←Index

10/25 Casting and Molding

## Week 6:

In this week, we learned how to mill a pcb and how to solder components.

# Class notes

Show and Tell

- Strapping Pin: voltage at boot is important, Pin 8,2,9

- LED can launch??

- ESC

- Shape memory alloy kinda sux

- servo motor with tendons

- inventory of [material](http://inventory.fabcloud.io/?purpose=Molding%20and%20Casting)

- algae gel for casting, skin safe

- painting the mold with material first can get a smooth surface

---

## Idea

- nudibranch, cell

- play with opacity

- Materiom sustainable material library

- puzzle for roots to solve

- make fins

# Assignment

group assignment:

review the safety data sheets for each of your molding and casting materials,

then make and compare test casts with each of them

extra credit: try other molding and casting processes

individual assignment:

design a mold around the stock and tooling that you'll be using,

mill it (rough cut + three-axis finish cut),

and use it to cast parts

extra credit: use more then two mold parts

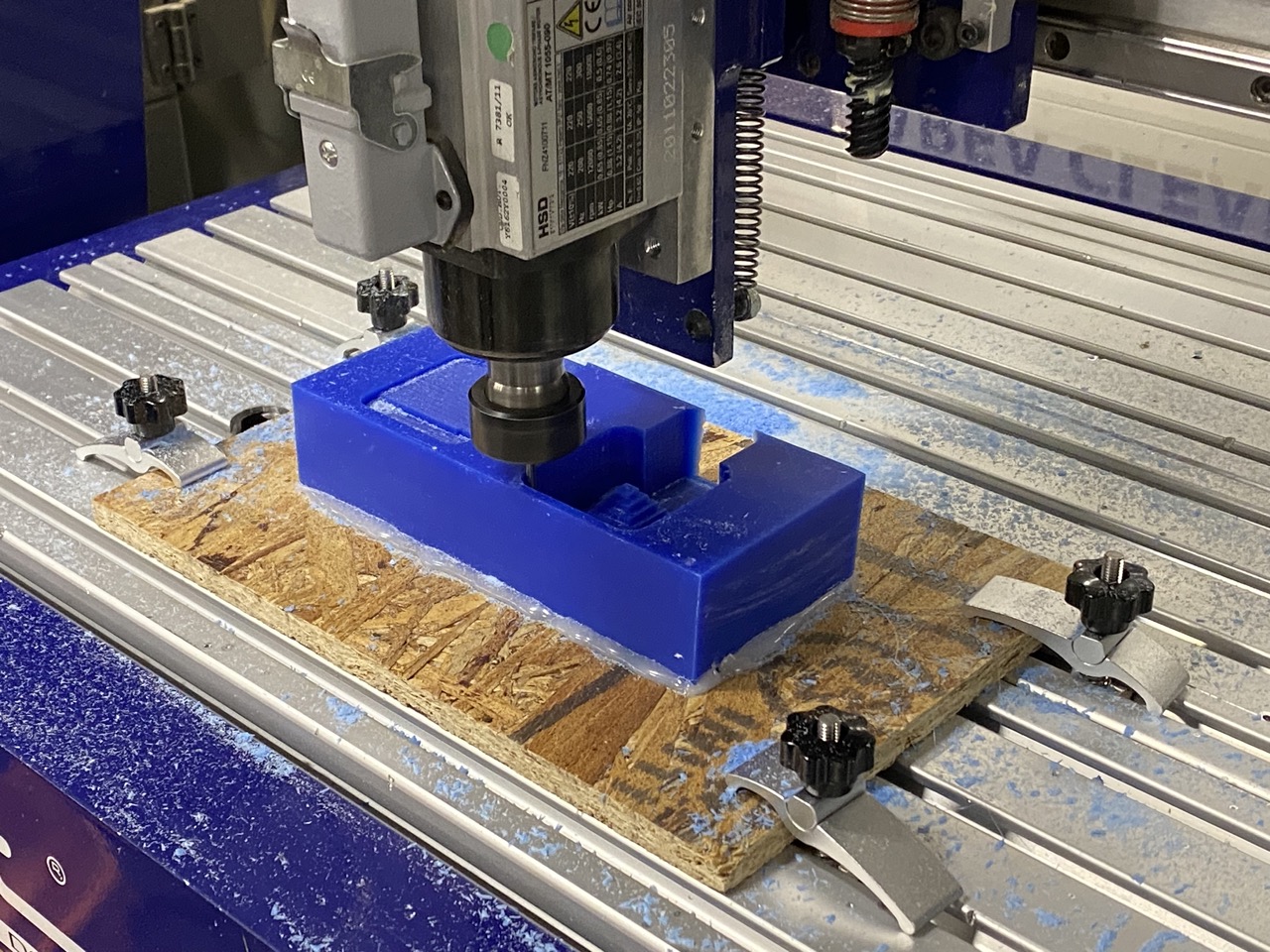

# 1) Milling

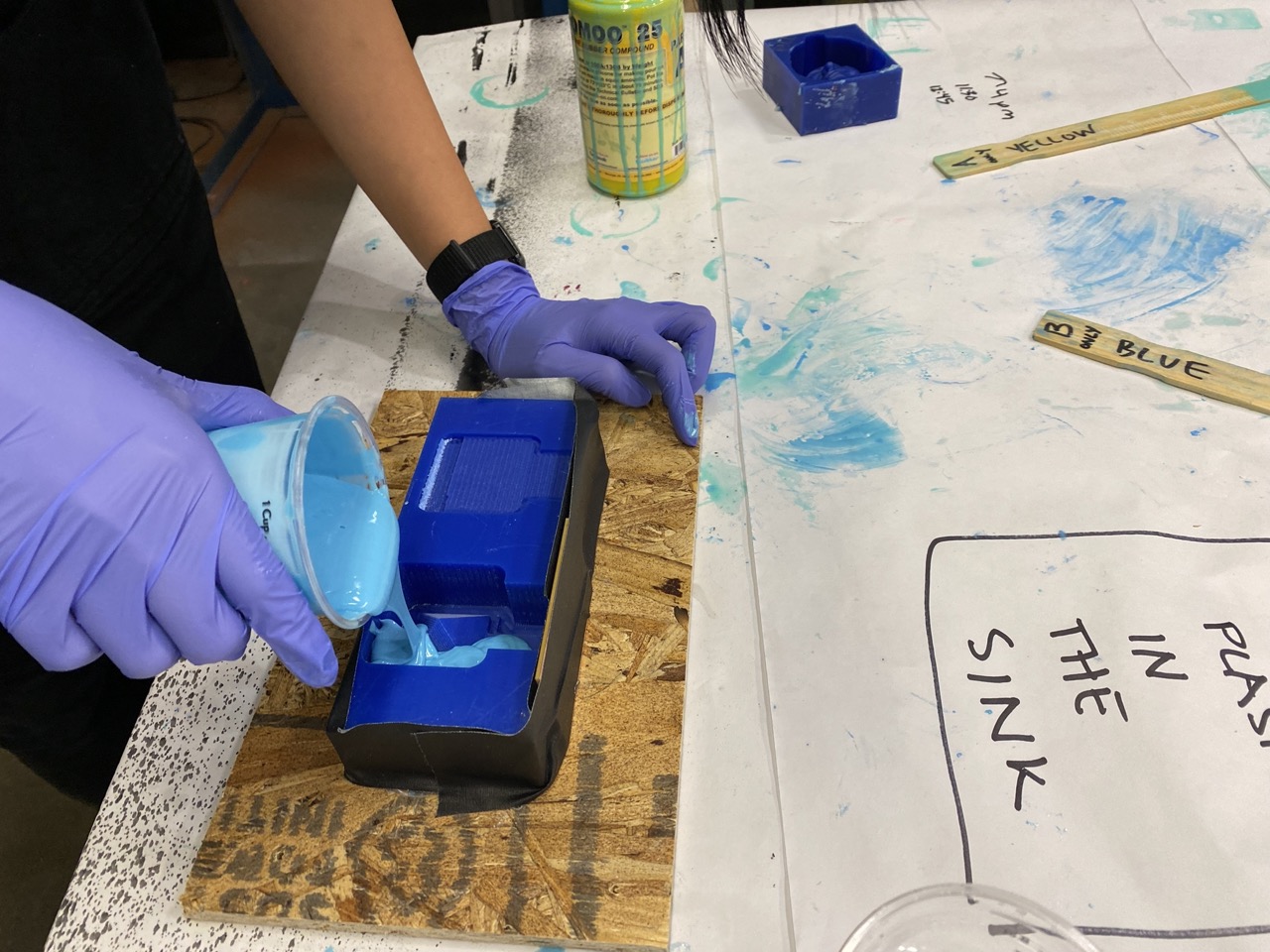

# 2) Casting Oomoo

My first Oomoo cast was not ideal. It had some air bubbles.

I did a 2nd Oomoo cast. I brushed the surface and poured in Oomoo in layers. Between each layer I tried to get out the air bubbles by hammering the mold against a flat surface.

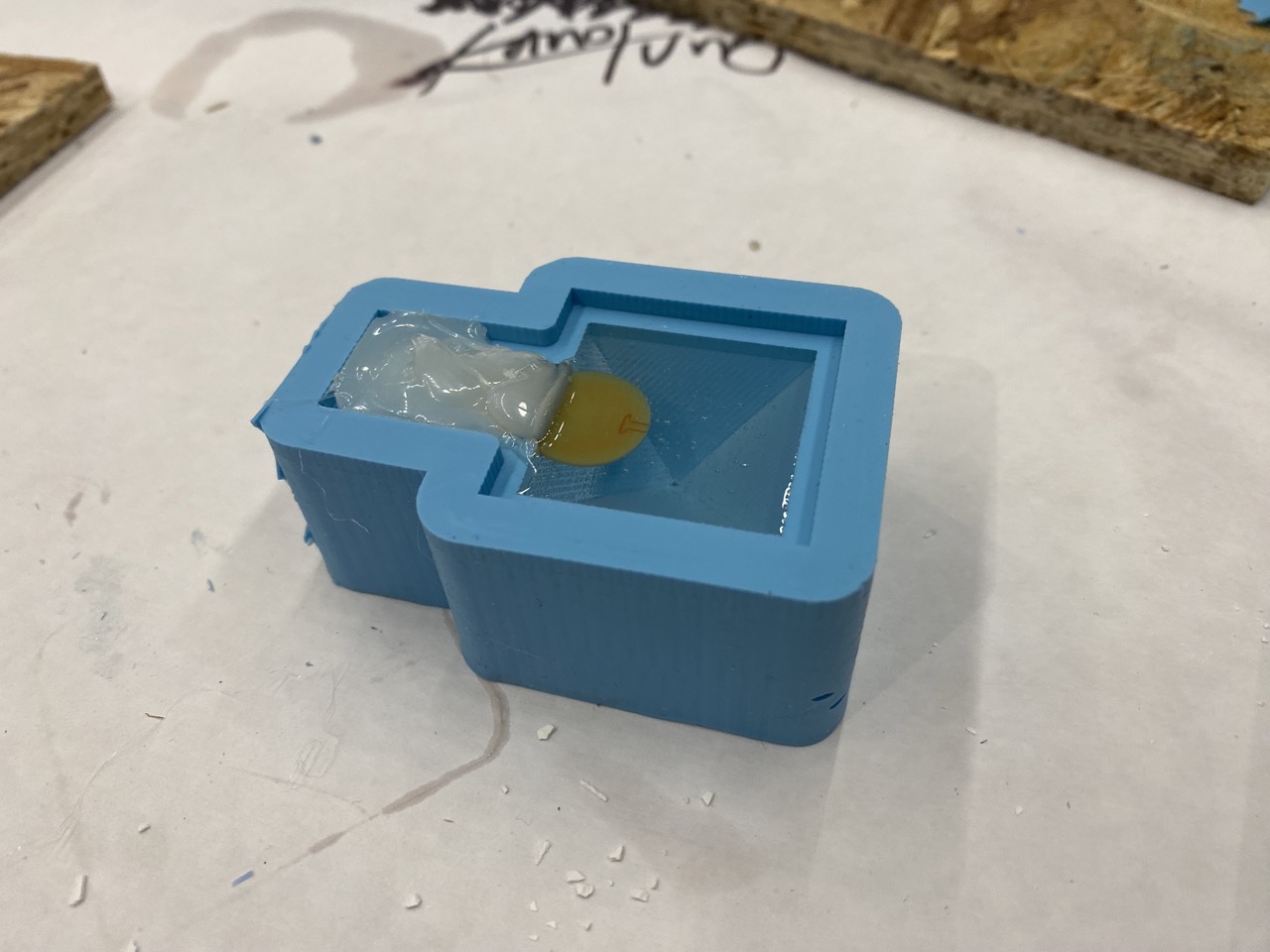

# 3) Casting Clear Epoxy

## Next Steps

---

# Resources

- files

- [positive pyramid](files/pyramid_small.stl)

- [negative pyramid](files/pyramid.stl)

---

↳About