3D Print

Trial and Error

It has been long since I tried printing a scanned model so I was really curious to see how things changed since Autodesk's 123Catch from 2016.

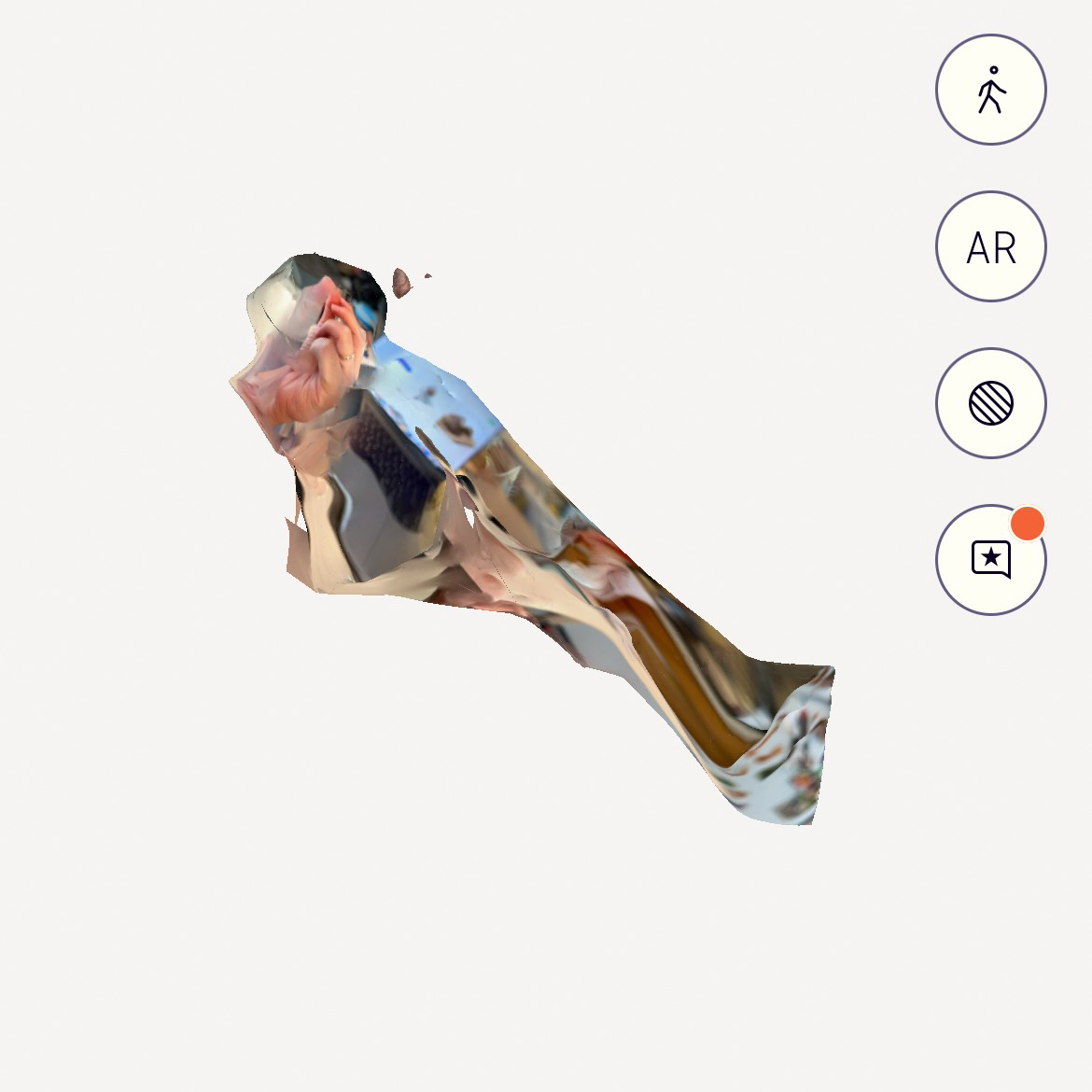

I started the scanning with Polycam, the first attempt was miserable. My hand appeared as an unrecognizable twisted surface.

Scanning and Modeling

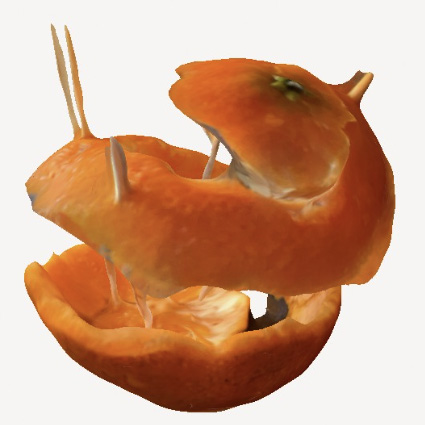

I pilled a clementine into a hollow spiral, just big enough to place a small candle in.

I stabilized the orange pill with some toothpicks that I'd have to model out later on.

The scan resulted in a really clean, watertight cloased mesh.

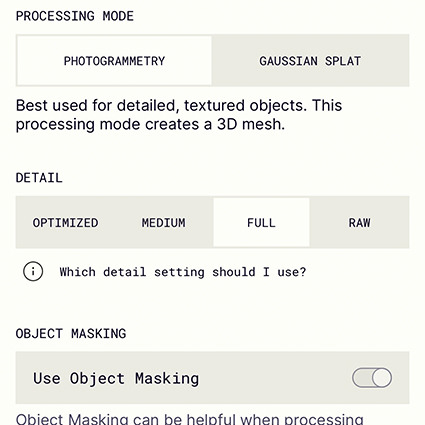

The advanced (payed version) definitions really helped, as well as the object masking option.

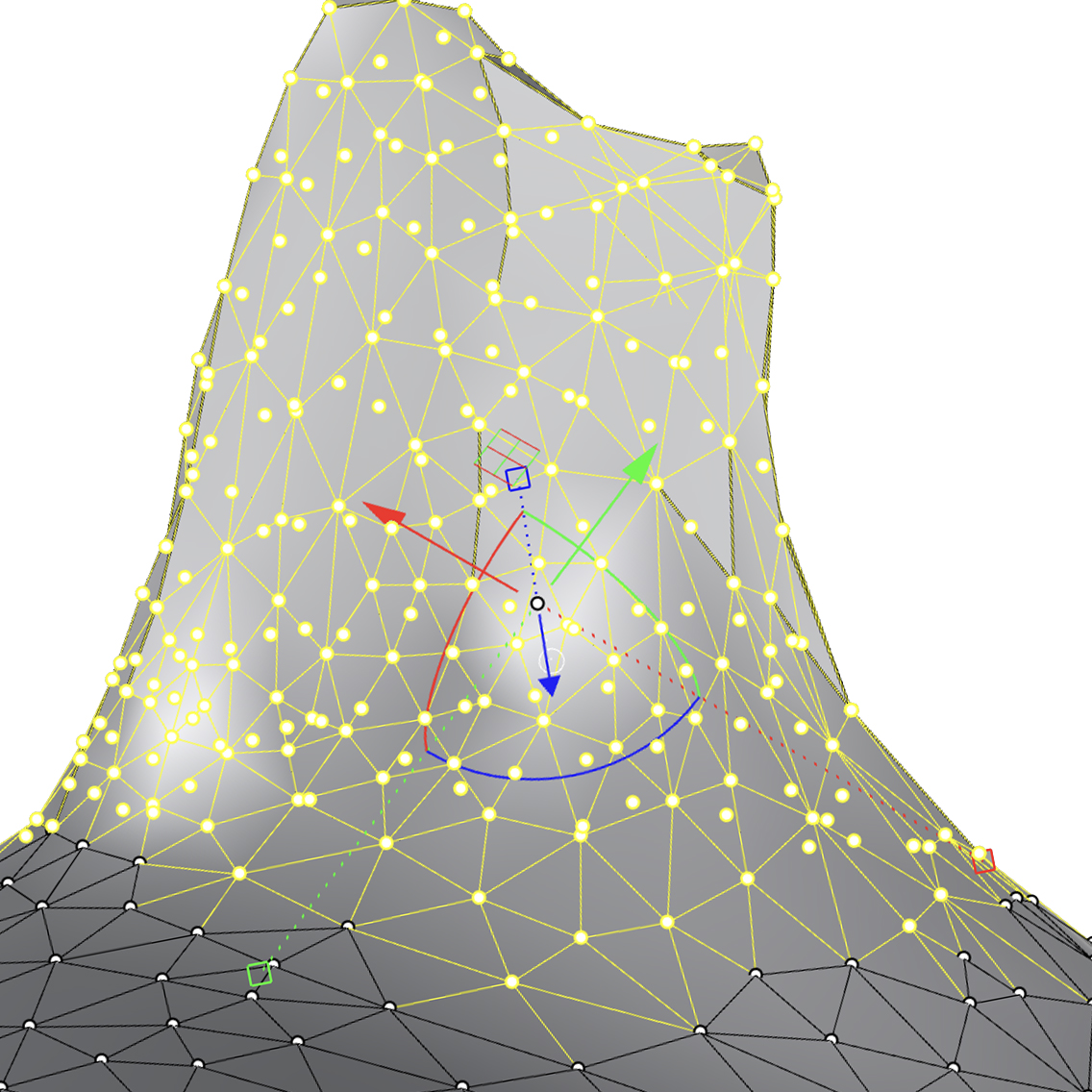

In the next step I cleaned the model in Rhino, got rid of the toothpicks, and made space for a round candle using boolean commands.

Selecting the points on the mesh

Deleting

And patching

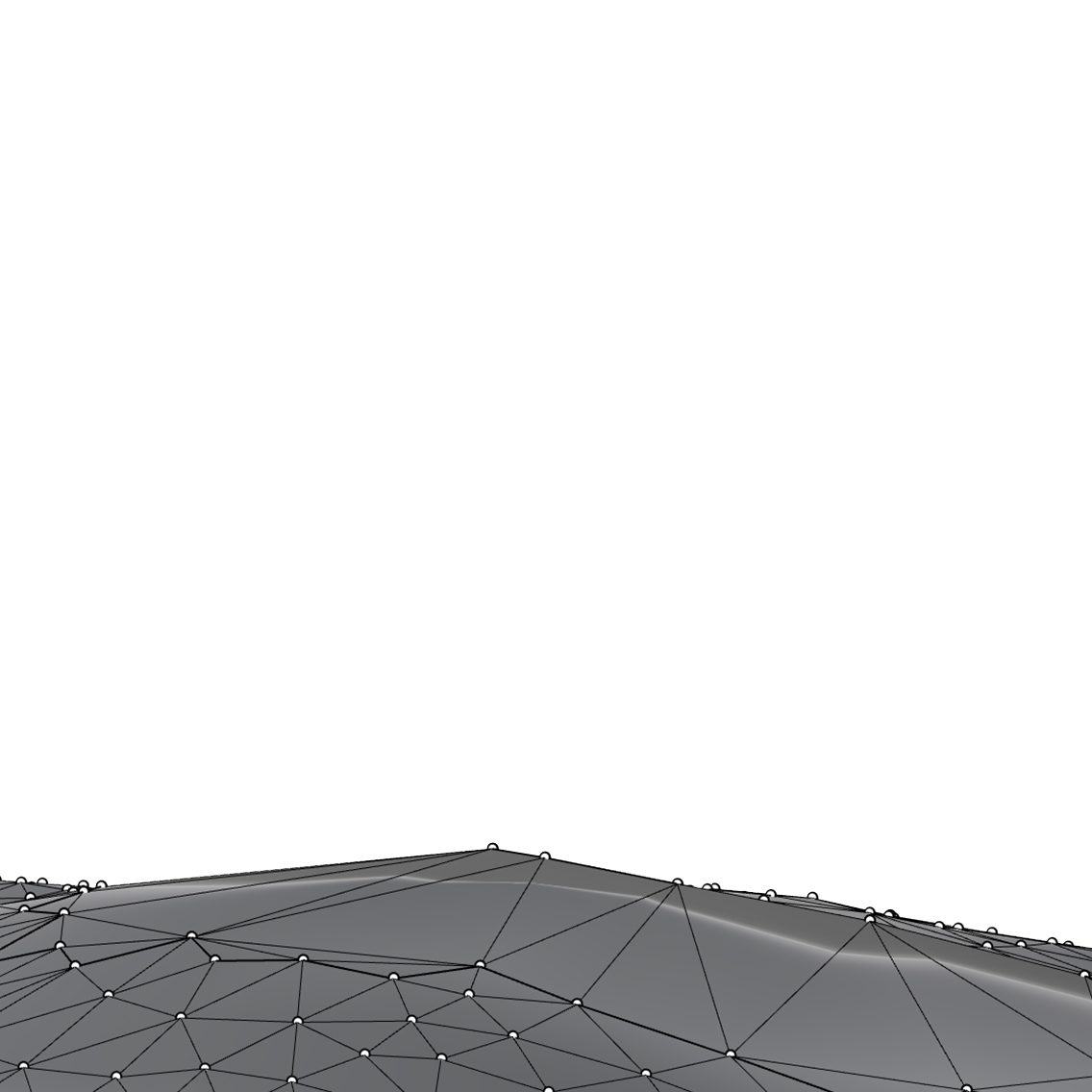

Here's a render of what I hoped it would look like as the final product:

Printing

The architecture workshop has PLA, ABS, and gypsum powder printers. Since PLA isn't durable for heat at all, and the gypsum powder is very brittle (would probably not support the hanging top), I chose the more durable ABS option. Shah printed the candleholders after I placed my files in the architecture workshop's que. There's no way for students to independently print ABS in the architecture workshop.

copy.jpg)

After 3.5 hours in the UV light box the support was dissolved.

We washed it thoroughly from the scraps of supportive material.

And let it dry.

Then after some filing this is the final result

Fail

It was a nice picture but then the kitchen started smelling of melted plastic and I realized ABS may be more durable than PLA but it's definitely not fire proof.

Maybe the next step going forward would be to turn this into a mould for some other material.

It was a nice picture but then the kitchen started smelling of melted plastic and I realized ABS may be more durable than PLA but it's definitely not fire proof.

Maybe the next step going forward would be to turn this into a mould for some other material.

Group Assignment

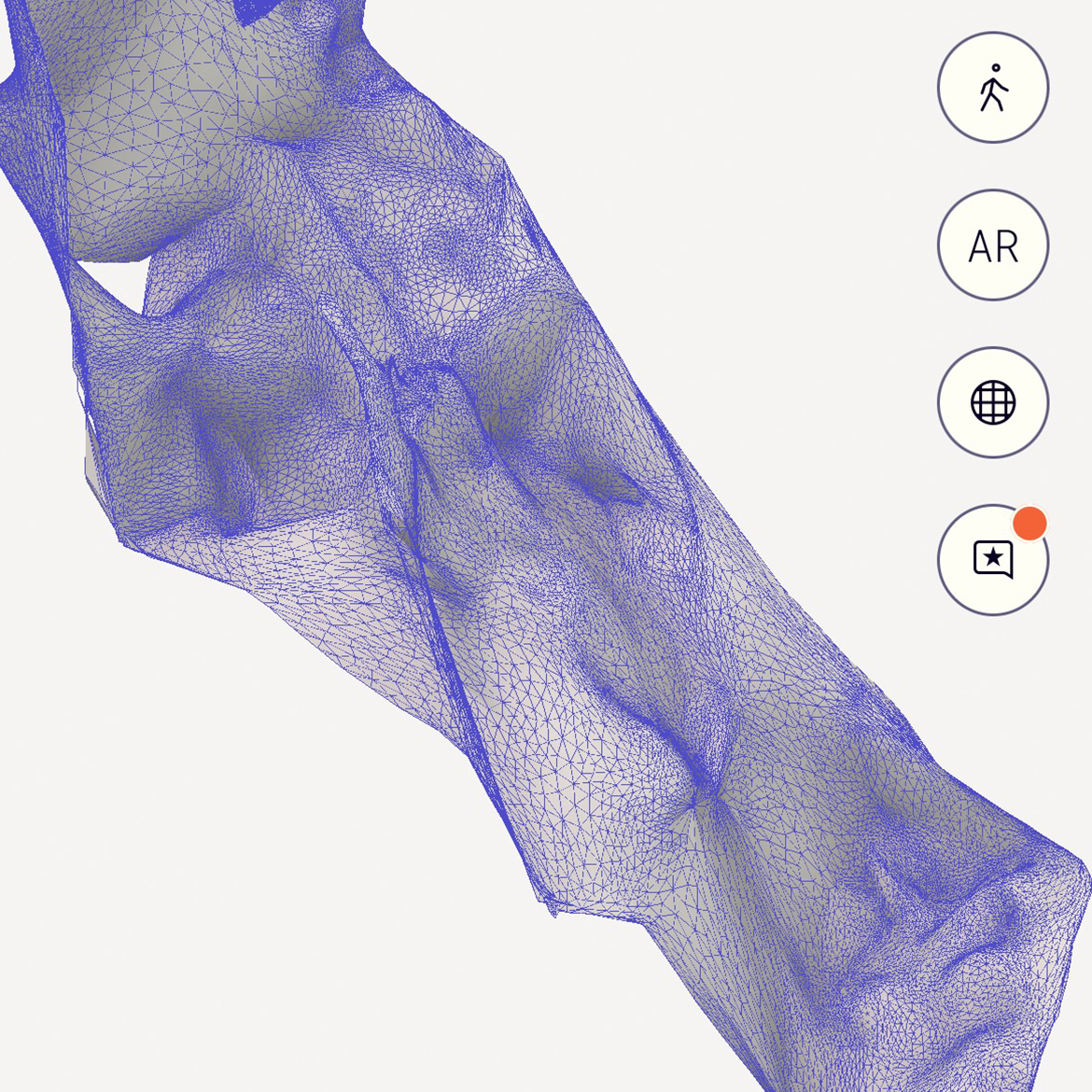

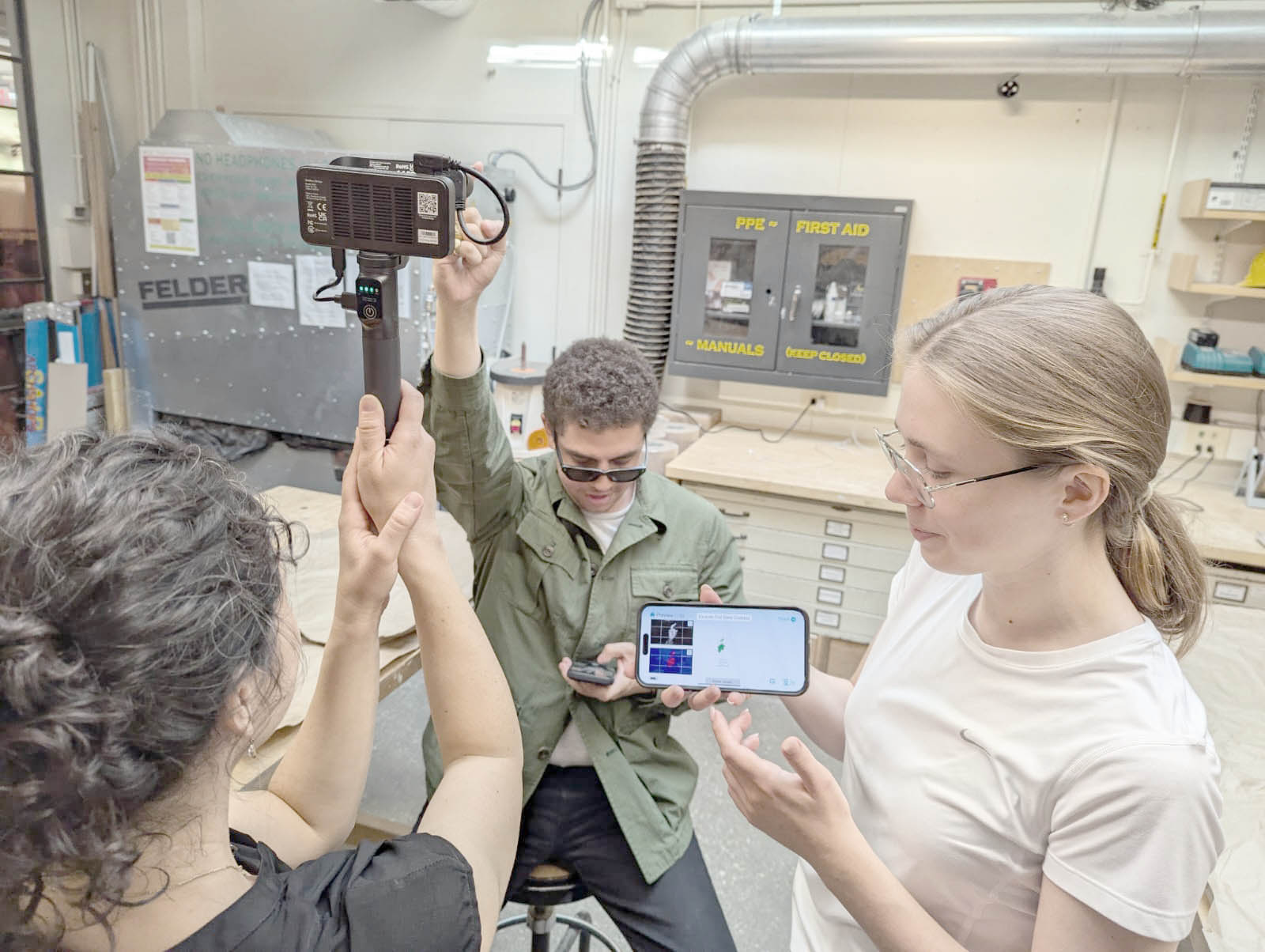

For this week's group assignment we tried out the architecture workshop's scan together, scanning out Kareem's hand. It was interesting to see how well it performed in comparison with me scanning my own hand on the Polycam app. Probably

due to my lack of coordination more than anything else... But also the details were amazingly granular with the scanner in relation to the quality I achieved on my Lidar-less iPhone.

For this week's group assignment we tried out the architecture workshop's scan together, scanning out Kareem's hand. It was interesting to see how well it performed in comparison with me scanning my own hand on the Polycam app. Probably

due to my lack of coordination more than anything else... But also the details were amazingly granular with the scanner in relation to the quality I achieved on my Lidar-less iPhone.

Files

Here is the file of the edited 3d model ready for print