vinyl

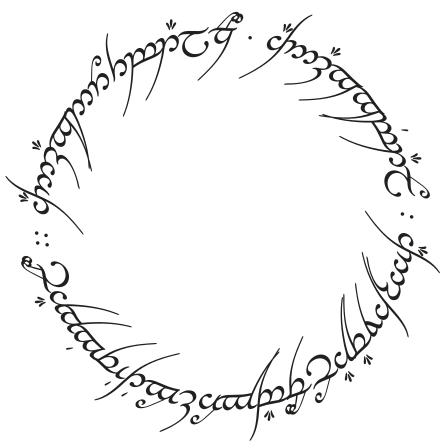

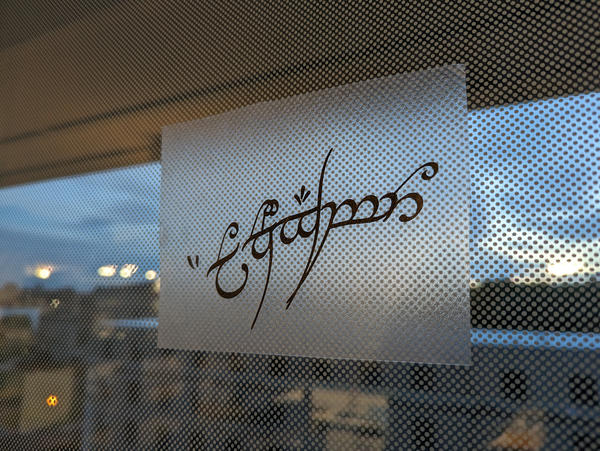

I cut this window sticker with the Roland vinyl cutter. The pattern I used was the last stanza of The Lord of the Rings' Ring Poem:

One ring to rule them all, one ring to bind them

One ring to bring them all and in the darkness bind them

or as more directly rendered in the Black Speech:

Ash nazg durbatulûk, ash nazg gimbatul

Ash nazg thrakatulûk agh burzum-ishi krimpatul

or finally the Black Speech in the Sindarin tengwar alphabet (actual cut pattern):

The circular Ring Poem pattern is common in Lord of the Rings art, but rather than use something preexisting, I made the figure myself in Adobe Illustrator using the venerable Tengwar Annatar font (input method documented here).

Tengwar notes

- A tengwa is a single character (tengwar being the plural) representing a consonant

- Tehtar (singular tehta) are diacritics that appear above and below tengwar representing vowels

Typography notes

- Vertical character stems are known as ascenders or descenders (depending on direction)

corel draw import

I followed the instructions for the Roland vinyl cutter and ran into two issues.

First, DXF v2018, the default DXF export option for current versions of Illustrator is (unsurprisingly) not valid in our version of Corel Draw (2017). Exporting as v2013 solved this problem.

Secondly, my image contained self-intersecting segments from overlapping characters:

|

|---|

| Selected tehta (blue) overlaps unselected (black). |

Cutting the image with these self-intersections would have produced undesired segmentation in the final pattern. I eliminated these intersections by using the path union tool in Illustrator.

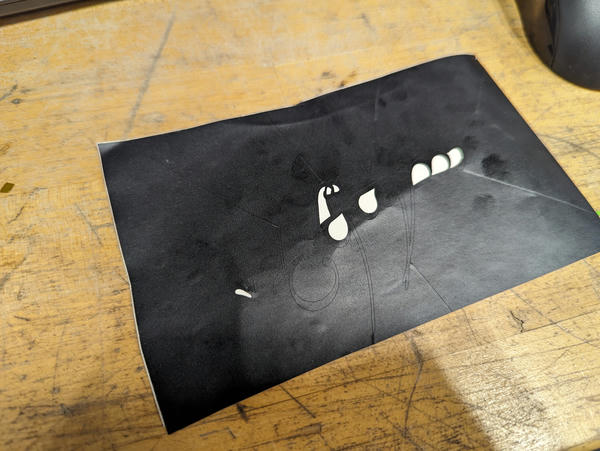

sample pattern

I cut a sample piece first to test my process using a section of the final pattern. I selected the sample pattern to intentionally include many of the elements I expected would be most recalcitrant (thin, long ascenders, disconnected tehtar, looping/spiral elements), to build confidence that the full pattern would be feasible.

I cut at 20 mm/second and 80 grams-force of pressure (default recommendation on the Roland). I found that 80 grams-force was slightly too light -- I was having to fight to shear the vinyl in some sections as I was weeding it. As a result, I increased the pressure to 85 grams-force for the final cut.

Just as I was starting to weed:

You can see that I subdivided the vinyl I needed to weed using a mat knife in order to enable smaller, individually-completable weeding actions in which I could control.

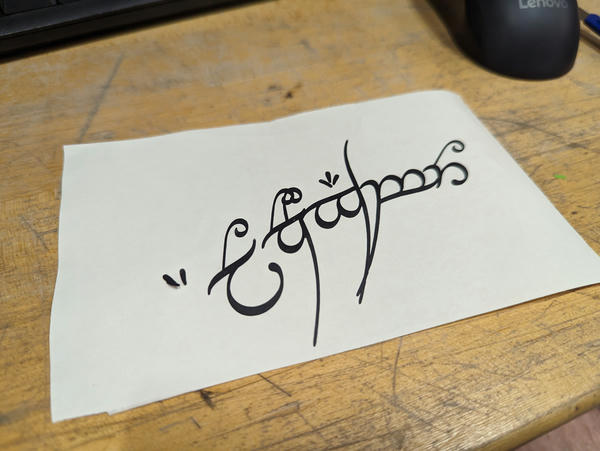

Weeding complete:

I lost a portion of the /a/ tehta on the left -- it should look like the one in the middle (three approximately-vertical marks). I wasn't careful touched the adhesive with my finger -- it lost enough stick as a result that it moved significantly when I placed it back down and loosely stuck to the middle mark. I didn't want to lose this one too, so I left them stuck together.

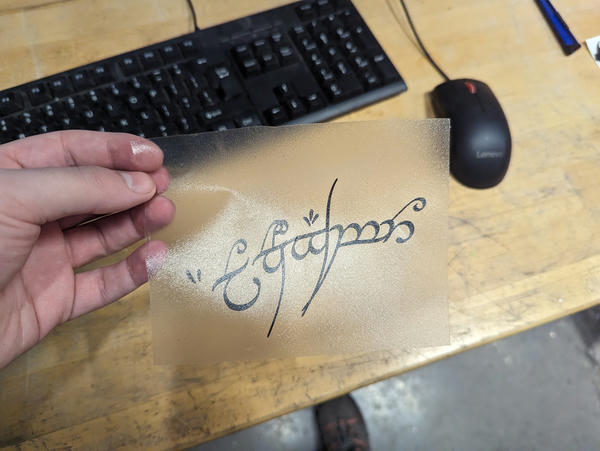

On the transfer:

I peeled the backing right after applying it to ensure I had applied enough pressure and that there wouldn't be any issues with the difficult pattern elements. There weren't, but I should have either taken the sample to completion and applied it to glass or not removed the backing to preserve the adhesive. I went halfway instead, and regret doing so (though it didn't result in any adverse consequences in this case).

full pattern

At this point I started on the complete pattern. As far as I could find, the shop was out of black vinyl (the color I wanted) except for a few strips and a ~300x400mm sheet with a crease in it that caused the vinyl to bulge. You can see this crease/bulge here (after I cut the pattern):

I knew this would cause some difficulties, but I tried it anyway. An additional feature of this full cut that I didn't see on the sample pattern was scoring apparently due to the knife dragging on the vinyl between pattern elements. I suspect this is because the vinyl was not very flat.

In the previous two images you can see that I had started to segment the non-pattern vinyl to make easier peels as I had done in the sample. This image provides some more detail on how I did this:

I cut a ring inside the tengwar descenders, then I separated the outside excess vinyl from the inside but cutting between characters. I made an cut from the tip of each descender and ascender to the inner ring or the outer edge of the vinyl, respectively. This was to ensure that I could pull each vinyl segment as much aligned with the axis of each ascender / descender as possible, to avoid these high aspect-ratio elements tearing or deforming.

This image shows the weeding partially done, and showcases protective cells I cut around each tehta. This technique allowed me to peel the bulk of the vinyl fairly quickly by avoiding these delicate, high-detail areas. I peeled them at the very end.

Here is a more zoomed out shot of the state of the weeding at this point (interior mostly complete):

I had weeded my sample using a pair of tweezers, but I discovered as I was weeding the complete pattern that I prefer to use the sharp corner of a mat knife to catch the vinyl. This gave me much more dexterity, and I almost never peeled anything I didn't mean to.

Fully weeded:

Transfer applied:

I used the side of the mat knife (retracted) to apply heavy pressure on the whole pattern to ensure it would all pull off of the backing.

sample pattern window application

At this point, I still had the sample pattern with its backing removed. I went to the window I wanted to transfer to and made a first try with the sample pattern on the other pane.

Sample applied:

I also rubbed this with the side of the mat knife to ensure the vinyl was as well-adhered as possible to the window.

I had no issues peeling the transfer -- I went very slowly and used the mat knife to catch anything that wanted to lift. I varied my peel angle to minimize lifting torque (generally aiming to peel along the axis of the typographic elements).

Sample transfer peeled:

full pattern window application

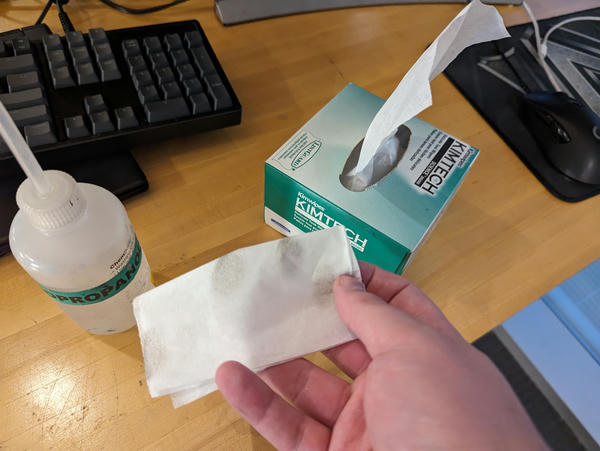

I then prepped the window for the full pattern by cleaning the application area with isopropyl alcohol in an attempt to improve adhesion.

Approach was the same as the sample -- I went slow and carefully ensured each pattern element released from the transfer cleanly.

To my knowledge, I didn't lose any of the tiny tehtar, and the ascenders/descenders are in-place mostly unmolested.

design files

Here.