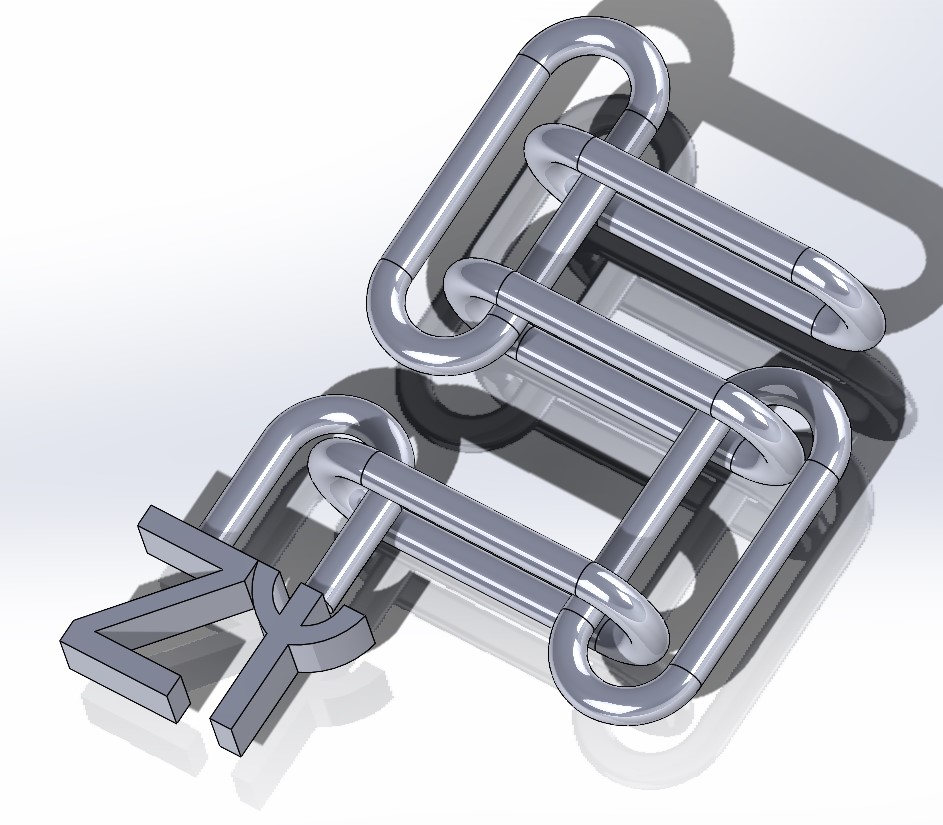

I begin every week by looking through old Fab Class assignments in case something jumps out at me and inspires me. I wasn't sure what I wanted to do yet, and I also wanted to make sure I didn't take up too much printer time (the class page suggested our design to be on the centimeter scale). This assignment by Sal Lama from 2018 stood out to me - he connected various chain links in his design and once he took away the supporting material from the print, his print was already constructed. I thought this was a super cool concept, so I decided to try it myself.

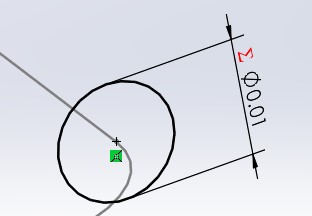

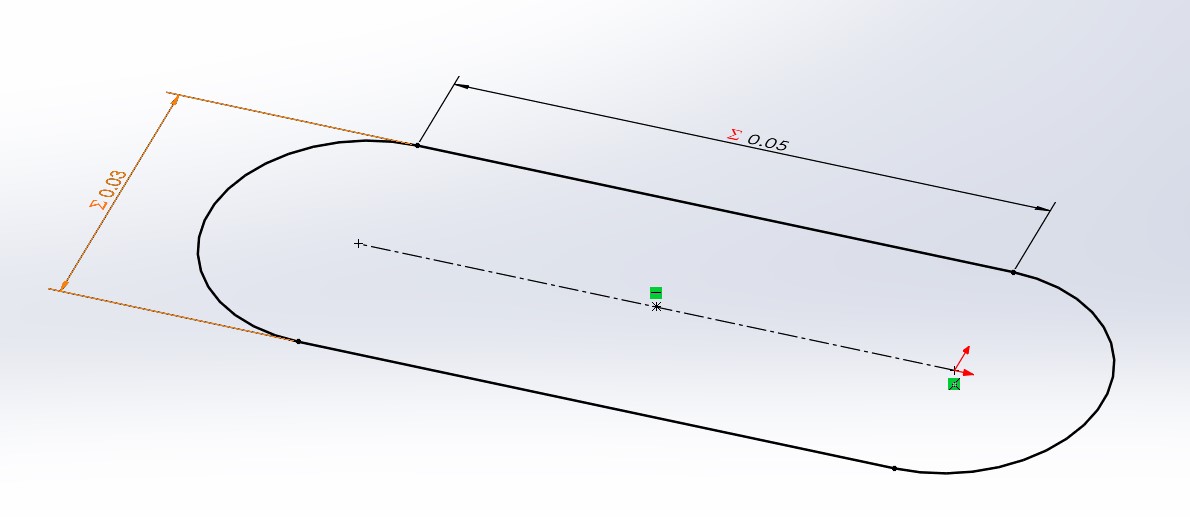

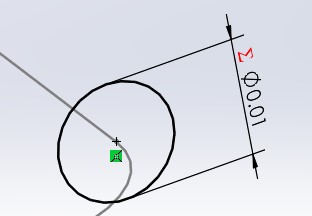

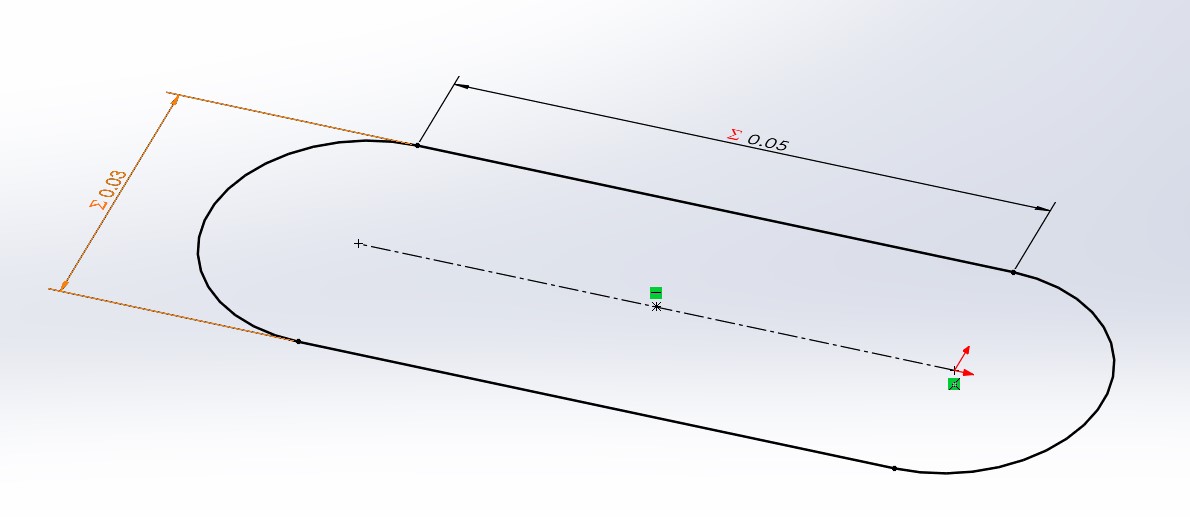

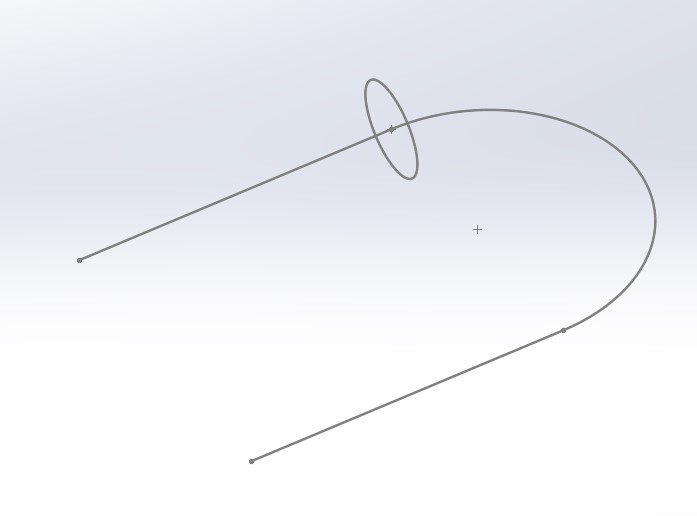

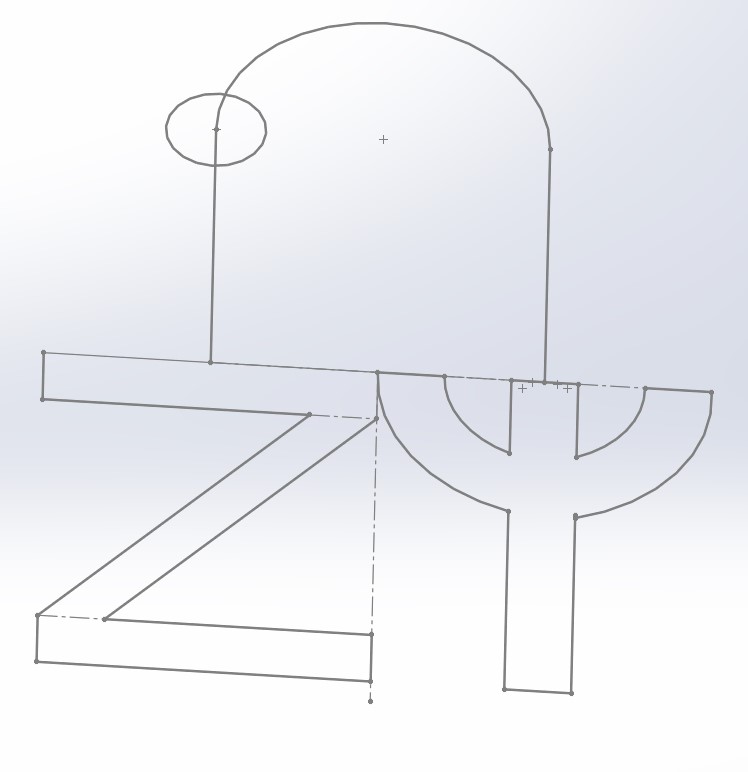

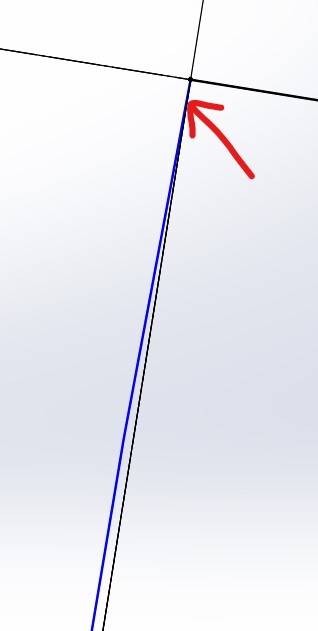

Making the basic chain link wasn't too difficult; I'm pretty comfortable with Solidworks, so I just made a sketch of a circle and swept it around a sketch of a slot that was on a perpendicular plane:

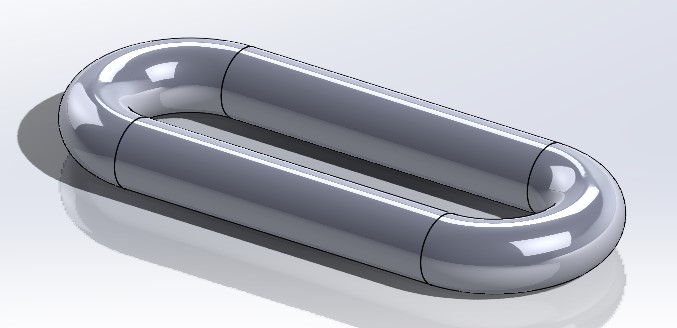

The sketches were fully defined, so I created the solid body and was happy with how it looked:

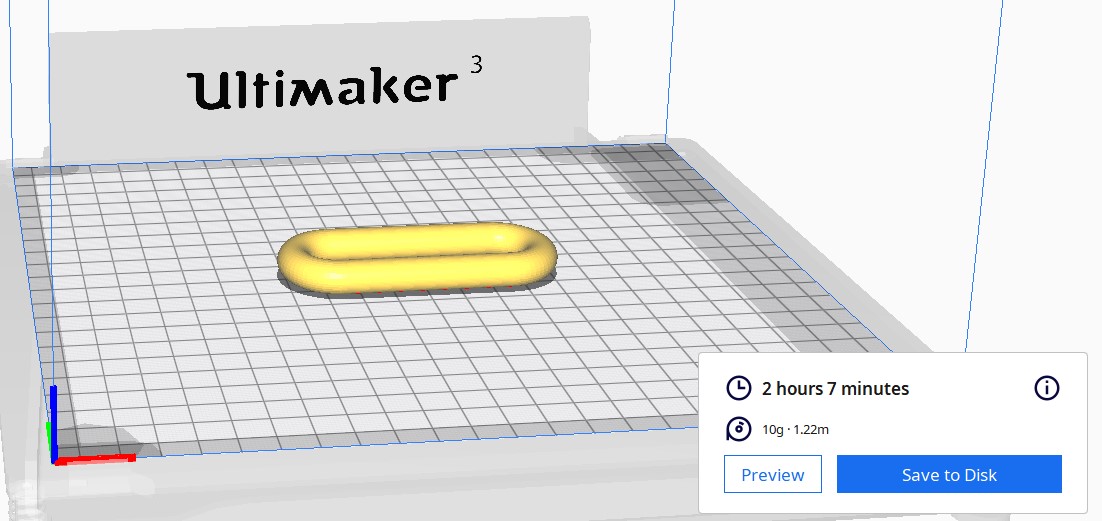

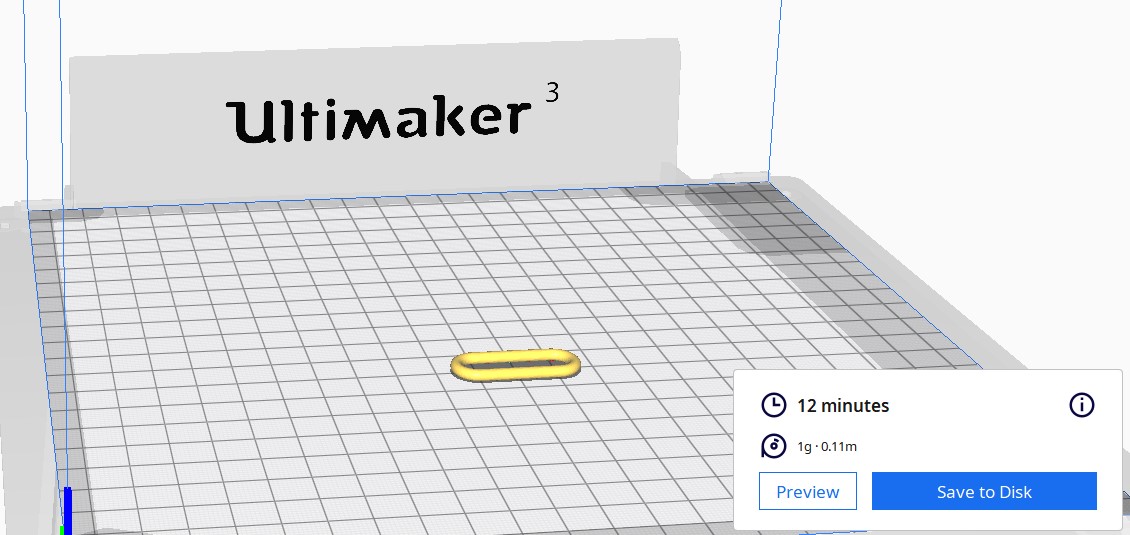

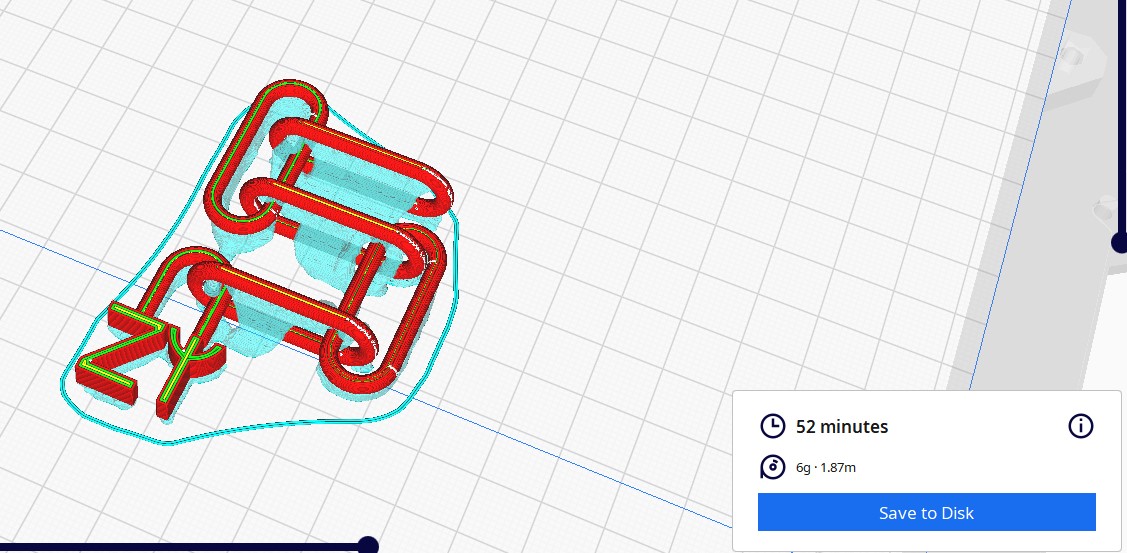

However, I soon ran into a problem once I decided to do a test slice of this singular chain link in Cura (I was very off with the dimensions I guessed for the first pass of the design, and it would be quite large and take way too long to print):

Chain Assembly: Chain_assembly.STEP | Chain_assembly.STL

Thoughts, Lessons, and Takeaways:

I love 3D printing and am quite comfortable with CAD. I did learn a lot about printer settings and how to tune a printer to best fit the task at hand - just another piece of the puzzle! The only issue I ran into was with some sloppy Solidworks sketching, which was quickly resolved; overall, I expected this week to be one of my most comfortable assignments, and that was true, but I'd love to get into lab and continue pushing the limits of what 3D printers can do in my free time (one week later update: I was sick this week, so I'll rain check that until I get recovered and caught up on work!). I'd love to explore the possibility of printing removable end links so that I can customize my chain further, and I also intend to attempt to create more complicated designs, even simple mechanisms, within a single 3D printing job. In summary, it was a blast of a week for me and a good step towards being able to make (almost) anything!