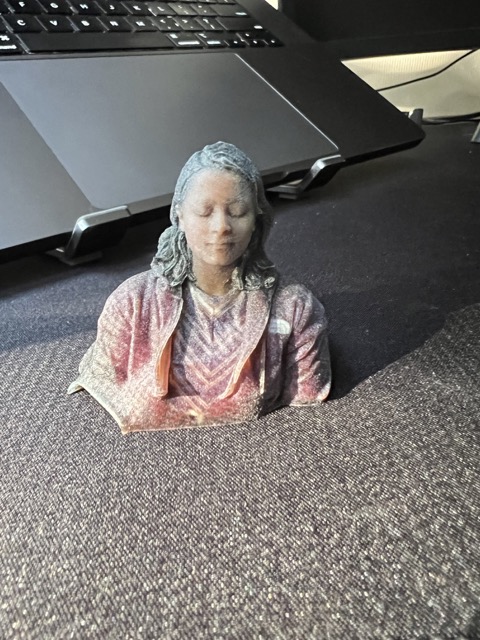

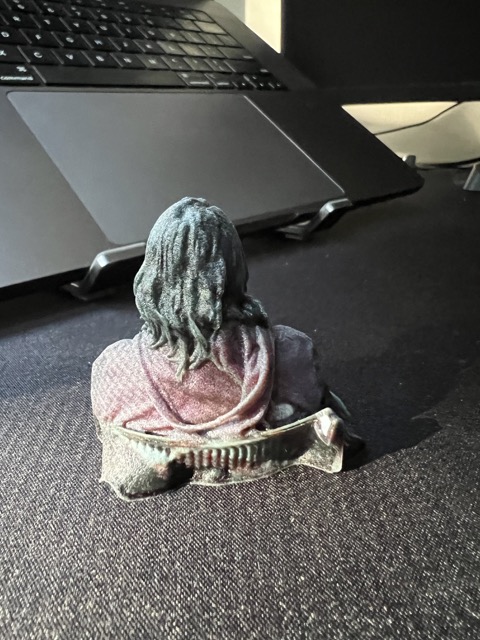

I did this with Char and Collette. I decided to scan my face using the Artec Leo Scanner and print it using Stratasys J55 printer.

Collette and Char helped me scan my face:

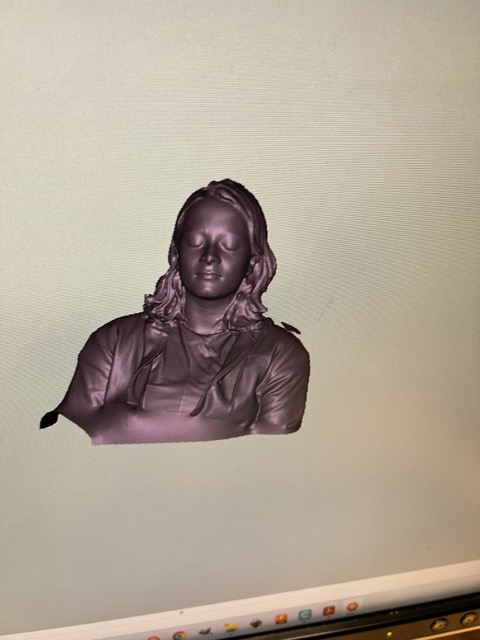

The scan had to be redone once, but the second time around, the scan was able to capture most of the features on my face!

Here are the results which are pretty uncanny. I was surprised that the scan was able to capture so many interesting details like my jacket folds, "The North Face logo" on the jacket and my wavy hair.

## 3D printing

For the 3d printing part of the assignment, I made the rookie mistake of spending a lot of time thinking of something cool to print and underestimating printing times. I had initially planned to print the Hoberman's sphere.

In the process of researching how to design one, I also came across another [fab lab project](http://fab.cba.mit.edu/classes/863.11/people/paulina.mustafa/final.html) using the Hoberman mechanism to build a collapsible hat which I thought was super cool.

Since I am only beginning to get CAD, building the sphere with 244 parts on time was pretty challenging, however, here are some fun shapes I built that would be hard to make subtractively, for example objects with many holes or objects inside objects.

1. Lampshade with a flower pattern.

2. Hollow Shpere inside a cube wireframe

Next time I do this project I will first try to reduce the scope of the idea to manageable chunks (fewer parts and less complex) and maybe taking inspiration from [this previous project](http://fab.cba.mit.edu/classes/863.11/people/paulina.mustafa/final.html) which takes the idea and builds a smaller yet functional version of it.