The 3D Trivet

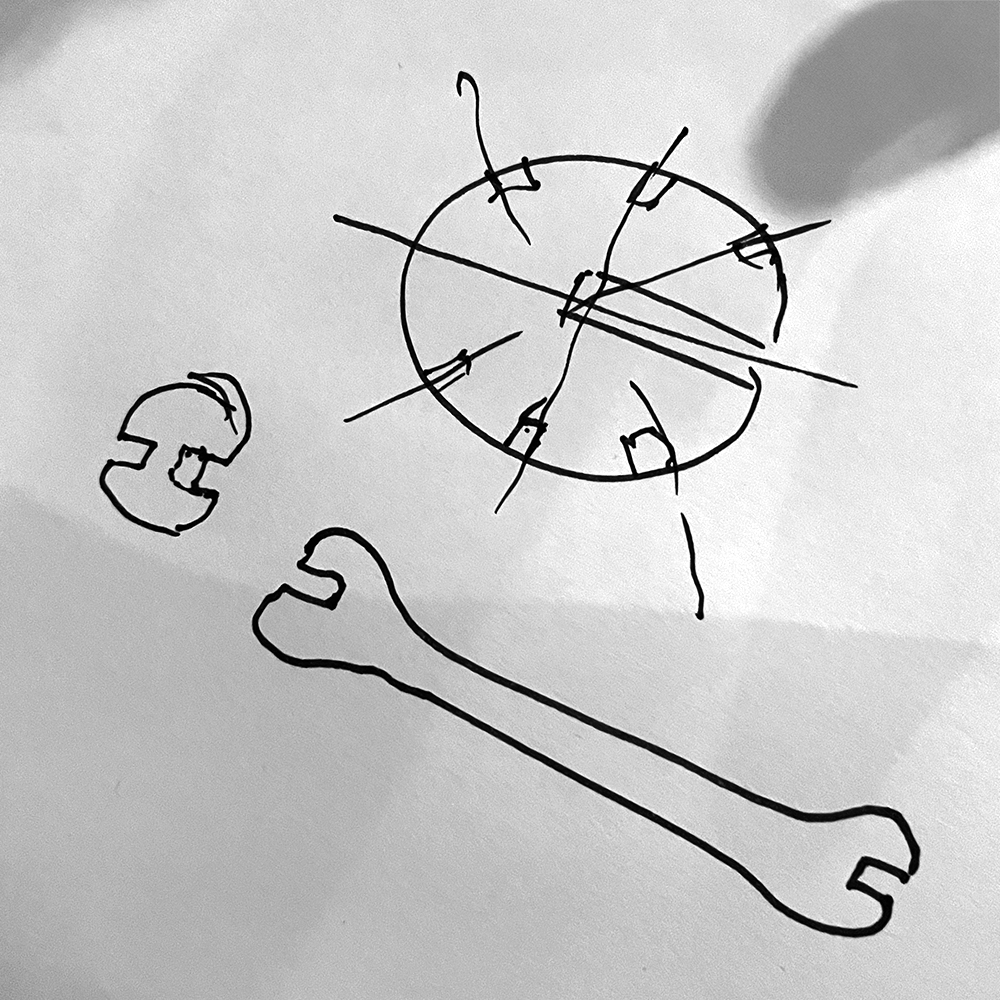

Ideation

The 3D trivet idea started from sitting in our living room and thinking of a simple kit for creating trivets, which can be compatible with all sorts of cake pans.

The idea was to use the quality of the curragetd cardboard's robustness carrying forces that are aligned with its curragetd direction. I initially thought of making small balls and connecting them with longer connectors, but was afraid it won't be dense enough to carry heavy weight of most kitchenware. Therefore I proceeded designing for the short connectors (on the left).

The idea was to use the quality of the curragetd cardboard's robustness carrying forces that are aligned with its curragetd direction. I initially thought of making small balls and connecting them with longer connectors, but was afraid it won't be dense enough to carry heavy weight of most kitchenware. Therefore I proceeded designing for the short connectors (on the left).

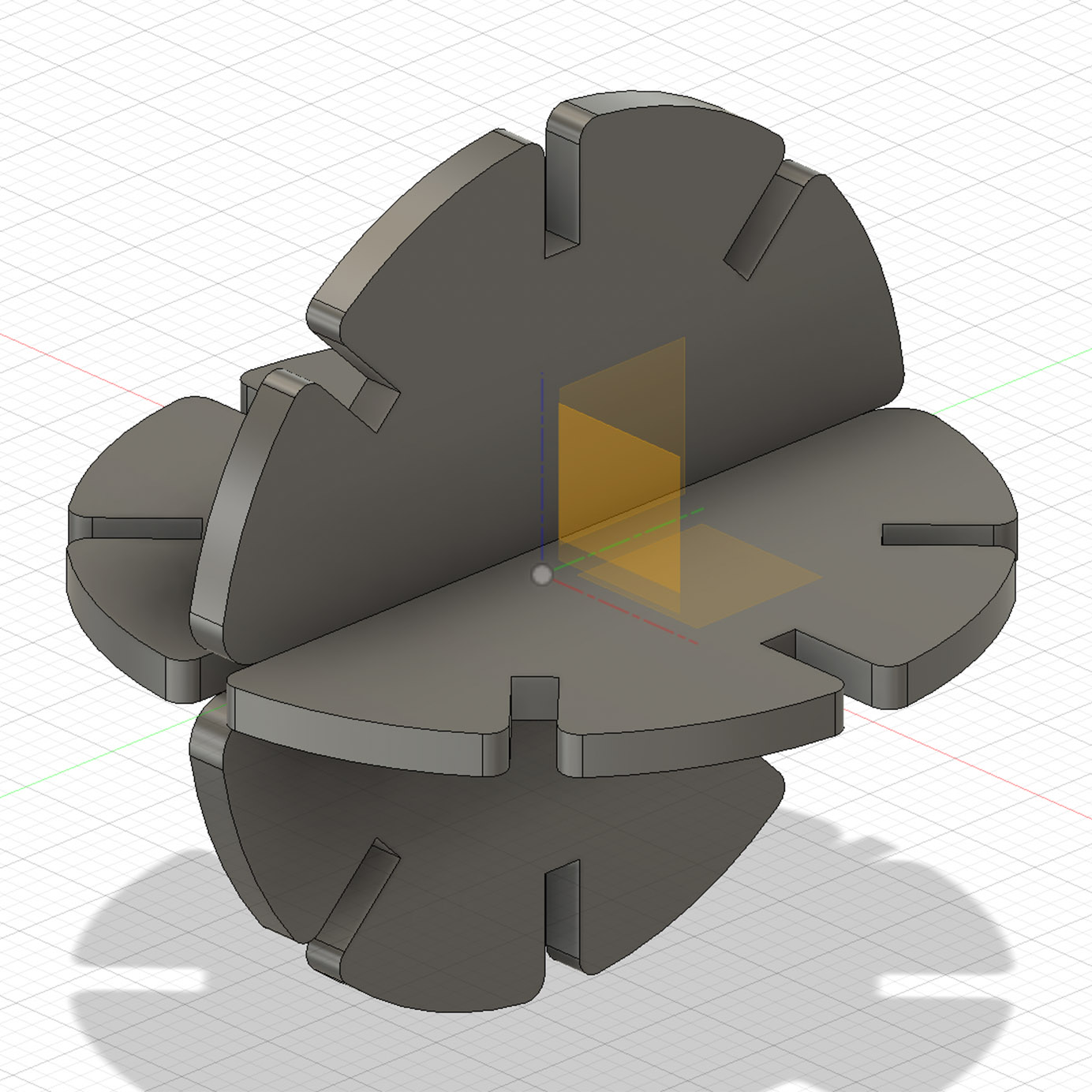

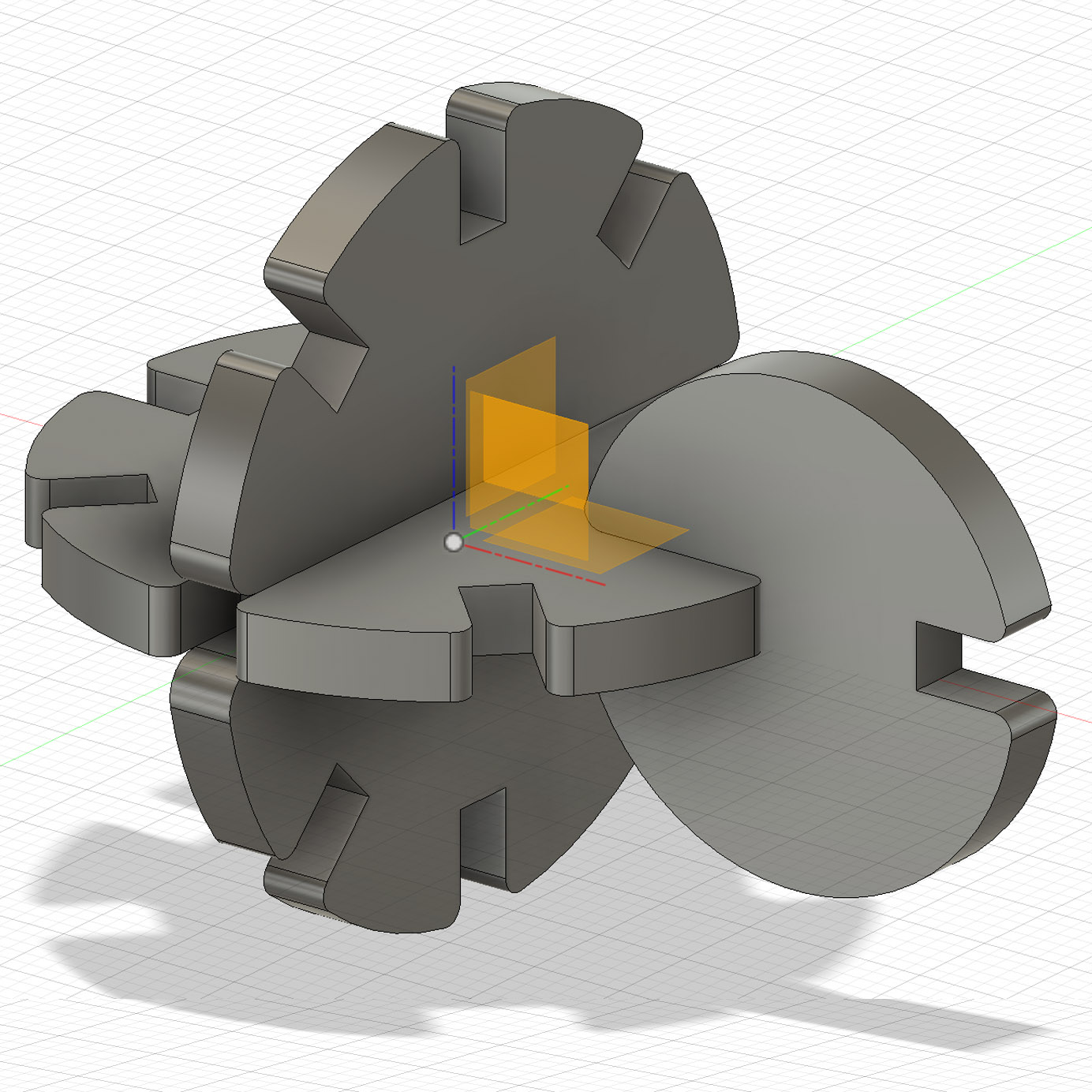

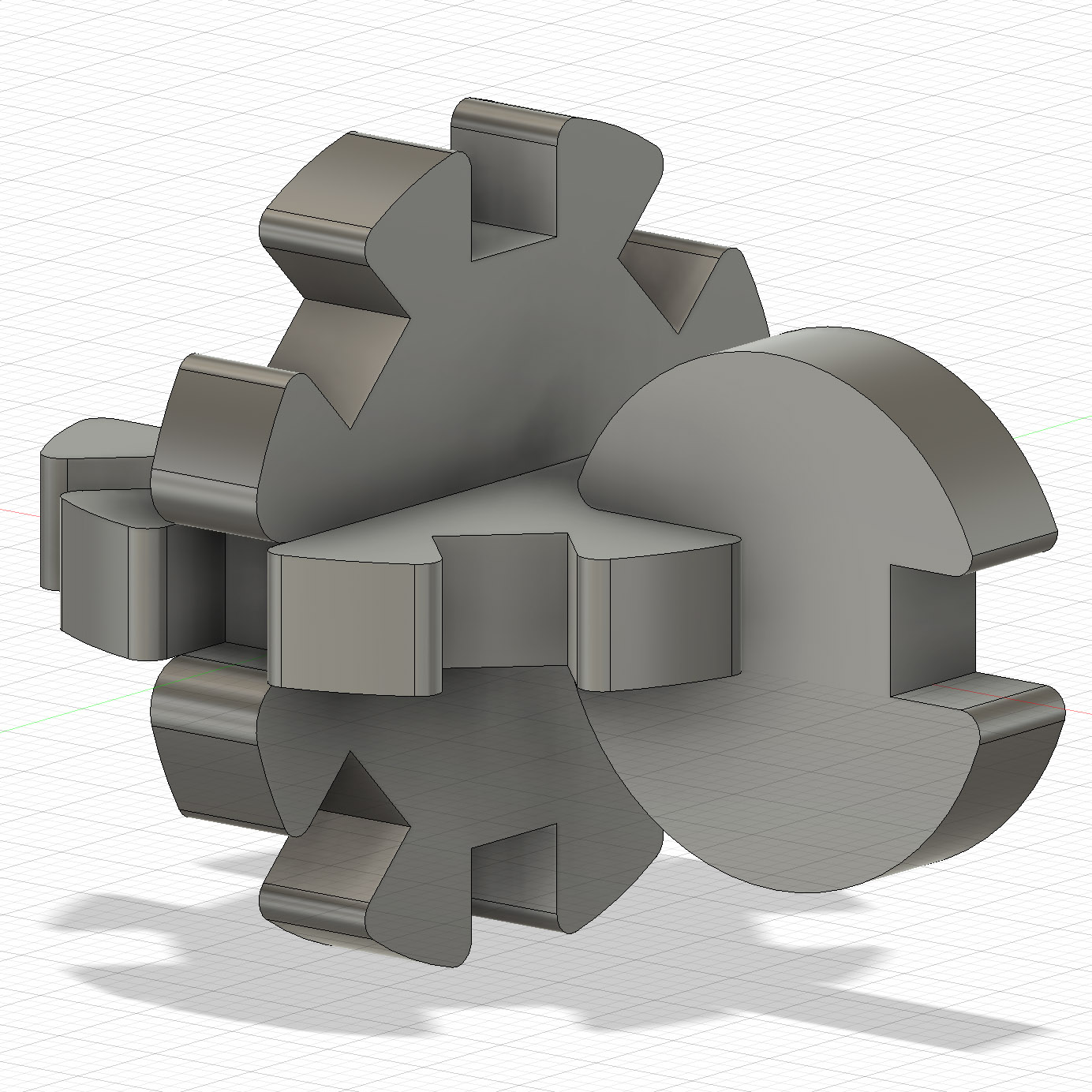

The next stage was protoyping a parametric model in Fusion 360. It was the first time I worked in Fusion and I'm really glad I did that, instead of working with Rhino's Grasshopper. The parametric design tools are a lot easier to implement in Fusion and requires less pre-planing of the modeling process. Also, the interface was intuitive enough for me to have a relatively short phase of the steep learning curve.

I limited the input parameters to: Cardboard thickness, ball diameter (determines the thickness of the trivet), and the fillets dimensions. All other modelling dimensions were defined as a function of those main parameters.

Fabrication

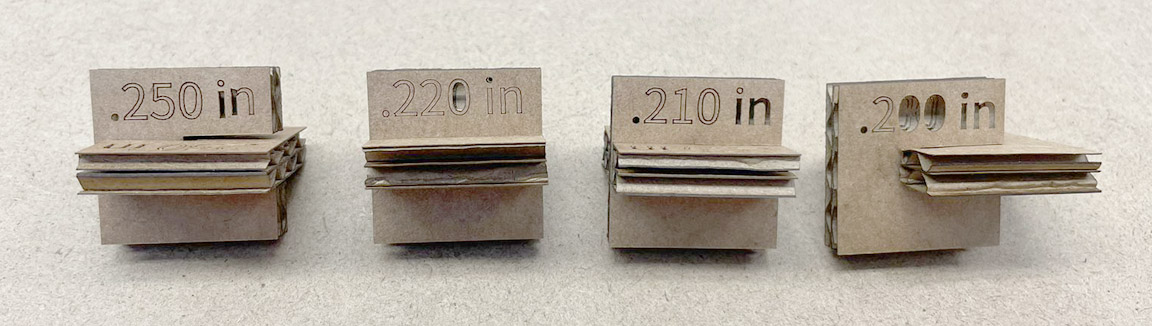

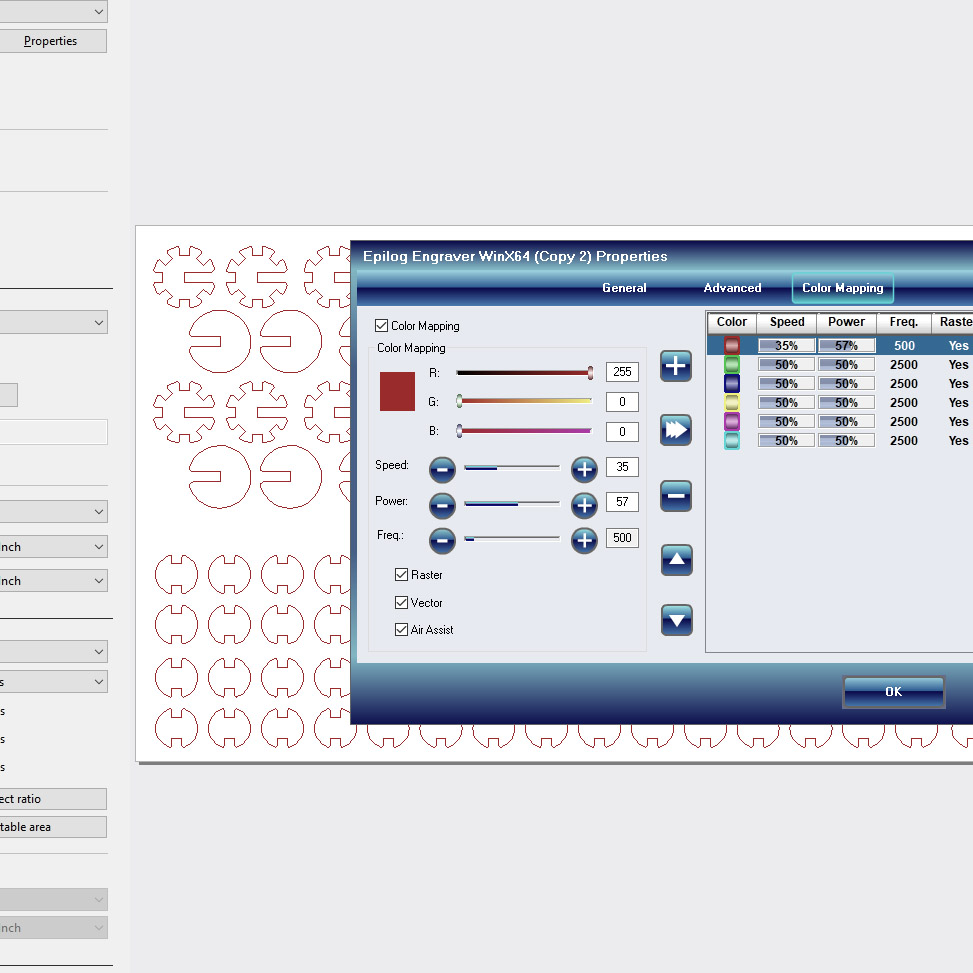

As a start, we ran some tests on the cardboard as a group to find the best definitions for the laser cutting machine. We examined a few options for the dimensions of the slits, according to the measurement of the cardboard's thickness. We also compared different power, frequency and speed definitions.

We cleaned and calibrated the beam distance from the material.

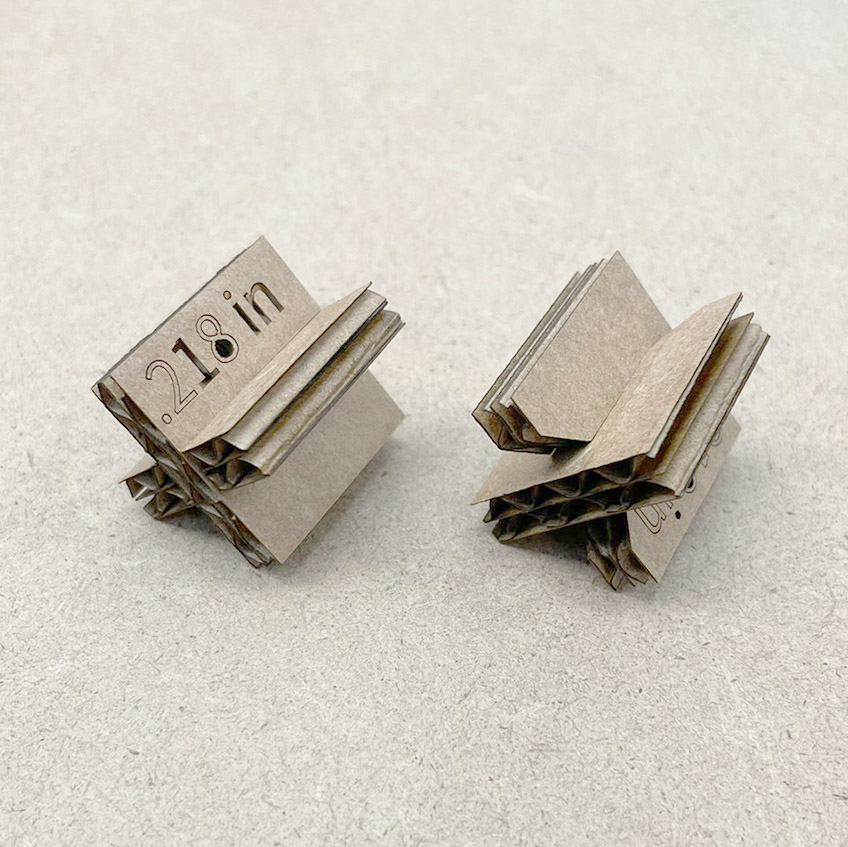

Then compared different thicknesses for the slits, 0.218" performed best.

And finally calibrated the machine to work in 35% speed and 57% power, 500 frq.

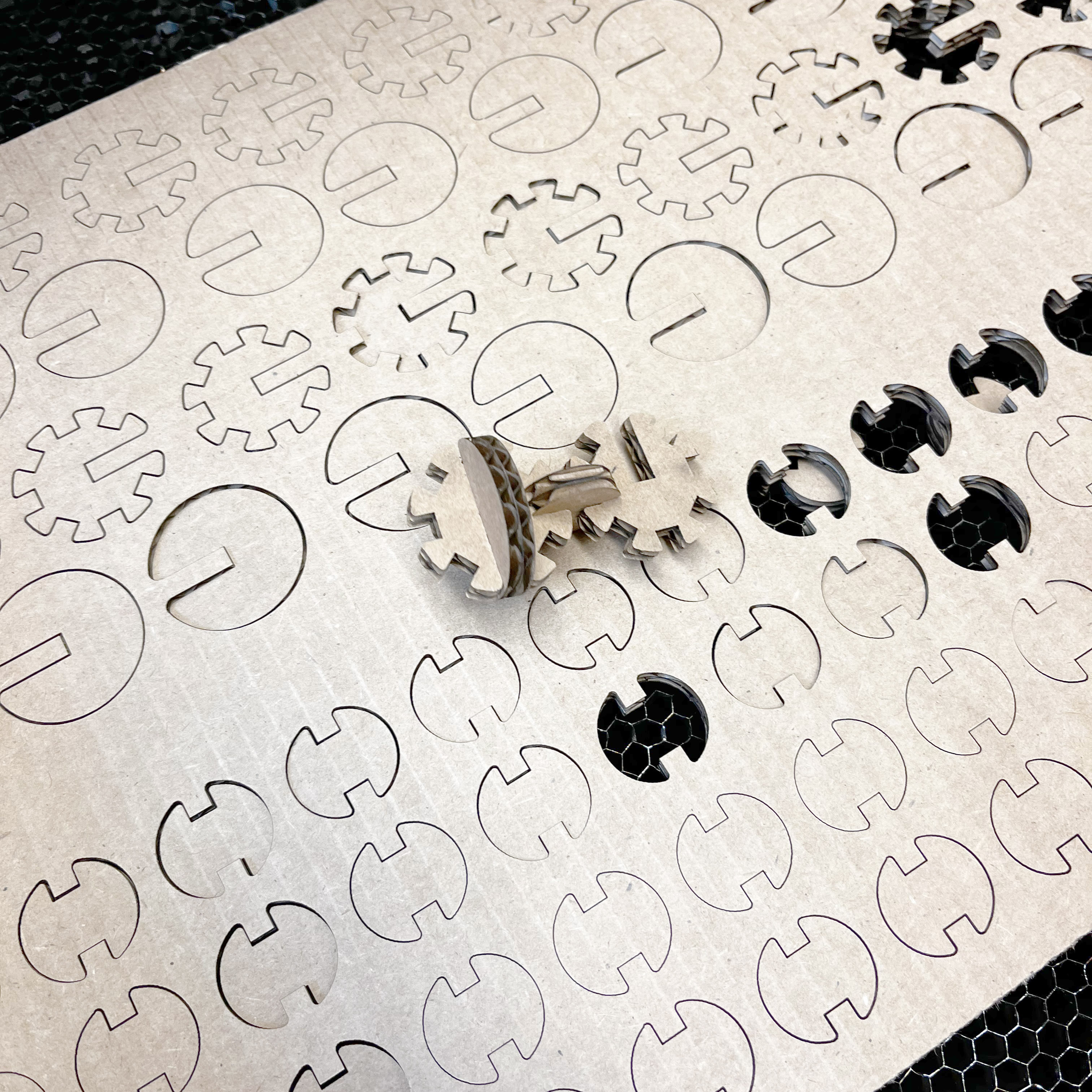

Then I cut my parts, after adjusting my model's cardboard thickness parameter to the one we measured as a group.

Also did a quick check in the workshop with Javi's phone to make sure it can carry something.

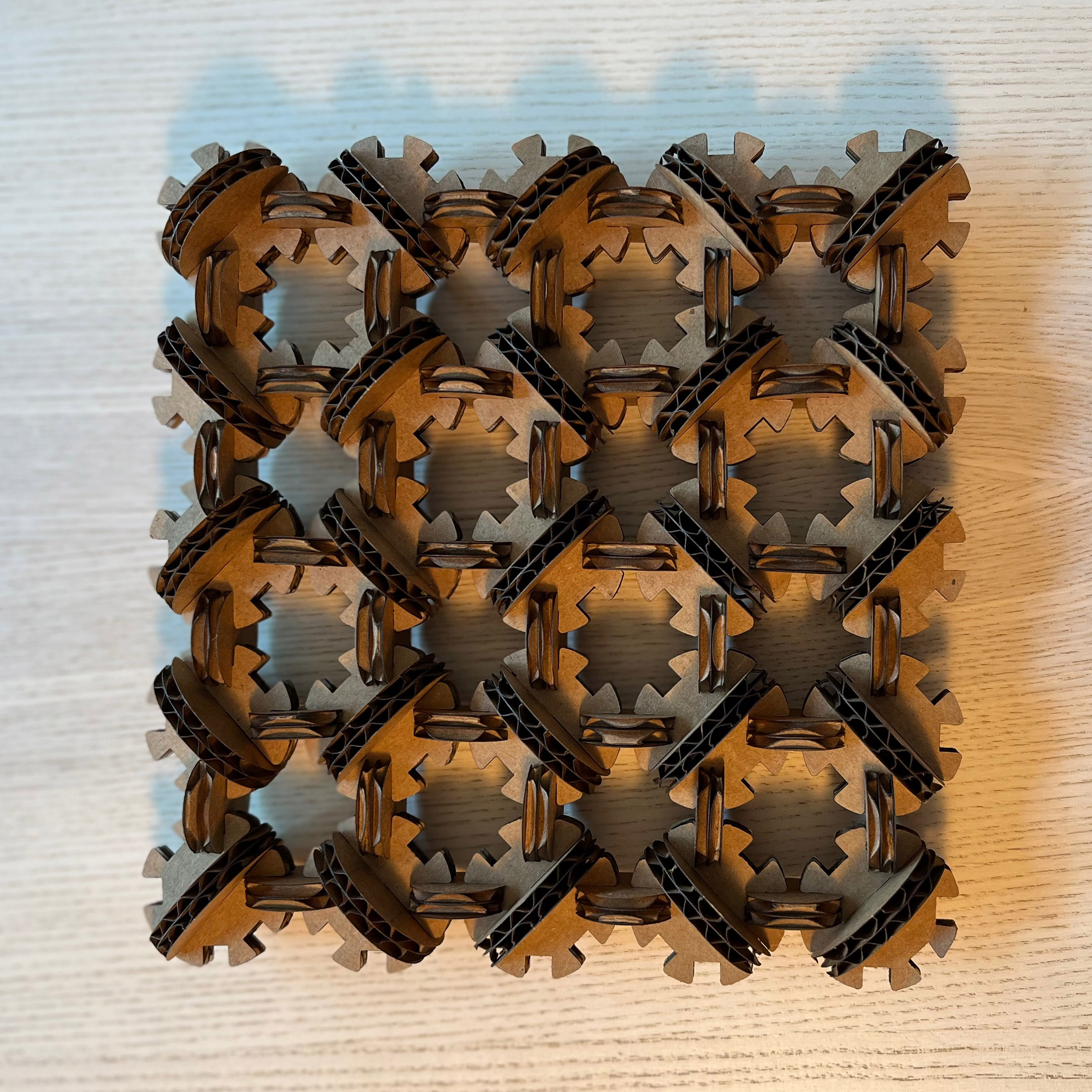

And started thinking about the different patterns I can make out of the kit.

Assembly

Next time when I'm laser cutting I will bring a bag to collect all the parts. Other then that, going home and trying to assemble it all was the best part! Here are some highlights:

My partner tried a round one

But I think sometimes simple is best.

**************************************************************

I also made a simple vinyl sticker!

I also made a simple vinyl sticker!