# Molding and Casting

I decided that I wanted to make a candle for my friend and freshman year roommate, Jason. His username on many platforms is "dumplinglife" so I decided to make him dumpling candles for his birthday!

I started by making a cad - I grabbed a dumpling off the internet and added a baseplate to it.

I spent some time trying to make a CAM for the dumpling, but I realized that the shape was not possible for a 3 axis mill. Hence 3D printing.

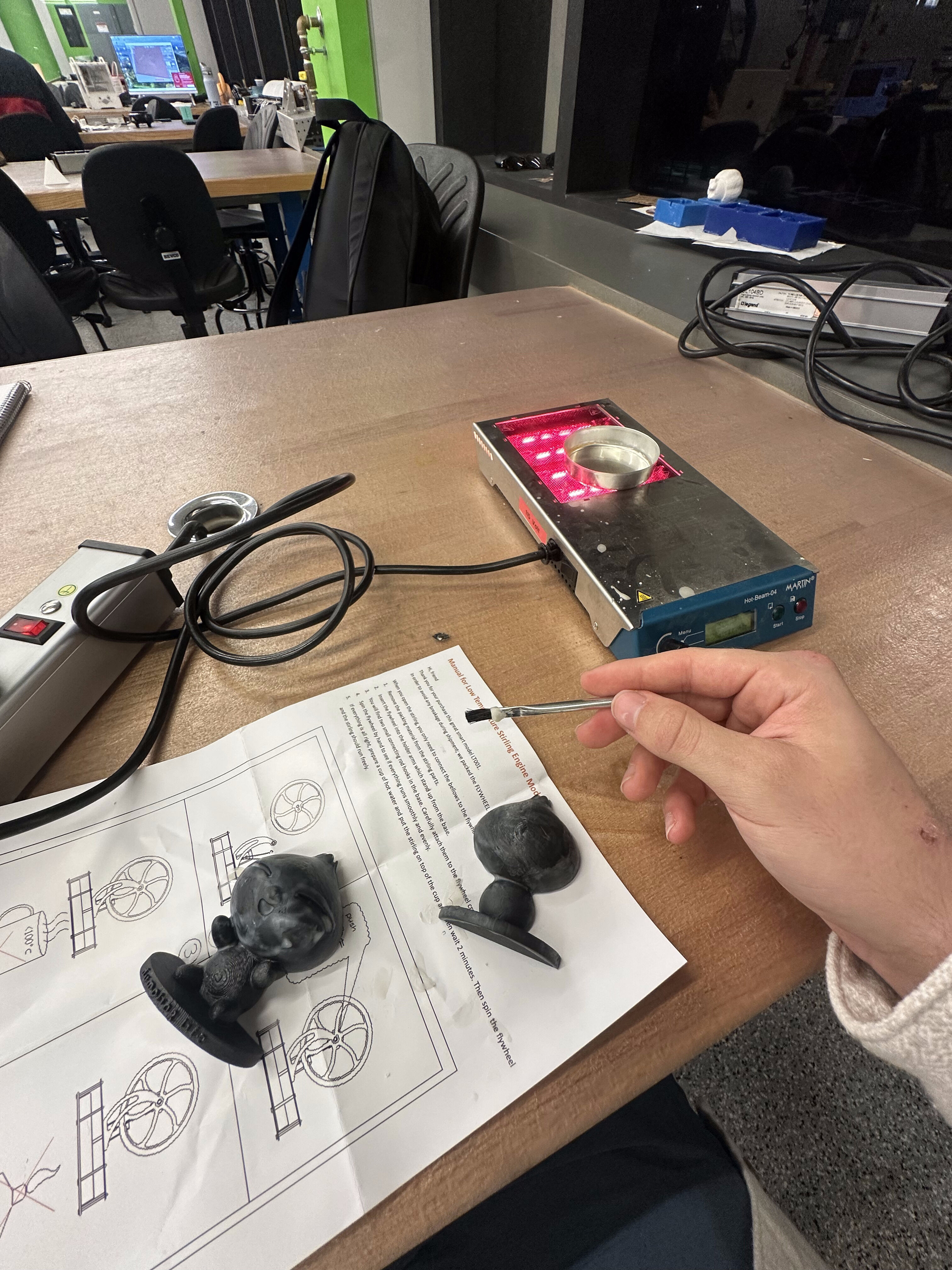

I melted some wax and coated the plastic in a thin layer, this would mitigate the ridges on the mold and lead to a cleaner final finish.

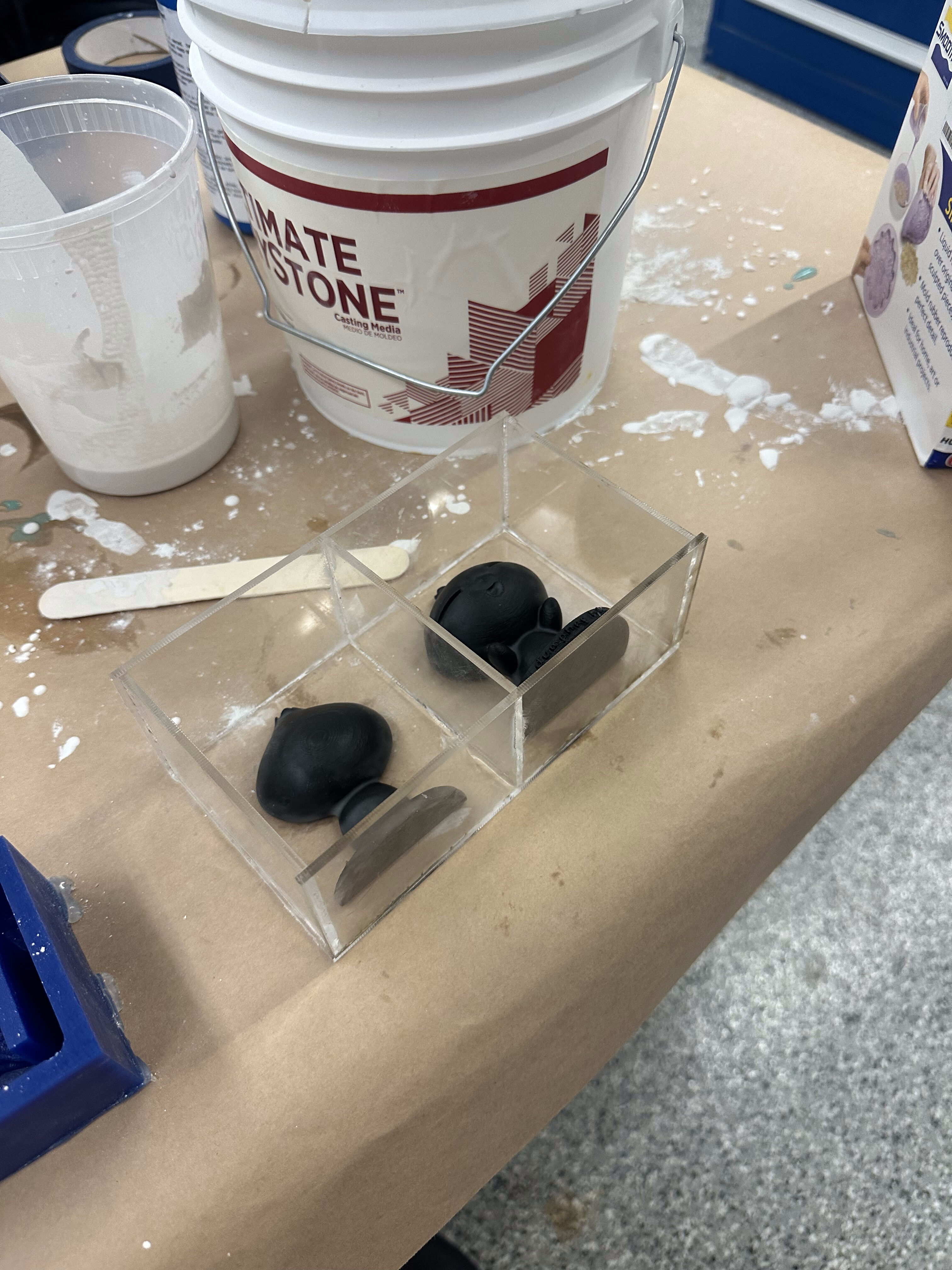

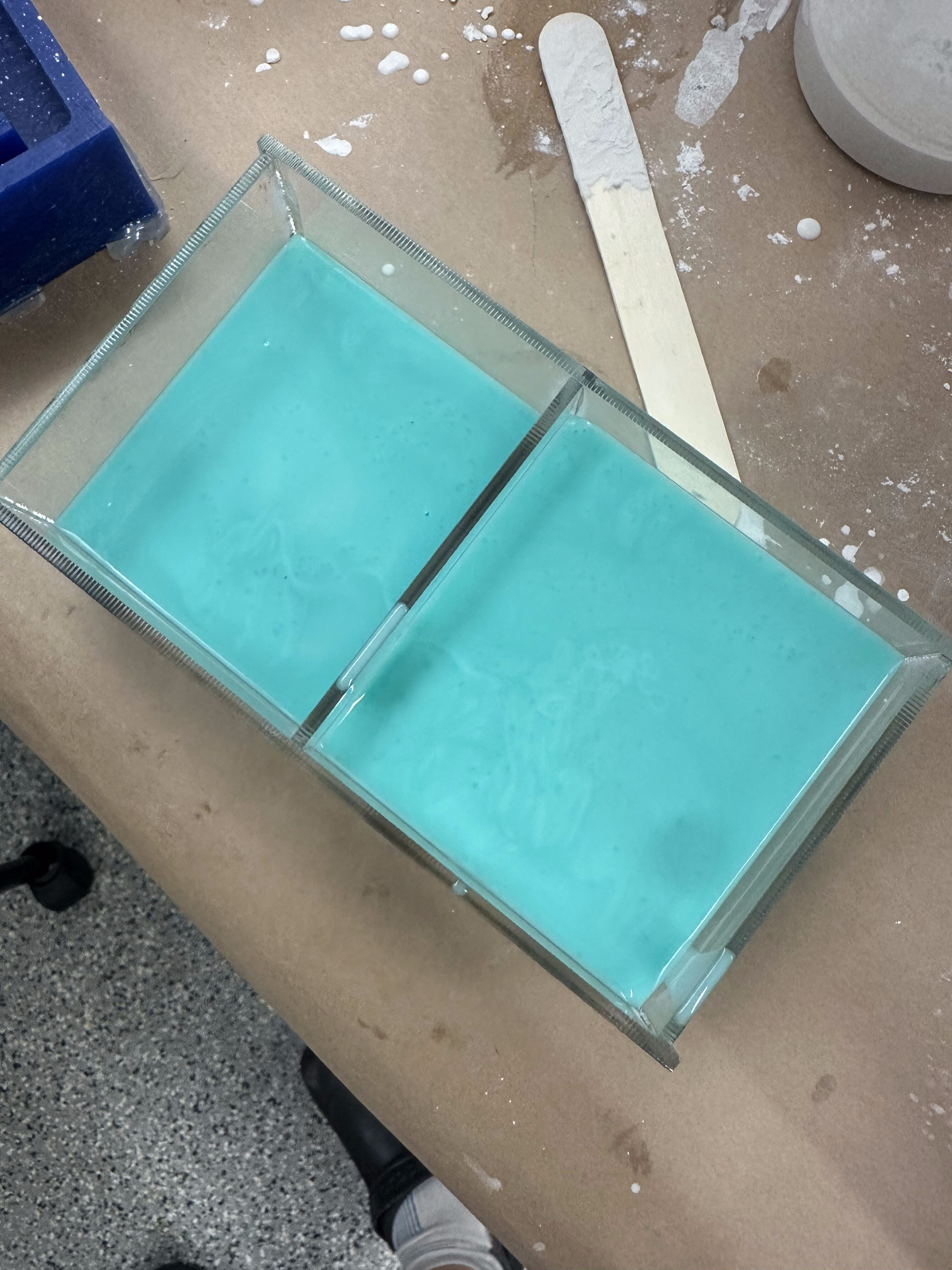

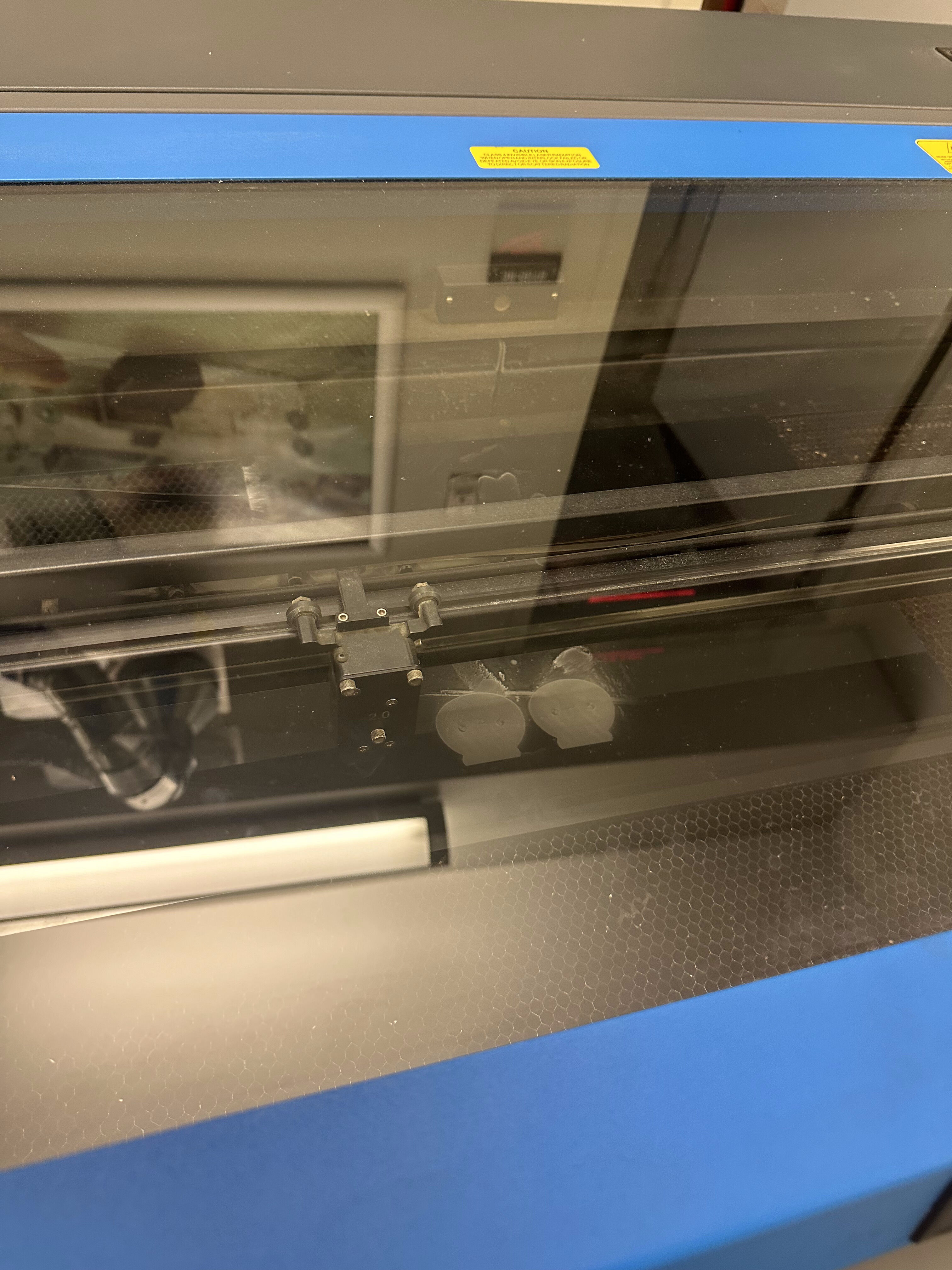

I was running short on time so I decided to make an acrylic case for the mold creation. In an ideal world this would be 3d printed to maximize precision

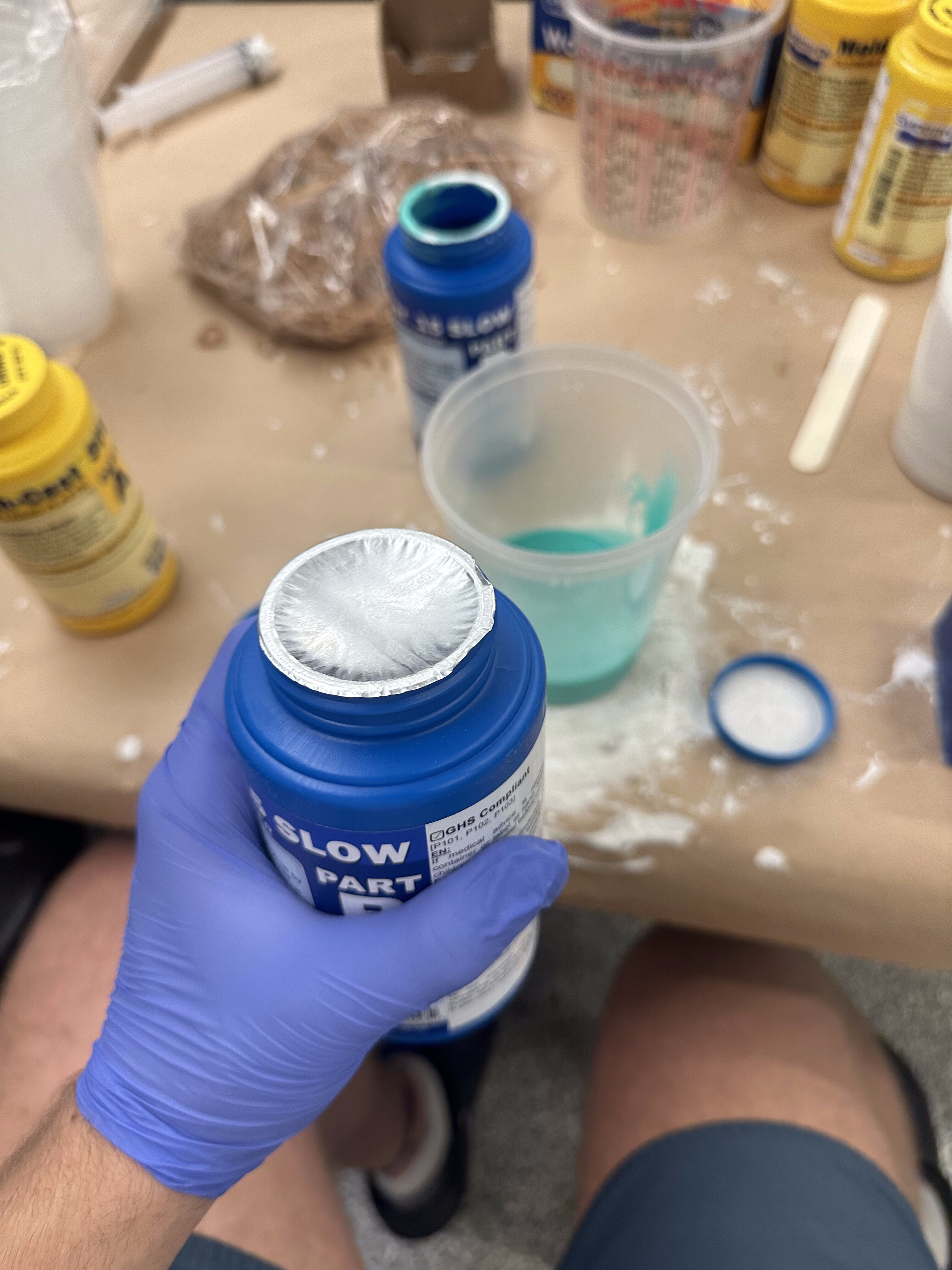

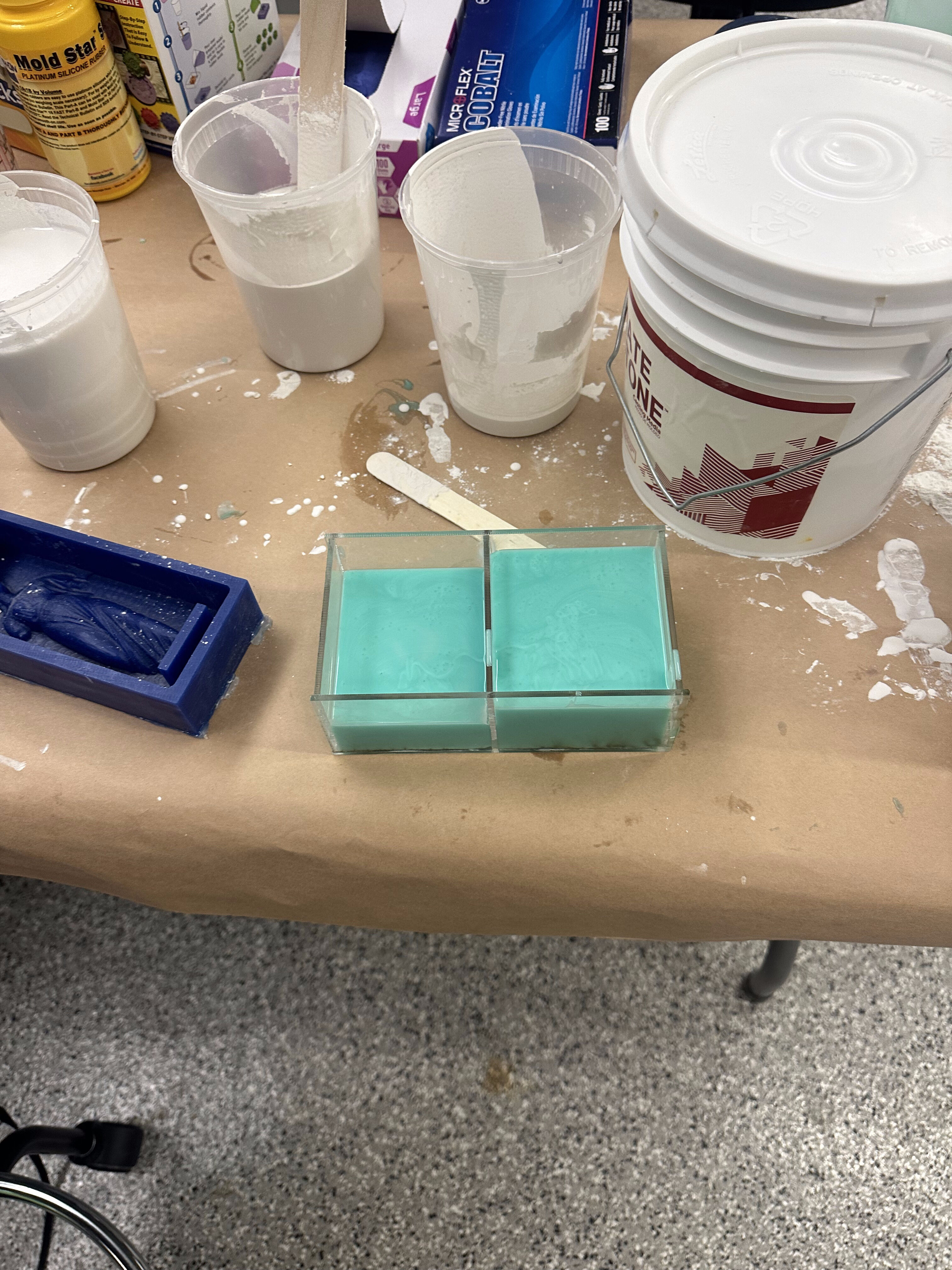

I mixed the chemicals. I originally accidentally mixed up the silicone with the plastic, and mixed one from plastic and one from silicone. This wasted an entire jar! Sorry Anthony

I put in the silicone to the mold and waited for it to cure.

I then poured the wax into a metal container to melt it.

This was a super quick process.

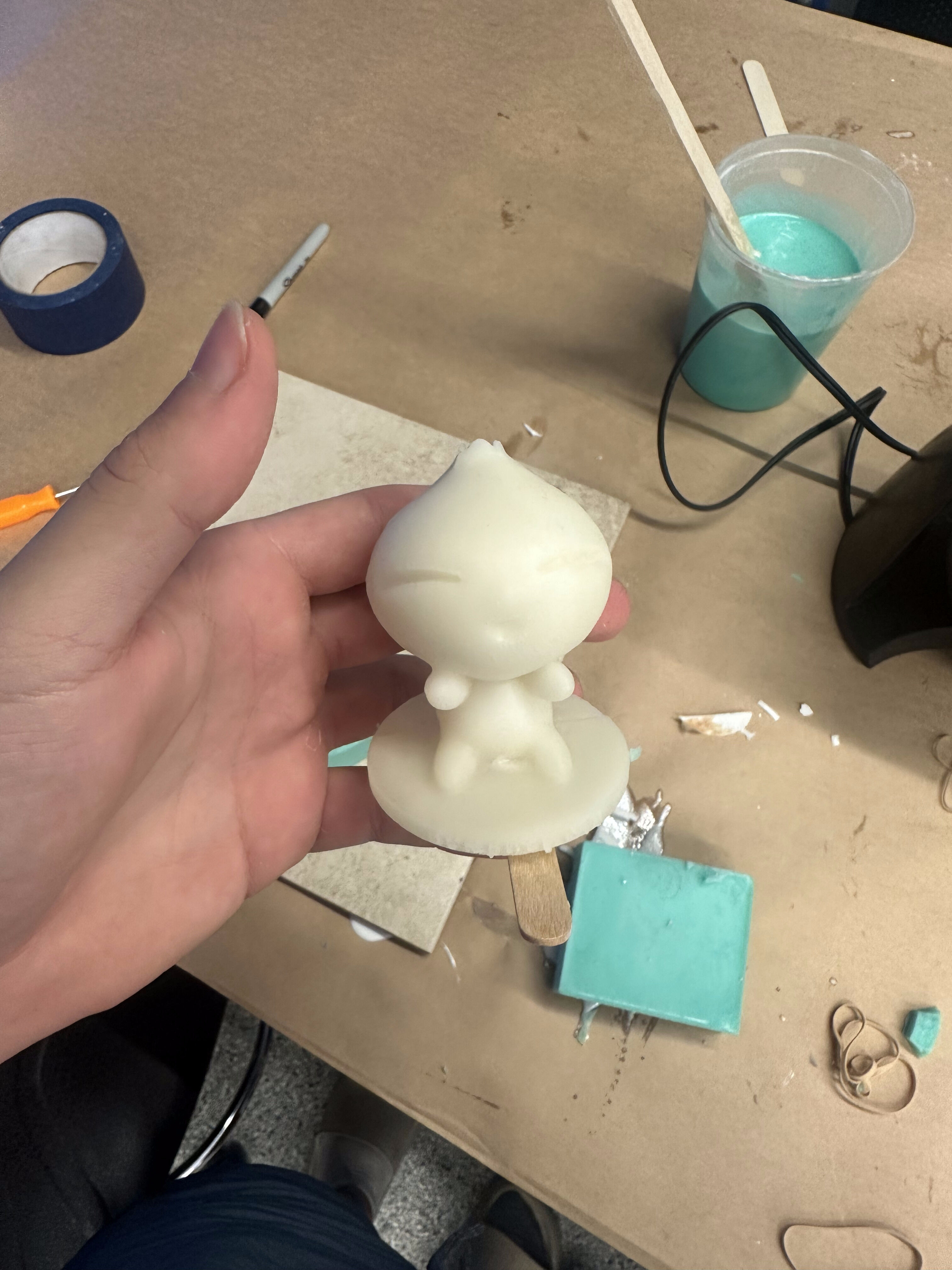

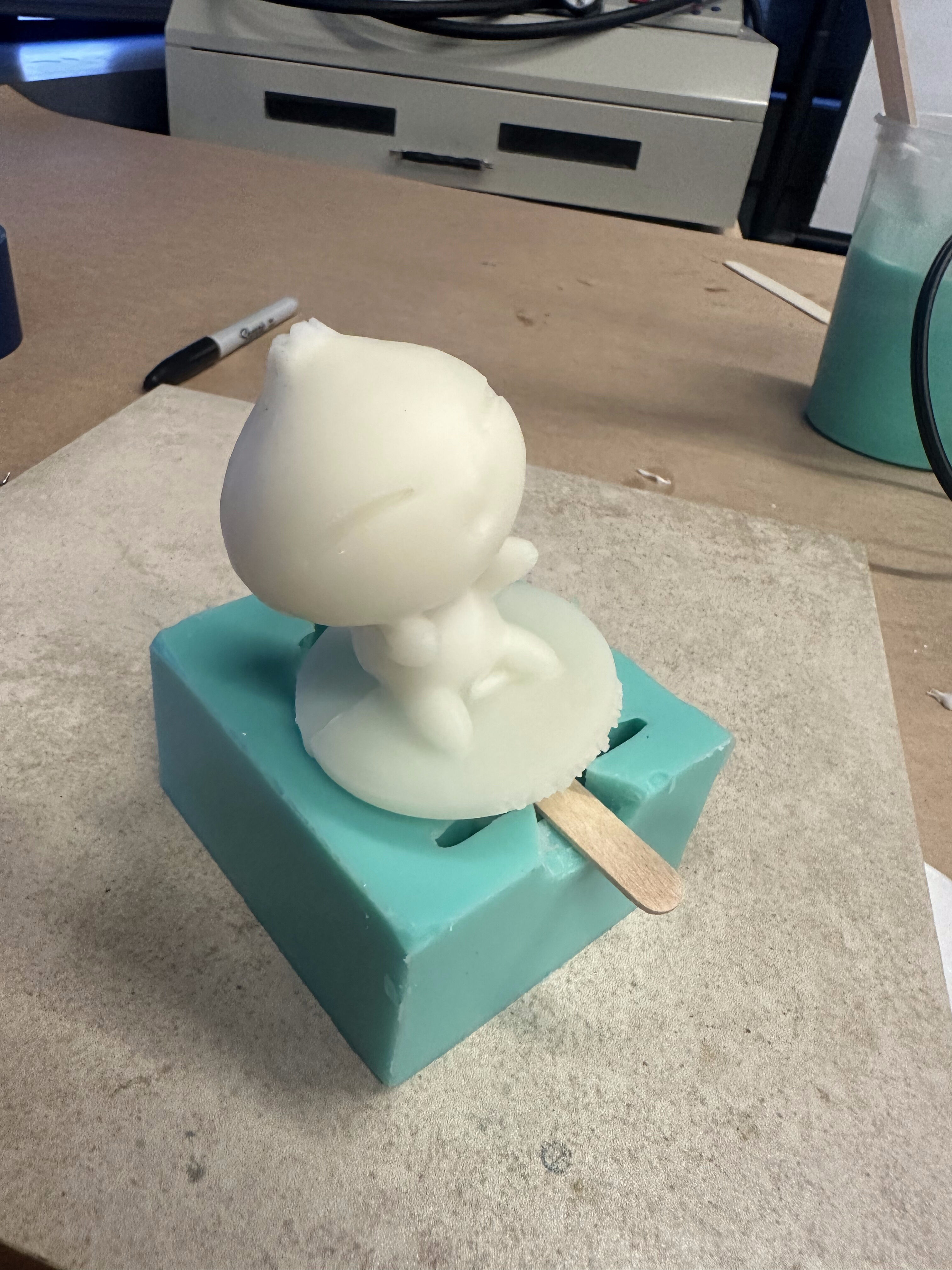

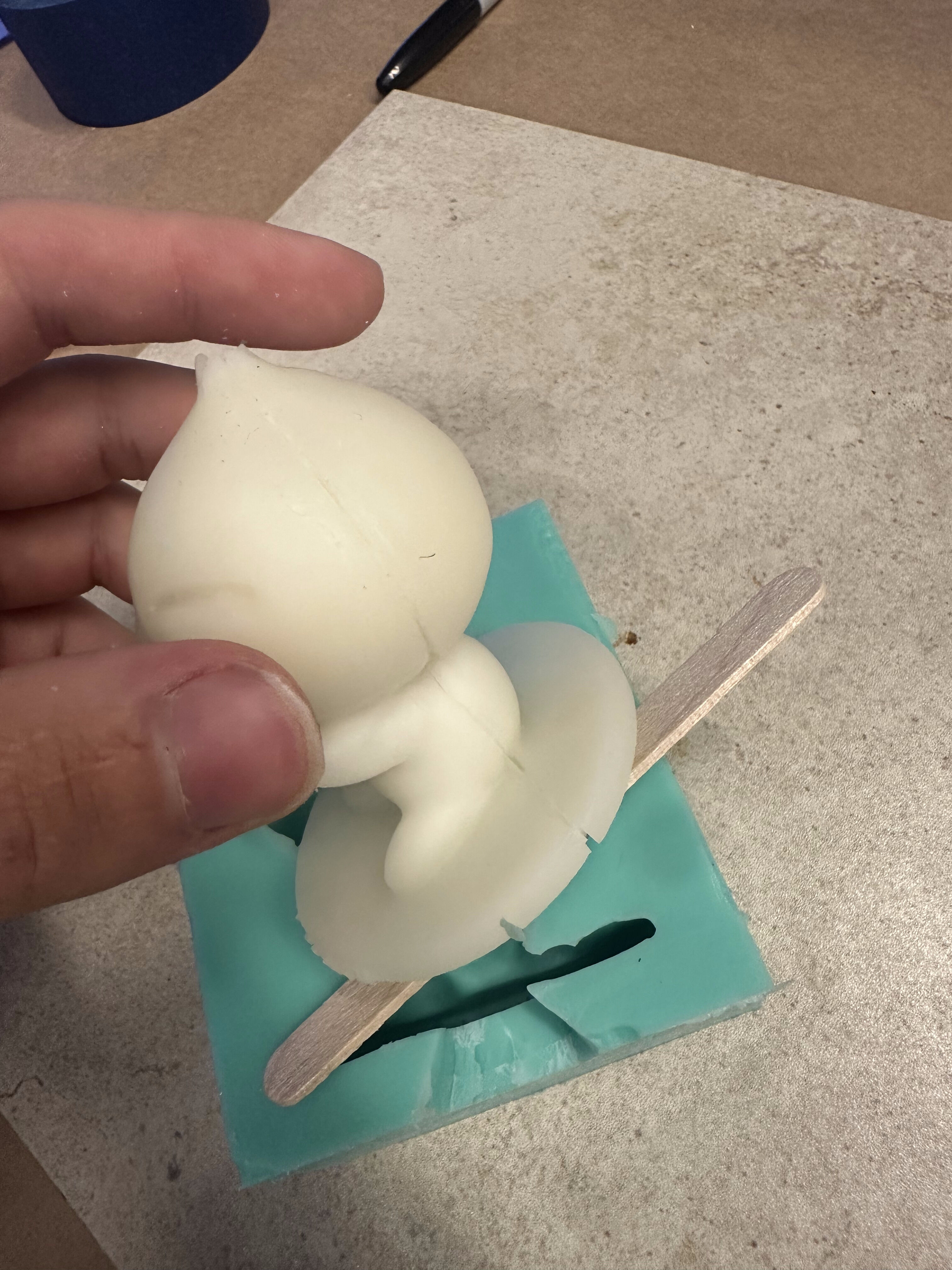

I put the molten wax into the mold and let it cool.

I then removed the wax from the mold and cleaned it up.

There were some issues with the siding where the two halves joined. I redid it a few times to minimize the disjunction.

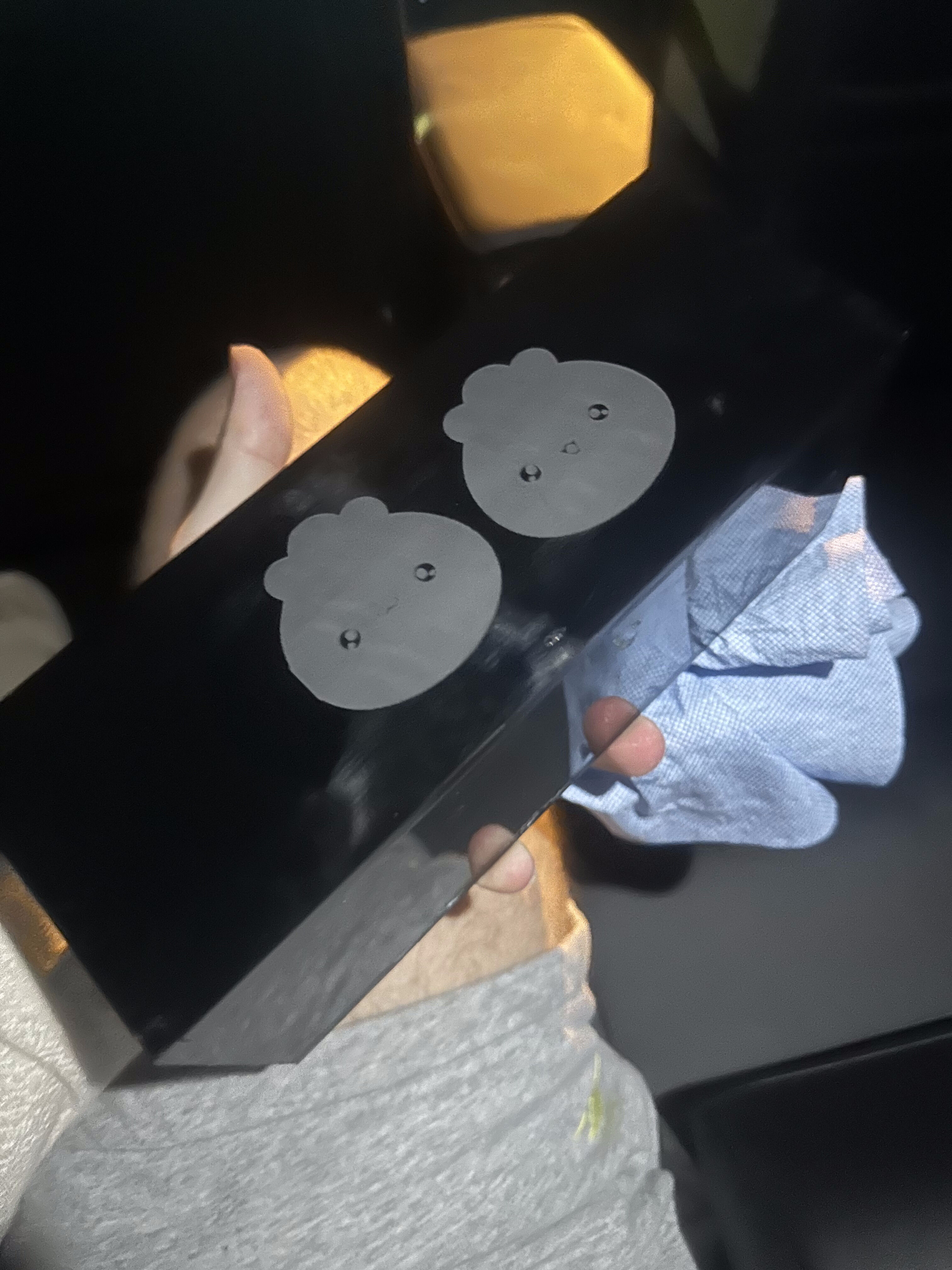

Presentation is the most important part of a gift! I made him an acrylic box to hold the candle. I etched two dumplings on the front cover!

I superglued the case together!

And boom, success, Happy Birthday Jason!