←Index

11/01 Computer Controlled Machining

## Week 7:

In this week, we learned how to ...

# Class notes

Show and Tell

- Climbing wall by [Alejandro Diaz](https://fab.cba.mit.edu/classes/863.20/EECS/people/AlejandroDiaz/index.html)

- [Turn buckle](https://www.homedepot.com/b/Hardware-Fasteners-Metal-Hooks-Turnbuckles/N-5yc1vZc2ge)

- multidimensional lidar VL53L7CX

---

## Idea

- make a couch for E14-348P office space.

# Assignment

group assignment: do your lab's safety training

test runout, alignment, fixturing, speeds, feeds, materials, and toolpaths for your machine

individual assignment:

- make (design+mill+assemble) something big (~meter-scale)

- extra credit: don't use fasteners or glue

- extra credit: include curved surfaces

# 1) Modeling

I wanted to make a couch for my office space, because I like inviting other people over for tea.

CAD first.

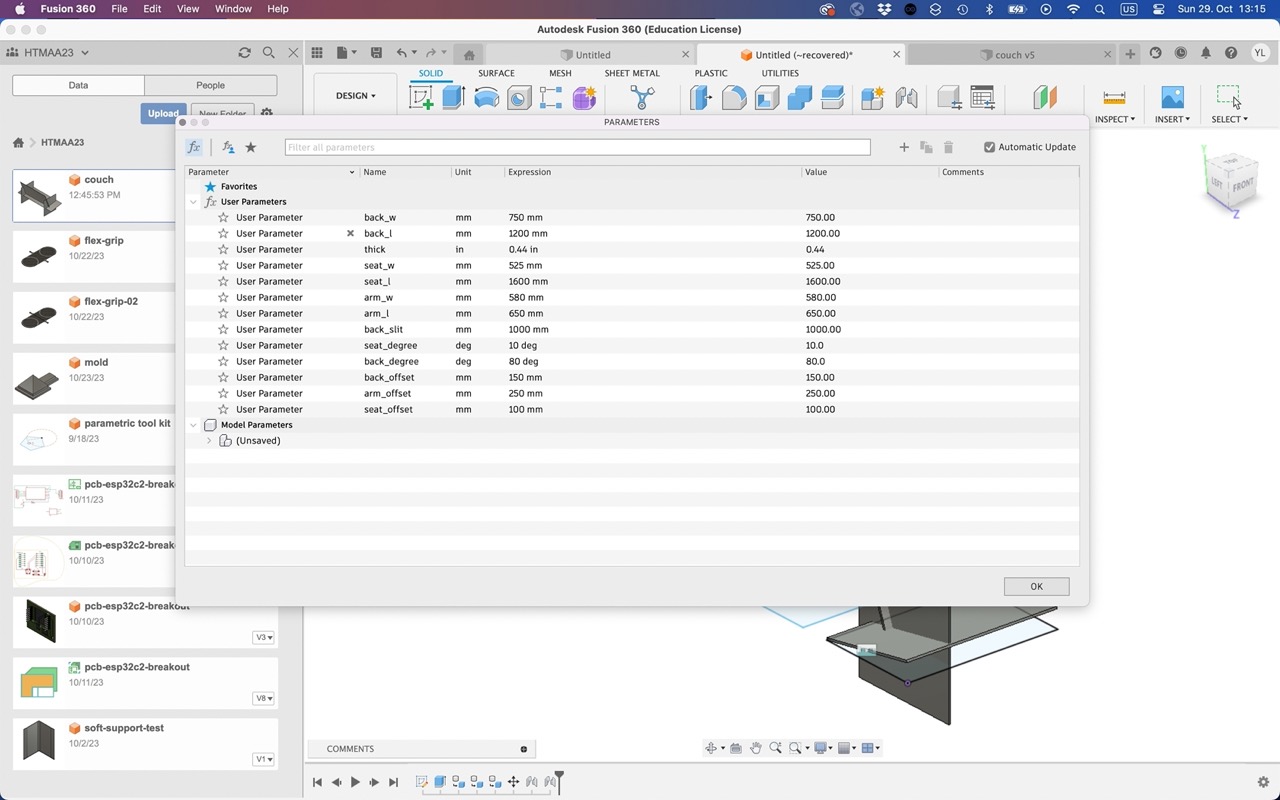

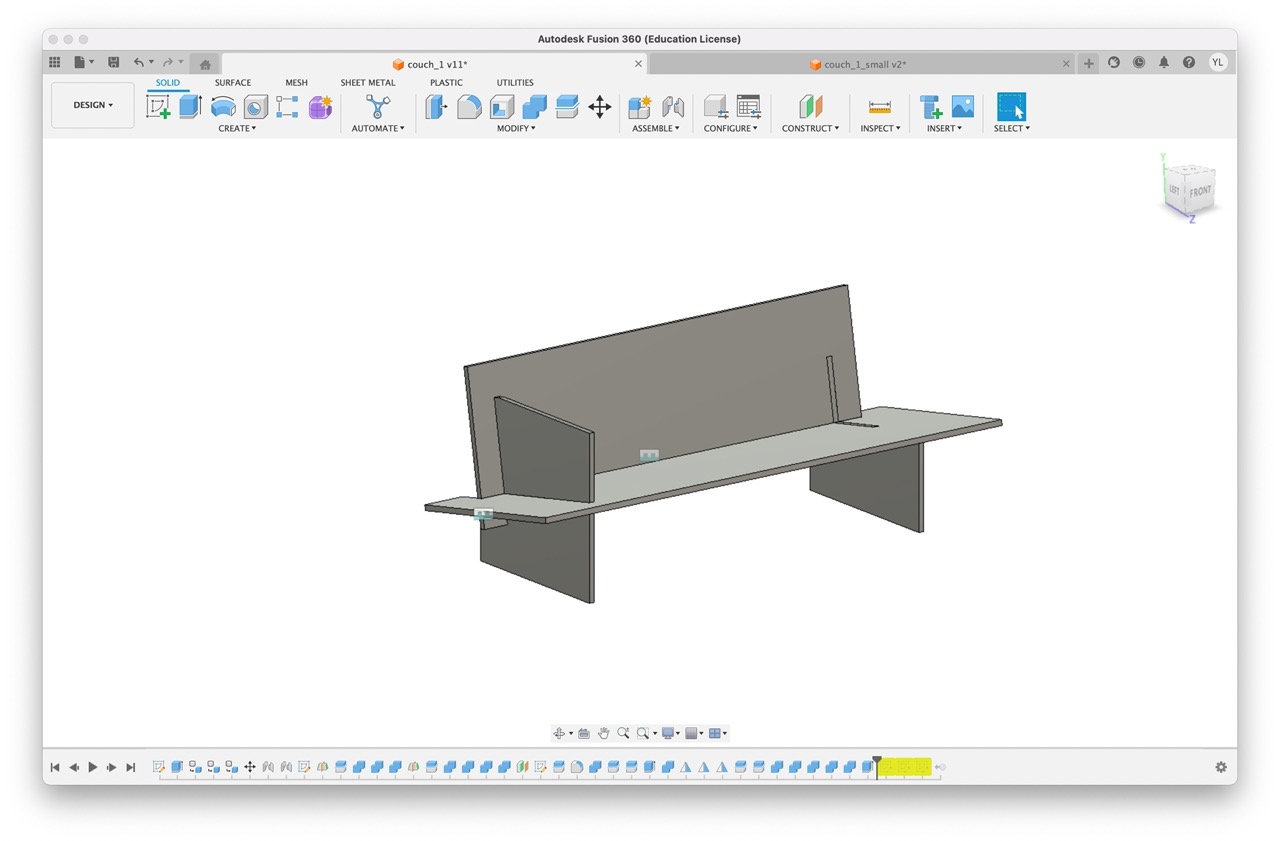

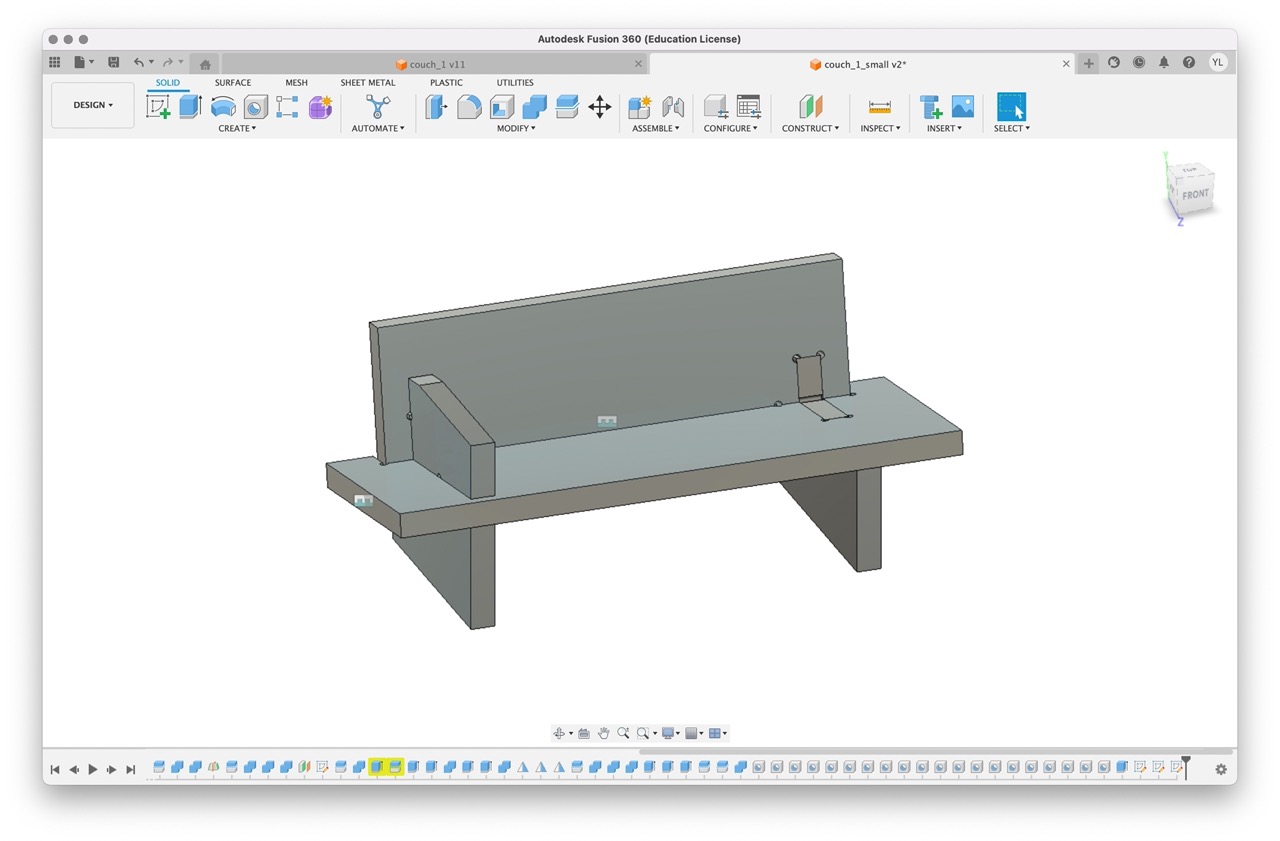

I built the couch parametrically. Making each step of CAD reversable took most of the time. Since it is parametric, I scaled it down and made a 1:4 model.

# 2) OSB Test

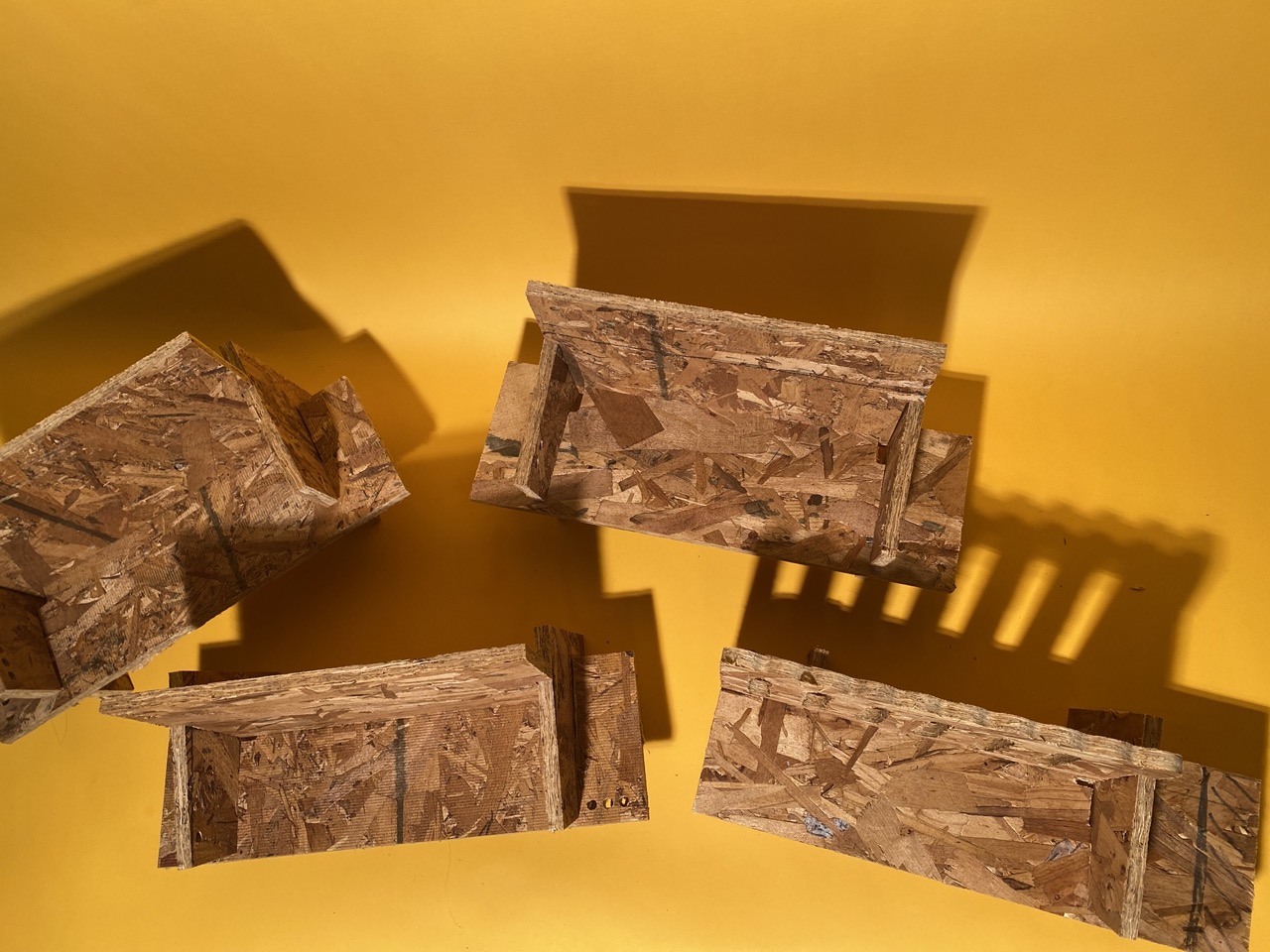

Then I used the OSB board provided by class to cut out 3 1:4 models and test the joint with different offsets (0.44, 0.50, 0.55).

For straight joints, 0.44, which is material thickness, was perfect. But for angled joints 0.50 was better.

Here you can see how the fit of the joint changes the angle.

Different shapes, feeling dimensions with my eyes and hands. I decided to shorten the 2nd arm, so I can fit as many people or lay down given the limit of the office space.

Army of 1:4 models.

# 3) Plywood Test

For the big version, I wanted to get a more comfortable wood. Gauri organized a U-Haul car and we adventured to Home Depot. This is the [wood](https://www.homedepot.com/p/23-32-in-x-4-ft-x-8-ft-Cabinet-Grade-Plywood-Panel-Actual-0-688-in-x-48-in-x-96-in-1077486/302610611) I got. Besides wood, we also got some plants.

The 4x8 Plywood was slightly bent to begin with but the rainy, humid weather did not help either. So, I pinned it down.

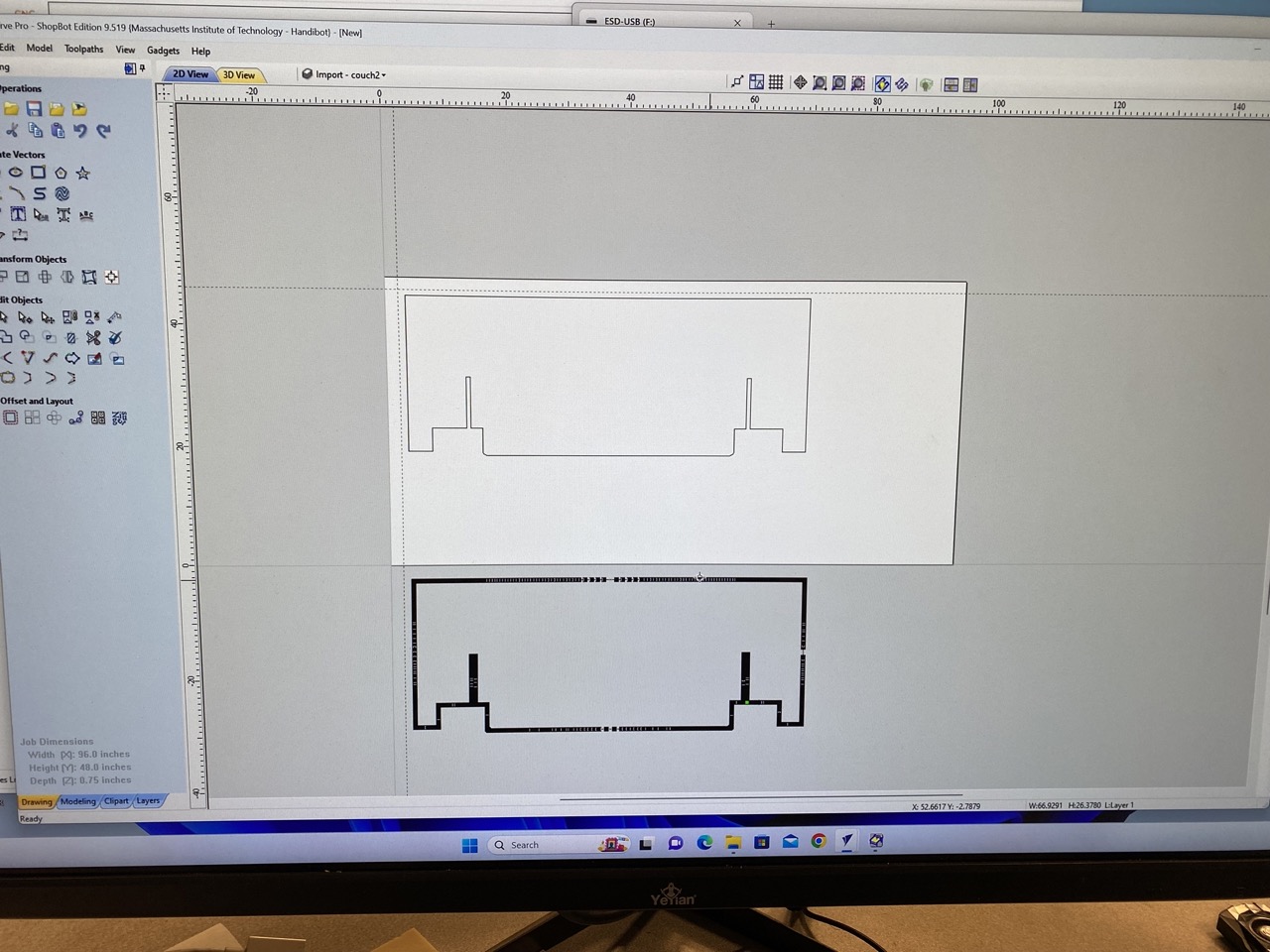

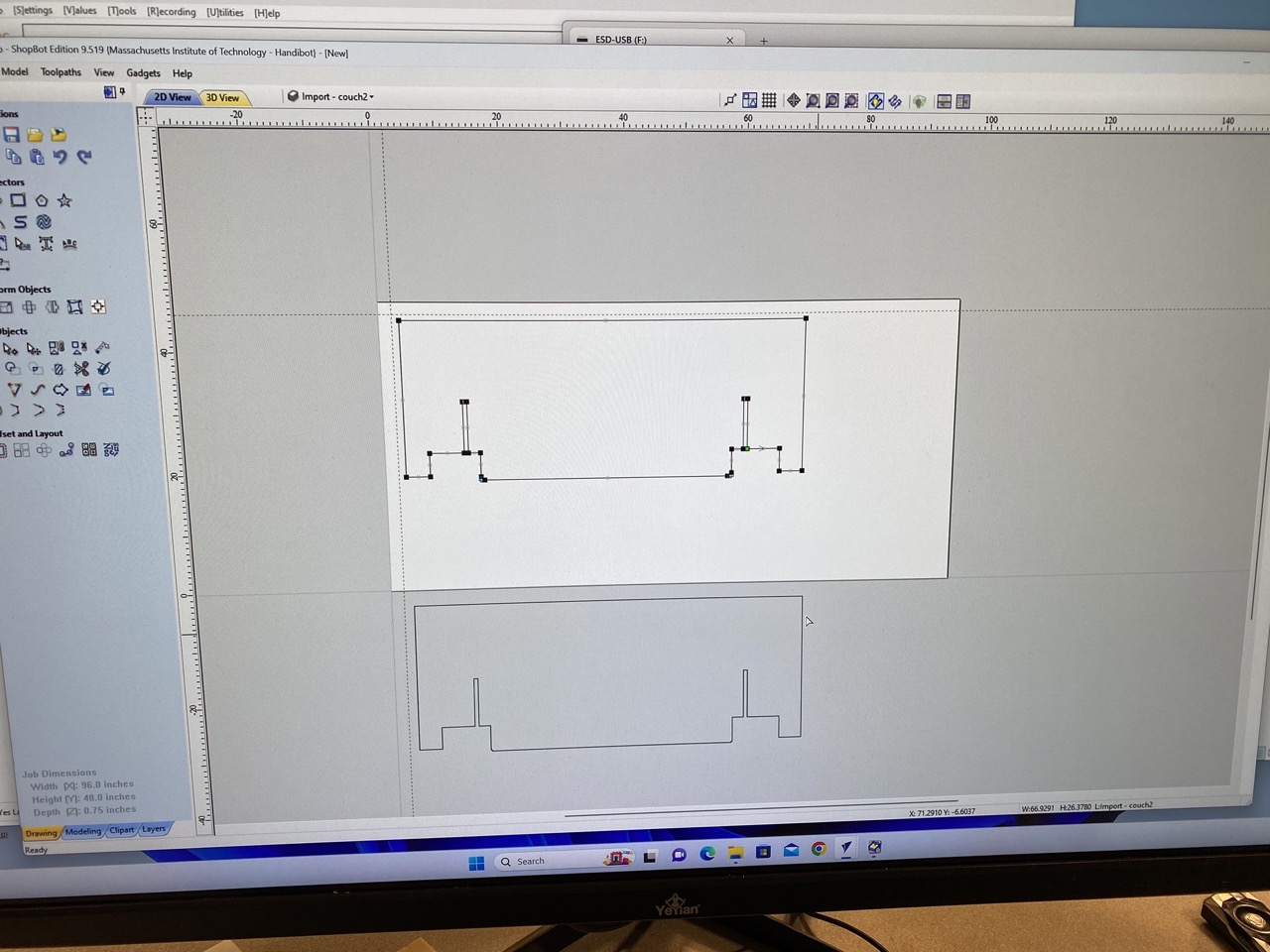

1:4 model of the couch with the 3/4" 4x8 plywood. The shorter arm was loose by 1.5mm. This workflow quickly switching between digital and physical model is efficient in trouble shooting.

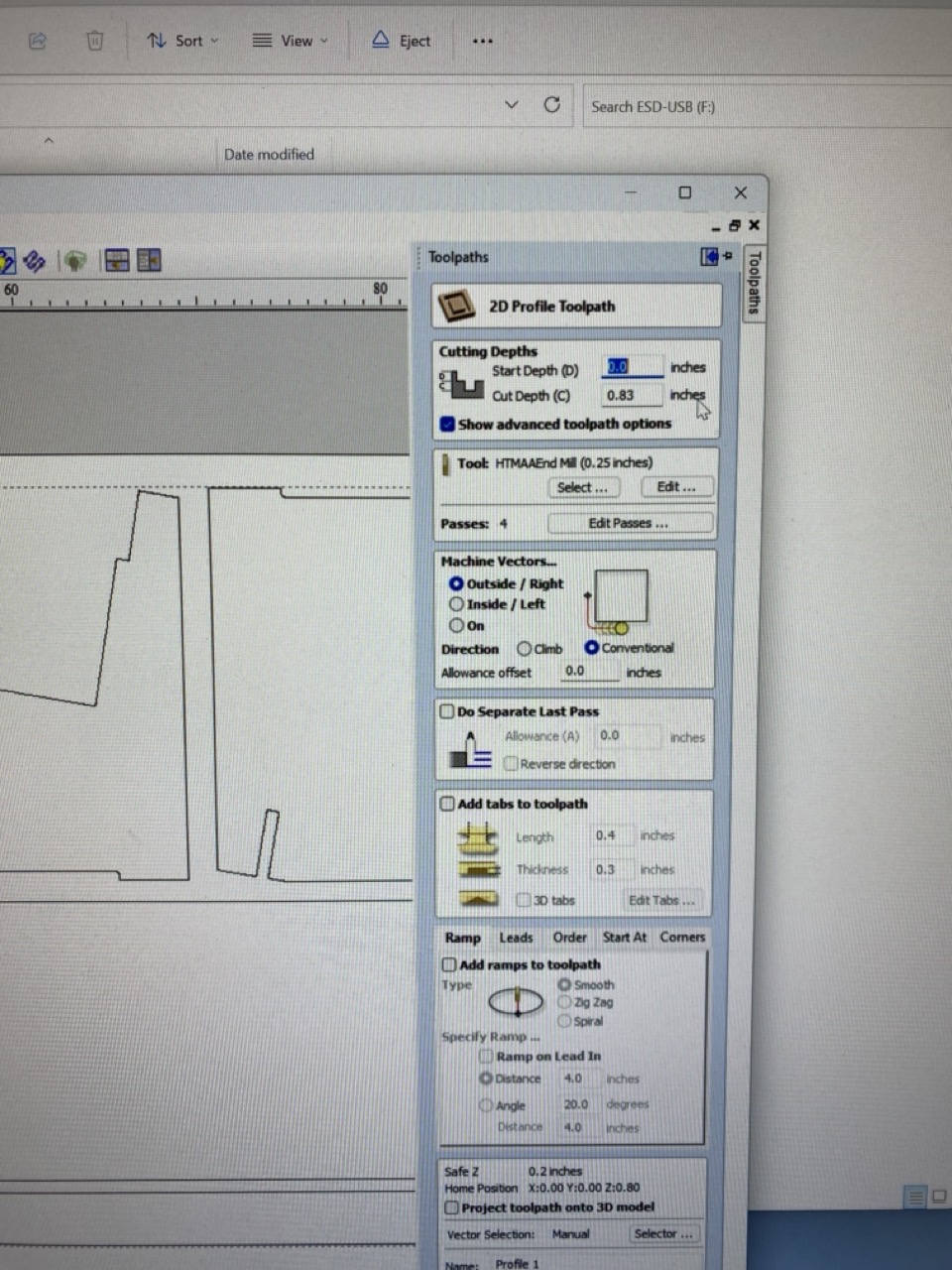

This depth cuts the 3/4" Plywood really clean!

**LEARNED**: For anyone using Adobe Illustrator, it exports dxf with wrong nodes. I used AI to arrange the pieces and change the scale from mm to inches. When I imported the DXF 2018 file to ShopBot, the simple line was spawned with nodes.

Assemble time! Wedyan helped me a lot doing it. The joints are nice and tight. A bit too tight on the longer arm now, but it makes the couch stable.

## Next Steps

- Use Wax and Gray Wood Stain to partially color the couch.

---

# Resources

- files

- [couch fusion file](https://a360.co/4avD58b)

- Home Depot Plywood, [beautiful wood](https://www.homedepot.com/p/23-32-in-x-4-ft-x-8-ft-Cabinet-Grade-Plywood-Panel-Actual-0-688-in-x-48-in-x-96-in-1077486/302610611)

- Get more hands for building.

---

DAC - Digital to Analog Converter

How do you change Analog to digital signals

I2C - Talk to multiple sensors, you can connect more sensors than pins

↳About