## Making something big!

### Procuring the wood

Lucy and I went on a home depot run to procure the wood. Since neither of us had a car, transporting 4' x 8' x 3/4' pieces of plywood and getting it to the shop was pretty time consuming, but we had some fun while doing it! Here are some photos from our adventure.

### 1. A coffee table

I designed a coffee table because the one I have at home was a give away and is falling apart. I wanted to make a stylish and sleek coffee table for my living room. In order to do this reliably with a 2.5 D machine, I looked at resources such as [AtFab](http://atfab.co/) for some insipiration on how to design the table with plywood less than an inch in thickness.

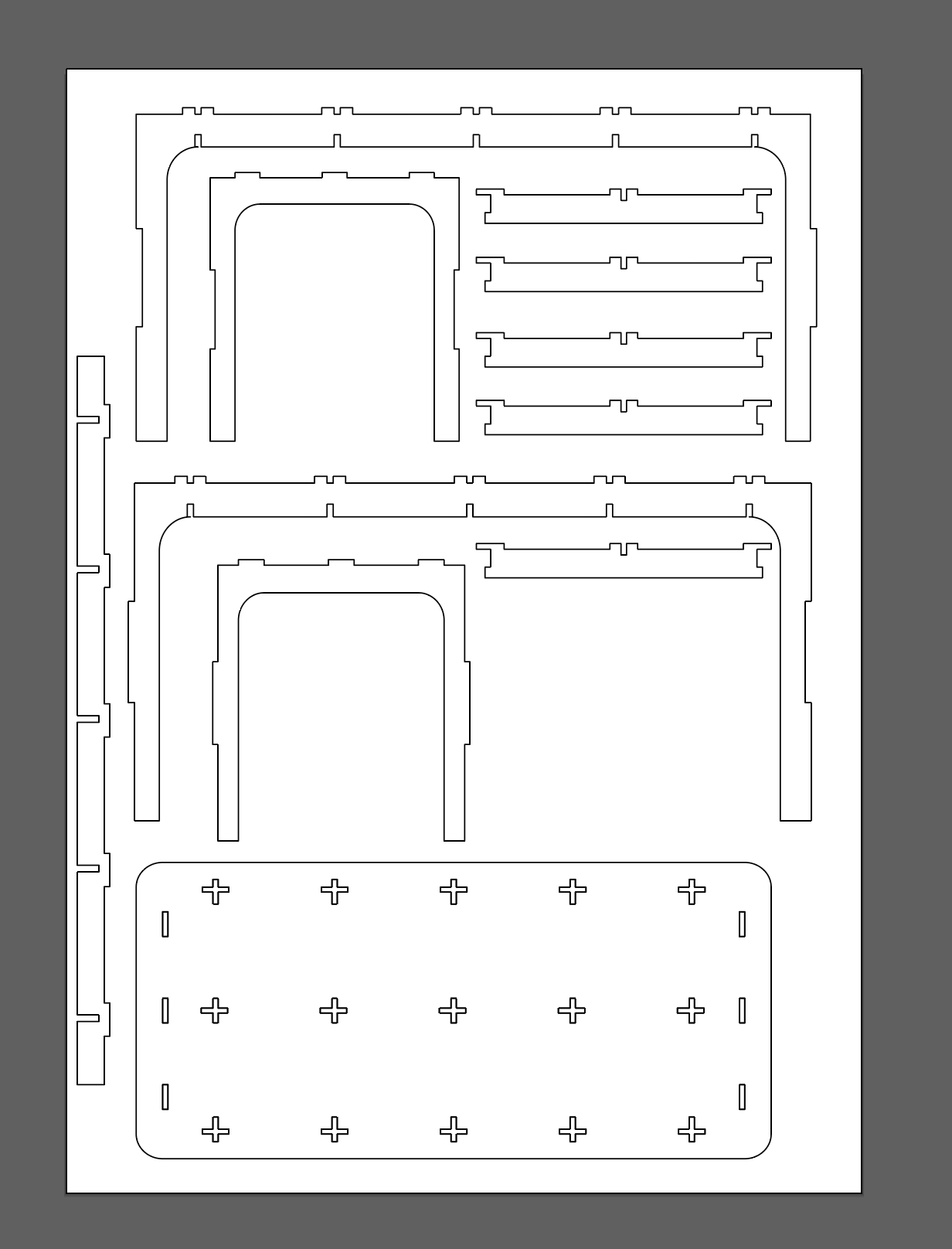

Here is my design in fusion 360:

Once I had my design, I had to cut it out of the Shopbot's PRSstandard machine. I used a 1/4" endmill to cut out the dxf parts.

Here is the shopbot in action:

Once I cut out all the parts, I realized that I made all the joints too small. The thickness of the plywood used was 0.44' and I decided to cut out the parts for 0.4' thickness. This was a mistake because the joints were too tight and I had to sand them or saw them down to make them fit. Since my design had several of these joints, this was a painful process. I managed to get most of the parts in. The black tape is just used to hold the parts together while the glue dries.

Here is the final look:

Lessons for next time:

- Always, always parametrize the model. After I cut out the parts, I realized I couldnt use one of my supports because it was designed for a 3/4' thickness plywood instead of a 0.4' thickness plywood. Although most of my design was parametrized, it seems I hardcoded this support's dimensions and got a part I couldnt use. This luckily didn't affect my design as I could still make a sturdy enough table without this support, however, for next time I am not going to take a shortcut and parametrize all values in my design.

- The shopbot's kerf is not 0.125' as I had assumed. I had to sand down the joints to make them fit. I should have accounted for this in my design. The kerf was more in order of 0.01' or 0.02' which is a lot less than I had assumed.

- I should have run some tests on the machine to categorize it. This would have saved quite some time on the making the parts fit.

- I eventually had to glue the legs of table. I think this is somewhat unavoidable with my design and the 0.44' thick plywood I was using, perhaps a thicker 3/4' plywood would be more sturdy.

- The other option is obviously to use lumber instead of plywood for the legs, and screw those in, but who wants to do that?

### 2. Boat

I am working on my final project for the boat. Although I couldn't cut out the parts for this week. I spent several hours researching on how to build a reliable dinghy and secured the plywood and epoxy resin necessary to make a boat. Stay tuned for more updates here.